Gravel material multistage screening and crushing method

A crushing method and material crushing technology, applied in the field of sand and gravel crushing, can solve the problems of interrupting screening and crushing, affecting crushing efficiency and output, poor production continuity, etc., achieving easy crushing process, improving crushing efficiency and output, and facilitating popularization and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

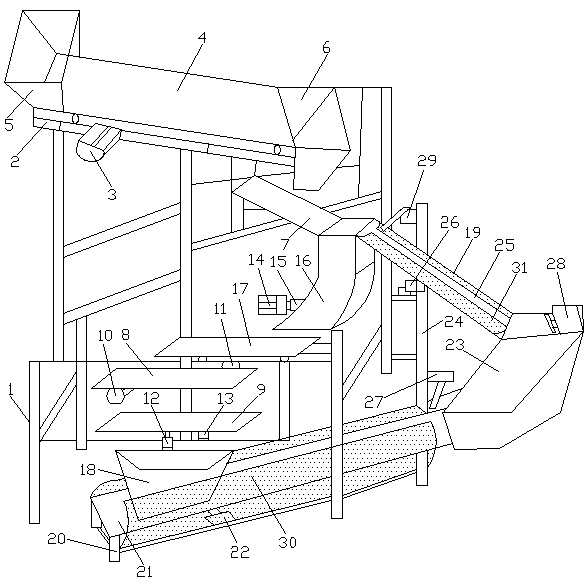

[0046] A multi-stage screening and crushing method for sand and gravel materials, comprising the following steps:

[0047] a. The sand and gravel materials are transported to the screening station through the material conveying device of the multi-stage screening crusher;

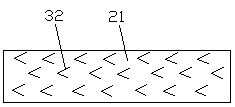

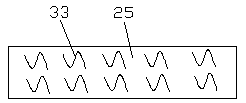

[0048] b. After the material screening device receives the sand and gravel materials conveyed by the material conveying device, it will pass through the primary screen 7 for primary screening, and the sand and gravel materials with large particle sizes will fall into the crushing station, and the crushed stones will be crushed by the material crushing device. The sand and gravel materials are conveyed to the secondary screen material net 8 by the crushing material conveying part 17 for horizontal swing screening, and the screened sand and gravel materials fall into the third-level screen material net 9, and pass through the third-level screen material net 9 to swing the screen material up and down. ;

[00...

Embodiment 2

[0052] A multi-stage screening and crushing method for sand and gravel materials, comprising the following steps:

[0053] a. The sand and gravel materials are transported to the screening station through the material conveying device of the multi-stage screening crusher;

[0054] b. After the material screening device receives the sand and gravel materials conveyed by the material conveying device, it will pass through the primary screen 7 for primary screening, and the sand and gravel materials with large particle sizes will fall into the crushing station, and the crushed stones will be crushed by the material crushing device. The sand and gravel materials are conveyed to the secondary screen material net 8 by the crushing material conveying part 17 for horizontal swing screening, and the screened sand and gravel materials fall into the third-level screen material net 9, and pass through the third-level screen material net 9 to swing the screen material up and down. ;

[00...

Embodiment 3

[0059] A multi-stage screening and crushing method for sand and gravel materials, comprising the following steps:

[0060] a. The sand and gravel materials are transported to the screening station through the material conveying device of the multi-stage screening crusher;

[0061] b. After the material screening device receives the sand and gravel materials conveyed by the material conveying device, it will pass through the primary screen 7 for primary screening, and the sand and gravel materials with large particle sizes will fall into the crushing station, and the crushed stones will be crushed by the material crushing device. The sand and gravel materials are conveyed to the secondary screen material net 8 by the crushing material conveying part 17 for horizontal swing screening, and the screened sand and gravel materials fall into the third-level screen material net 9, and pass through the third-level screen material net 9 to swing the screen material up and down. ;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com