Presser

A technology of presses and crushing devices, which is applied in the fields of presses, grain processing, and manufacturing tools, can solve the problems of residue leftover, residue can not be automatically discharged, and pure juice cannot be obtained, and achieves sufficient pressing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

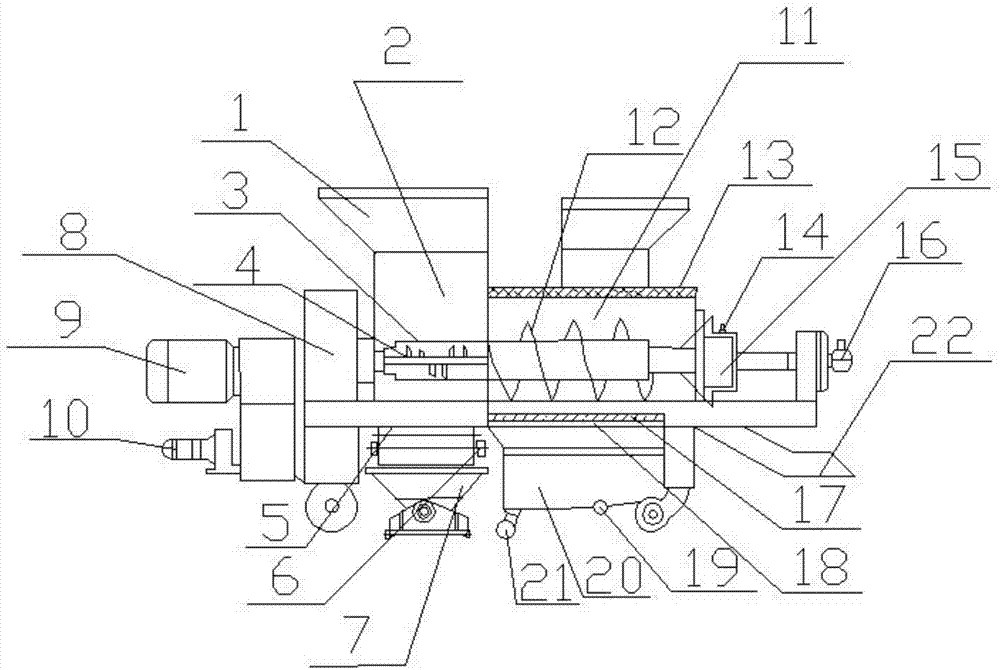

[0015] refer to figure 1 , figure 2 , a squeezing machine, its structure includes a crushing device 2, a squeezing device 11, and the crushing device 2 includes a feed port 1, a rotary screen 3, a destemming blade 4, a support 5, a crushing device 6, a slurry pump 7, The bottom of the feed inlet 1 is movably connected with the rotary screen 3, the rotary screen 3 is fixedly connected with the destemming blade 4, the rotary screen 3 is connected with the crushing equipment 6 through the support 5, and the crushing equipment 6 is connected with the conveying The pulp pump 7 is connected, one end of the crushing device 2 is connected with the reduction box 8, the reduction box 8 is connected with the speed reducer 9 through the support 5, the speed reducer 9 is connected with the hydraulic pump 10, and the press The device 11 includes a squeeze screw 12, a juice collection tank 20, and a liquid outlet 19. The squeeze screw 12 is connected to the screen cylinder assembly 13, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com