Crusher for preparation of agricultural fertilizer

A pulverizer and fertilizer technology, applied in mixers, mixer accessories, cleaning methods and utensils, etc., can solve the problems of coarse pulverized particles, low pulverization output, long storage time, etc., to speed up the pulverization speed, speed up the mixing process, avoid The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

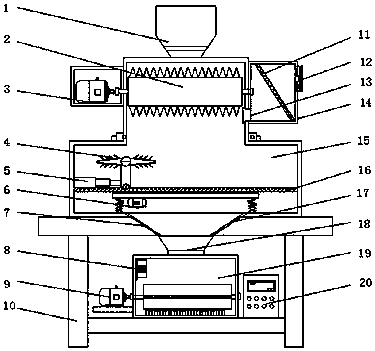

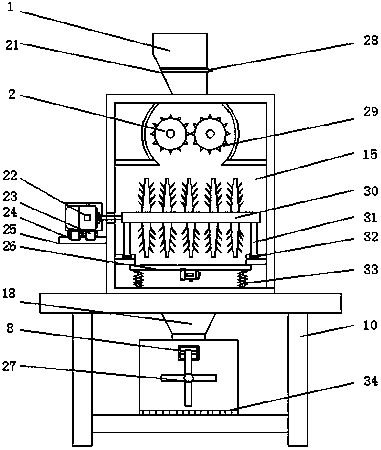

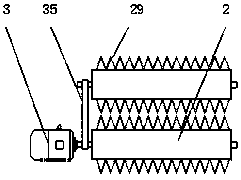

[0019] see Figure 1-4 , an embodiment provided by the present invention: a pulverizer for agricultural fertilizer preparation, comprising a frame body 10 and a crushing box 15 arranged thereon, the top of the crushing box 15 is provided with a feed hopper 1, and the bottom is provided with a storage Material chamber 7, described feeding hopper 1 is provided with chute 21, and baffle plate 28 is fixed in described chute 21, is used for controlling the feeding amount of fertilizer; The inner side wall of described material storage chamber 7 is equipped with magnet 17. It is used to absorb iron impurities in the fertilizer and improve the purity of the fertilizer. The storage chamber 7 is funnel-shaped to facilitate the collection of fertilizers; the bottom of the storage chamber 7 is connected to a discharge hopper 18, and the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com