Pulping agitator

A mixer and pulping technology, used in mixers, mixers with rotating containers, dissolving, etc., can solve the problems of uneven pulp, poor fluidity, prolonged beating time, etc., to improve pulp quality, particle fineness, and crushing speed. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

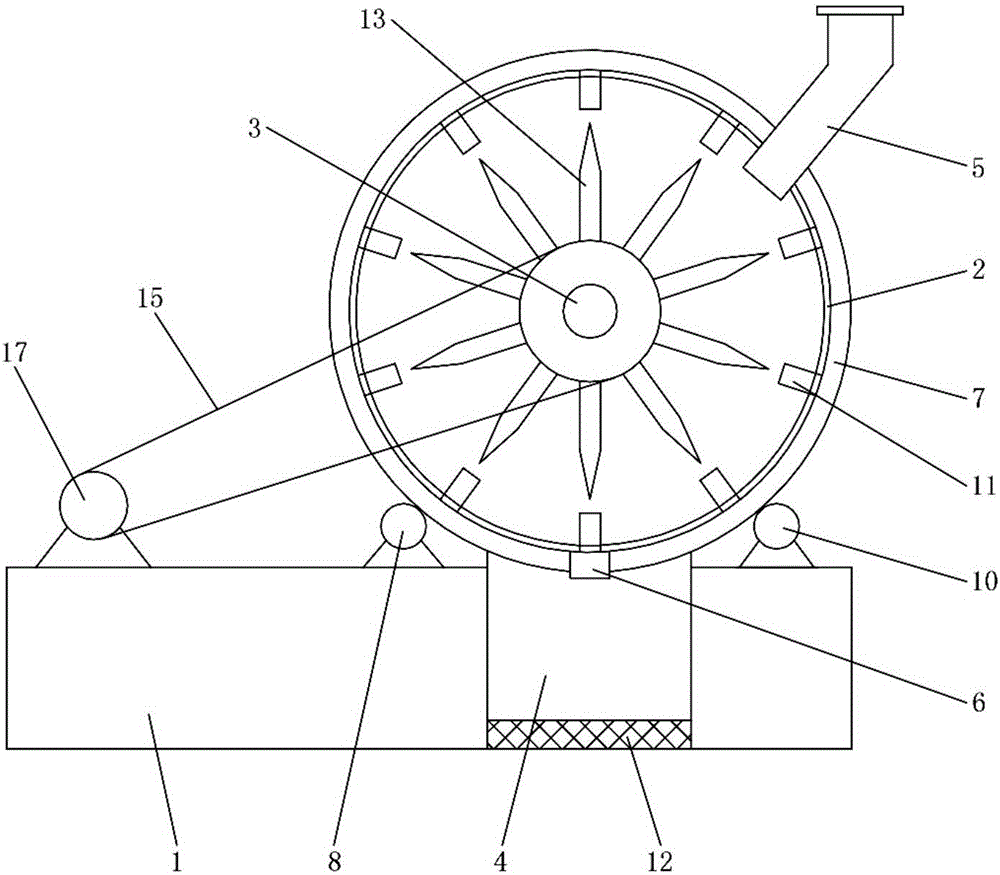

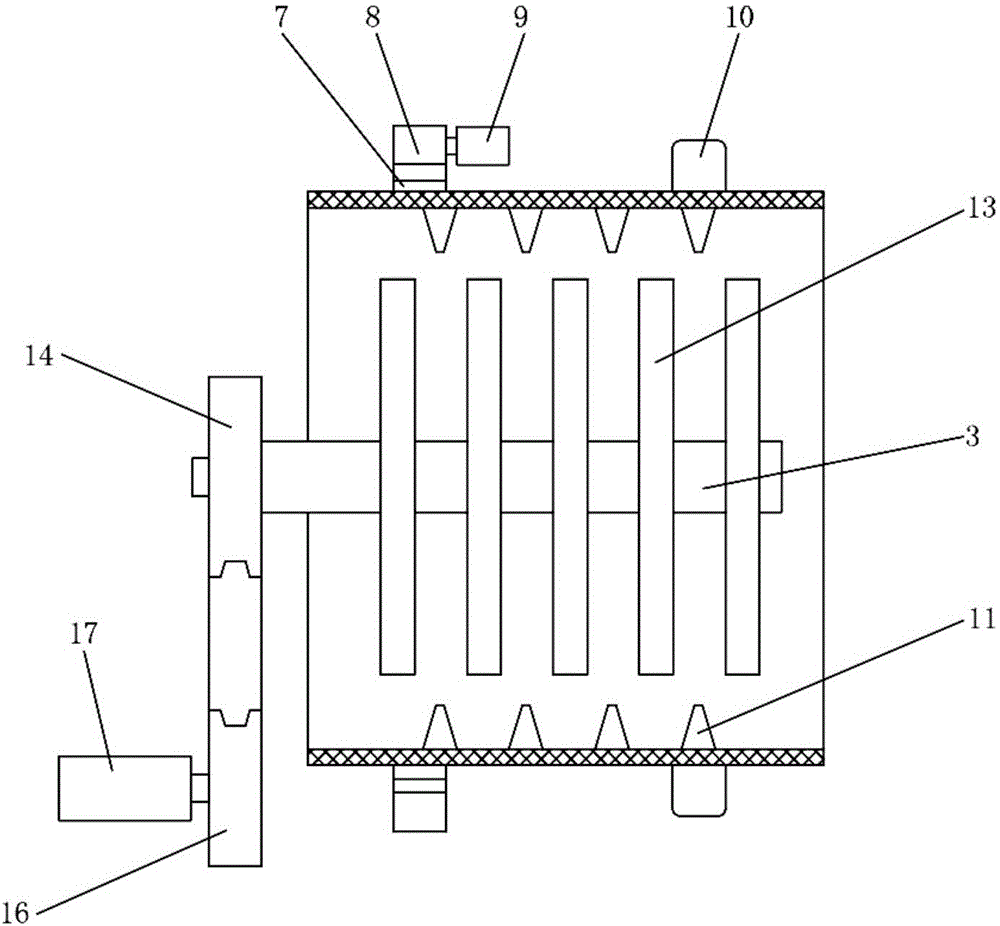

[0008] Such as figure 1 As shown, the pulping mixer is mainly composed of a base 1, a barrel 2, a rotating shaft 3 and a storage chamber 4.

[0009] A barrel 2 is arranged on the base 1 . A feed pipe 5 is arranged above one side end of the barrel 2, and a discharge port 6 is arranged below the other side end of the barrel 2, and a storage chamber 4 is located below the discharge port 6, and a heater 12 is arranged at the bottom of the storage chamber 4 to heat The device 12 effectively prevents the slurry from solidifying, so that the slurry is always in a liquid state.

[0010] The outer circumference of the barrel 2 is fitted with a driven gear 7, the driven gear 7 is meshed and driven by the driving gear 8, the driving gear 8 is driven by the gear motor 9, the barrel 2 is supported by a pair of support wheels 10, and the inner wall of the barrel 2 is provided with several Strip mixing knife11.

[0011] A rotating shaft 3 is installed in the middle of the barrel 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com