Multistage high-efficiency crushing device for ceramic raw materials

A high-efficiency crushing and ceramic raw material technology, applied in cocoa, grain processing, food science, etc., can solve the problems of excessive wear of the crushing device, energy waste, slow discharge, etc., achieve easy crushing of ceramic raw materials, ensure high-efficiency crushing, The effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

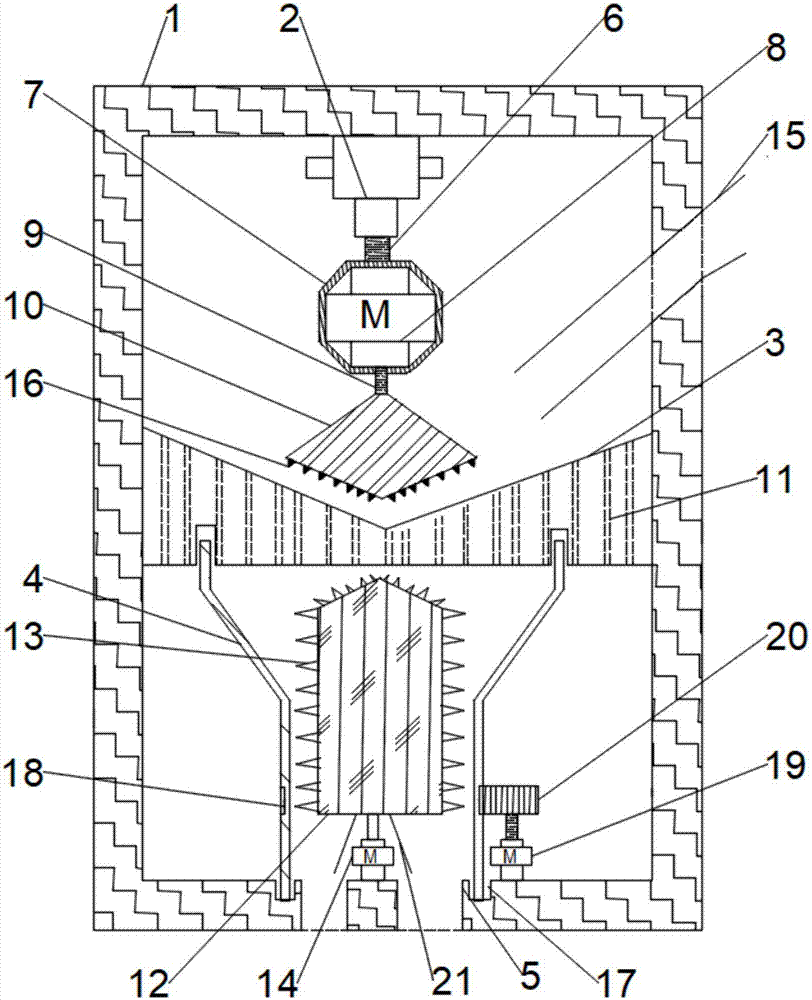

[0024] like figure 1 As shown, the present invention provides a multi-stage high-efficiency crushing device for ceramic raw materials, including a housing 1, a hydraulic vibrator 2 is fixedly installed on the top surface of the inner wall of the housing 1, and a crushing groove 3 is respectively installed in the middle and bottom of the housing 1 and the crushing barrel 4, the bottom of the crushing tank 3 is funnel-shaped, and the top of the side of the crushing tank 3 is provided with a feed port 15, and the feed port 15 passes through the side wall of the shell 1, and the ceramic raw material is fed from the feed port 15 After falling into the periphery of the crushing tank 3, it slides toward the center of the bottom of the crushing tank 3 due to its own gravity and the vibration of the vibrating screen 11, so that the breaking hammer 10 can better crush the ceramic raw materials.

[0025] It should be added that the hydraulic vibrator 2 described above is not particularly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com