Humidifying processing method for manufacture of shaving board material

A processing method and particleboard technology, which can be used in the production of flat surface processing machines, manufacturing tools, wood processing appliances, etc., can solve the problems of uneven humidity and low humidity control efficiency of particleboards, and can prolong the spraying time and reduce the occupation of land. area, the effect of improving work continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

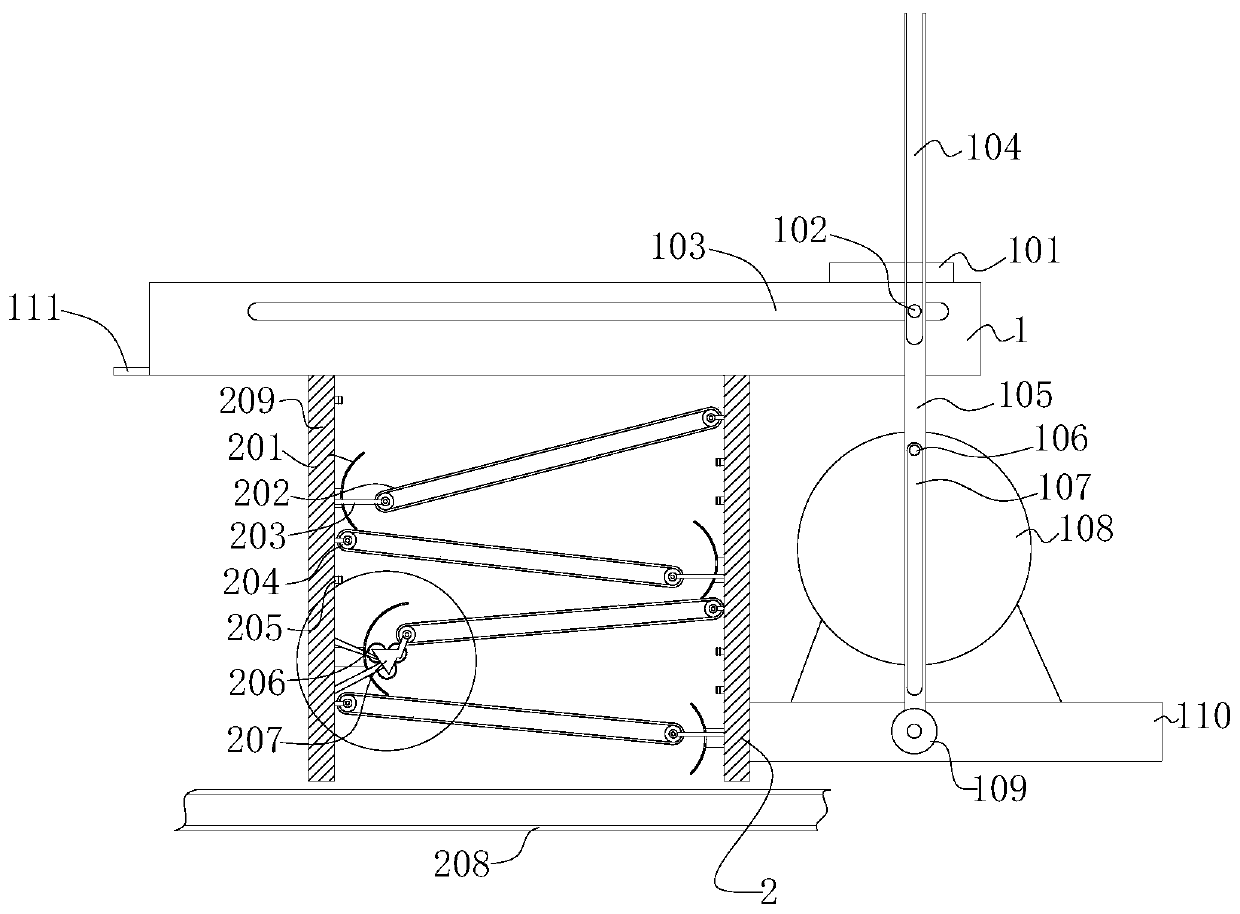

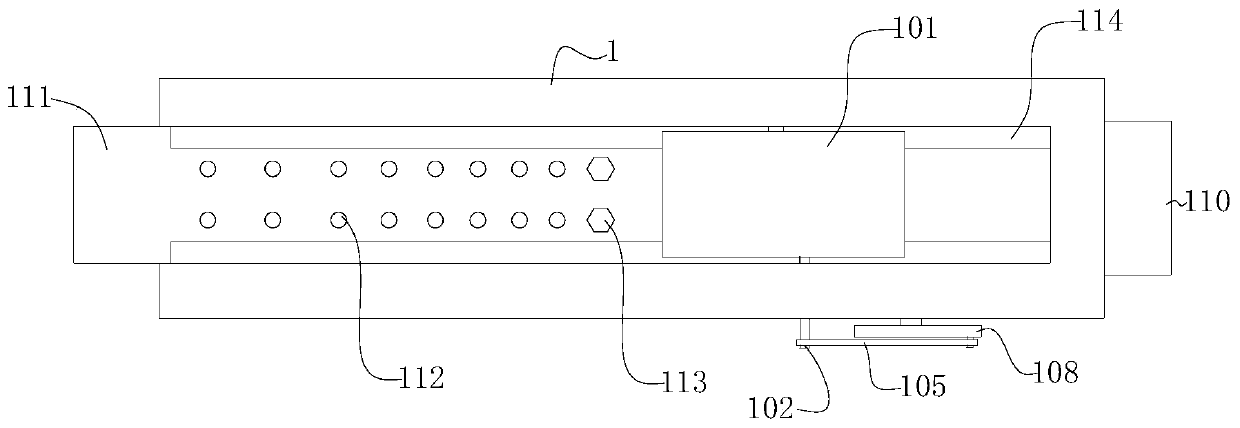

[0053] see Figure 1-5 as well as Figure 11 , is a schematic diagram of the overall structure of a humidity-controlling processing method for manufacturing particleboard boards, and performs humidity-controlling and chopping processing on regular wood in the shape of a square prism, including the following steps:

[0054] S1, planing processing, planing the regular wood surface, and planing the regular wood into sheet materials;

[0055] S2, spray wet treatment, carry out wet spray treatment to the sheet material surface obtained after planing in step S1, make the sheet material surface humidity uniform;

[0056] S3, crushing and cutting, crushing and cutting the flake material with uniform humidity obtained after spraying in step S2 to obtain finely divided wood scraps;

[0057] S4, evenly apportion, the timber scrap obtained in step S3 is evenly apportioned on the conveyer belt, is transported in next working procedure by conveyer belt;

[0058] The processing method des...

Embodiment 2

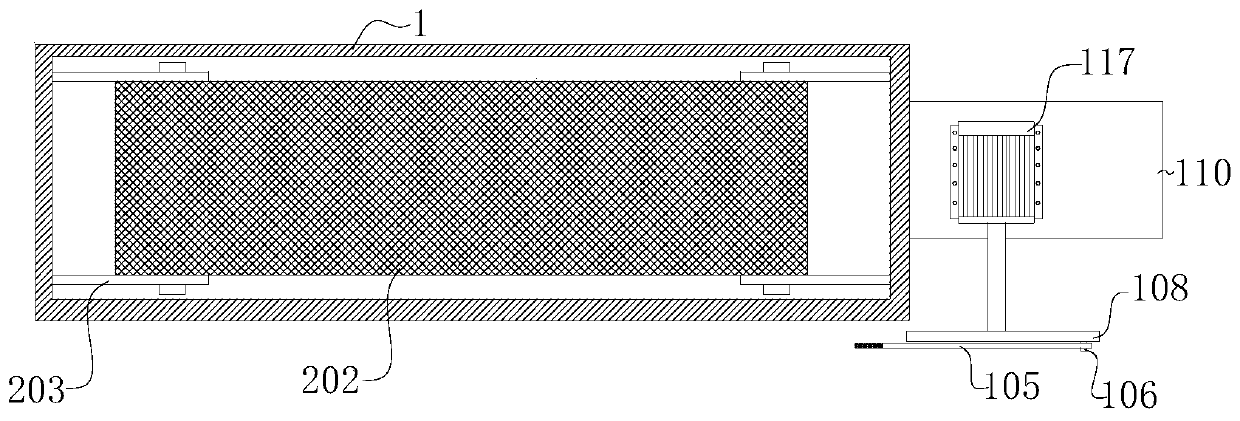

[0079] see Figure 1-11 , is a schematic diagram of the overall structure of the humidity-conditioning processing method for particle board manufacturing. This embodiment has similarities with the above-mentioned embodiment 1, and the similarities will not be described in this embodiment. The specific differences are:

[0080] The spray assembly 205 comprises a spray nozzle base 2051, the spray nozzle base 2051 is arranged as a quadrangular structure, the inside of the spray nozzle base 2051 is provided with a cavity, the spray nozzle 2053 is set to a cylindrical bullet structure, and the bullet end of the spray nozzle 2053 A conical opening 2058 is provided at the center of the circle, and a conical structure cavity is arranged inside the spray nozzle 2053. A cone-shaped spoiler rod 2056 is fixed in the conical structure cavity; one end of the spoiler rod 2056 is fixed on the support base 2055, the support base 2055 is set to a cylindrical structure, and the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com