Application method of high-flux plant leaf crusher

A plant leaf and pulverizer technology, which is applied in the field of agricultural scientific research, can solve the problems of unclean mortar cleaning, cross-contamination of samples, time-consuming and labor-intensive, etc., and achieves the effects of convenient sample transfer, easy operation and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

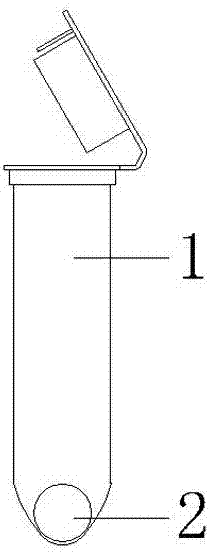

Image

Examples

Embodiment 1

[0028] The rapid crushing of embodiment 1. sorghum blade:

[0029] ① Cut the leaves of sorghum except the large veins into small pieces and put them in a shredder.

[0030] ② The amount of blades put in should not exceed 1 / 4 of the volume of the pulverizer.

[0031] ③ Close the shredder cover.

[0032] ④ Put multiple pulverizers into a foam plastic box, inject liquid nitrogen into the box, and the injection volume must submerge all the pulverizers.

[0033] ⑤ Cover the foam box and let it stand for 1 minute.

[0034] ⑥ Use a colander to fish out the pulverizer, and take 36 pieces and put them into one end of a 72-hole centrifuge tube box.

[0035] ⑦ Close the lid of the centrifuge tube box, hold the other end of the centrifuge tube box with both hands, and use the elbow as the fulcrum to vibrate up and down quickly for 10 seconds. The blades in the shredder are smashed to pieces under the strong repeated impact of steel balls.

[0036] ⑧ Open the lid of the box, quickly t...

Embodiment 2

[0038] The rapid crushing of embodiment 2. corn blades:

[0039] ① Remove the large veins from the corn leaves and cut them into small pieces and put them in a shredder.

[0040] ② The amount of blades put in should not exceed 1 / 4 of the volume of the pulverizer.

[0041] ③ Close the lid of the shredder.

[0042] ④ Put multiple pulverizers into a foam plastic box, inject liquid nitrogen into the box, and the injection volume must submerge all the pulverizers.

[0043] ⑤ Cover the foam box and let it stand for 1 minute.

[0044] ⑥ Use a colander to fish out the pulverizer, and take 36 pieces and put them into one end of a 72-hole centrifuge tube box.

[0045] ⑦ Close the lid of the centrifuge tube box, hold the other end of the centrifuge tube box with both hands, and use the elbow as the fulcrum to vibrate up and down quickly for 10 seconds. The blades in the shredder are smashed to pieces under the strong repeated impact of steel balls.

[0046] ⑧ Open the box cover, qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com