Medical garbage smashing and extrusion-forming device

A technology for extrusion molding and medical waste, applied in presses, grain processing, manufacturing tools, etc., can solve the problems of cross-infection, occupying a large space, cross-flow of sewage, etc., achieving fast crushing speed, ensuring stability, and reducing noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

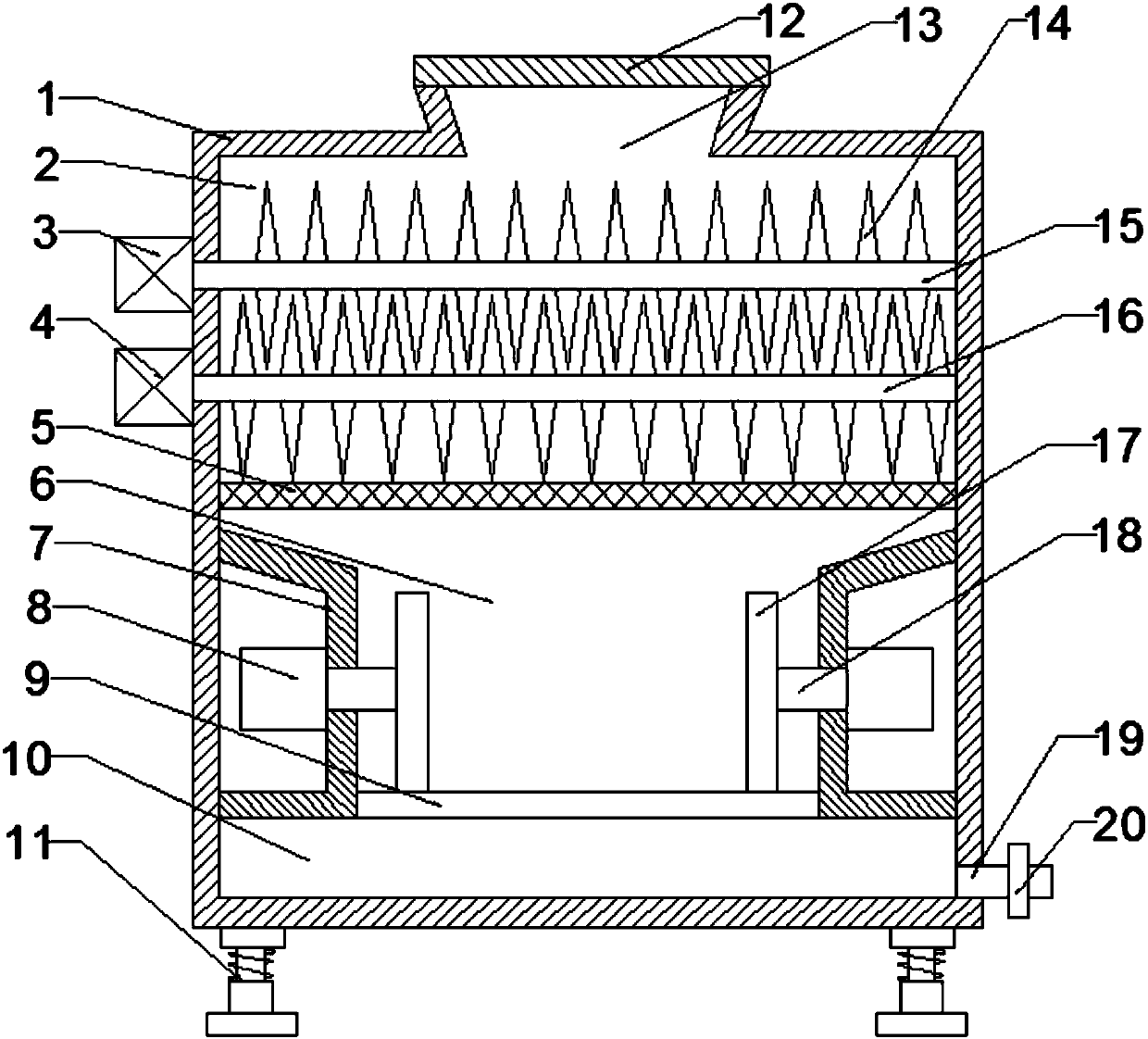

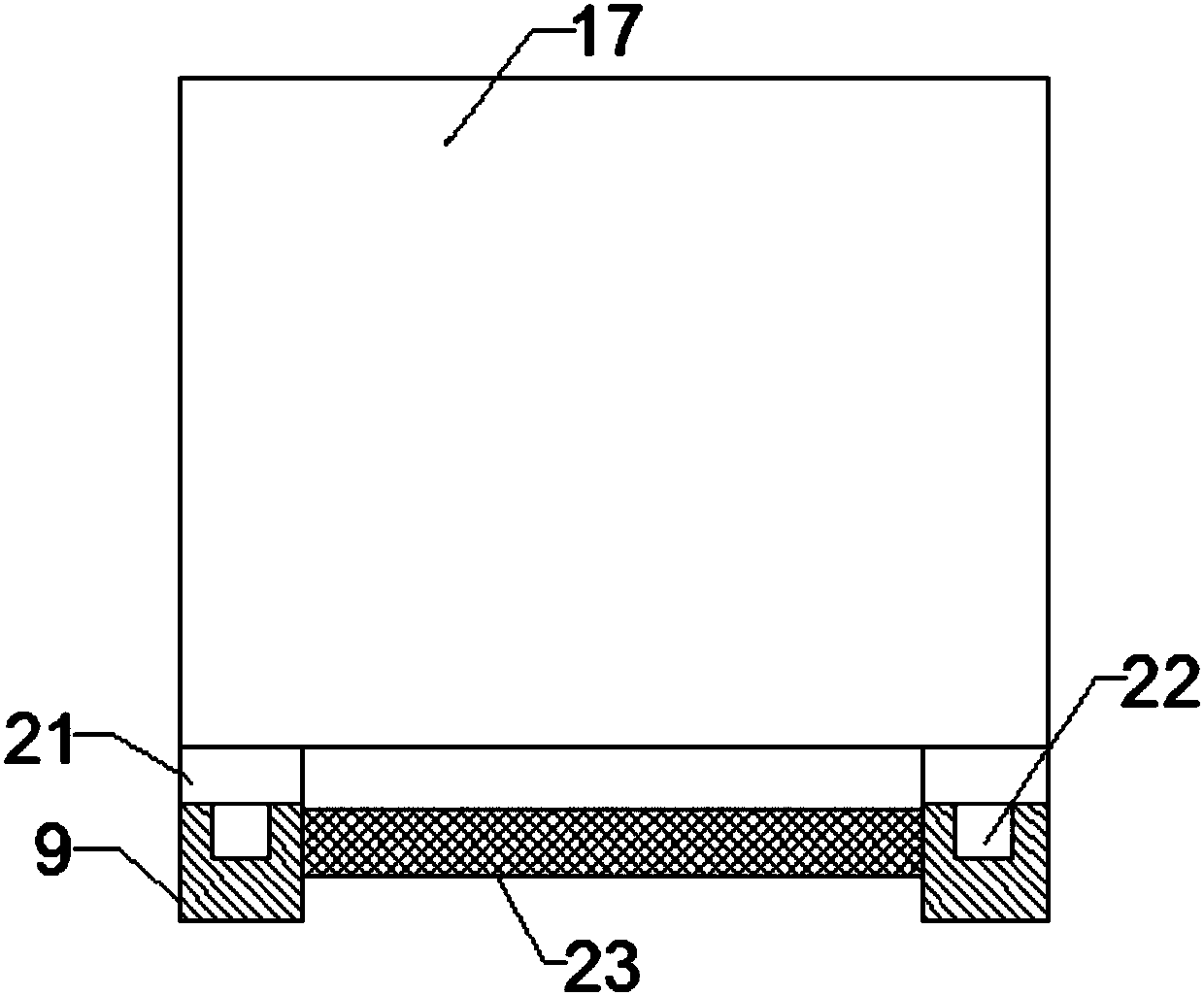

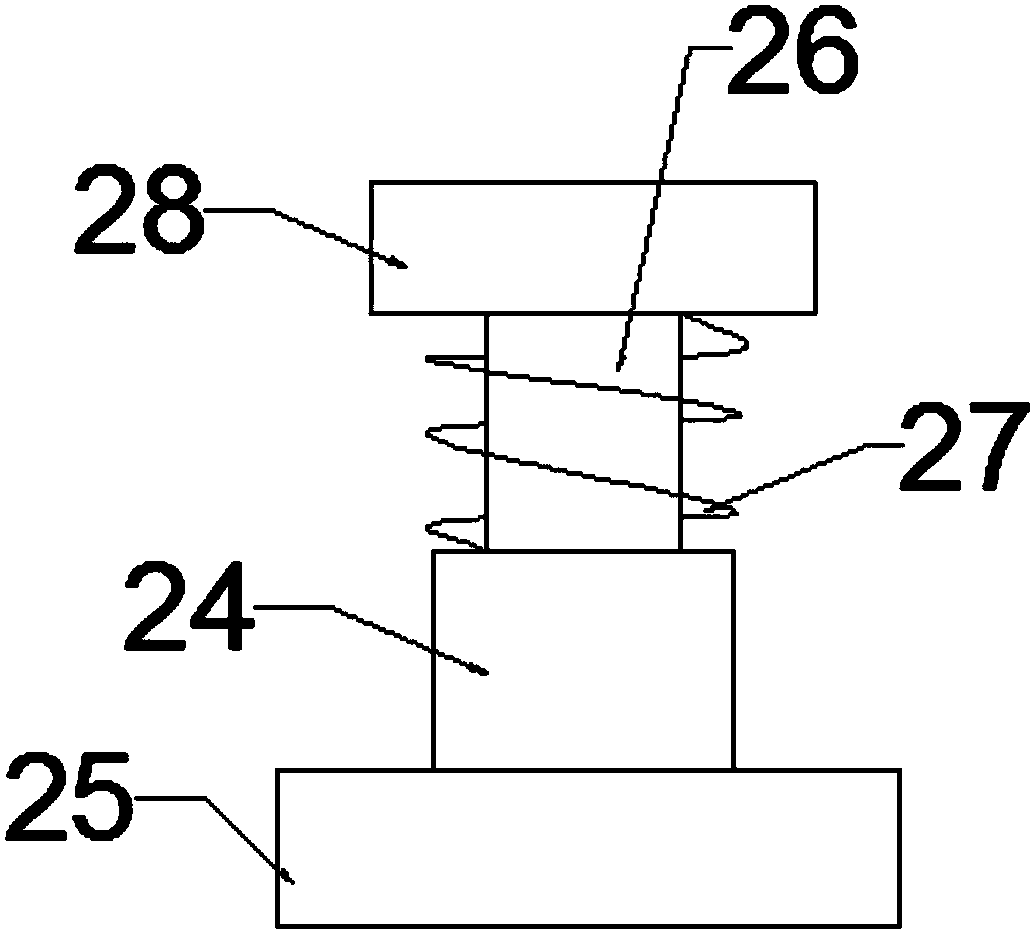

[0016] see figure 1 , the present embodiment provides a crushing and extruding device for medical waste, including a box body 1; a crushing chamber 2, an extrusion chamber 6 and a liquid storage tank 10 are arranged inside the box body 1; the bottom of the box body 1 is provided with There is a feed hopper 13, and the feed hopper 13 communicates with the crushing chamber 2; the top of the feed hopper 13 is provided with a cover plate 12 through a hinge, and the cover plate 12 can prevent the medical waste from jumping out during the crushing process; the crushing chamber 2 A crushing blade 14, a first rotating shaft 15 and a second rotating shaft 16 are provided; the first rotating shaft 15 is horizontally arranged on the upper side of the crushing chamber 2, and the left end of the first rotating shaft 15 is connected to the output shaft of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com