Feed drying and crushing integrated device for cultivation

A drying and feed technology, applied in the direction of drying solid materials, heating to dry solid materials, feed, etc., can solve the problems of unstable feed particle size, lack of equipment preparation time, increase of breeding costs, etc., to achieve simple structure, convenient operation, The effect of less moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

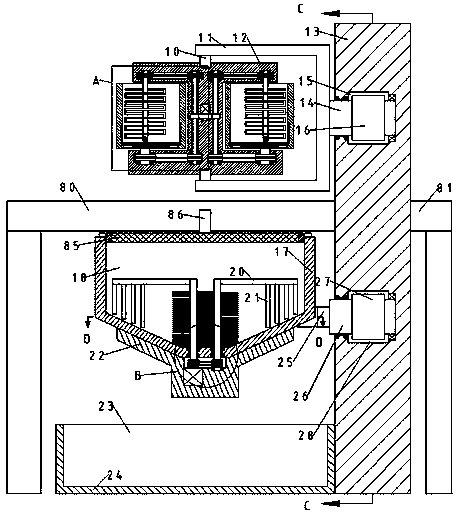

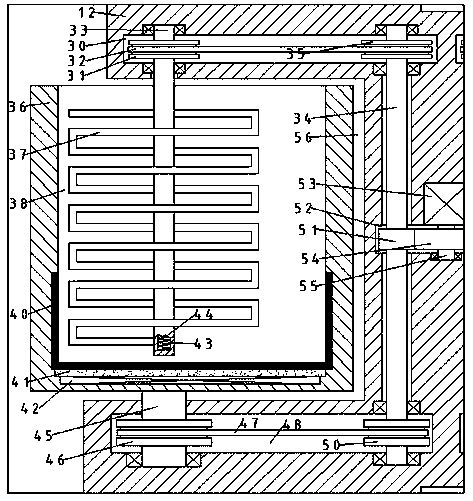

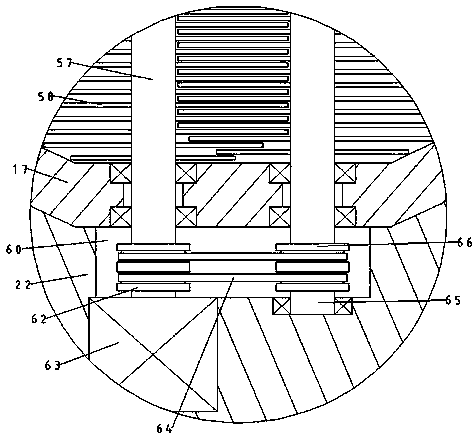

[0017] Combine below Figure 1-5 The present invention will be described in detail.

[0018] refer to Figure 1-5 According to the embodiment of the present invention, the feed drying and pulverizing integrated device for breeding includes a device main board 13, the rear side end surface of the device main board 13 is fixedly installed with a right side support 81, and the front and rear end surfaces of the device main board 13 are fixedly installed with a left side. Side support 80, the main body plate 13 of the device is provided with an up and down rotation fixing device, and the up and down rotation fixing device includes a hydraulic cylinder 73 that provides rotation power, a lifting slide plate 71 that converts lifting power into rotation power, and an overturning engagement slider 75, It also includes a rotating upper turning shaft 14 and a lower turning shaft 26. The upper turning shaft 14 is fixedly installed on the left end surface of the upper clamping turning pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com