Patents

Literature

202results about How to "Fast crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

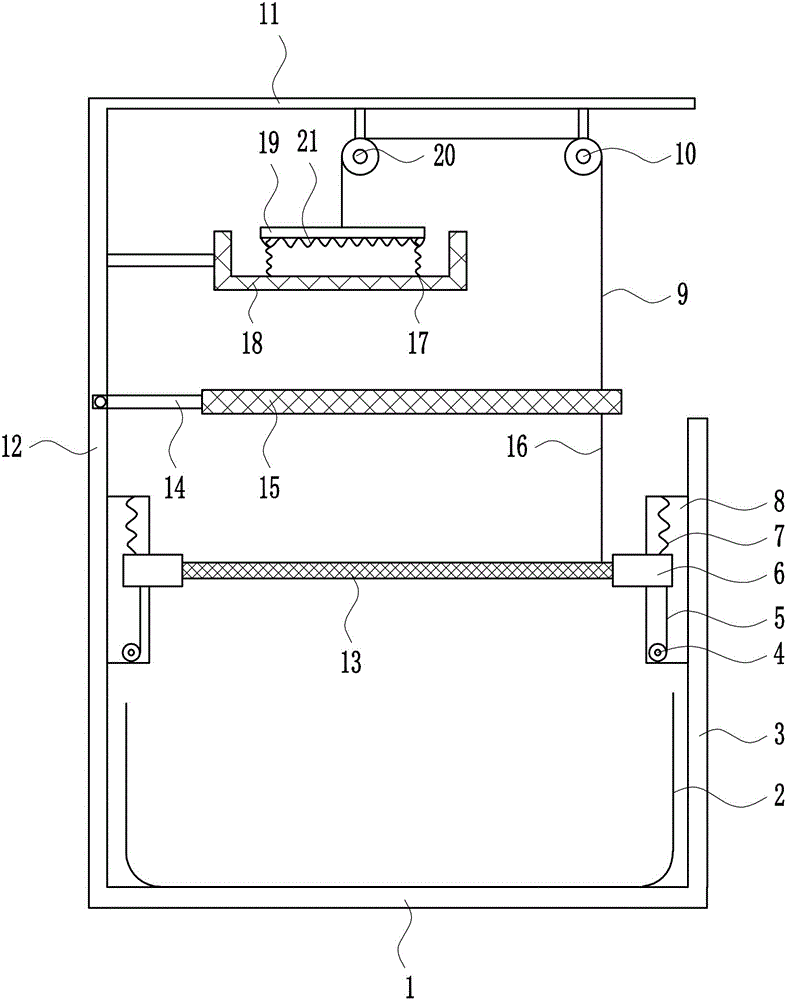

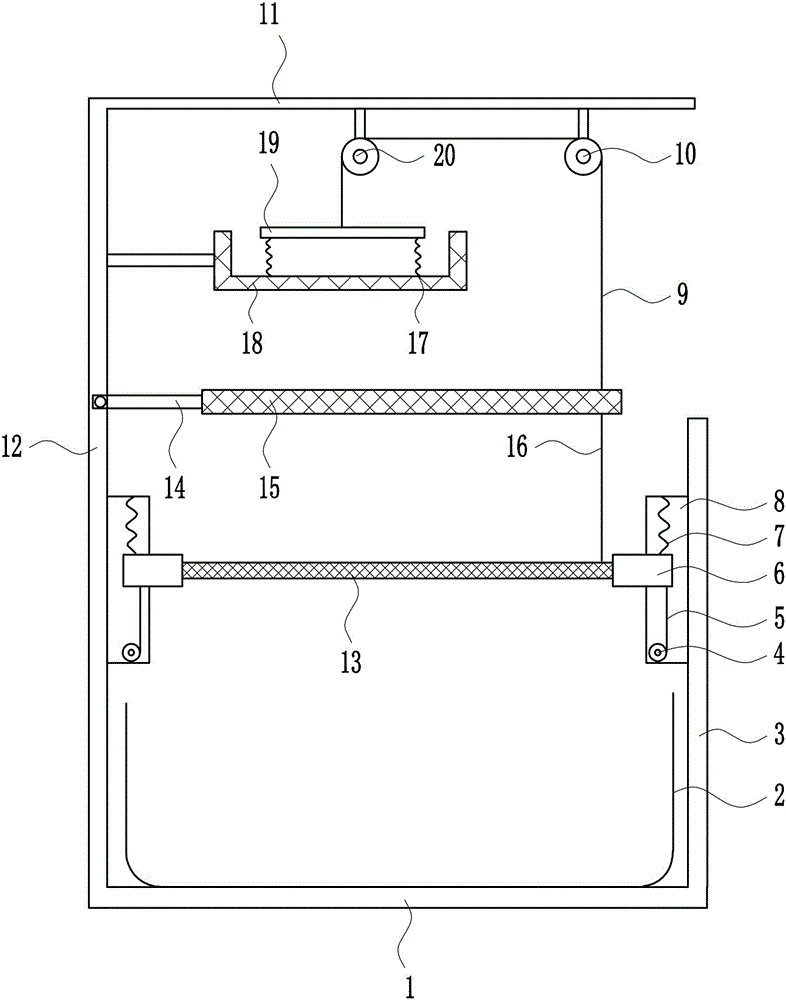

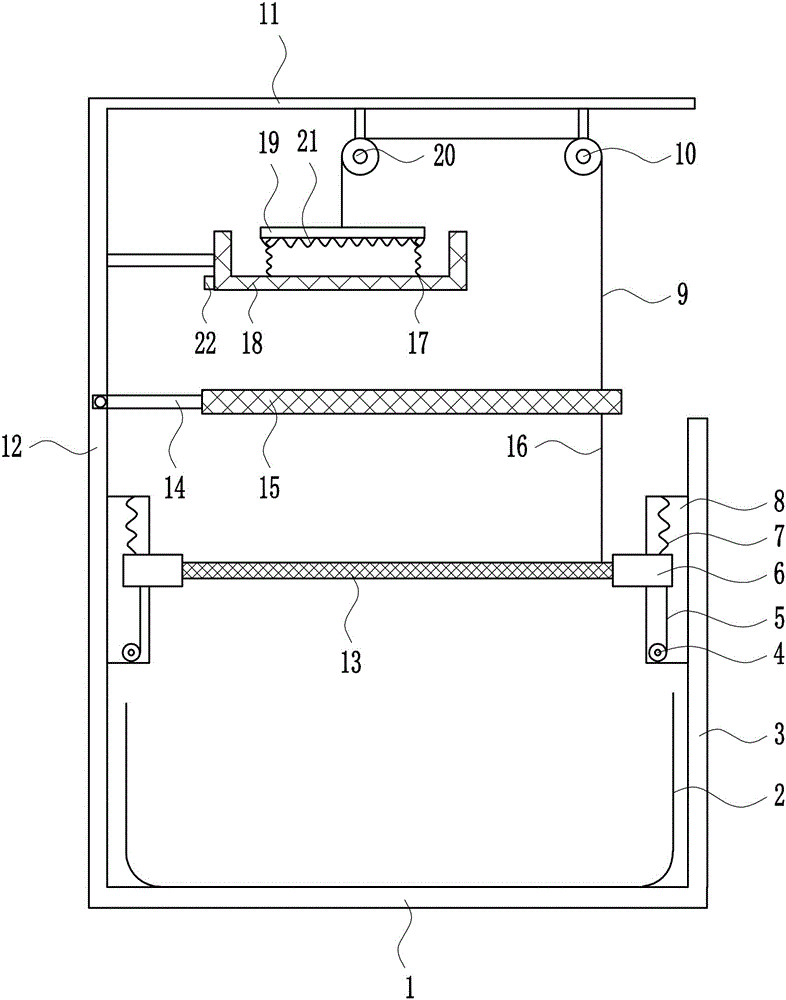

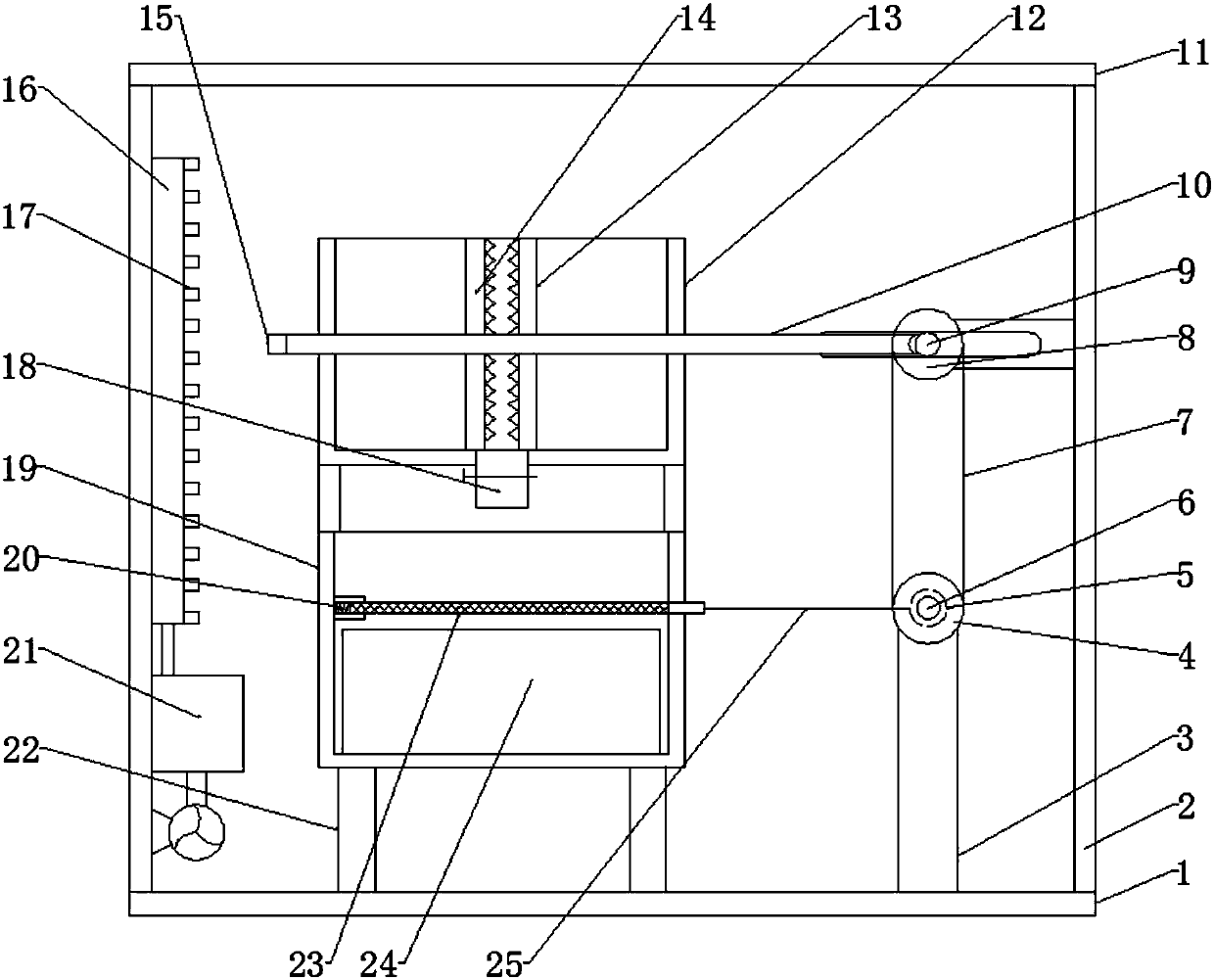

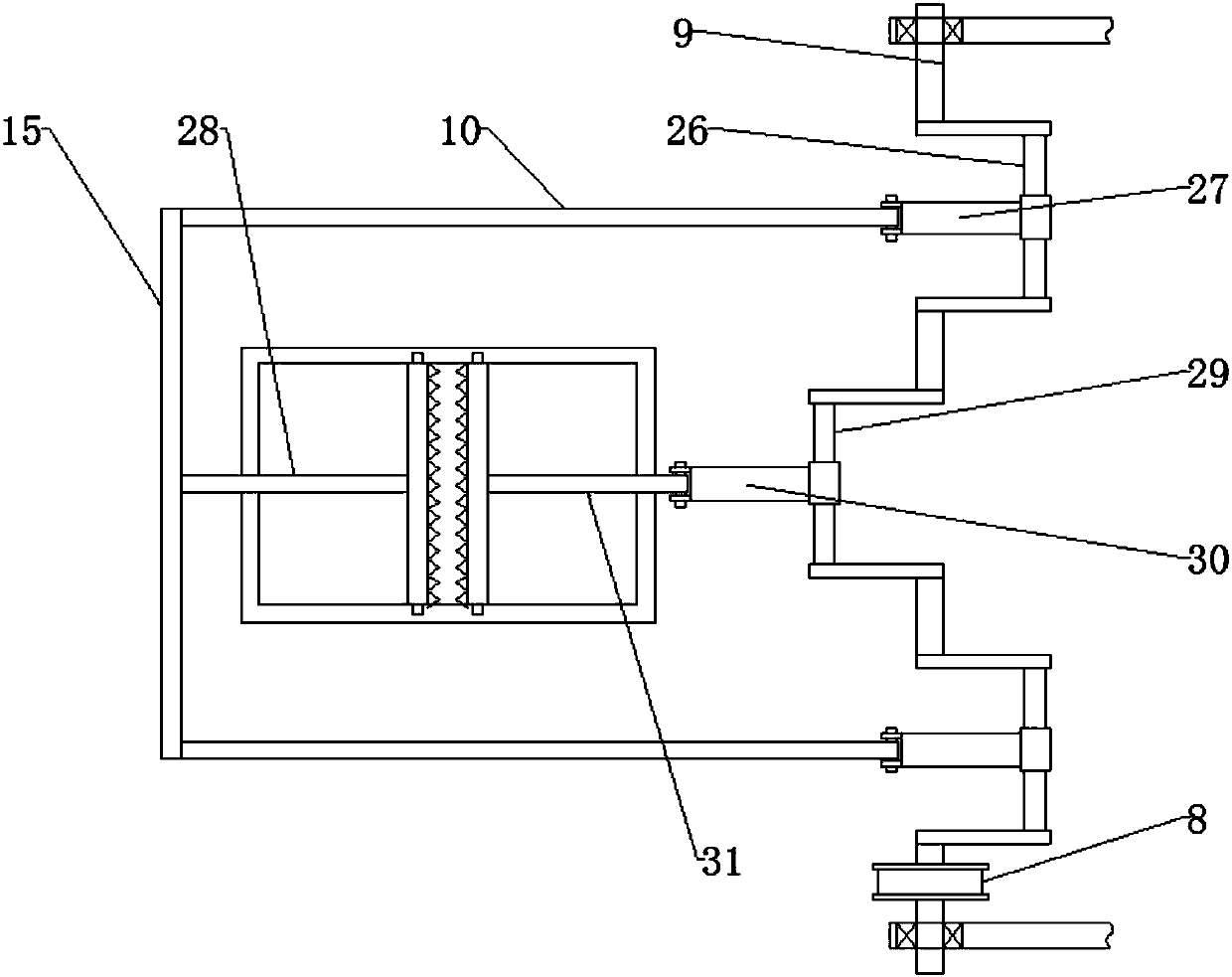

Agricultural soil block crushing device

The invention relates to a crushing device, in particular to an agricultural soil block crushing device. The agricultural soil block crushing device is capable of achieving crushing easily, convenient to operate and high in crushing speed. The agricultural soil block crushing device comprises a bottom plate, a collection box, a right frame, electric wheels, pulling ropes, sliding blocks, springs I, sliding rails, a steel wire rope II, a rolling wheel I, a top plate, a left frame, a filter screen III, a connecting rod, a filter screen II, a steel wire rope I, springs II, a filter screen I, a pressing block and a rolling wheel II. The left frame, the collection box and the right frame are arranged at the top of the bottom plate from left to right in sequence. The top plate is arranged at the top of the right side of the left frame. The rolling wheel II and the rolling wheel I are sequentially arranged at the bottom of the top plate from left to right. The filter screen I is connected to the upper portion of the right side of the left frame. By the adoption of the agricultural soil block crushing device, the effects that crushing is easy, operation is convenient and the crushing speed is high are achieved, and soil blocks can be crushed rapidly.

Owner:奉节县仙鑫蜜蜂养殖有限公司

Environment-friendly smashing and recovering device for waste electronic products

The invention discloses an environment-friendly smashing and recovering device for waste electronic products. The environment-friendly smashing and recovering device comprises a barrel, a screen, a crank, a second motor, a shaft bushing, a connection rod, a movable rod, a smashing plate, a ring-shaped baffle, a tank, a first motor, a threaded rod, a first sleeve, a connection rod, a pressing plate, an air outlet pipe, an air inlet pipe, a rotating sleeve, a third motor, a first gear and a second gear. Through arrangement of the second motor, the crank, the connection rod, the movable rod, thesmashing plate and the ring-shaped baffle, intermittent discharging is achieved, sufficient and uniform smashing is ensured, and the smashing efficiency is improved; through arrangement of the third motor, the first gear, the second gear and the rotating sleeve, rotating smashing is carried out, fertilizer can be ground, the smashing speed is further increased, and the smashing efficiency is improved; and through arrangement of the first motor, the threaded rod, the connection rod and the pressing plate, smashed electronic products are automatically compressed, then a door is opened, the compressed products are pushed out, and discharging and collection are facilitated.

Owner:童拓

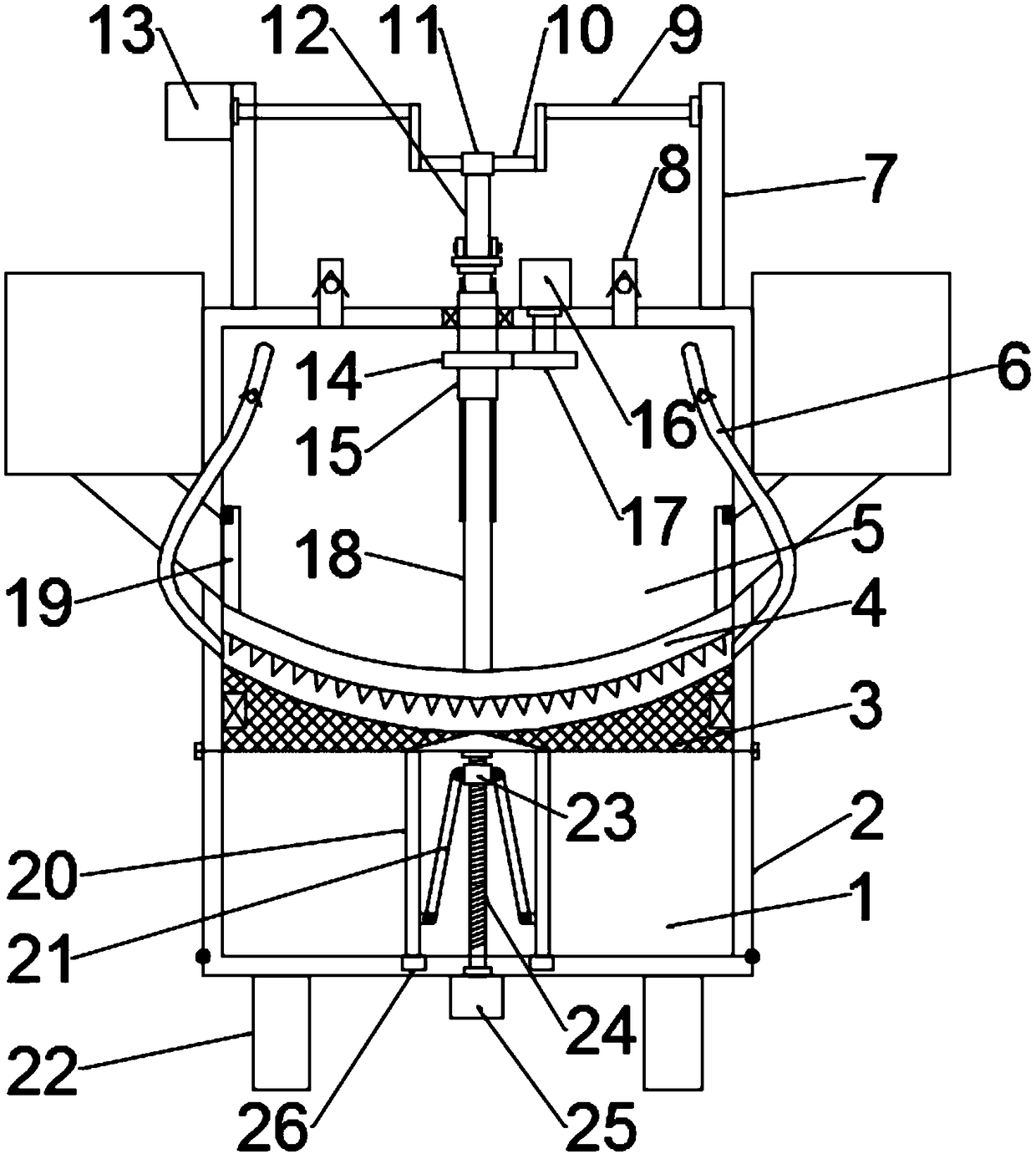

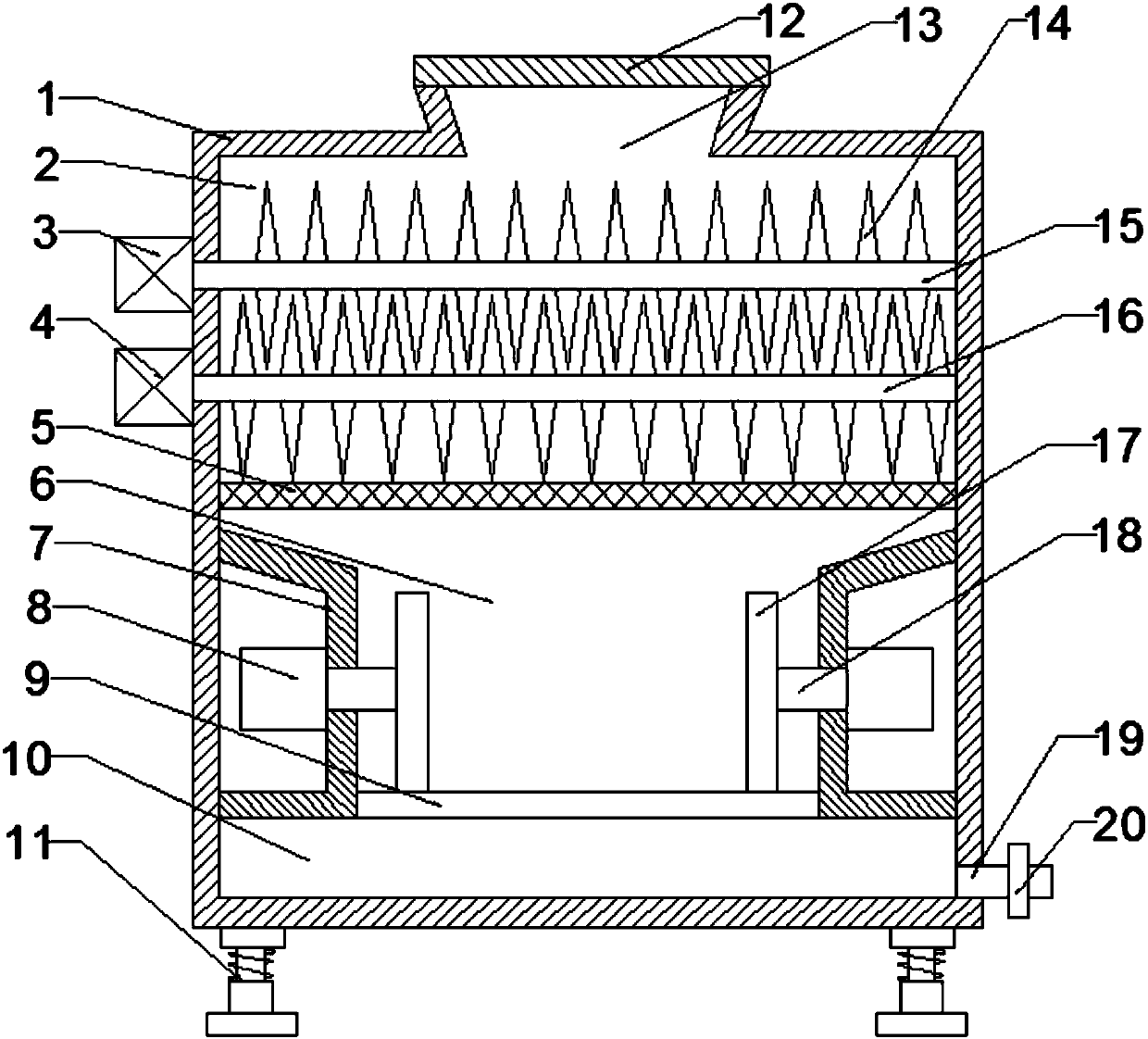

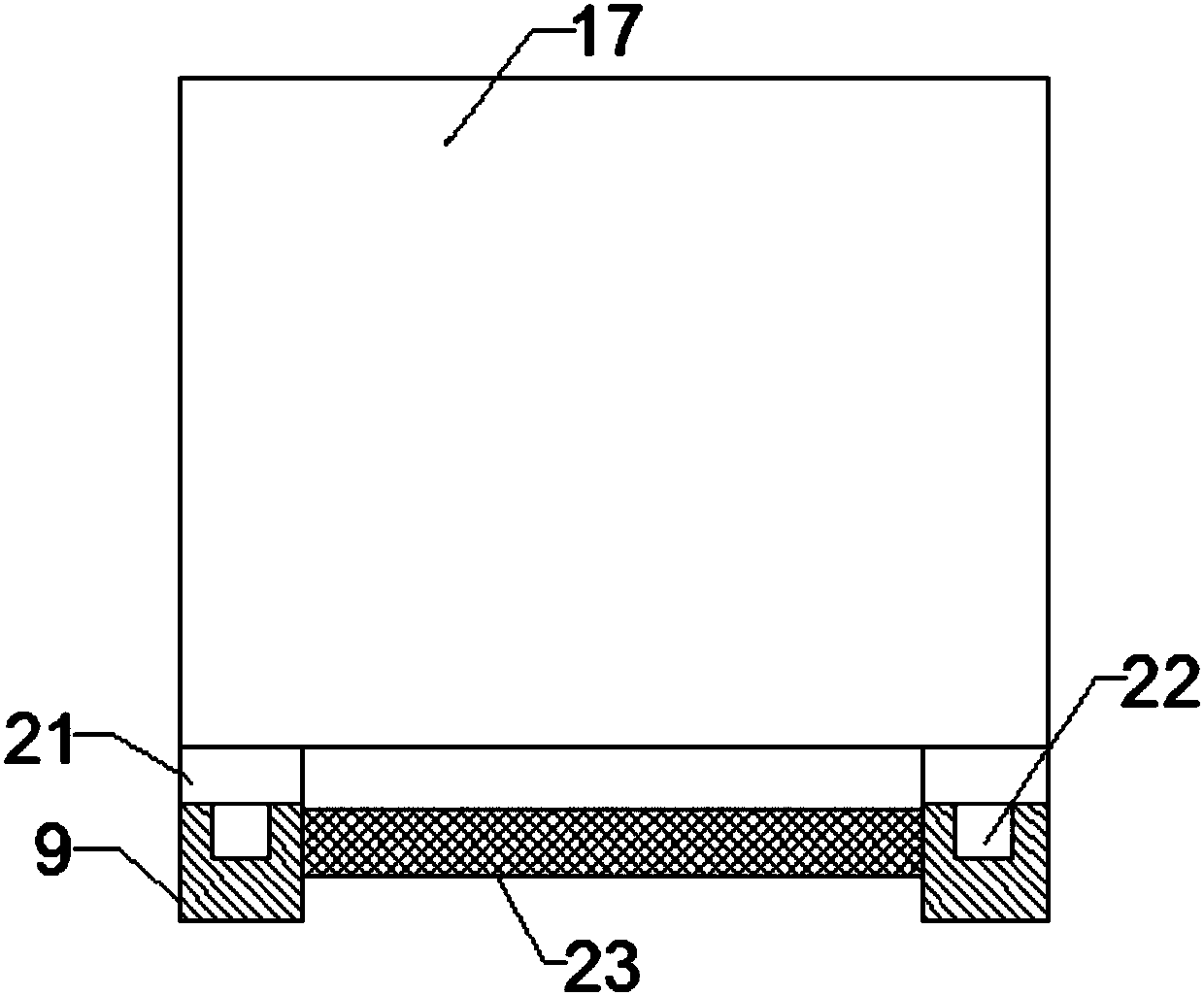

Medical garbage smashing and extrusion-forming device

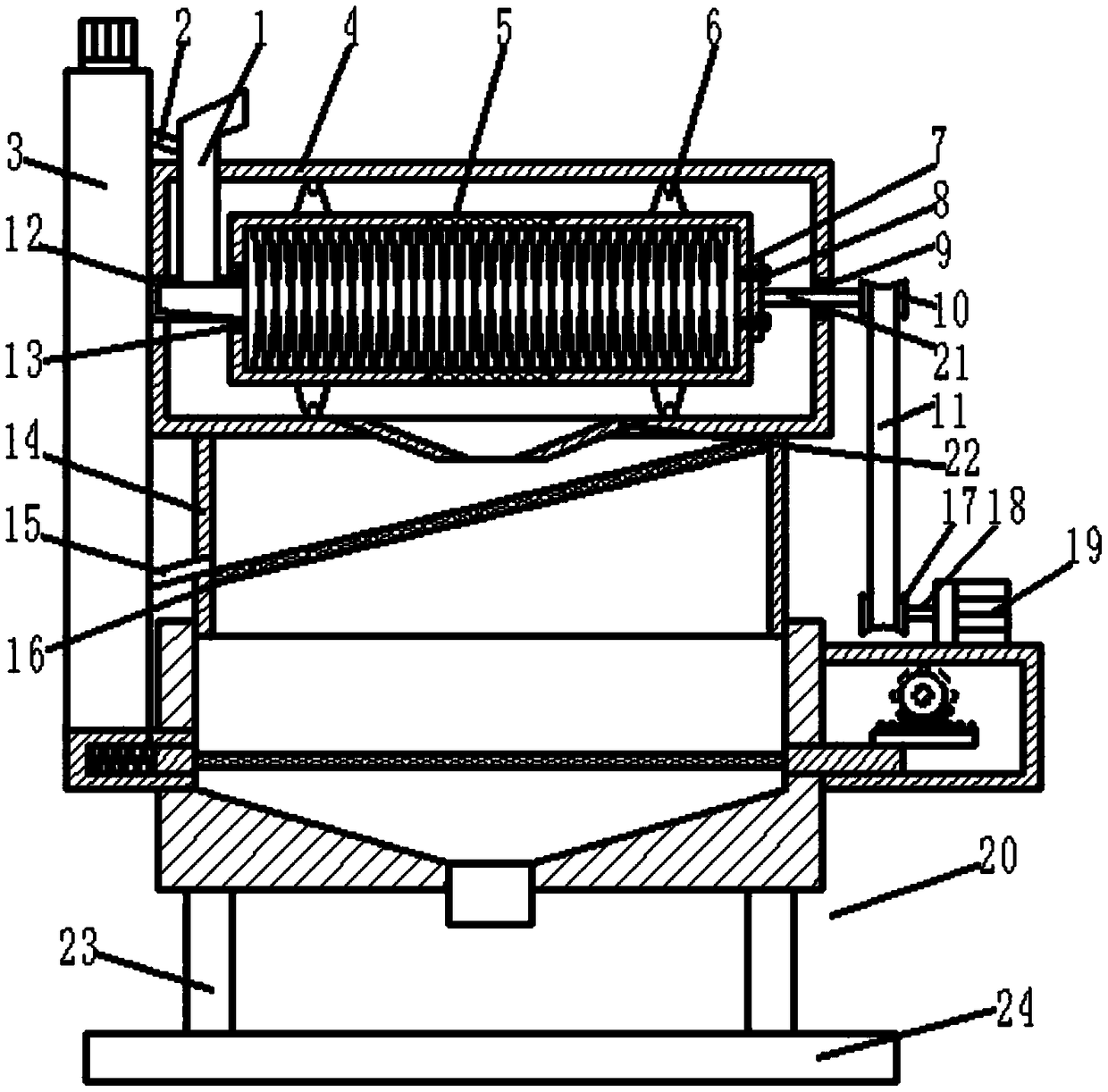

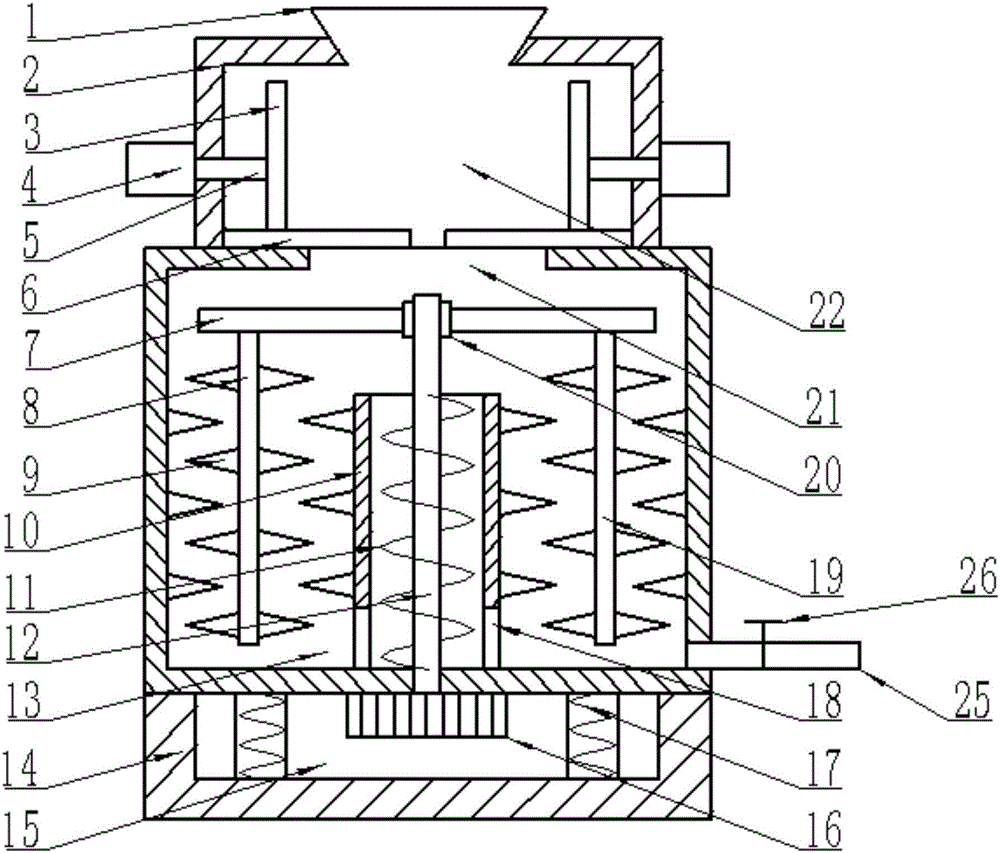

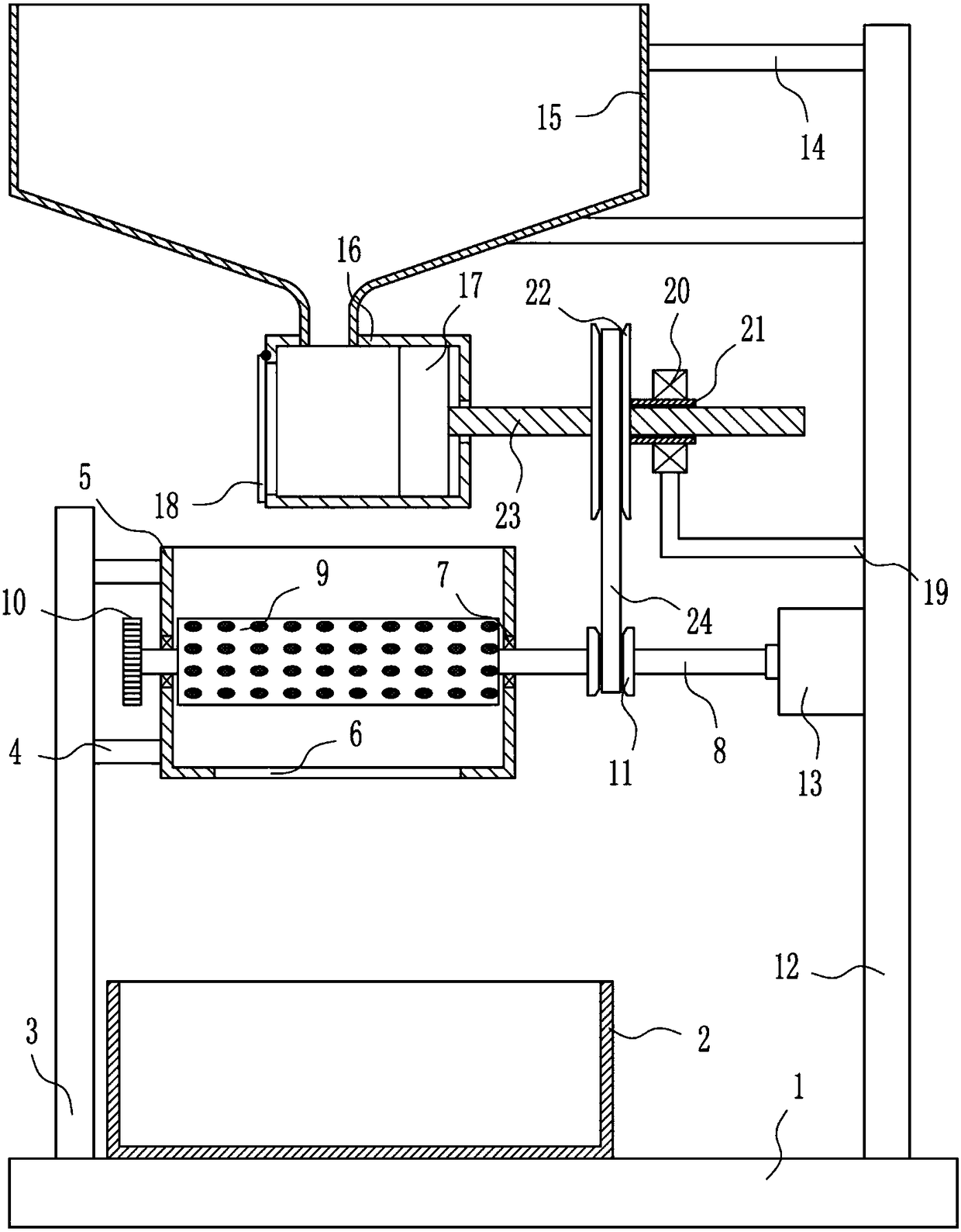

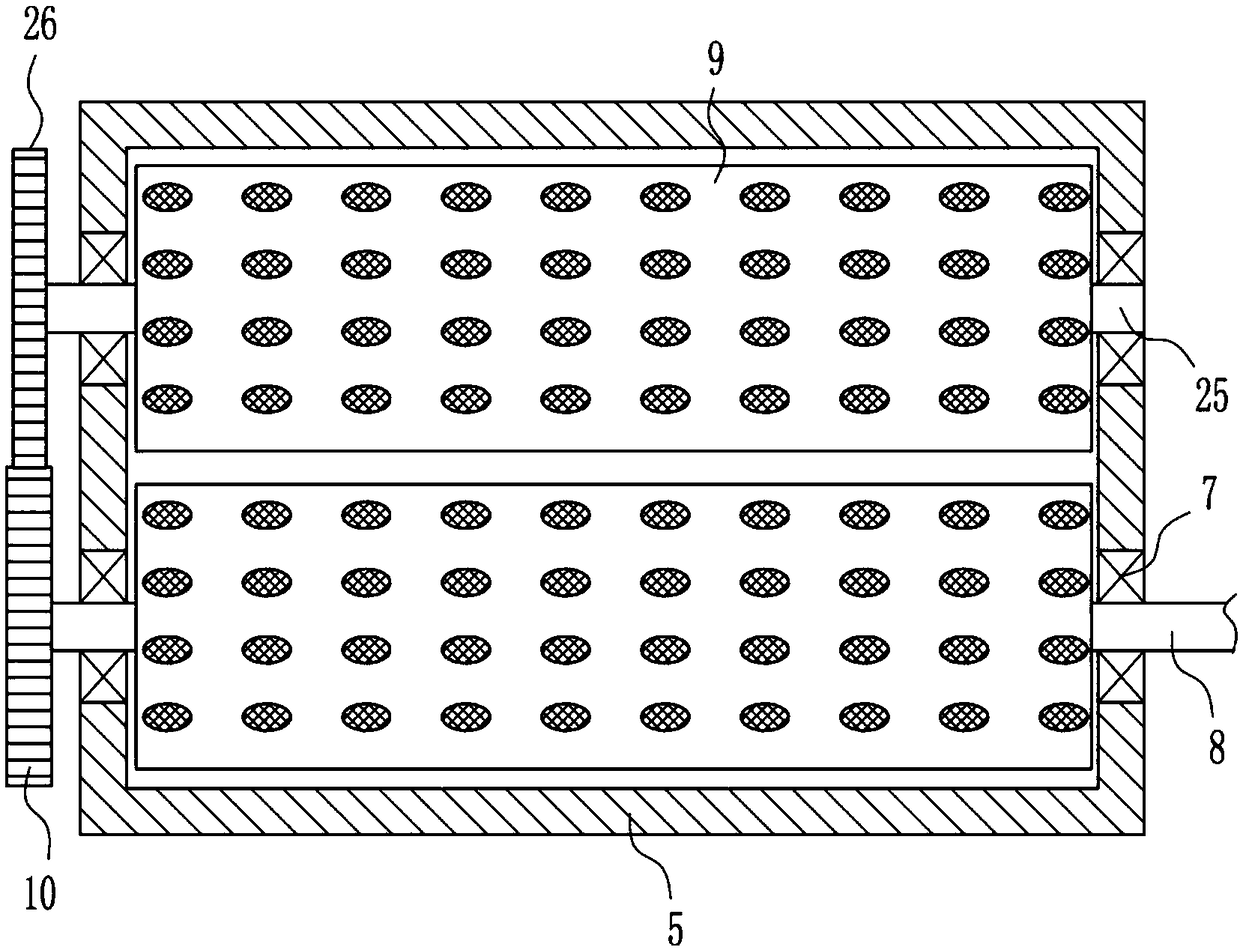

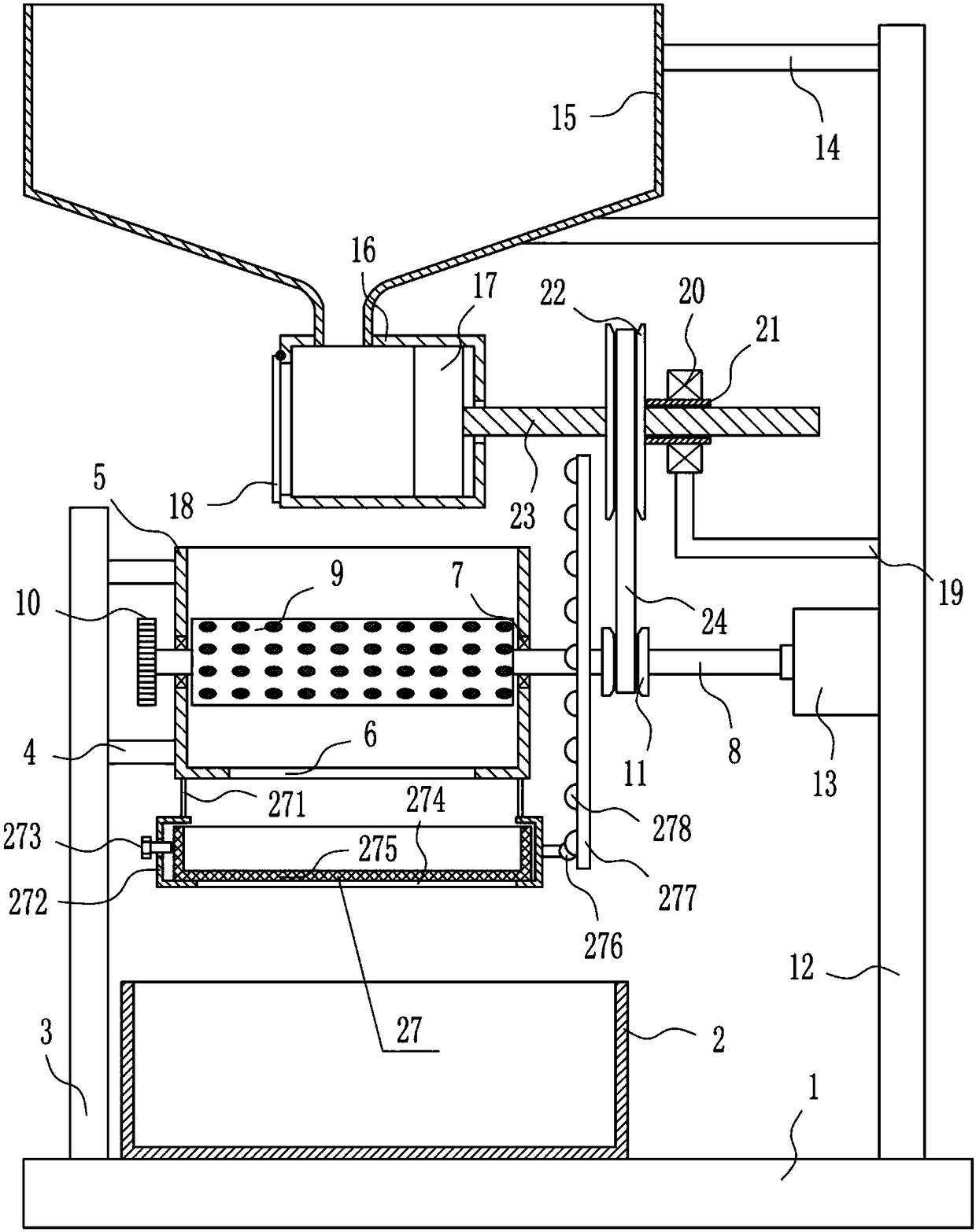

InactiveCN107552537ASqueeze fullyFast crushingSolid waste disposalGrain treatmentsElectric machineryLiquid storage tank

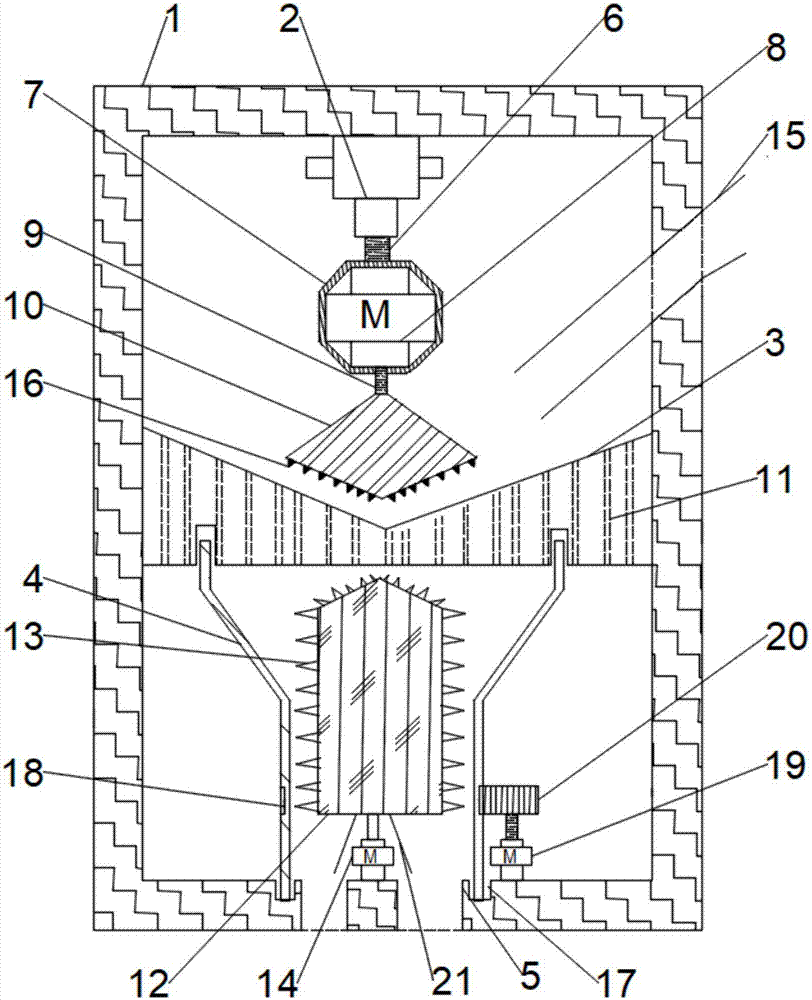

The invention discloses a medical garbage smashing and extrusion-forming device and belongs to the technical field of medical garbage treatment. The medical garbage smashing and extrusion-forming device comprises a box body. A smashing cavity, an extruding cavity and a liquid storage tank are formed inside the box body; a feeding hopper is arranged at the bottom of the box body and communicates with the smashing cavity; a cover plate is arranged on the top of the feeding hopper through a hinge; smashing blades, a first rotating shaft and a second rotating shaft are arranged in the smashing cavity; the first rotating shaft is horizontally arranged on the upper side of the smashing cavity, and the left end of the first rotating shaft is connected with an output shaft of a first motor; and the second rotating shaft is horizontally arranged below the first rotating shaft, and the left end of the second rotating shaft is connected with an output shaft of a second motor. The structural design is reasonable, an arranged double-smashing device can smash medical garbage thoroughly, and the smashing efficiency is high; and arranged extruding plates fully extrude the medical garbage, so thatthe garbage is flattened, and subsequent machining can be conveniently conducted.

Owner:郑州莉迪亚医药科技有限公司

Efficient crushing and grinding equipment for traditional Chinese medicine

PendingCN107486321AAvoid cloggingAvoid insufficient crushingSievingScreeningGear wheelElectric machinery

The invention discloses efficient crushing and grinding equipment for traditional Chinese medicine. The efficient crushing and grinding equipment for traditional Chinese medicine comprises a grinding barrel, a crushing barrel, a first screen mesh, an round feed inlet, a first motor, a rotary shaft, an annular baffle plate, a first crushing blade, a second crushing blade, a brush, a second motor, a first installing shaft, a first grinding roller, a second installing shaft, a second grinding roller, an active gear, a driven gear, an inner gear ring and a second screen mesh. The efficient crushing and grinding equipment for traditional Chinese medicine is provided with the first motor, the rotary shaft, the round feed inlet and the annular baffle plate, and through cooperation of the first motor, the rotary shaft, the round feed inlet and the annular baffle plate, intermittent feeding is achieved, insufficient crushing caused by excessive feeding at one time is avoided and the crushing efficiency is improved; the first crushing blade and the second crushing blade are further provided and set dislocated, so that the crushing speed is high and the crushing efficiency is high; and the second motor, the active gear, the driven gear, the inner gear ring, the first grinding roller and the second grinding roller are further provided, and through cooperation, continuous grinding of traditional Chinese medicine is conducted, the grinding is sufficient and fast, and the grinding efficiency is improved.

Owner:ZHENGZHOU UNIV

Anti-blocking type drug crushing iron removing device

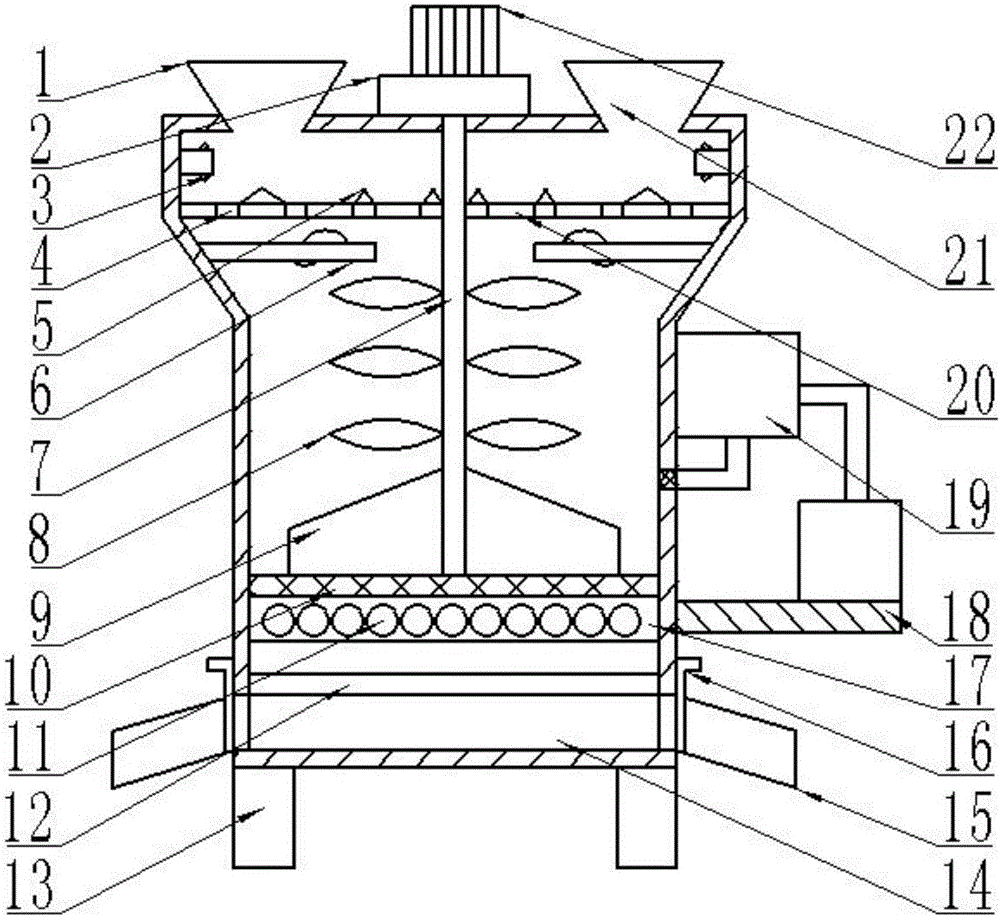

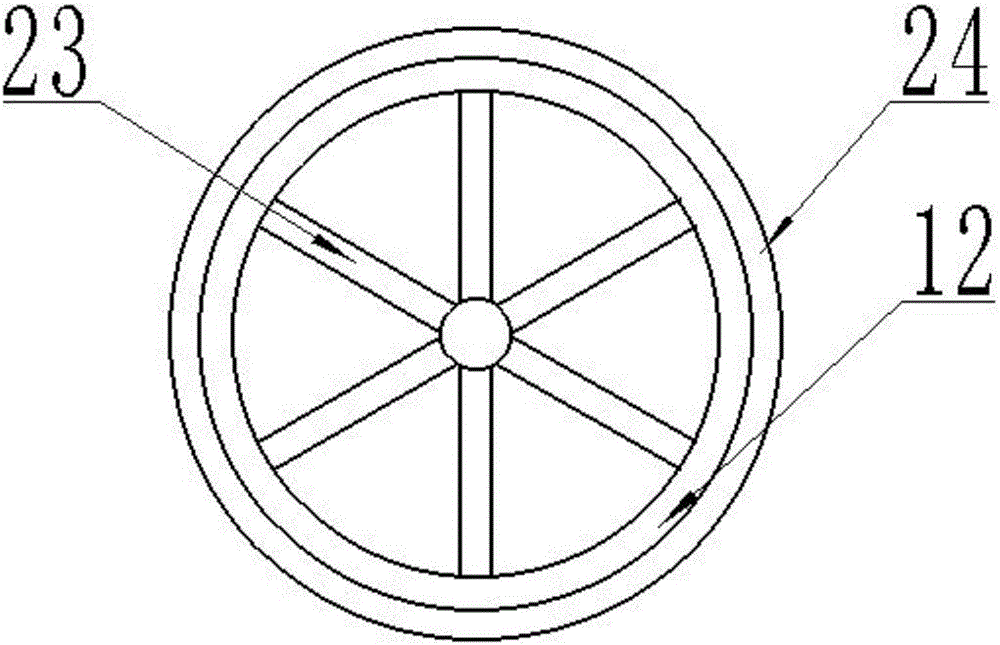

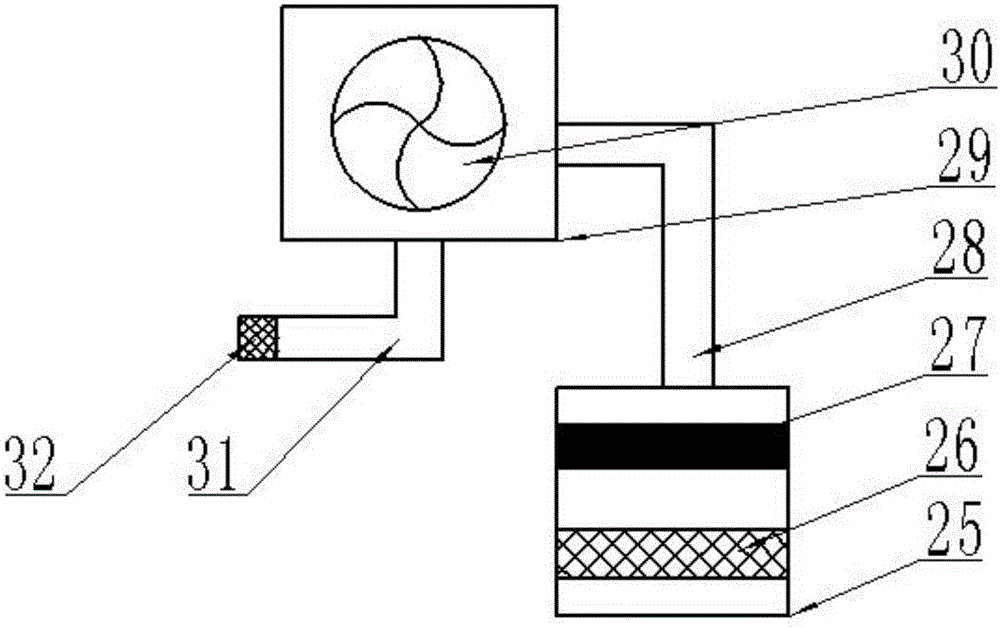

InactiveCN106583001AEffective dispersionFast crushingMagnetic separationGrain treatmentsDrive motorEngineering

The invention provides an anti-blocking type drug crushing iron removing device. The anti-blocking type drug crushing iron removing device comprises a left feeding hopper, a motor base, an anti-blocking device, a screen, an iron removing plate, a material storage bin, an extrusion bin, a placing plate and a right feeding hopper. The motor base is fixed to the position, between the left feeding hopper and the right feeding hopper, of the upper end of a box body. A driving motor is arranged at the upper end of the motor base. The lower end of the driving motor is connected with a rotating shaft. The rotating shaft is provided with crushing blades and a crushing knife. The anti-blocking device comprises distribution pieces, a partition plate and distribution rods. The iron removing plate is fixed in the box body and provided with iron removing rods and a fixing ring. The material storage bin is provided with discharging pipes. The extrusion bin is arranged at the lower end of the screen and internally provided with extrusion rollers. The placing plate is connected to the right end of the box body in a welded mode and provided with a drying device. The drying device comprises a filtering box, a first air inlet pipe, an air blower and a second air inlet pipe. According to the anti-blocking type drug crushing iron removing device, crushing is thorough; material blocking can be prevented; iron removing is convenient; and drying is thorough and rapid.

Owner:河南常青藤信息科技有限公司

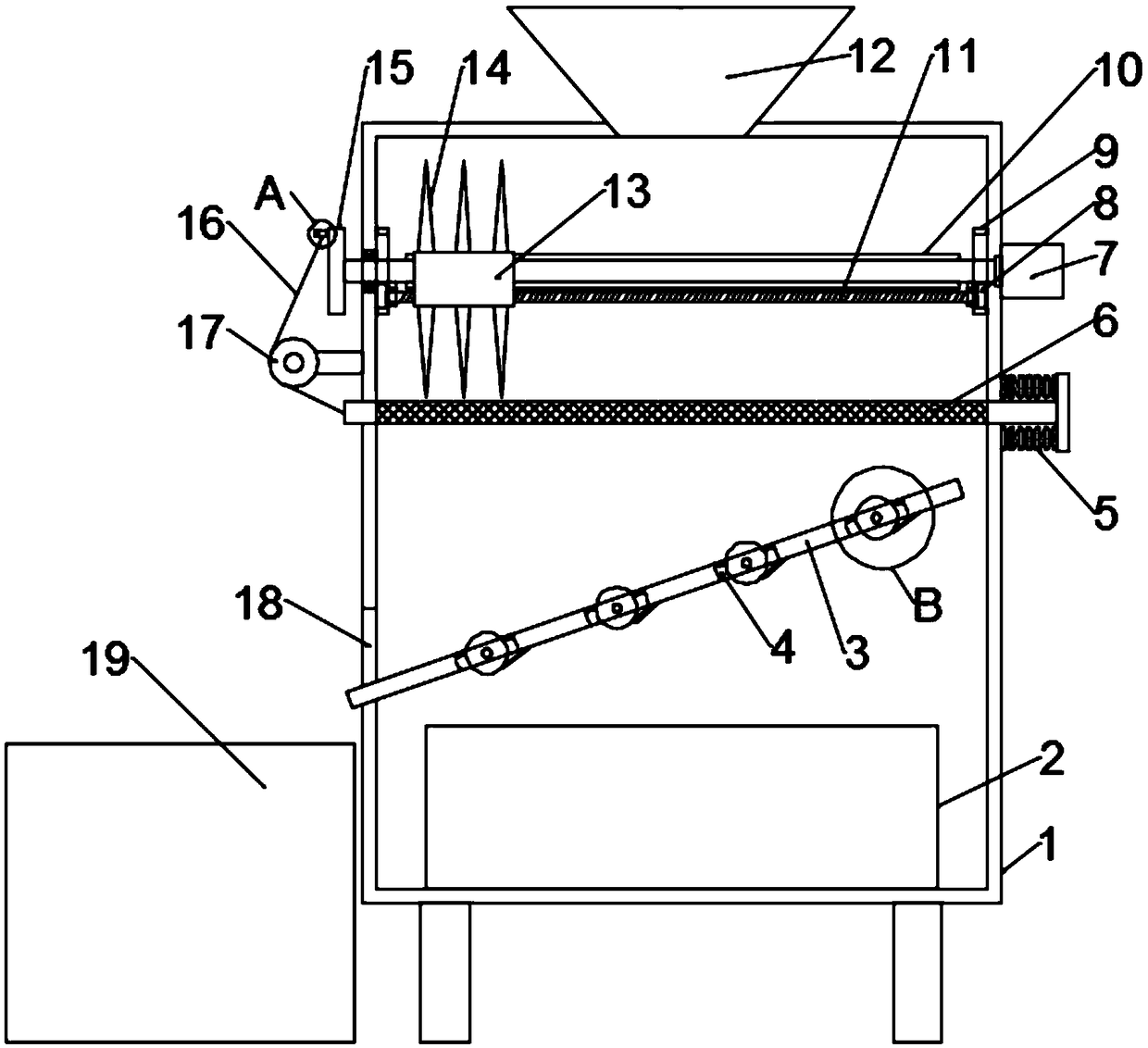

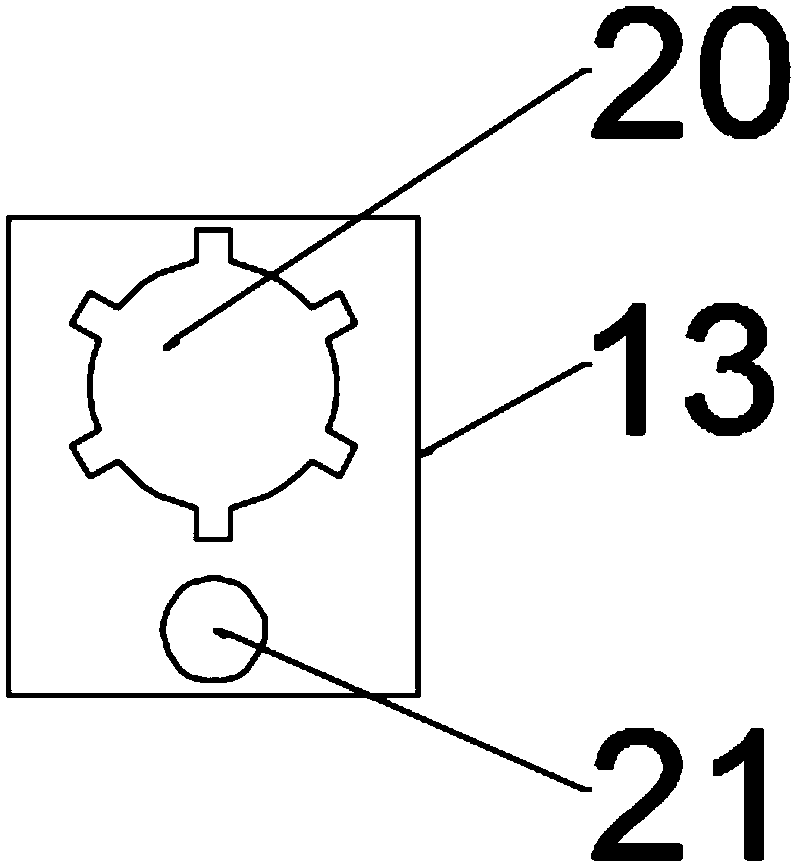

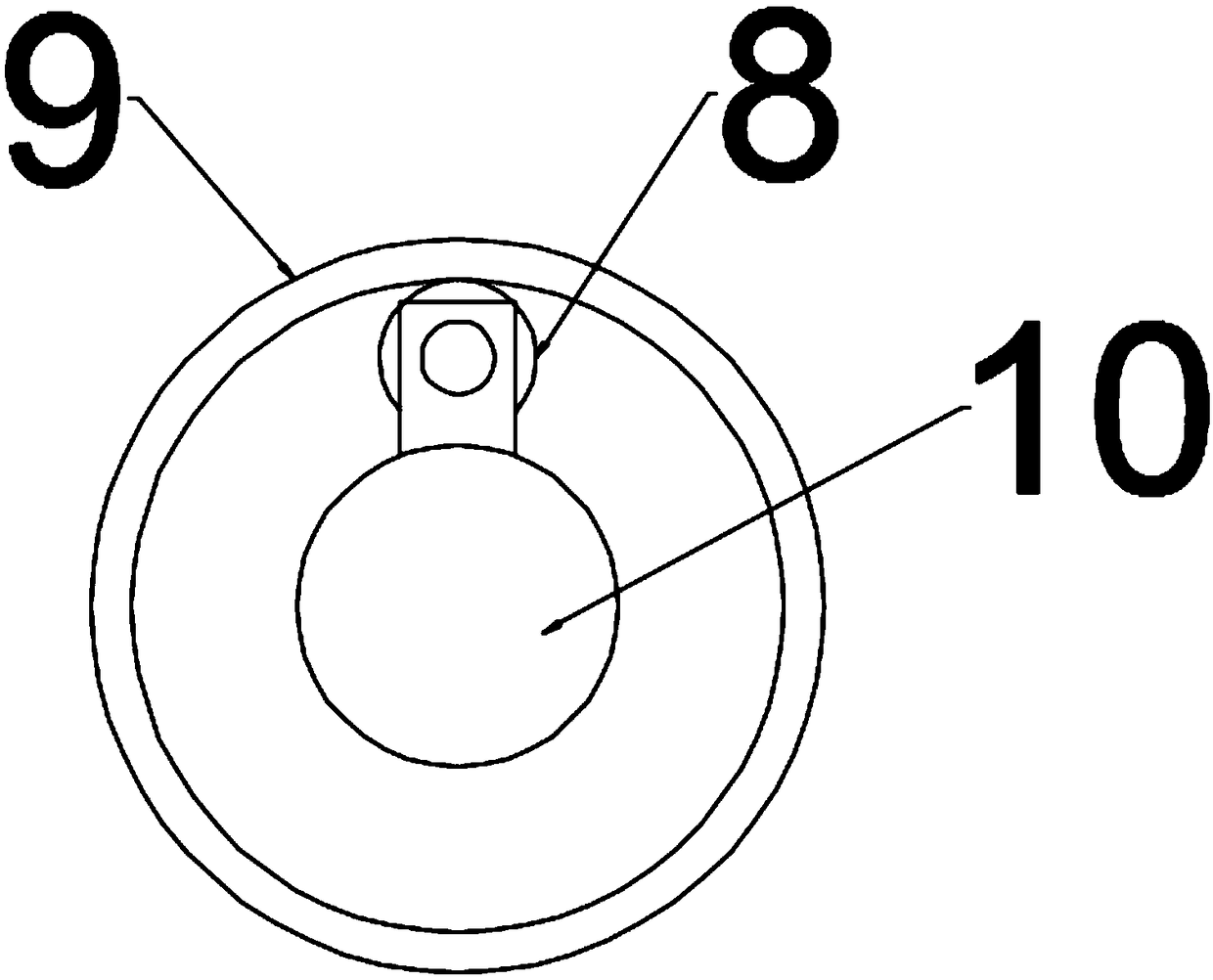

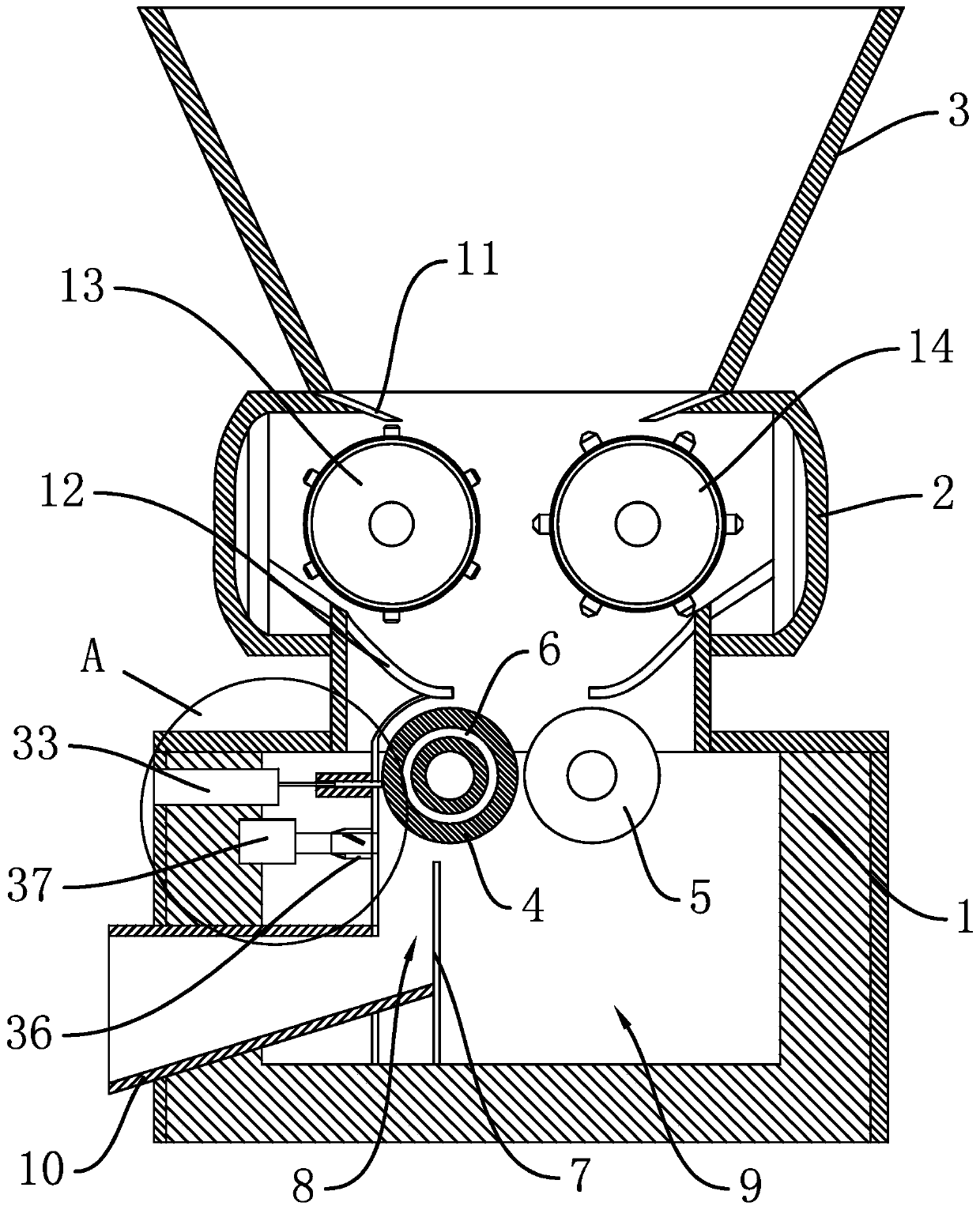

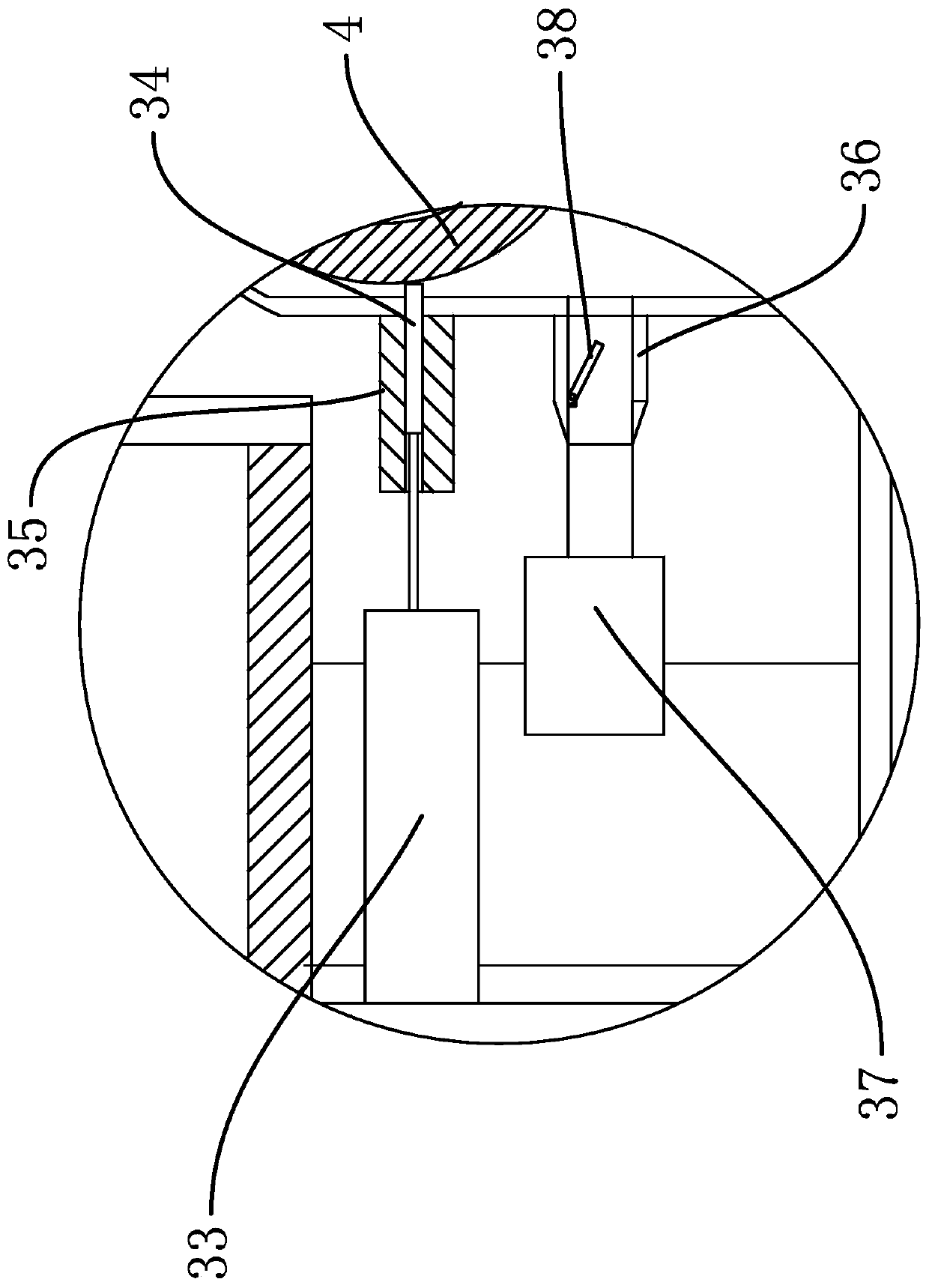

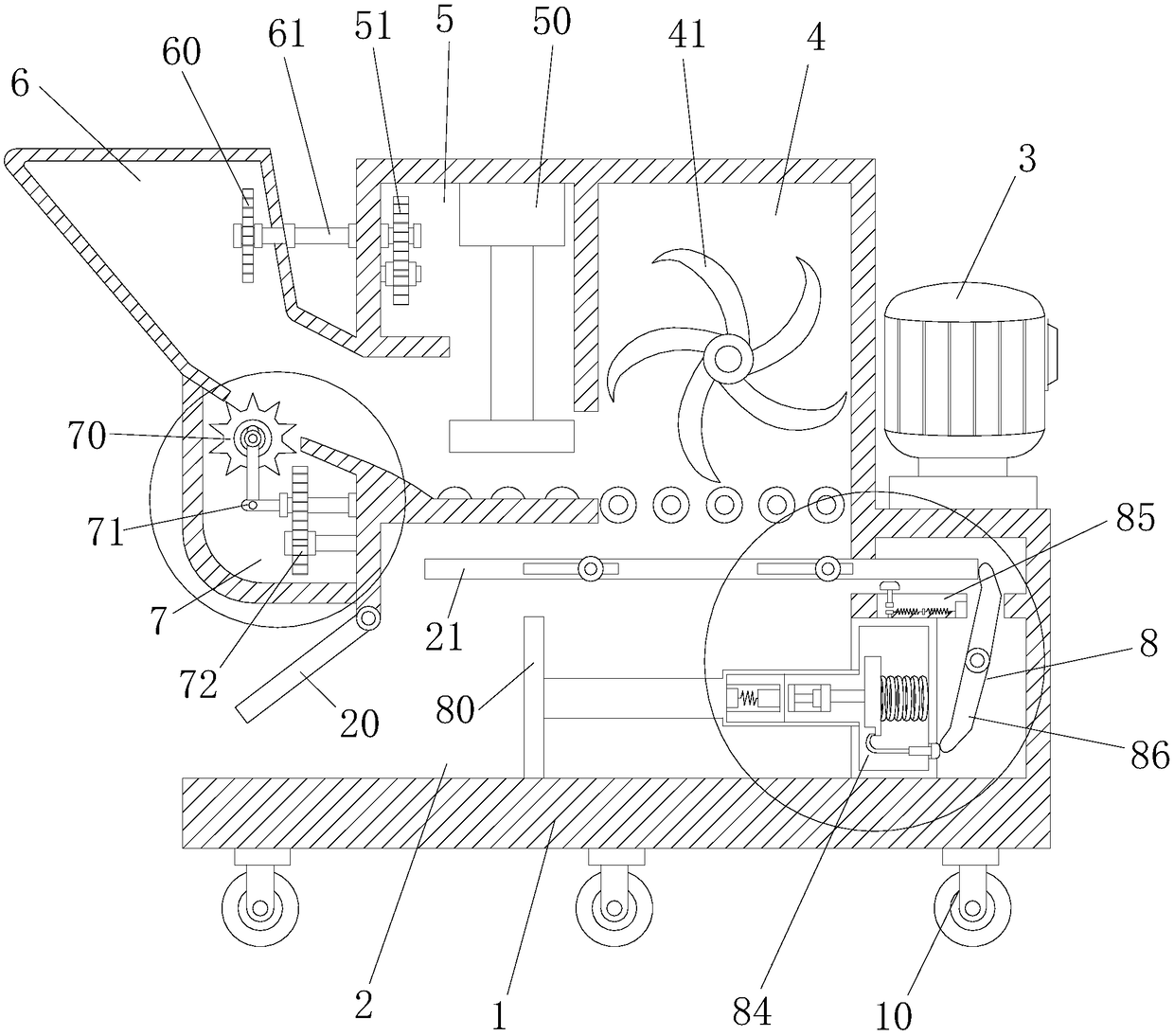

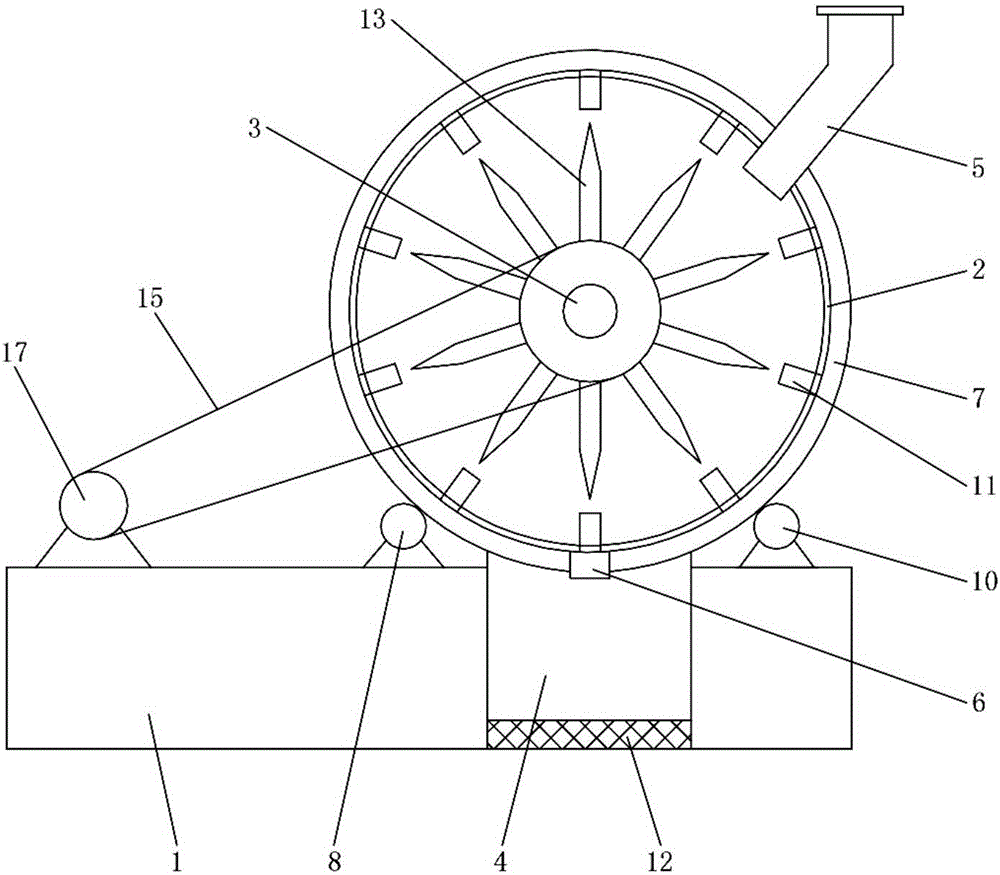

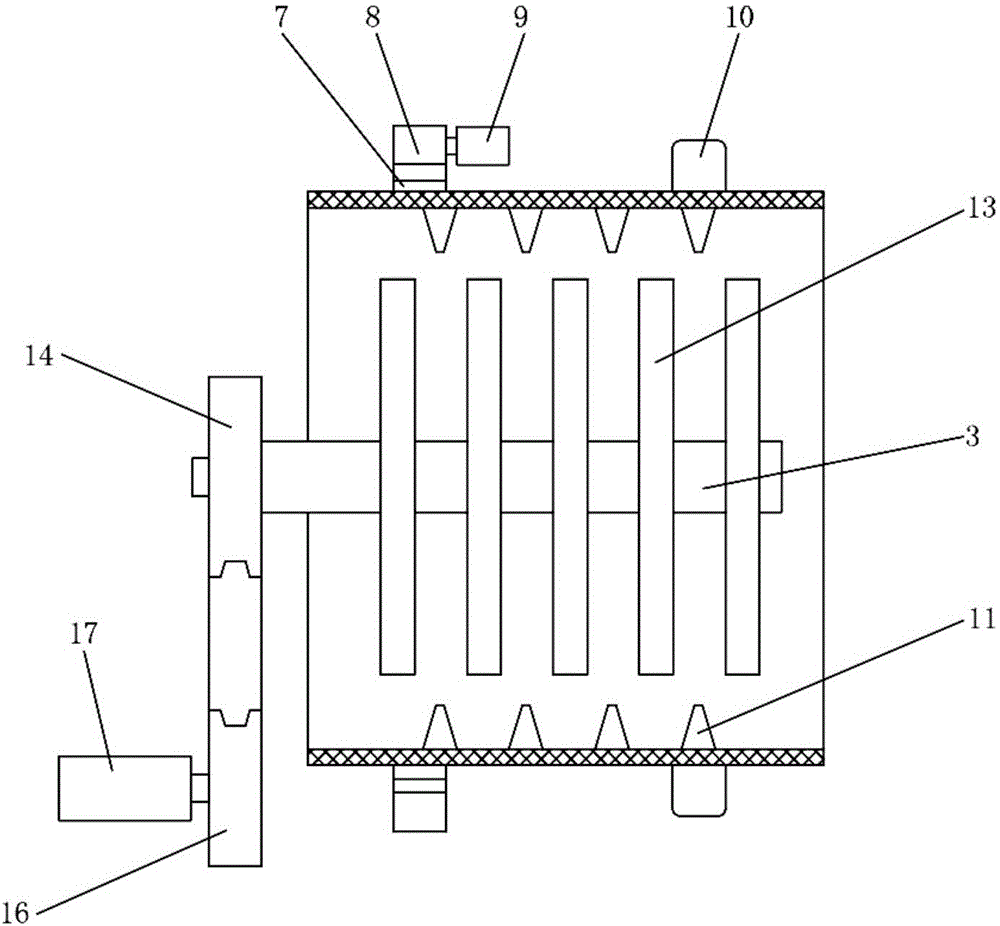

Crusher for preparation of agricultural fertilizer

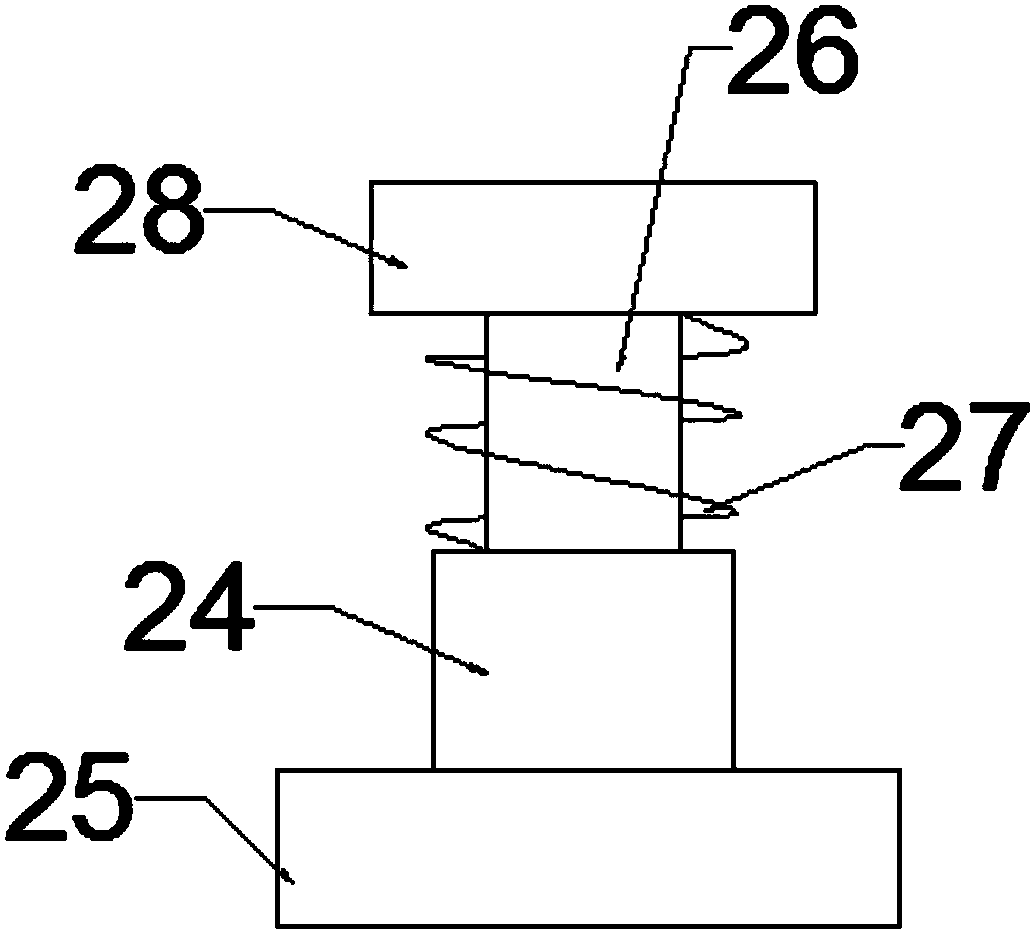

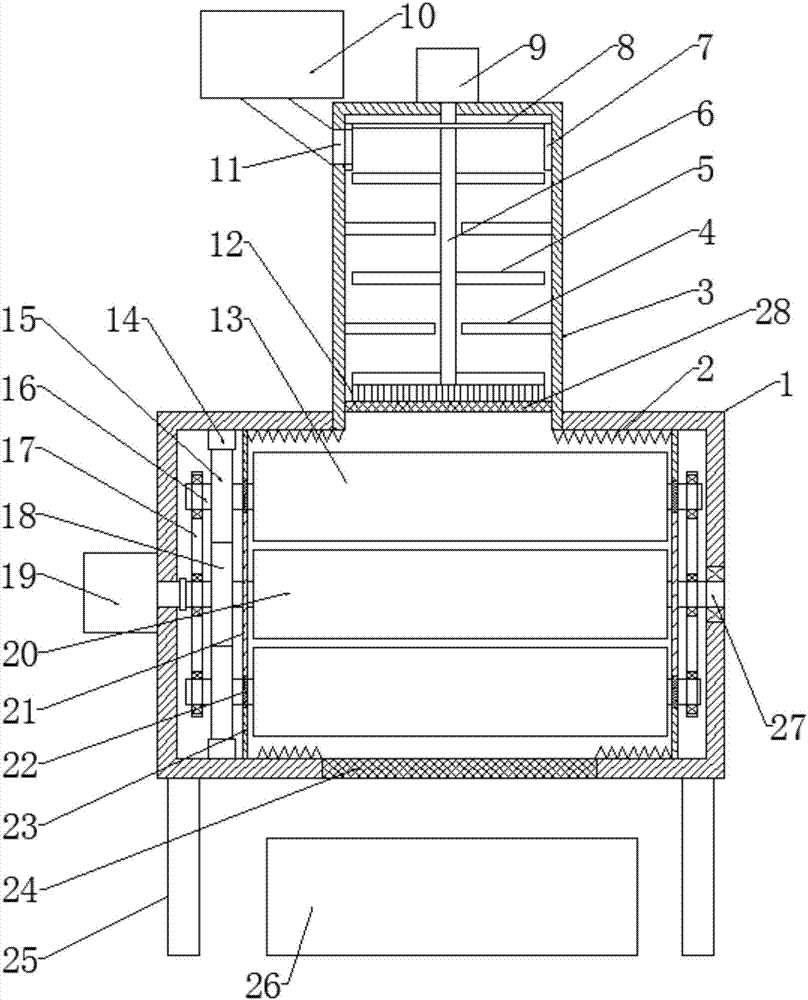

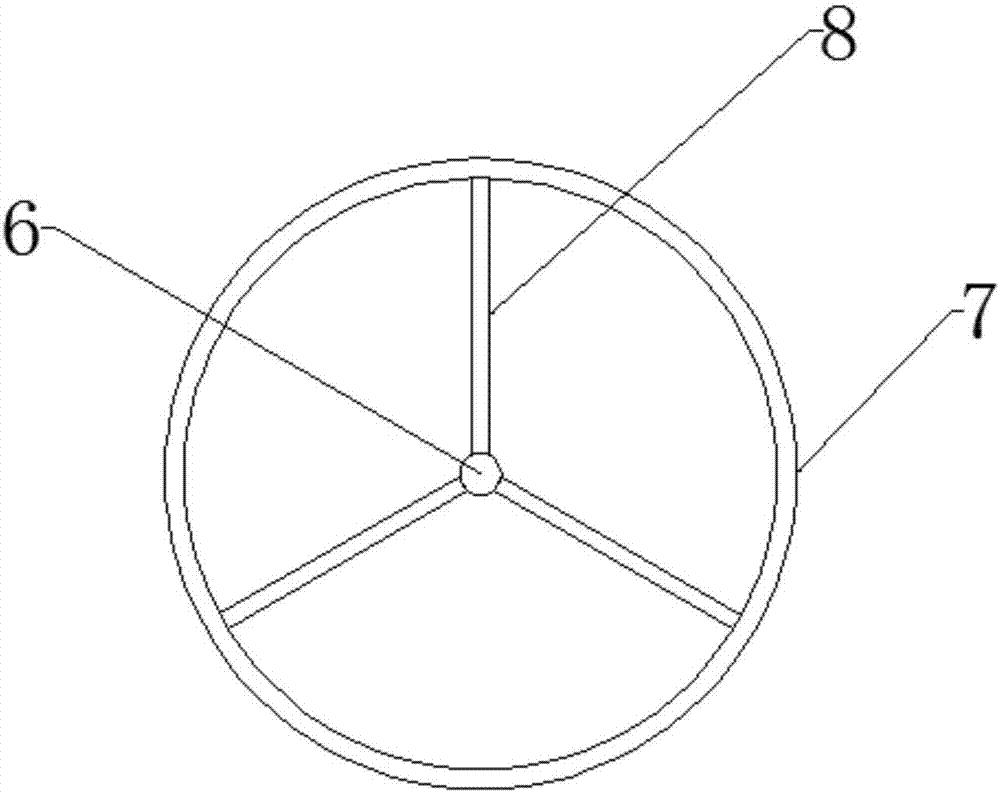

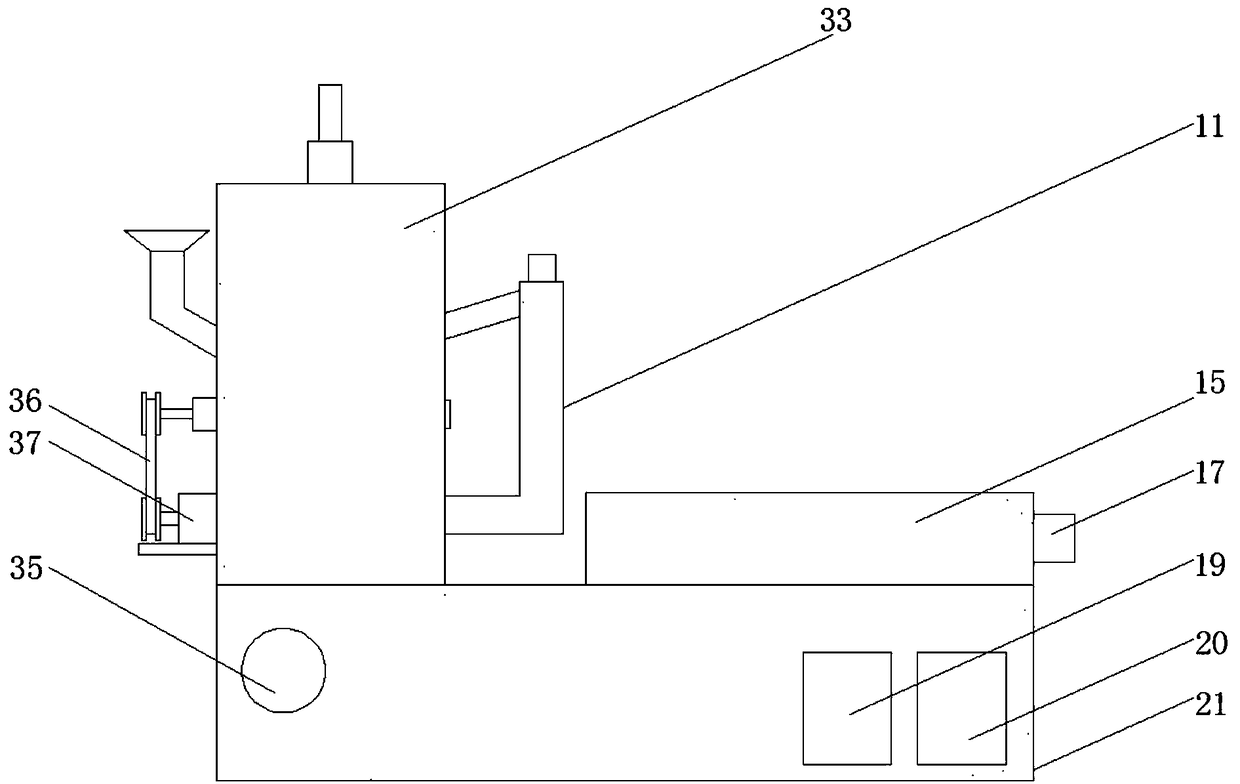

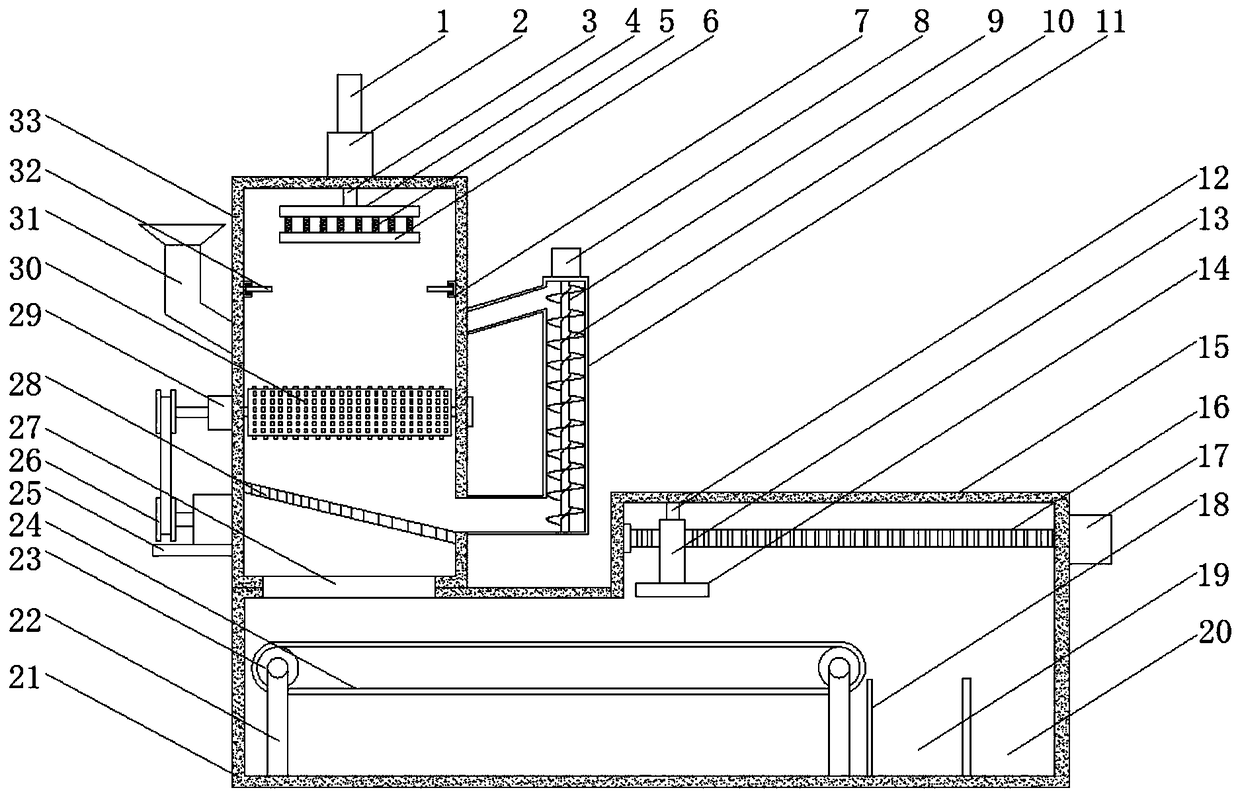

InactiveCN107876140AStir quicklyFast crushingRotary stirring mixersTransportation and packagingAgricultural scienceReciprocating motion

The invention discloses a crusher for preparation of agricultural fertilizer. The crusher comprises a frame body and a crushing box arranged on the frame body, wherein a feeding hopper is arranged onthe top of the crushing box; a material storage cavity is formed in the bottom of the crushing box; the bottom of the material storage cavity is connected with a discharging hopper; a material storagebox is arranged under the discharging hopper; a second motor is fixed to one side of the material storage box, and a control box is arranged on the other side of the material storage box; a dust collecting box is arranged on the side, far away from a first motor, of the top end of the crushing box; and a fan is arranged on the outer side of the dust collecting box. Stirring blades are arranged inthe material storage box of the crusher and can be used for rapidly stirring the fertilizer, a heating wire is arranged inside the material storage box and can be used for heating the fertilizer, thus the wet caking fertilizer can be rapidly stirred into particles, and the stirring process is accelerated. A sliding rod, a hydraulic telescopic rod and a third motor are arranged, so that crushing fan blades can do reciprocating motion back and forth while rotating and crushing is more thorough.

Owner:CHANGSHU HAOYU ELECTRONICS INFORMATION TECH

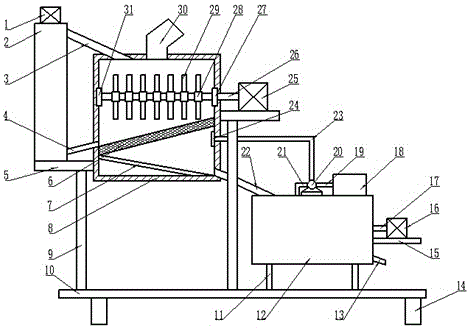

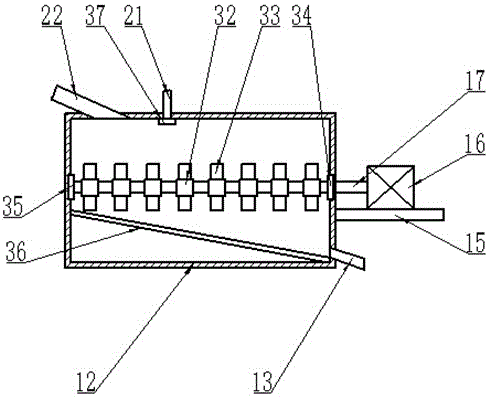

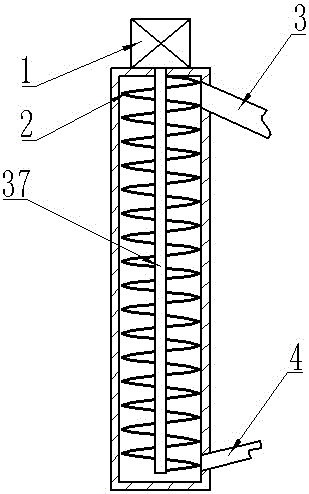

Yeast block pulverizer for white spirit processing

InactiveCN107812556AImprove processing efficiencyReduce labor intensityGrain treatmentsPulverizerYeast

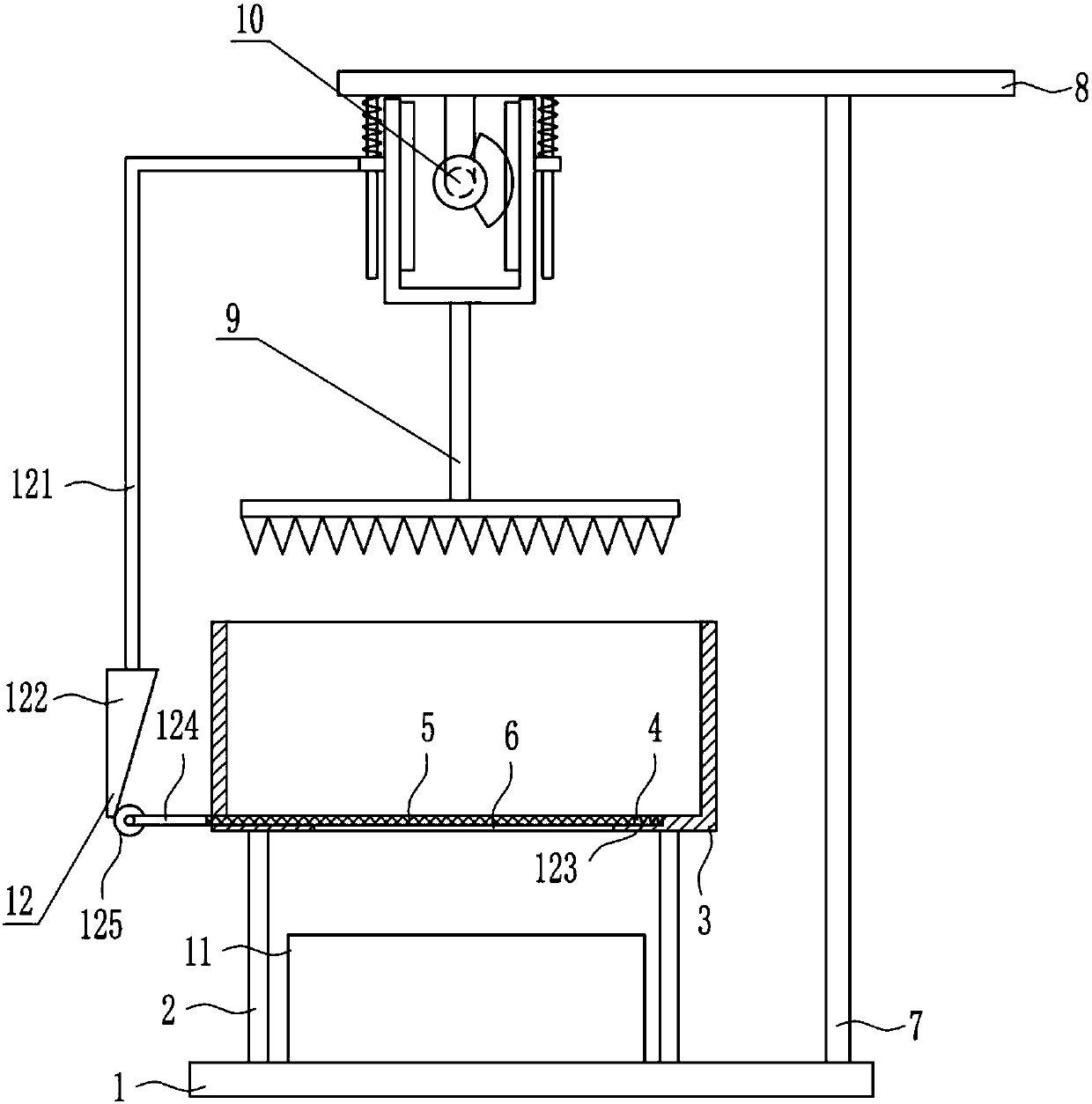

The invention relates to a pulverizer for white spirit processing, in particular to a yeast block pulverizer for white spirit processing. The yeast block pulverizer for white spirit processing can reduce the labor intensity, can improve the pulverizing speed, can improve the processing efficiency of white spirit, and is convenient to use. The yeast block pulverizer for white spirit processing comprises a base and the like. The left side of the top of the base is vertically connected with two supporting rods. The two supporting rods are symmetrical left and right. A box body is connected with the position between the top ends of the two supporting rods. The top of the box body is arranged in an opening mode. A sliding groove is formed in the bottom in the box body. The sliding groove is internally provided with a net plate. A discharging opening is formed in the middle of the bottom of the box body. The discharging opening communicates with the sliding groove. According to the yeast block pulverizer for white spirit processing, a pulverizing device can be driven to work by a driving device, and then the pulverizing device pulverizes yeast blocks, so that the effects that the labor intensity can be reduced and the processing efficiency of the white spirit can be improved are achieved.

Owner:闫存

Environment-friendly microbial method garbage treatment device and garbage treatment method thereof

ActiveCN109759417AImprove crushing efficiencyFast crushingBio-organic fraction processingSolid waste disposalOrganic matterToxicity

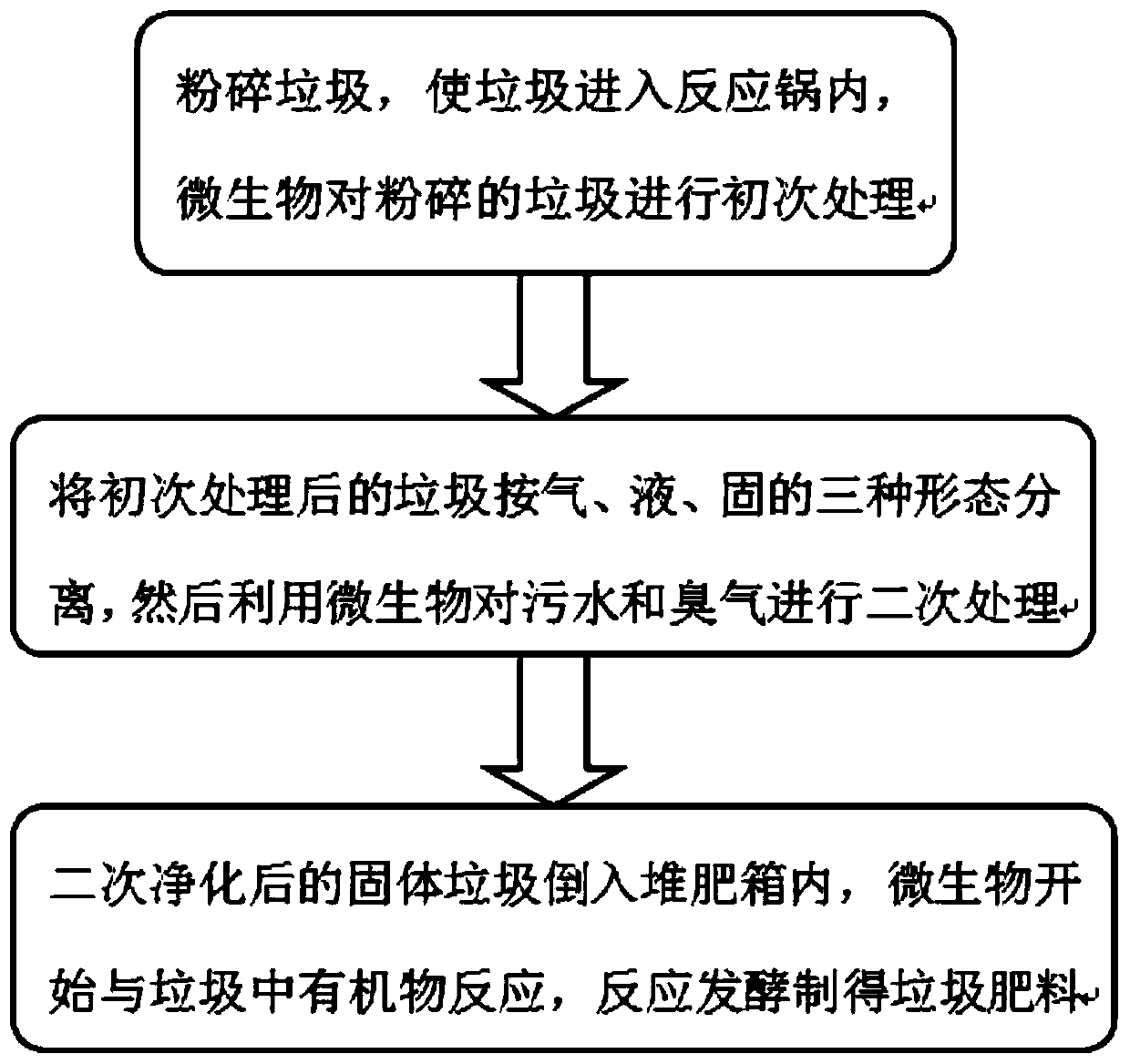

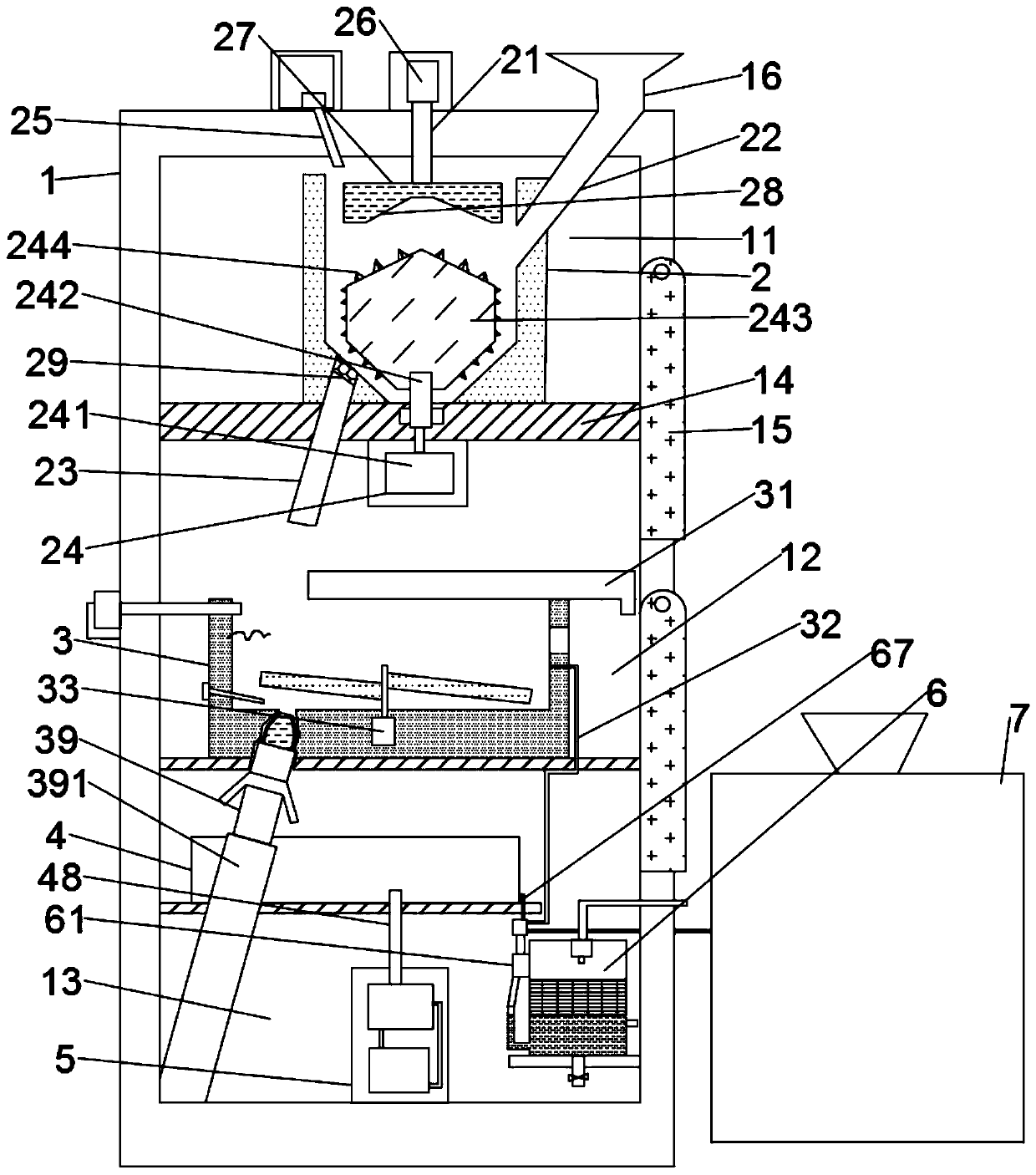

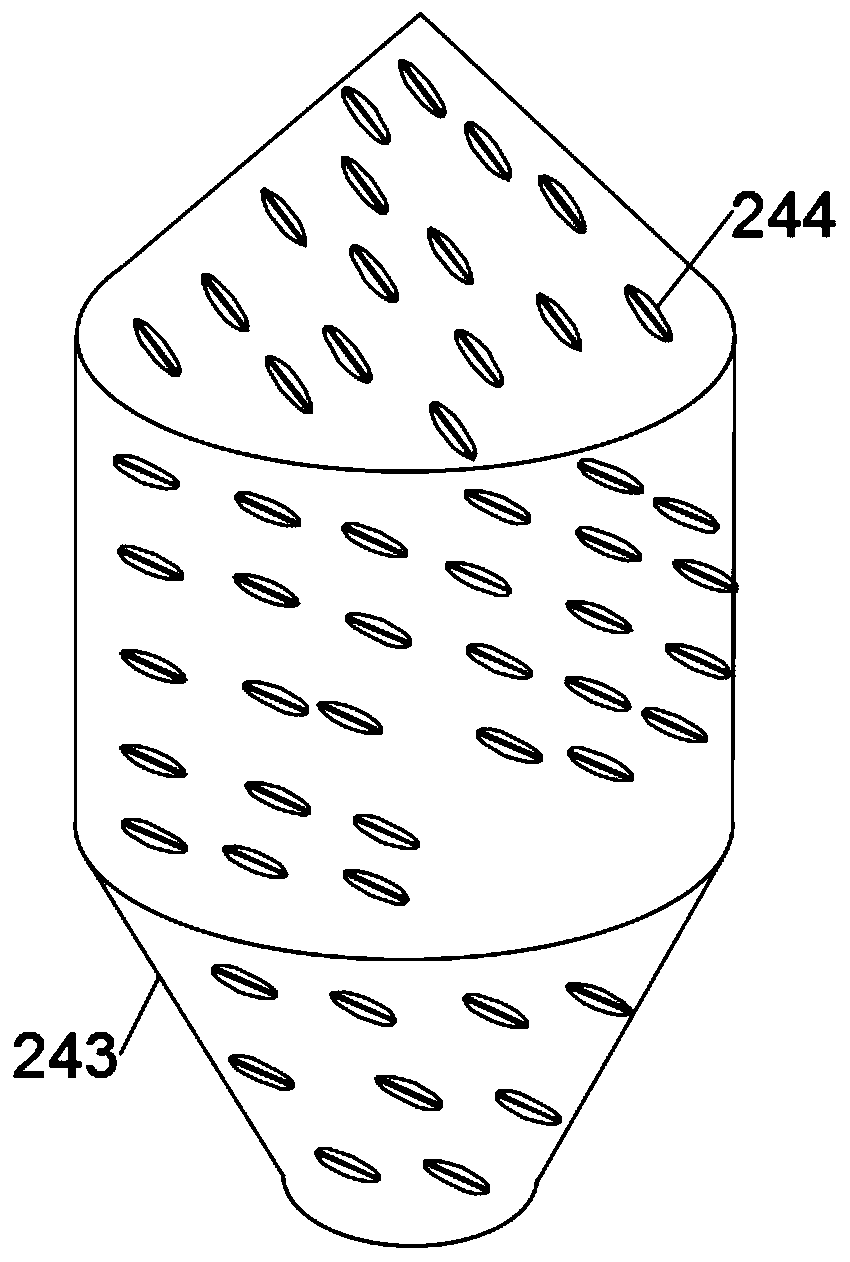

The invention discloses an environment-friendly microbial method garbage treatment device. The device comprises a treatment box, the upper part and the lower part of the treatment box are sequentiallyinstalled with a crushing cylinder, a reaction pot and a product classification and purification device through a grinding chamber, a microbial reaction chamber and an enzymolysis product treatment chamber; a rotary grinding cutting device is arranged in the crushing cylinder, a uniform rolling stirring device is arranged in the reaction pot, efficient crushing of the rotary grinding device enables the garbage particles to be more finely crushed, the speed of organic matters in the microbial enzymolysis waste is higher, the uniform rolling stirring device can enable the garbage to be fully and uniformly contacted with microorganisms, the area and the toxicity killing efficiency of the primary purification of the garbage are improved; the method comprises the following steps of crushing and grinding the garbage by the rotary grinding cutting device, then the garbage enters the reaction pot, the microorganisms in the reaction pot carry out enzymolysis reaction on the crushed garbage forthe first time, the crushed garbage is uniformly mixed with the microorganisms, the enzymolysis reaction efficiency is high, and the garbage purification treatment is more thorough.

Owner:安徽科柏盛环保设备有限公司

Sorting equipment for electronic trash recycling

The invention discloses sorting equipment for electronic trash recycling. The sorting equipment comprises a box, a crushing device and a screening device, the crushing device is arranged at the top ofan inner cavity of the box, the screening device is arranged in the box and positioned below the crushing device, a sorting device is arranged below the screening device, the crushing device comprises a positive and negative rotation motor, a spline shaft, a threaded rod, a movable block, a gear, an inner gear ring and a crushing blade, the screening device comprises a screen, a disk, a pulling rope and a spring, and the sorting device comprises a sliding plate, a magnetic roller and a scraper. By the aid of the crushing device, electronic trashes can be sufficiently crushed, crushing speed is high, and working efficiency is improved. By cooperation of the disk, the pulling rope and the spring of the screening device, the screen moves left and right, and screening efficiency is improved.By the aid of the sorting device, magnetic metal in the electronic trashes can be rapidly sorted out and recycled, the labor intensity of workers is relieved, and the working efficiency is further improved.

Owner:苏州和必尔斯电子科技有限公司

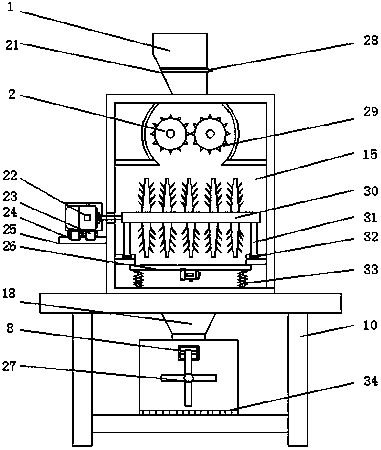

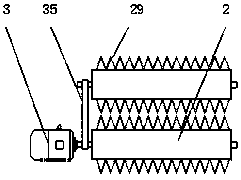

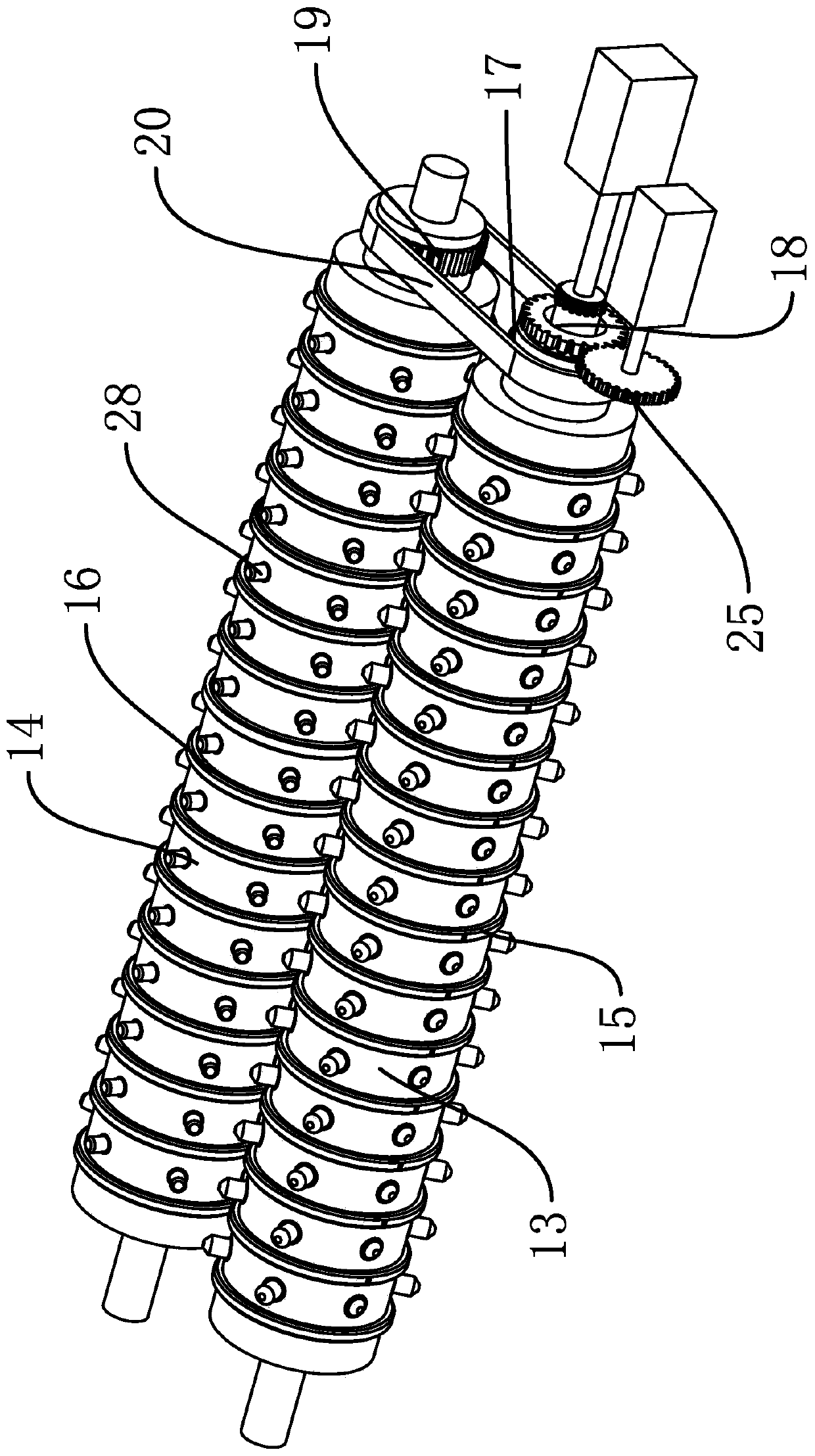

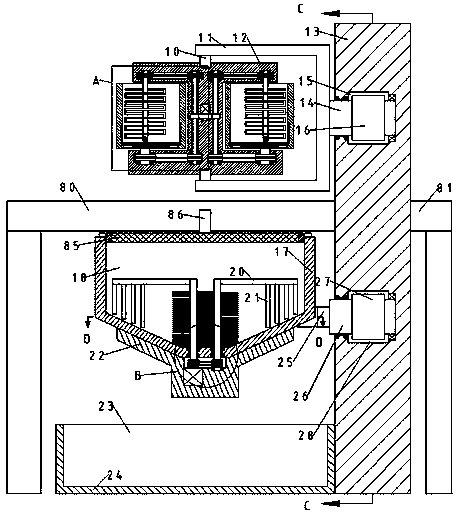

Crushing mechanism in concrete crushing machine

ActiveCN109772554AFast crushingGood effectGas current separationMagnetic separationPulverizerEngineering

The invention provides a crushing mechanism in a concrete crushing machine, and belongs to the technical field of buildings. The technical problems that the existing concrete crushing effect is poor,and the existing crushing efficiency is low are solved. According to the crushing mechanism in the concrete crushing machine, the crushing machine comprises a material return box, a crushing box and afeeding hopper, the crushing box is fixed to the material return box, and the feeding hopper is fixed to the crushing box; and the crushing mechanism comprises a first crushing roll and a second crushing roll, the first crushing roll and the second crushing roll are rotatably arranged in the crushing box and adjacently arranged, a plurality of first crushing rings are fixed to the first crushingroll, a plurality of second crushing rings are fixed to the second crushing roll, a first gear and a second gear are coaxially fixed to the first crushing roll, a third gear is coaxially fixed to thesecond crushing roll, the first gear and the third gear are sleeved with a chain, and the second gear is connected with a driving assembly used for driving the second gear to rotate. The crushing mechanism in the concrete crushing machine has the advantages that the concrete crushing effect is good, and the crushing efficiency is high.

Owner:淮北金辉绿建科技有限责任公司

Dendrobium officinale healthcare product with auxiliary blood glucose reducing function and preparation method thereof

ActiveCN104784505APromote absorptionImprove playbackMetabolism disorderFood preparationMedicinal herbsSide effect

The invention discloses a dendrobium officinale healthcare product with an auxiliary blood glucose reducing function. The dendrobium officinale healthcare product comprises the following raw materials in parts by weight: 35 to 45 parts of fresh dendrobium officinale bars, 1 to 2 parts of American ginseng, 2 to 4 parts of the root of kudzu vine, 2 to 4 parts of radix trichosanthis and 1 to 2 parts of fructus schizandrae. A preparation method for the dendrobium officinale healthcare product with the auxiliary blood glucose reducing function comprises the following steps: weighing the raw materials; processing the fresh dendrobium officinale bars; processing the American ginseng; performing alcohol extracting; performing water extracting; drying; batching. According to the dendrobium officinale healthcare product with the auxiliary blood glucose reducing function disclosed by the invention, the raw material formula is from clinical practice under the guidance of the theory of traditional Chinese medicine; the herbal medicines in a prescription are concise and are high in pertinency; the medicines in a raw material formula can nourish yin, benefit qi, clear heat and promote the secretion of saliva or body fluid; the active ingredients of the medicines are easy to absorb and are favorable to play efficacy; the medicinal materials in the raw material formula have the homology of medicine and food, and have no toxic or side effect.

Owner:广西弄峰山铁皮石斛科技有限公司

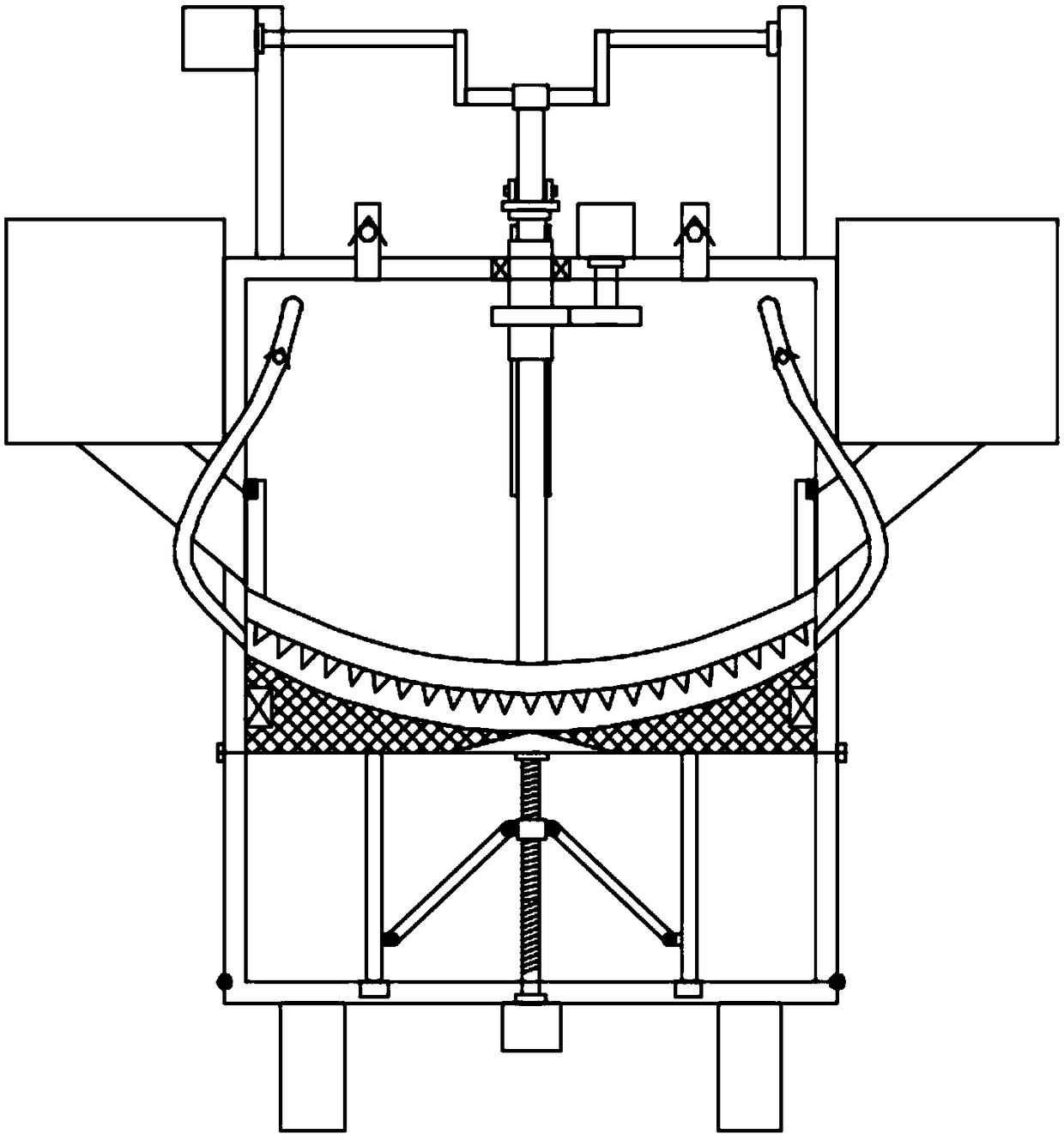

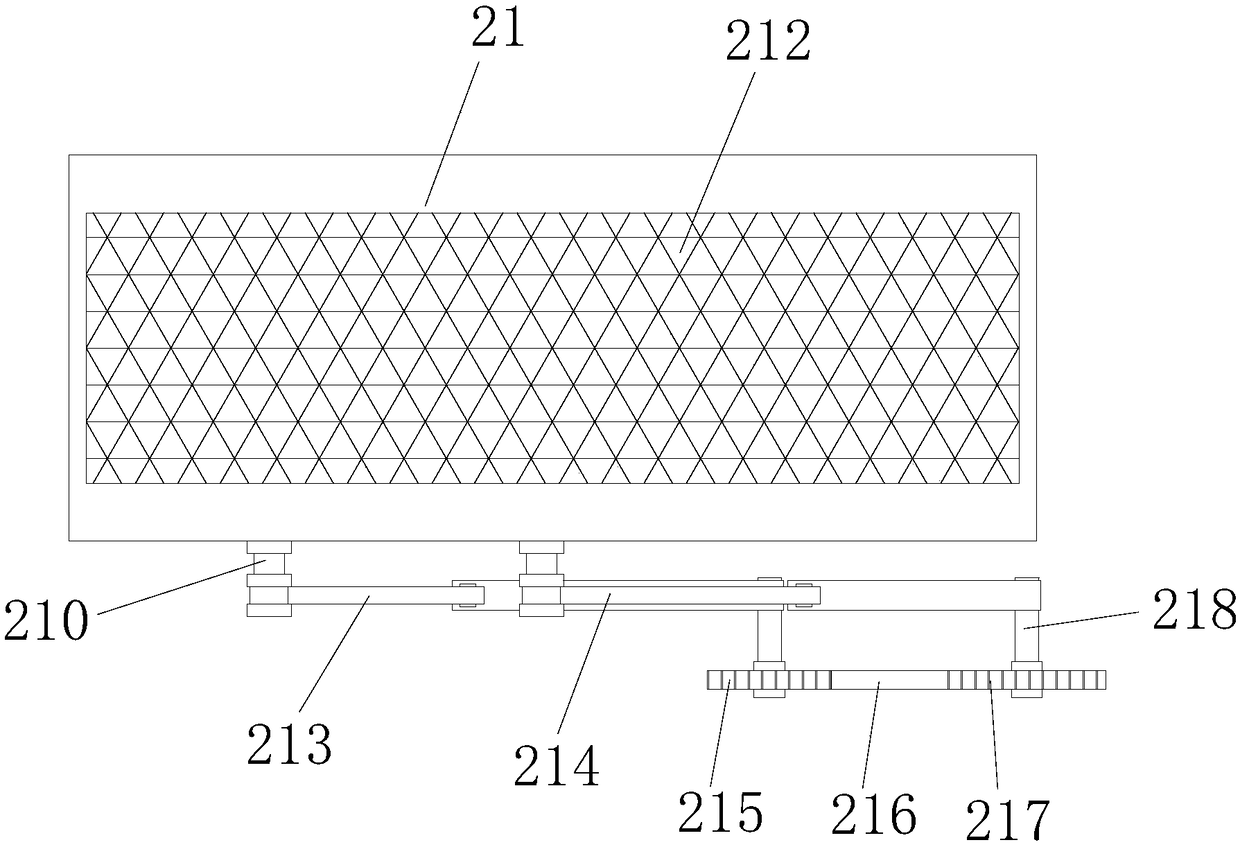

Pelletizing and screening integrated device for lithium ion battery cathode material

The invention relates to a pelletizing and screening integrated device for a lithium ion battery cathode material. The pelletizing and screening integrated device for the lithium ion battery cathode material comprises a charging box, a circulating lifting apparatus, a smashing barrel apparatus, a material conveying barrel, an inclined screen and a swinging screening apparatus. The swinging screening apparatus is welded to the upper ends of four supports; the inclined screen is welded to the inner wall of a first screening box; the left end of the inclined screen is lower than the right end ofthe inclined screen in position; the left end of the material conveying barrel is welded to the left side wall of a smashing outer barrel, and the right end of the material conveying barrel is disposed in a second bearing; the lower end of the charging box passes through the left side wall of the upper end of the smashing outer barrel to be fixedly disposed in the material conveying barrel, and the upper end of the charging box is disposed at the upper end of the smashing outer barrel; the circulating lifting apparatus is fixedly disposed at the upper end of a spring restoration box; and the smashing barrel apparatus is fixedly disposed among eight rotating rolling wheels. The pelletizing and screening integrated device for the lithium ion battery cathode material is reasonable in design,convenient to use and capable of performing circulating smashing and multi-level screening, the graphite particles are uniformly sized, and the smashing speed is improved.

Owner:合肥亚卡普机械科技有限公司

Environment-friendly waste crusher for constructional engineering

ActiveCN108906201AMuch frictionAvoid damageMagnetic separationGrain treatmentsHydraulic cylinderArchitectural engineering

The invention discloses an environment-friendly waste crusher for constructional engineering, which comprises a feeder, a slide chamber, a bottom tank, a crushing tank, and a crushing motor, the crushing tank is fixedly mounted on the left side of the top of the bottom tank, the right side of the top of the bottom tank is open, the slide chamber is fixedly mounted on the right side of the top of the bottom tank, moreover, the slide chamber communicates with the bottom tank, an opening is arranged at the joint between the bottom of the crushing tank and the bottom tank, the opening is a squareopening, the crushing tank communicates with the bottom tank via the opening, a hydraulic cylinder support is fixedly mounted on the top of the crushing tank, a hydraulic cylinder is fixedly mounted on the top of the hydraulic cylinder support, a retractable rod is fixedly mounted on the bottom of the hydraulic cylinder, the bottom of the retractable rod extends into the crushing tank, furthermore, a first pressing plate is fixedly mounted on the bottom of the retractable rod, and a second pressing plate is arranged on the bottom of the first pressing plate. According to the environment-friendly waste crusher for constructional engineering, the design is reasonable, functionality is diversified, the crushing effect is good, the speed is high, moreover, metal parts can be recycled, resources are saved, and the working efficiency is increased.

Owner:济南四建(集团)有限责任公司

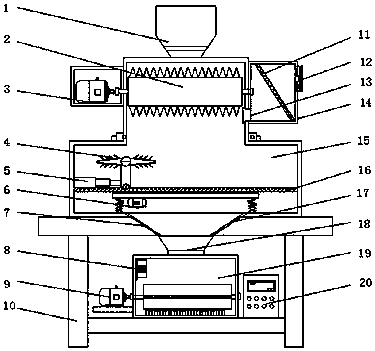

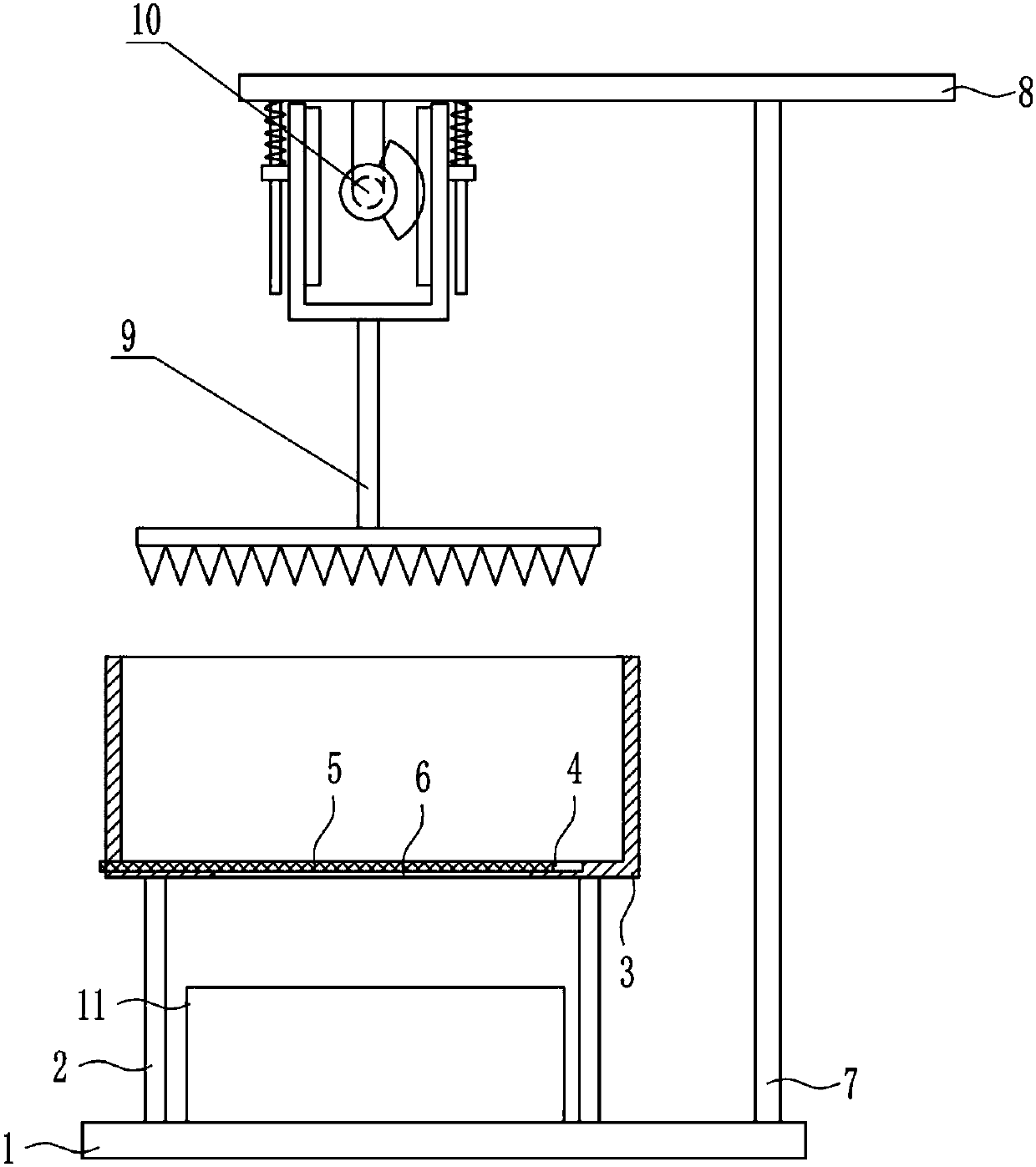

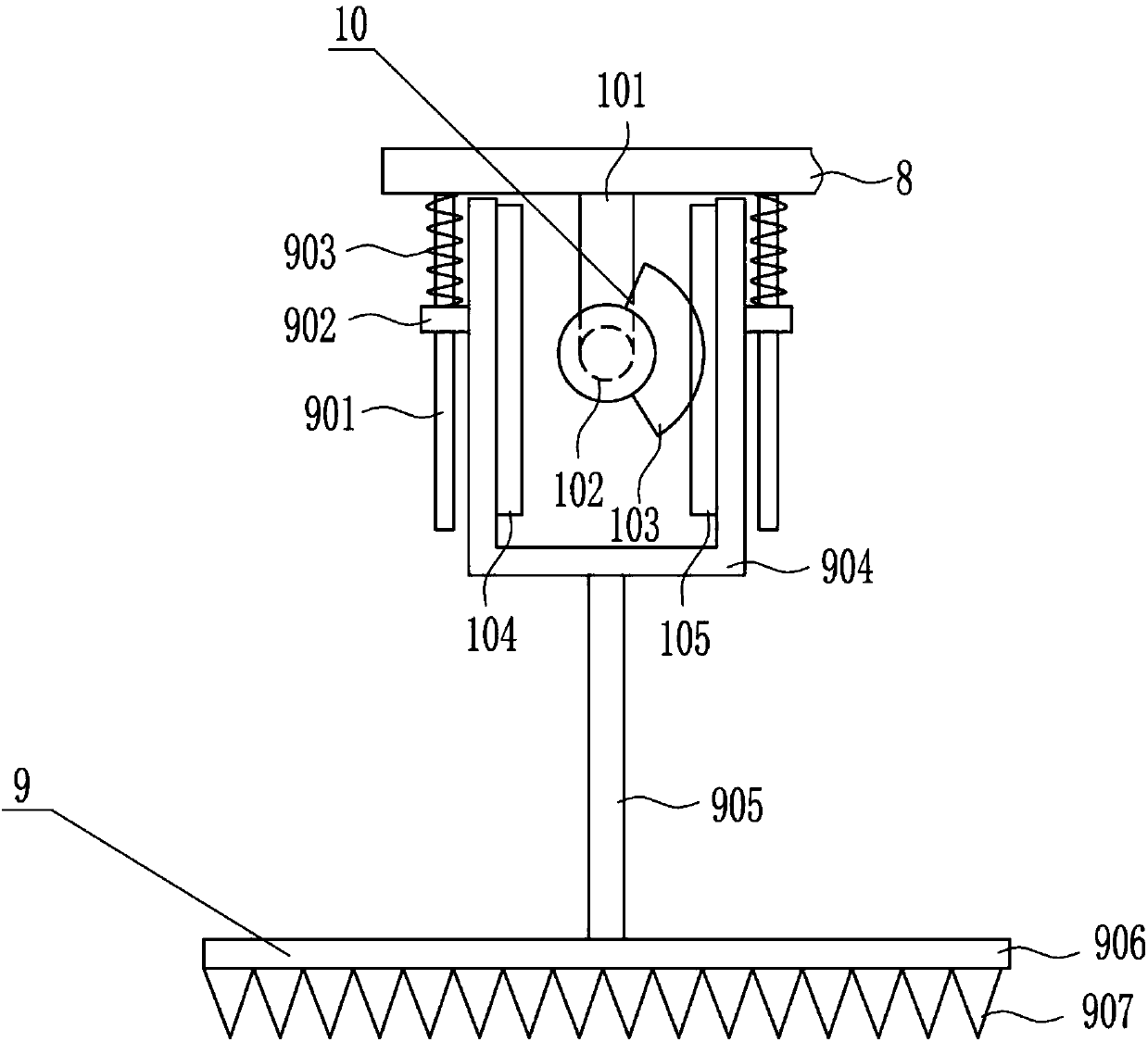

Efficient compression smashing device of straw

The invention provides an efficient compression smashing device of straw. The efficient compression smashing device of the straw comprises a case, a compression cavity, a smashing cavity and a motor cavity, wherein the case is provided with a feed hopper, a bottom seat and a discharge pipe, the compression cavity is formed in the lower end of the feed hopper, compression plates, an air cylinder, a telescopic shaft and a sliding chute are arranged in the compression cavity, the number of the compression plates is two, the compression plates are connected with the telescopic shaft, support legs are arranged at lower ends of the compression plates, the smashing cavity is formed in the lower end of the compression cavity, the smashing cavity is provided with a discharge outlet, a cross rod, a left vertical rod, a feeding case and a right vertical rod, the feeding case is arranged in the middle of the smashing cavity, and fixed on the inner wall of the lower end of the case, the feeding case is provided with a smashing blade, a rotation shaft and a feed inlet, the rotation shaft runs through the lower end of the case, a conveying blade is arranged on the rotation shaft, the upper end of the rotation shaft is connected onto a bearing, the motor cavity is formed in the lower end of the case, and a drive motor and a damping device are arranged in the motor cavity. The efficient compression smashing device of the straw can be stretched out and drawn back, is prevented from jamming, performs cyclic grinding, is thorough in smashing and high in smashing efficiency, and can achieve shock absorption.

Owner:郑州吉音动漫科技有限公司

Multistage high-efficiency crushing device for ceramic raw materials

The invention discloses a multistage high-efficiency crushing device for ceramic raw materials. The crushing device comprises a shell; a hydraulic vibrator is fixedly arranged on the top surface of the inner wall of the shell; a crushing groove is formed in the middle of the shell, and a crushing barrel is arranged at the bottom of the shell; a discharge port is formed in the bottom surface of theshell; a motor base is arranged at the bottom of the hydraulic vibrator through a vibrating rod; a motor is fixedly arranged in the motor base; a crushing hammer is fixedly arranged on the motor through a motor shaft; a vibrating screen is arranged at the bottom of the crushing groove; a rotary body is arranged right in the middle of the crushing barrel; the crushing barrel and the rotary body rotate coaxially; and a plurality of crushing cutters are arranged on the circumferential wall of the rotary body. According to the crushing device, the ceramic raw materials are primarily crushed through vibration rotation of the crushing hammer and then are crushed again by rotating the cutters at a high speed so that the crushing effect of the ceramic raw materials can be better, the vibrating screen and the crushing barrel are matched so that the ceramic raw materials cannot block the discharge port, the funnel structure and the low-speed rotation of the crushing barrel enable the crushing cutters to perform crushing step by step in the rotating process, and therefore the crushing cutters can be protected, and high-efficiency crushing and the quality of the ceramic raw materials can be guaranteed.

Owner:李南翔

Tire crusher

ActiveCN105345946AFast crushingImprove work efficiencyPlastic recyclingMechanical material recoveryPulverizerEngineering

The invention discloses a tire crusher which comprises a base, a feed opening, a tire pretreatment chamber and a tire crushing cylinder, wherein a first driving motor and a second driving motor are fixedly mounted on two sides of the base; the tire crushing cylinder is arranged between the first driving motor and the second driving motor; the lower end of the tire crushing cylinder is fixedly mounted on the base; the tire pretreatment chamber is arranged at the upper end of the tire crushing cylinder; the feed opening is formed in the upper end of the tire pretreatment chamber; a coarse crushing chamber is arranged at the upper part in the tire crushing cylinder; a crushing chamber is arranged in the lower part in the tire crushing cylinder; a first roll and a second roll are arranged in the coarse crushing chamber; the crushing chamber is divided into a first crushing chamber and a second crushing chamber; the first crushing chamber and the second crushing chamber are separated by a partition plate; and the first crushing chamber and the second crushing chamber adopt the same structure. Under certain cost control, the energy consumption is reduced, the production efficiency of the crusher is improved, and different grades of rubber blocks with a smaller crashing ratio are obtained.

Owner:上海孚祥生态环保科技股份有限公司

Abandoned waste recovery processing equipment for producing solar cell panel assembly

The invention discloses abandoned waste recovery processing equipment for producing a solar cell panel assembly. The abandoned waste recovery processing equipment structurally comprises a machine bodybase, a bottom transmission box, a transmission motor, a smashing cutting box, a waste extrusion box, a waste putting box, a waste dredging mechanism and a waste discharging mechanism; a waste shaking screen plate is provided with a shaking screen plate connecting shaft, a screen plate limiting groove, a shaking screen net, a shaking screen front strut, a shaking screen back strut, a shaking screen small gear, a shaking screen conveying belt, a shaking screen large gear and a gear set fixing shaft; and when the equipment is used, solar cell panels can be quickly smashed when processed, cutting is even, the smashing speed is accelerated, sufficient preparation is made for follow-up recovery work, and the problems that difficulties are caused by uneven waste smashing on the follow-up recovery work, the machining process is increased, and resource waste is caused are solved.

Owner:东阳市天杨建筑工程设计有限公司

Efficient crushing and screening device for ores

The invention discloses an efficient crushing and screening device for ores. The efficient crushing and screening device comprises a bottom plate, a supporting plate, a roof, a screening frame, a crushing frame, a discharging opening, a crankshaft, a first mounting plate, a first connecting rod shaft neck, a second connecting rod, a first crushing plate, a third connecting rod, a fourth connectingrod, a transverse rod, a five connecting rod, a second crushing plate, a first belt pulley, a belt, a second belt pulley, a motor, a disc, a traction rope, a screening net, a spring, a collecting frame and a dedusting device. The efficient crushing and screening device is provided with the motor, the crankshaft, the first crushing plate and the second crushing plate, the ores can be continuouslycrushed, the crushing speed is high, the efficiency is high, the disc, the traction rope and the screening net are arranged, the screening net is driven to move left and right through matching, the screening efficiency is improved, the dedusting device is arranged and includes a dust sucking pipe, an air purifying device and an exhaust fan, dust produced in the crushing process is purified, and the situation that the dust affects health of workers is avoided.

Owner:凤阳阮氏工贸有限公司

Abandoned LED lamp bead smashing device

The invention relates to a smashing device, in particular to an abandoned LED lamp bead smashing device. According to the technical aim, the abandoned LED lamp bead smashing device is high in smashingspeed and can conduct sorted treatment on disintegrating slag and pins after smashing. According to the technical scheme, the abandoned LED lamp bead smashing device comprises a base plate, a collecting frame, a support plate, connecting rods, a smashing frame, a first bearing block, a first rotating shaft, a smashing barrel, a first barrel and the like; the support plate is installed on the leftside of the top of the base plate, the connecting rods are symmetrically installed at the upper portion of the right side face of the support plate, the smashing frame is installed between the rightends of the connecting rods on the upper and lower sides, and a first discharging opening is formed in the middle of the bottom of the smashing frame. The disintegrating slag and the pins can be screened through a screening device, and follow-up treatment by an operator is facilitated; and through the effect of an electromagnet, scrap iron in the disintegrating slag can be separated out and collected, and the effects that the smashing speed is high, and the disintegrating slag and the pins can be subject to sorted treatment after smashing are achieved.

Owner:泉州市菲式生物科技有限公司

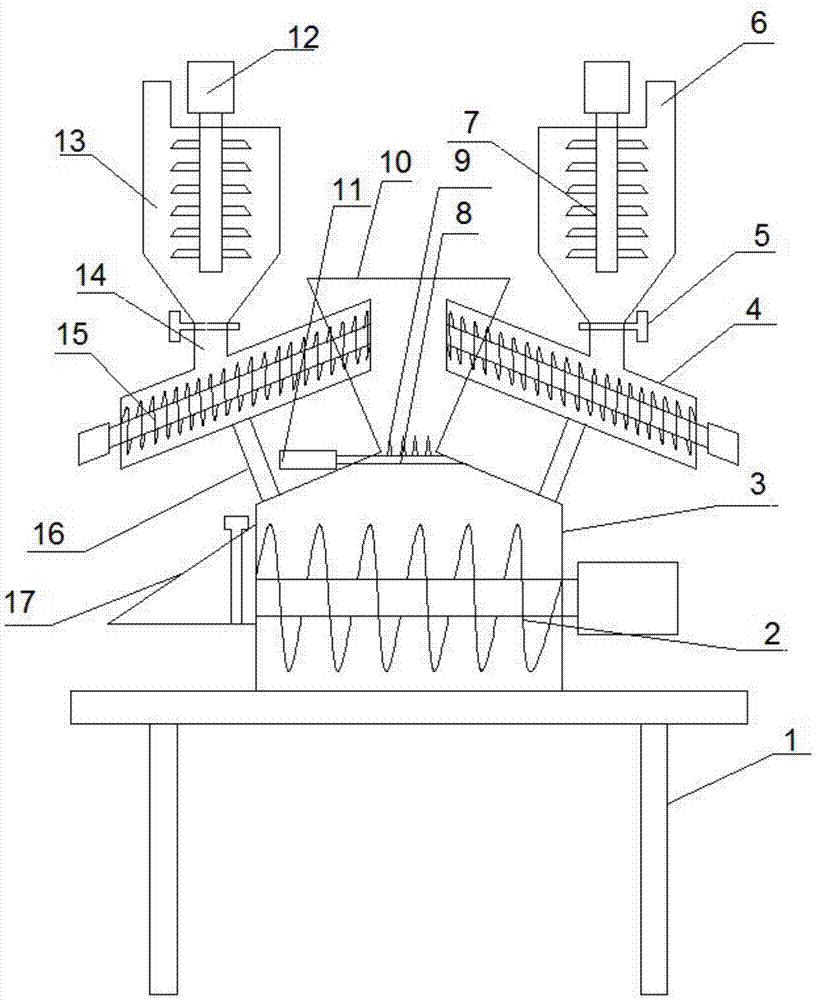

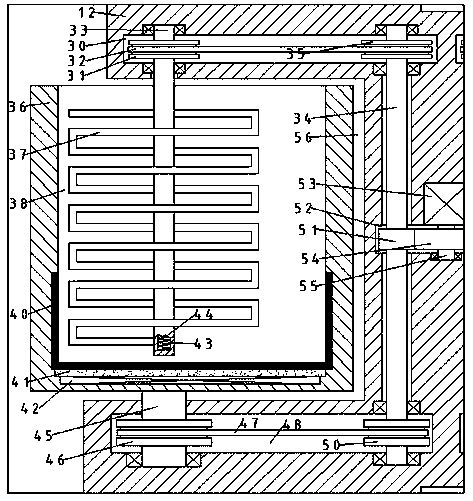

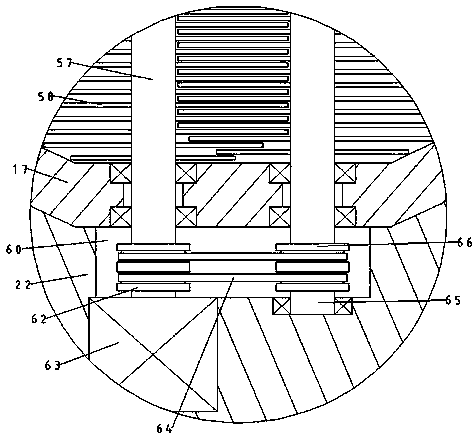

Two-stage crushing device for graphite for manufacturing negative electrode materials for lithium ion batteries

InactiveCN106733042AUniform sizeFast crushingDirt cleaningGrain treatmentsElectrical batteryLithium electrode

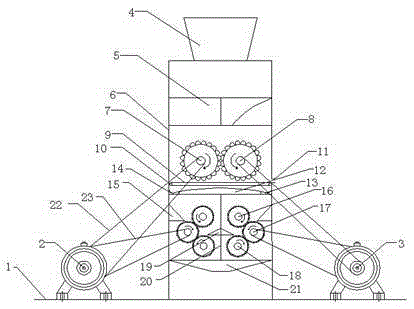

The invention provides a two-stage crushing device for graphite for manufacturing negative electrode materials for lithium ion batteries. The two-stage crushing device comprises a first-stage crushing device body, a second-stage crushing device body and a dust removal device; the first-stage crushing device body comprises a feeding cylinder, a screen plate and a first-stage crushing box, wherein the first-stage crushing box is welded on the left side surface and the right side surface of two carrying plates, the screen plate is welded on the inner parts of the two sides of the first-stage crushing box, and the feeding cylinder is fixedly arranged on the left carrying plate; the second-stage crushing device body comprises a second-stage crushing box and a second motor, wherein the second-stage crushing box is welded on two second-stage crushing support frames, and the second motor is fixedly arranged on a motor carrying plate; and the dust removal device comprises a dust collection box and a dust suction machine, wherein the dust suction machine is fixedly arranged on the second-stage crushing box. The two-stage crushing device for the graphite for manufacturing negative electrode materials for lithium ion batteries has the advantages that the size of graphite particles can be uniform through a two-stage crushing mode, the crushing speed can be increased, dust can be removed while crushing is conducted, and the environment can be protected.

Owner:SHENZHEN JUOCAN TECH CO LTD

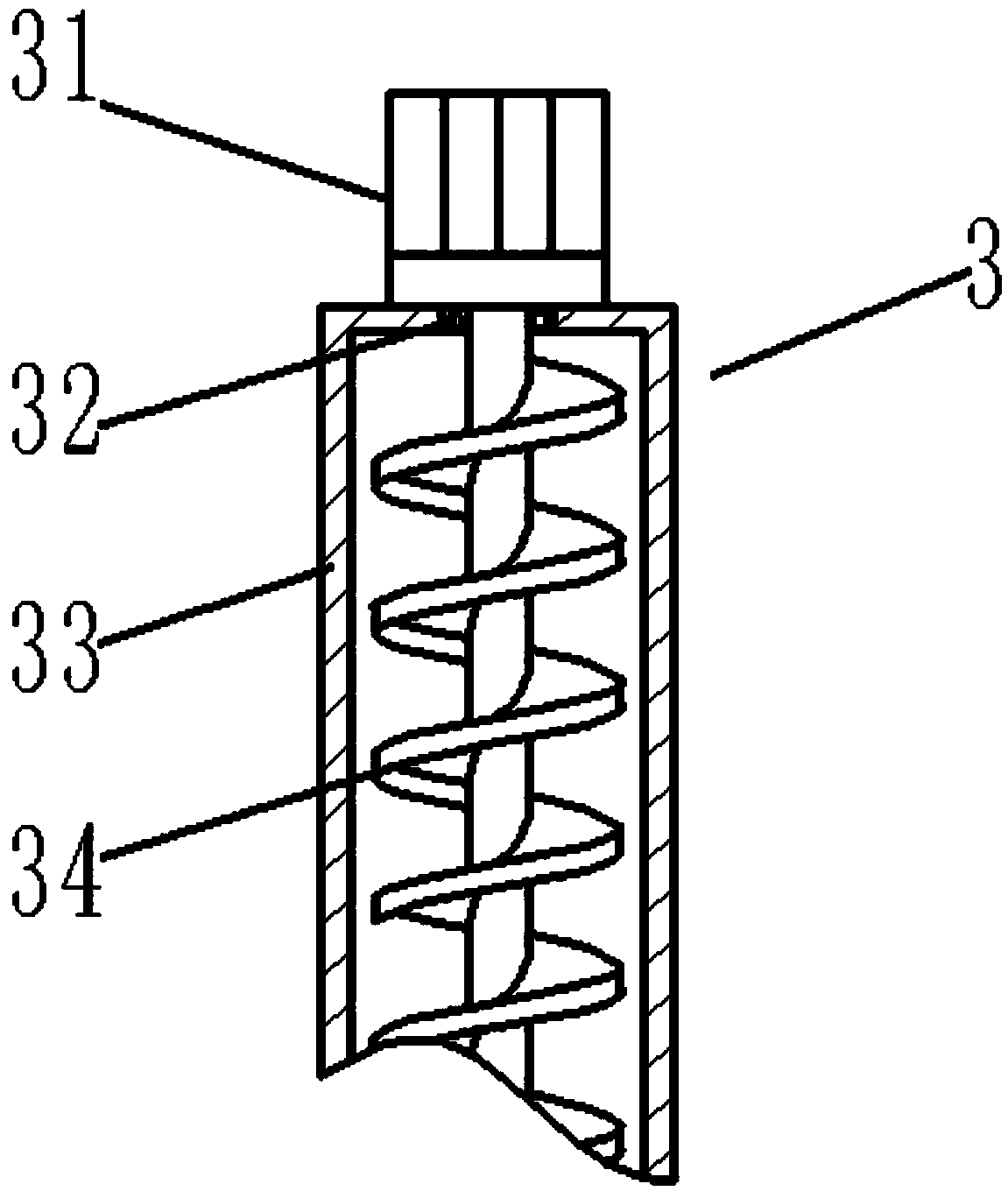

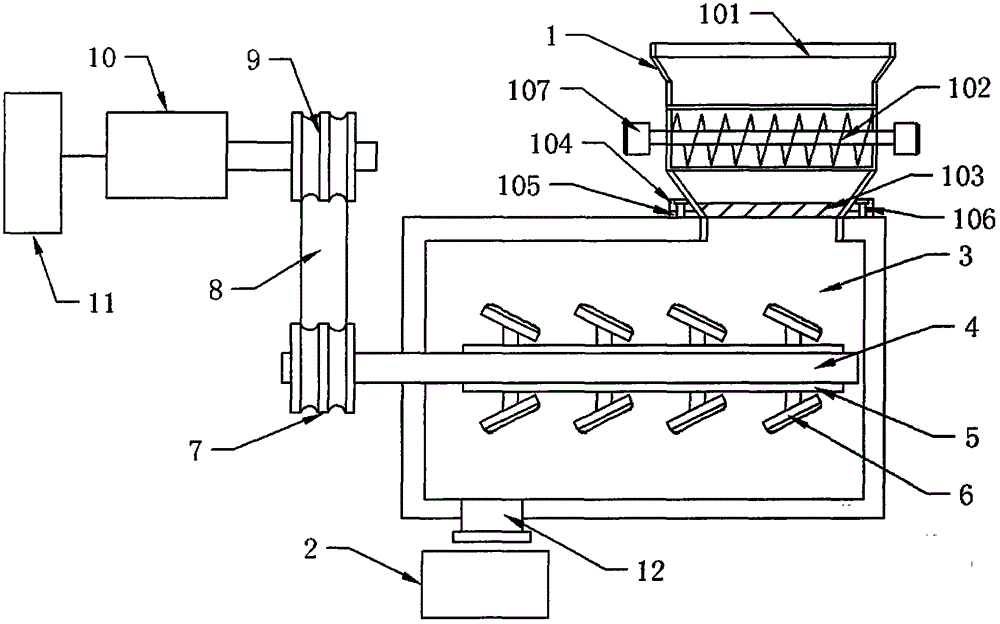

Feed anti-blocking type straw pulverizer

The invention discloses a feed anti-blocking type straw pulverizer. The feed anti-blocking type straw pulverizer comprises a smashing chamber, a feeding device and a discharging channel. The feeding device is arranged on the top of the right side of the smashing chamber and comprises a feeding inlet, a feeding screw rod and a discharging outlet. The feeding inlet is in a horn shape and is perpendicularly located above the feeding screw rod. A rotary shaft is arranged in the center inside the smashing chamber. One end of the rotary shaft is arranged inside the smashing chamber. The other end of the rotary shaft extends out of the smashing chamber. A driven wheel is arranged at the tail end of the rotary shaft and connected with a driving wheel through a transmission belt. The driving wheel is arranged on a motor, and the motor is electrically connected with a frequency changer. The feeding device is arranged to avoid the stacking and stagnated returning problems of materials to be smashed in the feed smashing process. A transmission mechanism composed of the driving wheel, the transmission belt and the driven wheel is arranged, so that compared with a transmission mode adopted in a motor part on a prior straw pulverizer, the feed anti-blocking type straw pulverizer has the advantage of being high in transmission efficiency and can achieve the transmission efficiency approaching 1: 1.

Owner:刘海明

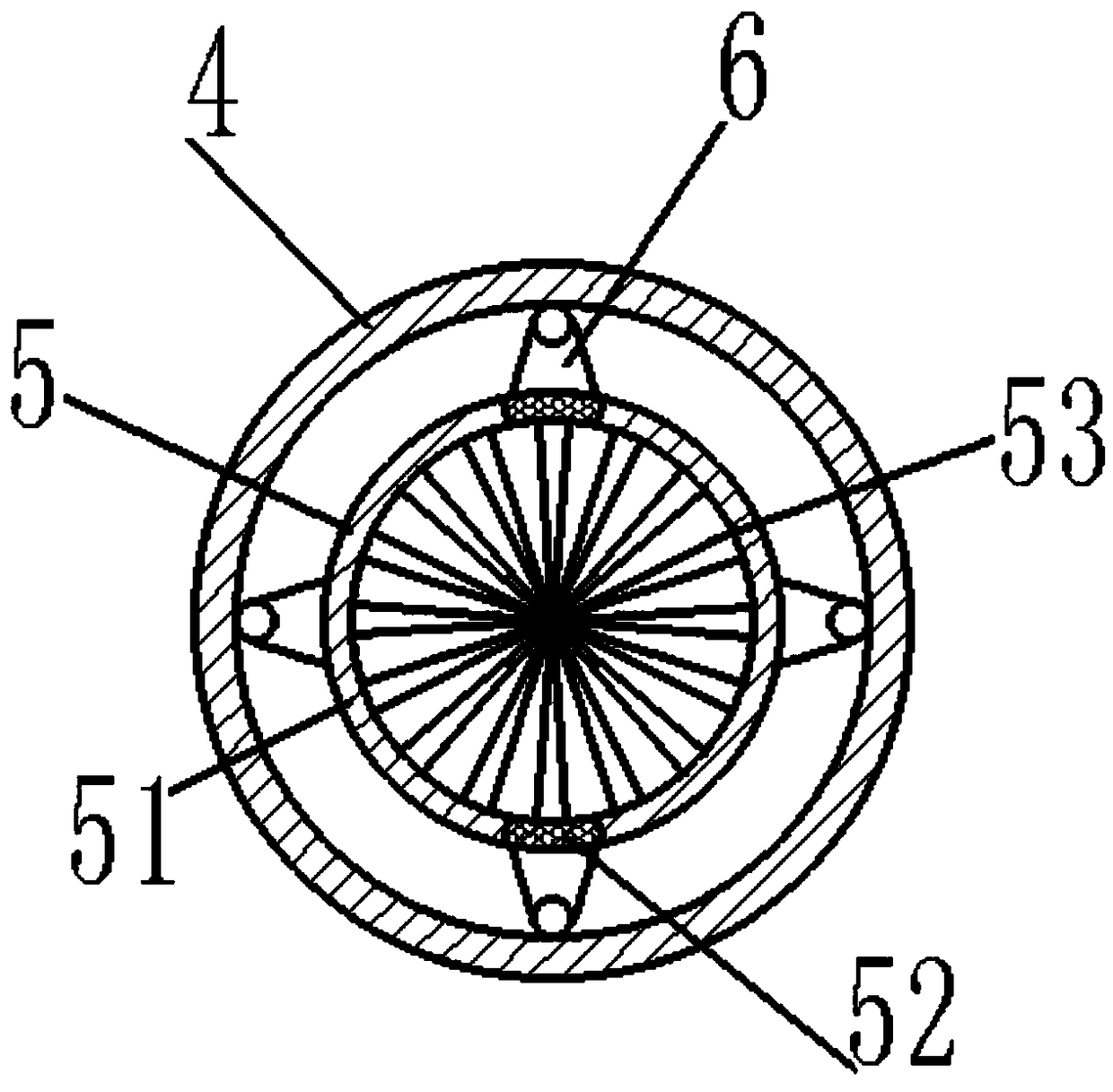

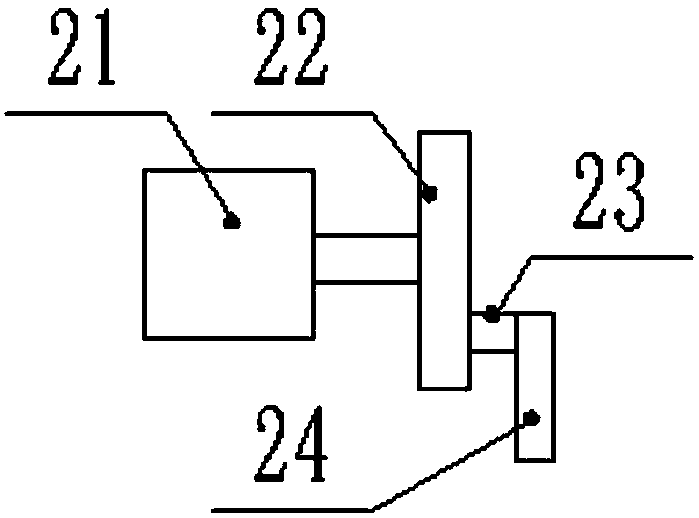

Pulping agitator

PendingCN106311042AFast crushingFine particleRotating receptacle mixersTransportation and packagingMotor driveLeather belt

The invention discloses a pulping agitator and belongs to the technical field of pulping equipment. A belt motor and a gear motor are arranged on a base of the pulping agitator; the output shaft of the belt motor is connected with a driving pulley; the driving pulley drives a driven pulley through a belt; the driven pulley is connected with a rotating shaft; a plurality of crushing knives are assembled on the rotating shaft radially; the output shaft of the gear motor is connected with a driving gear; the driving gear is in engaging transmission with the driven gear; a charging barrel is arranged on an inner ring of the driven gear in a sleeving manner; a plurality of stirring knives are arranged on the inner side wall of the charging barrel; and the rotating shaft coaxially penetrates through the center of the charging barrel. The belt motor drives the rotating shaft to rotate clockwise, so that the crushing knives perform pulping along the clockwise direction; meanwhile, the gear motor drives the charging barrel to rotate anticlockwise, so that the stirring knives perform stirring along the anticlockwise direction, the charging barrel rotating anticlockwise is matched with the rotating shaft rotating clockwise, pulp crushing and stirring can be performed in an interacting way, the pulping agitator can be suitable for pulping of complicated pulp, the grinding precision is high, the obtained granules are fine, and the paper pulp quality is improved.

Owner:ZHONGSHAN WEIKE PACKAGE PROD CO LTD

Honeysuckle-scutellaria baicalensis-forsythia superfine powder and production method thereof

InactiveCN103463203AFast crushingImprove efficacyPowder deliveryAnimal feeding stuffCoptis chinensisCommon Skullcap

The invention discloses a honeysuckle-scutellaria baicalensis-forsythia superfine powder and a production method thereof. The honeysuckle-scutellaria baicalensis-forsythia superfine powder is the mixture of 1 part of honeysuckle, 1 part of scutellaria baicalensis and 2 parts of forsythia, and the particle size of the superfine powder is 5-10mu m. The production method comprises the following steps of selecting and drying the honeysuckle, then smashing the honeysuckle into superfine powder by an ultrafine grinder, and setting aside; selecting the scutellaria baicalensis, then washing, drying and slicing, smashing the scutellaria baicalensis into superfine powder by the ultrafine grinder, and setting aside; selecting the forsythia, then washing, steaming, drying and slicing, smashing the forsythia into superfine powder by the ultrafine grinder, and setting aside; mixing the honeysuckle powder, the scutellaria baicalensis powder, and the forsythia powder in a weight part of 1:1:2; smashing the mixture into superfine powder by the ultrafine grinder, and sieving to obtain the superfine powder with particle size of 5-10mu m. The particle size of the honeysuckle-scutellaria baicalensis-forsythia superfine powder is less than 5-10mu m, the wall broken rate of the cells is more than or equal to 95%, the specific surface area is increased, the honeysuckle-scutellaria baicalensis-forsythia superfine powder is accelerated to dissolve out, and the bioavailability is improved; the honeysuckle-scutellaria baicalensis-forsythia superfine powder can be mixed with fodder and portable water so as to be taken by livestock, is convenient to dose, and is applicable to large-scale livestock farms.

Owner:SICHUAN LONGHAIYANG ANIMAL PHARMA CO LTD

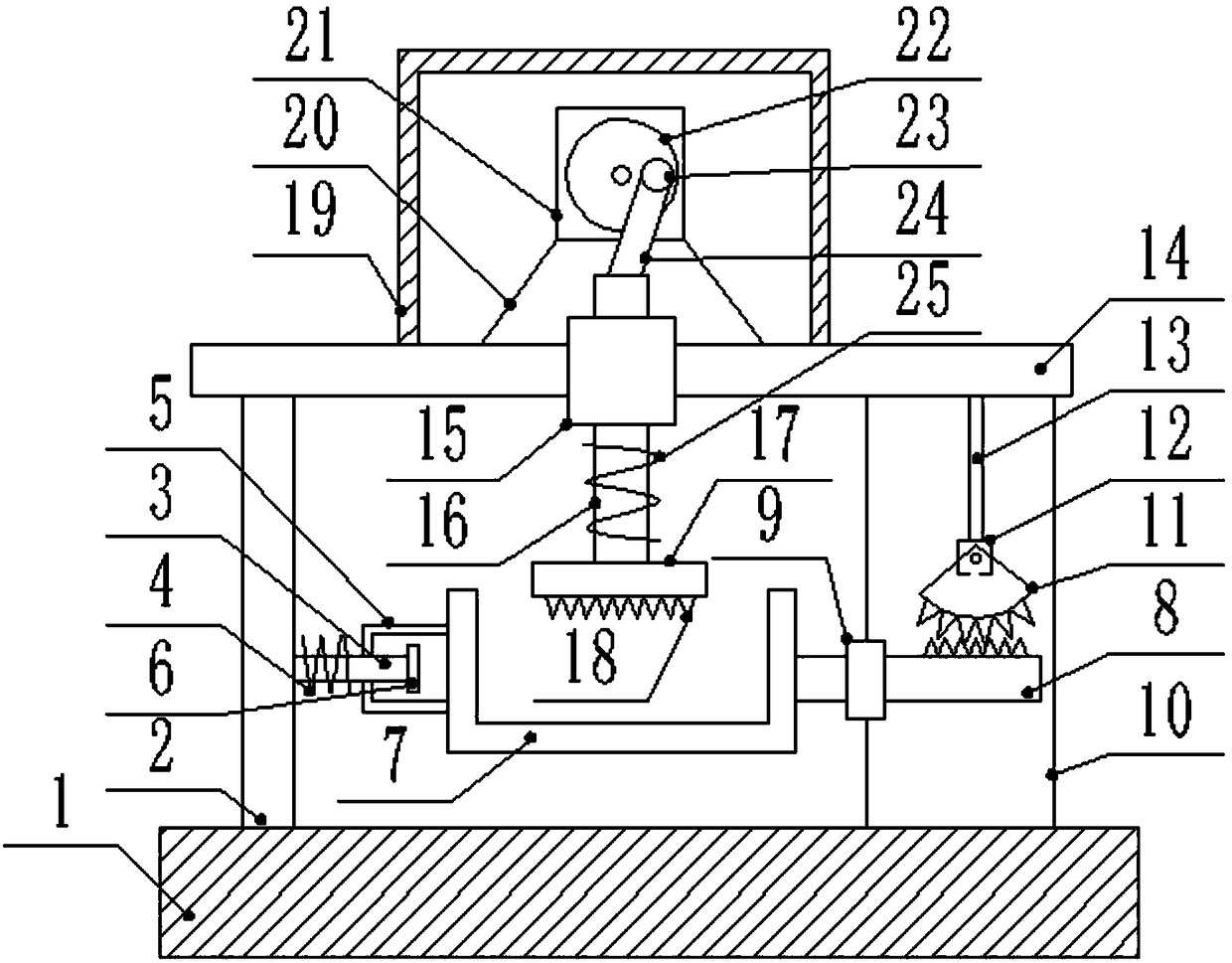

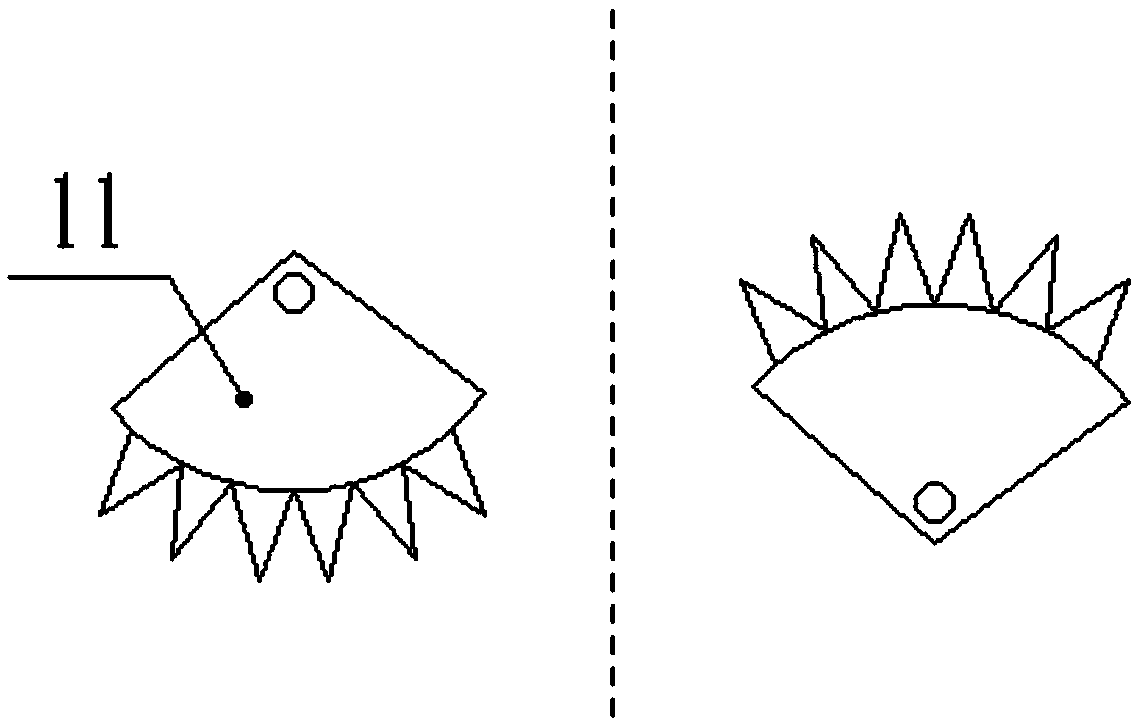

Sector gear-controlled crushing device for solid raw materials for food processing

The invention discloses a sector gear-controlled crushing device for solid raw materials for food processing. The crushing device comprises a base, wherein a support is fixedly connected to the uppersurface of the left side of the base, a connecting rod is fixedly connected to the upper end of the support in the horizontal direction, and a fixing box is fixedly installed on the right side of thelower surface of the connecting rod; a first fixing sliding block is fixedly connected to the middle of the left side of the fixing box, a second fixing sliding block is fixedly connected to the middle of the connecting rod, a push rod is connected to the interior of the middle of the second fixing sliding block in the vertical direction in a contact mode, and the lower end of the push rod is fixedly connected to a fixing plate; the lower surface of the fixing plate is fixedly provided with crushing teeth, the lower surface of the second fixing sliding block is fixedly connected to a second spring, and the lower end of the push rod penetrates through the middle of the second spring; and an outer cover is fixedly installed in the middle of the upper surface of the connecting rod, a second motor is arranged above the middle of the interior of the outer cover, and a motor support is fixedly installed at the lower end of the second motor. According to the crushing device, the solid raw materials can be fully crushed, the crushing effect is very good, and the crushing speed is high and the efficiency is high.

Owner:孙明

Construction waste smashing device economical in usage

InactiveCN107282256AEconomical to useEasy to useGrain treatmentsArchitectural engineeringConstruction waste

The invention discloses an economical construction waste crushing device, which comprises a main motor, a rotating shaft, a gear, a gear plate, a pressure hammer, a guide pipe, a mounting plate, a spring hinge, a turning plate, an auxiliary motor, a roller knife, and a discharge port , column, feet and feed hopper, the main motor is connected with the gear through the rotating shaft, the gear is connected with the pressure hammer through the gear plate, the outside of the pressure hammer is provided with a guide tube, and the right side of the guide tube is welded There is a mounting plate, the mounting plate is connected with the turning plate through a spring hinge, the underside of the turning plate is equipped with an auxiliary motor, and the auxiliary motor is connected with the roller knife through the rotating shaft, and the underside of the roller knife is provided with an outlet A feed port, the discharge port is connected with the pad through a column. The equipment has strong integrity, adopts symmetrical design, integrates crushing and crushing, and adopts double feeding ports, which makes feeding faster and crushing more thorough. It is a set of economical construction waste crushing device with excellent performance.

Owner:泰州市乐律金属制品有限公司

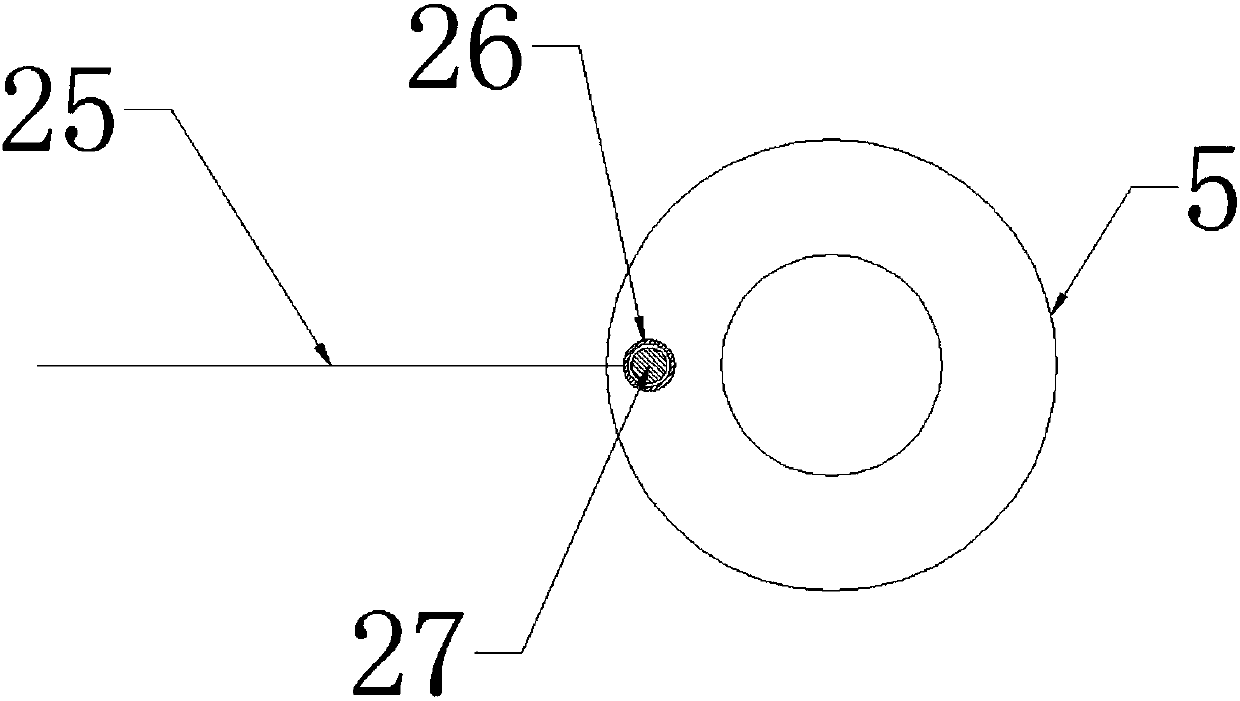

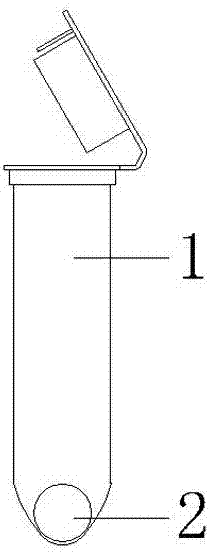

Application method of high-flux plant leaf crusher

A high-flux plant leaf crusher comprises a plastic centrifugal pipe and a steel ball, wherein the steel ball is positioned at the bottom of the crusher. When in use, plant leaves are cut into pieces; the pieces are placed into crushers; the crushers are covered; a plurality of crushers containing samples are added into a foamed plastic box; liquid nitrogen is injected into the box; the foamed plastic box is covered, and are subjected to standing for approximately 1min; the crushers are fetched and are placed in a centrifugal pipe box; and the centrifugal pipe box is covered and is violently oscillated for 10 seconds by using hand, such that the leave samples are completely crushed. The crusher provided by the invention has the advantages of simple operation, high speed, high efficiency, and no cross contamination among the samples.

Owner:王丽华

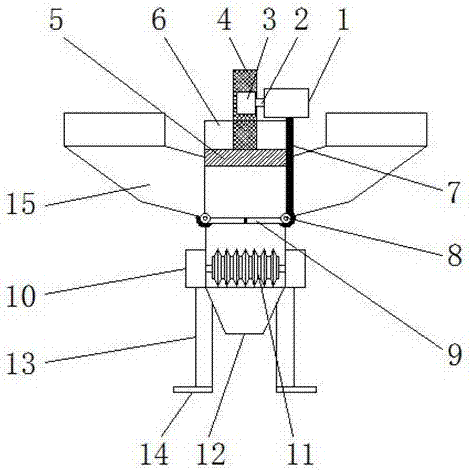

Material mixing device for processing of lick bricks and application method thereof

InactiveCN107261976AFast crushingImprove crushing effectRotary stirring mixersTransportation and packagingBrickMotor drive

The invention discloses a material mixing device for processing of lick bricks; the material mixing device comprises a support; a mixing mechanism is fixed on the support; a crushing mechanism is fixedly connected to the mixing mechanism through a support rod and includes two crushing chambers having a top feed port and symmetrically arranged at the tops of two sides of the mixing mechanism, a motor-driven crusher is disposed in each crushing chamber, and the bottom of each crushing chamber is provided with a feeding mechanism communicated with the mixing mechanism. The two crushing chambers are symmetrically arranged at the tops of the two sides of the mixing mechanism, the mixture to be crushed is divided into two parts that are crushed at the same time, crushing speed can be increased, the crushing effect is good, the crushed material is fed into the mixing mechanism directly via the feeding mechanisms after crushing, manual feeding is not required, time is saved, and operating is simplified. The material crushing step and the material mixing step are performed at the same time in the same device, so that operating is simple, machine cost is low and operating efficiency is high.

Owner:合肥荣电环境电器有限公司

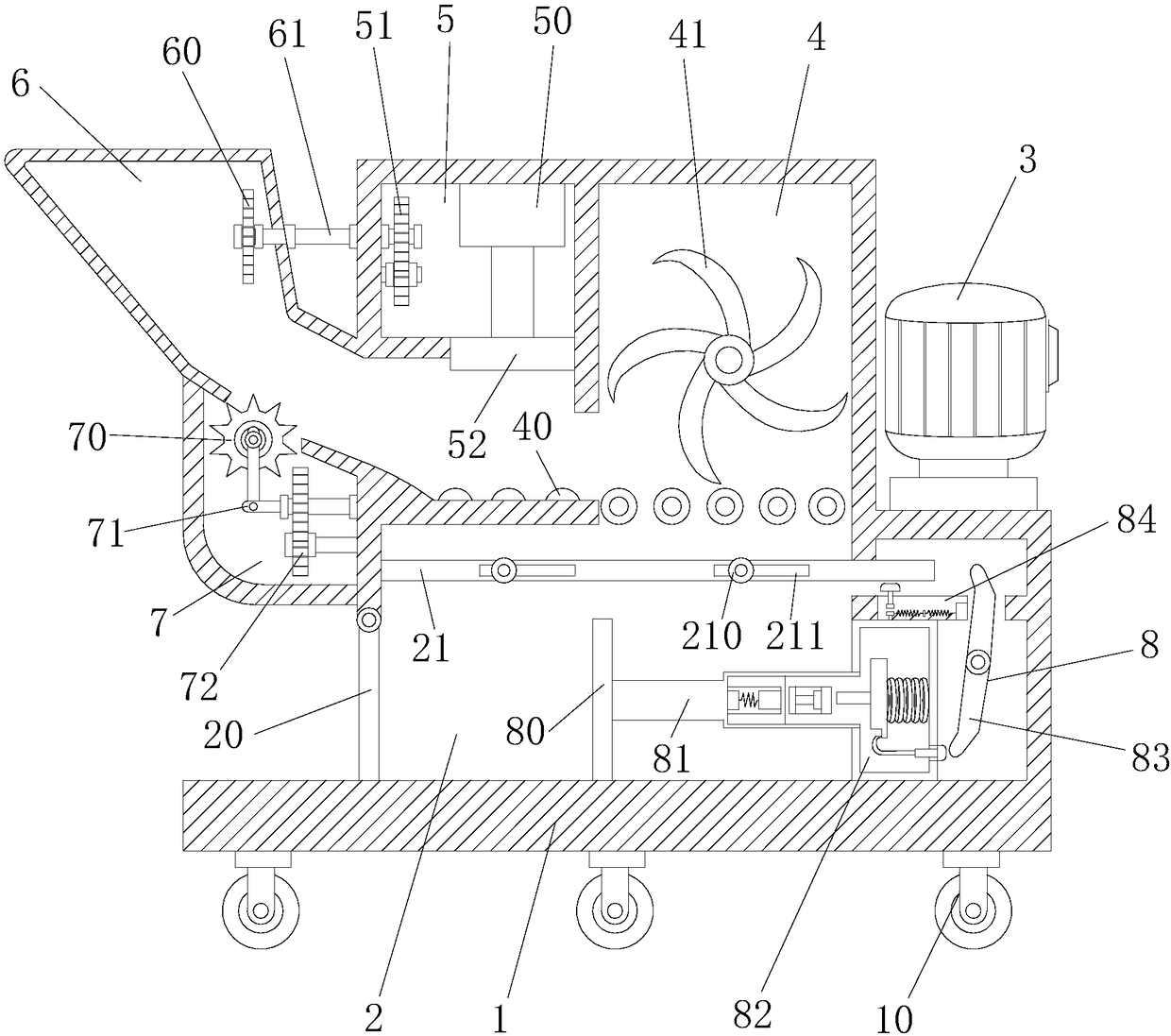

Feed drying and crushing integrated device for cultivation

InactiveCN109907349AEasy accessReduce moistureDrying solid materials with heatFeeding-stuffHydraulic cylinderEddy current effect

The invention discloses a feed drying and crushing integrated device for cultivation. The feed drying and crushing integrated device for cultivation comprises a device main body plate, wherein end surface of the rear side of the device main body plate is fixedly provided with a right side support; a left side support is fixedly mounted on the front end surface and the rear end surface of the device main body plate; an up-and-down rotation fixing device is arranged in the device main body plate; and the up-down rotation fixing device comprises a hydraulic cylinder for providing rotation power,a lifting sliding plate for converting the lifting power into the rotation power and a turnover engagement sliding block. The device heats by an eddy current effect, an eccentric drying cup moves eccentrically while heating, feed can be stirred to a great extent, and the drying speed is increased; and the dried feed can be quickly crushed into powder through staggered cutting knives. Meanwhile, eccentric connecting rods on the two sides rotate during crushing, so that the feed on the edge is driven to the center as much as possible; and the crushing speed is high, the efficiency is high, and the feed can conveniently enter the next step under the action of the up-down rotation fixing device.

Owner:嘉兴歆瑶新能源有限公司

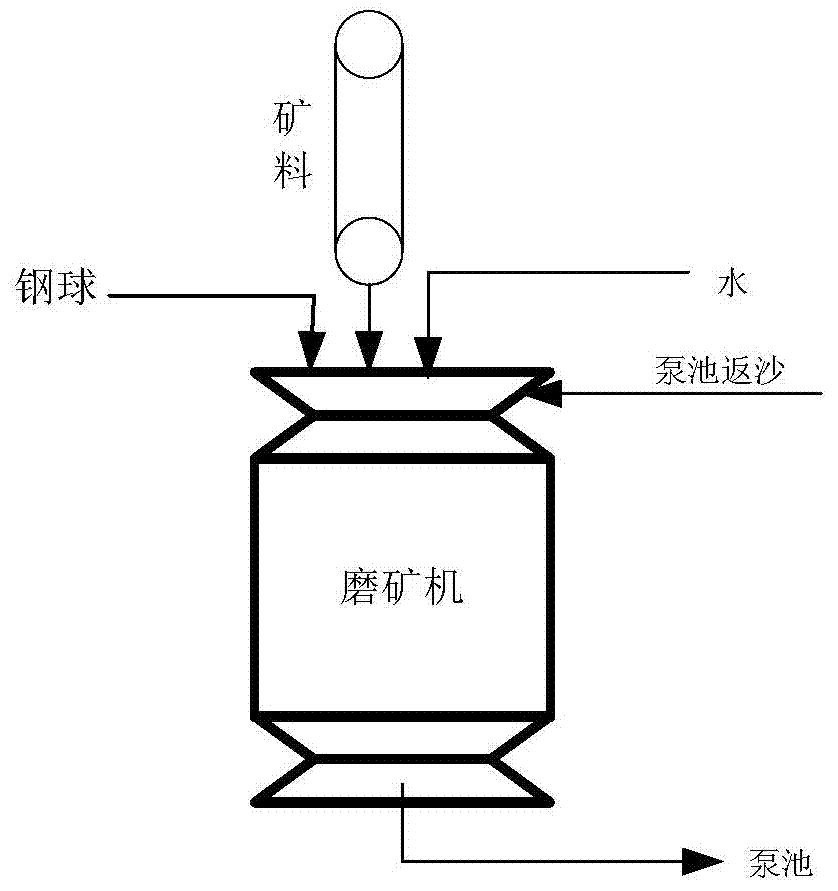

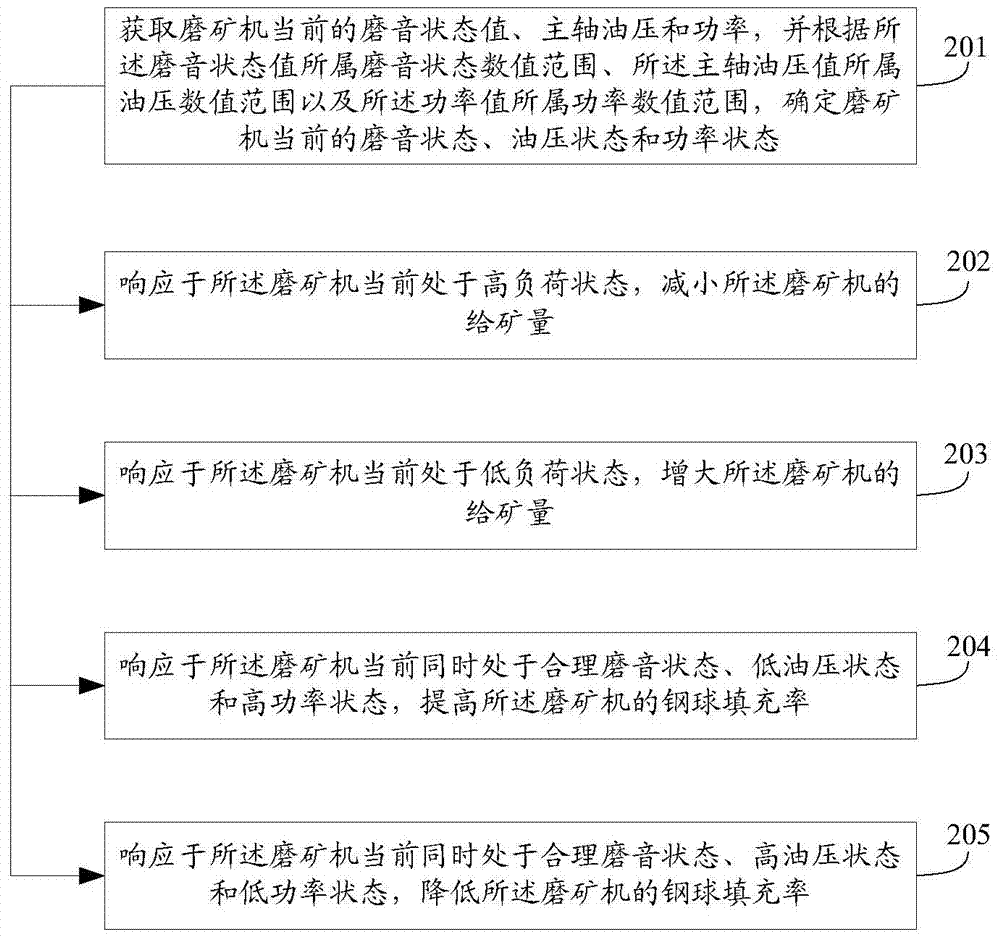

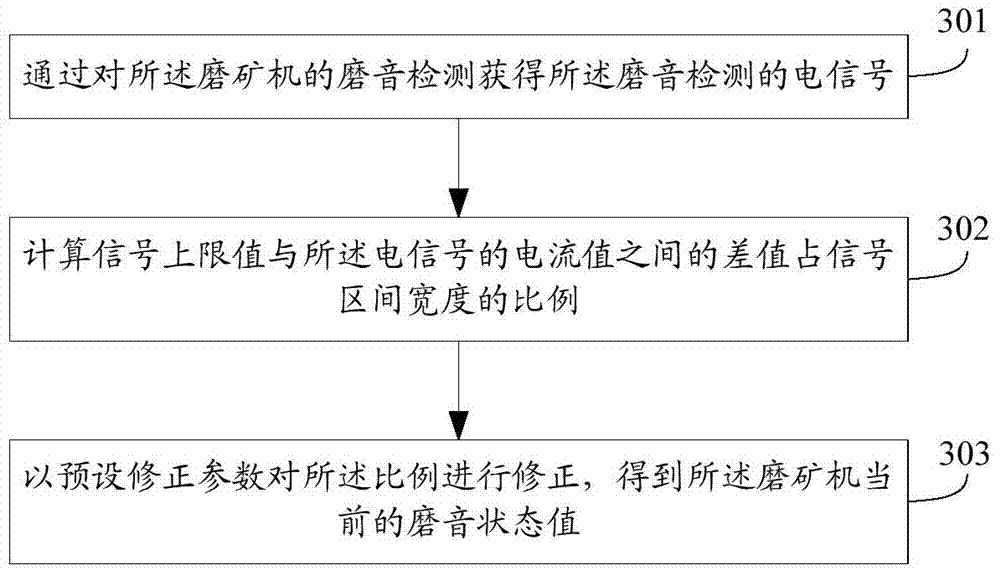

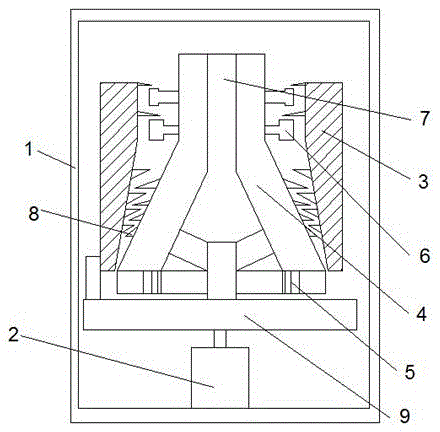

Method and device for adjusting ball filling rate in ore mill control

The invention discloses a method and a device for adjusting ball filling rate in ore mill control. The method includes: acquiring current milling sound status, spindle oil pressure and power of an ore mill, and determining current milling sound status, oil pressure status and power status of the ore mill; in response to the current high load status of the ore mill, reducing the feeding capacity of the ore mill; in response to the current low load status of the ore mill, increasing the feeding capacity of the ore mill; in response to the ore mill being simultaneously in current reasonable milling sound status, low oil pressure status and high power status, increasing ball filling rate of the ore mill; in response to the ore mill being simultaneously in current reasonable milling sound status, high oil pressure status and low power status, decreasing the ball filling rate of the ore mill. The method and the device have the advantages that the ball filling rate can be increased when balls in the ore mill are few, the ball filling rate can be decreased when the balls in the ore mill are many, and accordingly production efficiency of the ore mill can be improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Powder pulverizer

The invention discloses a powder pulverizer. The powder pulverizer comprises a casing, a motor, a primary pulverizing device, a pulverizing barrel, a pulverizing core and a fan, wherein the motor is fixed on the casing; the pulverizing barrel is arranged above the motor; the fan is arranged at the bottom of the pulverizing barrel; the upper end of the fan is connected with the pulverizing core; the upper end of the pulverizing core is connected with the primary pulverizing device; the pulverizing barrel and the pulverizing core rotate relatively, the pulverizing barrel and the pulverizing core are conical, but the conicity of the pulverizing barrel is smaller than that of the pulverizing core, and the pulverizing barrel and the pulverizing core are coaxially arranged. The powder pulverizer can pulverize large materials by the aid of a knife or a hammer, the adaptability to raw materials is improved, the materials can be pulverized by means of the conical pulverizing barrel and the conical pulverizing core which rotate relatively, the particle fineness is high, the pulverizing speed is high, and discharge of the materials is facilitated.

Owner:SUZHOU KAIYE METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com