Patents

Literature

55results about How to "Realize automatic laying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

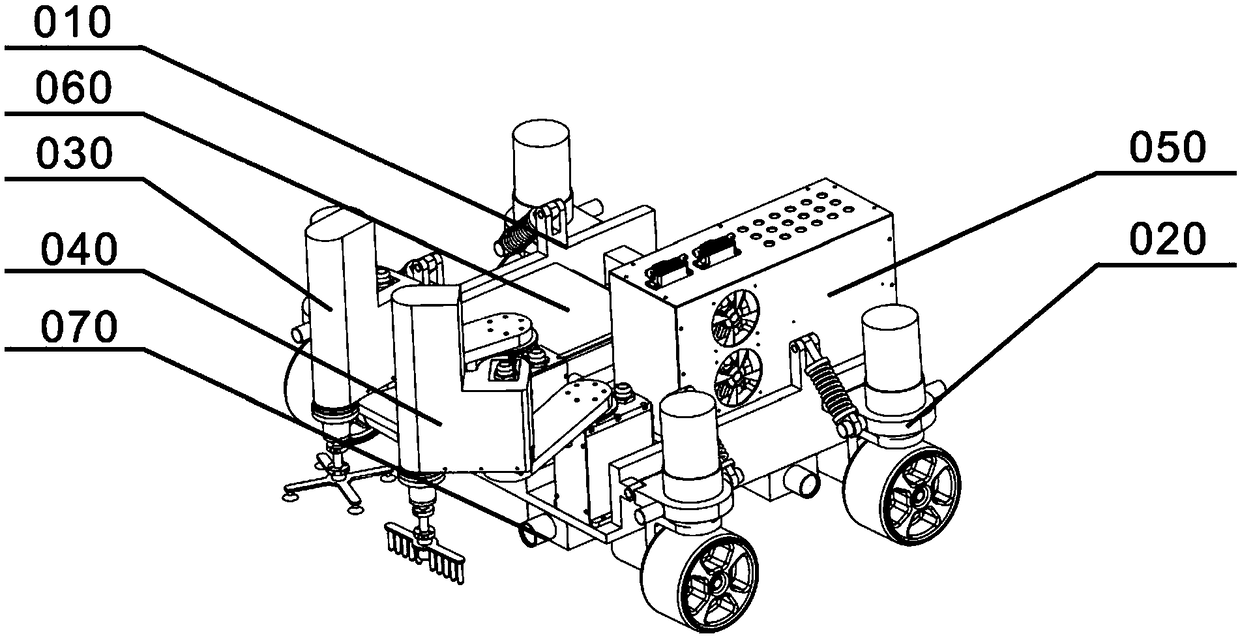

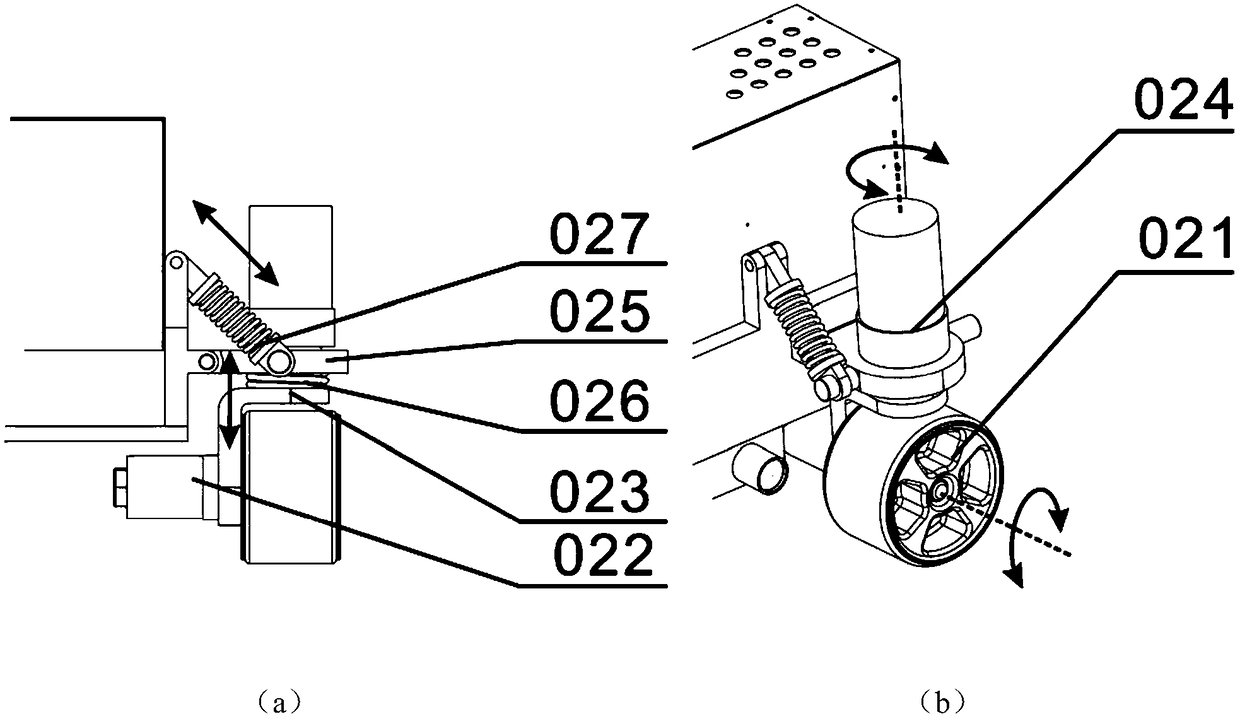

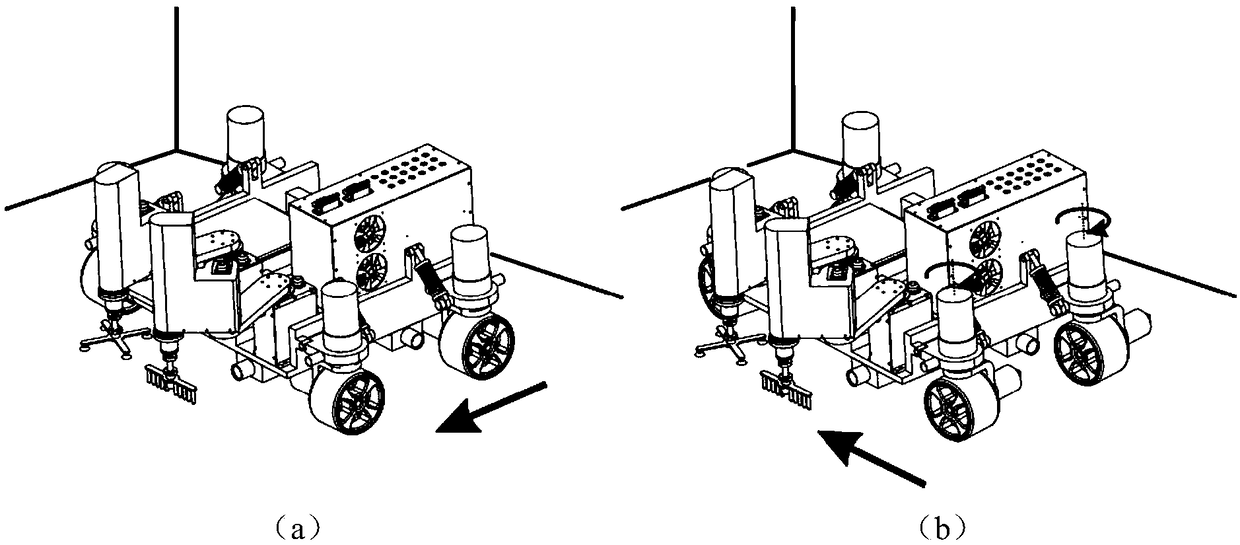

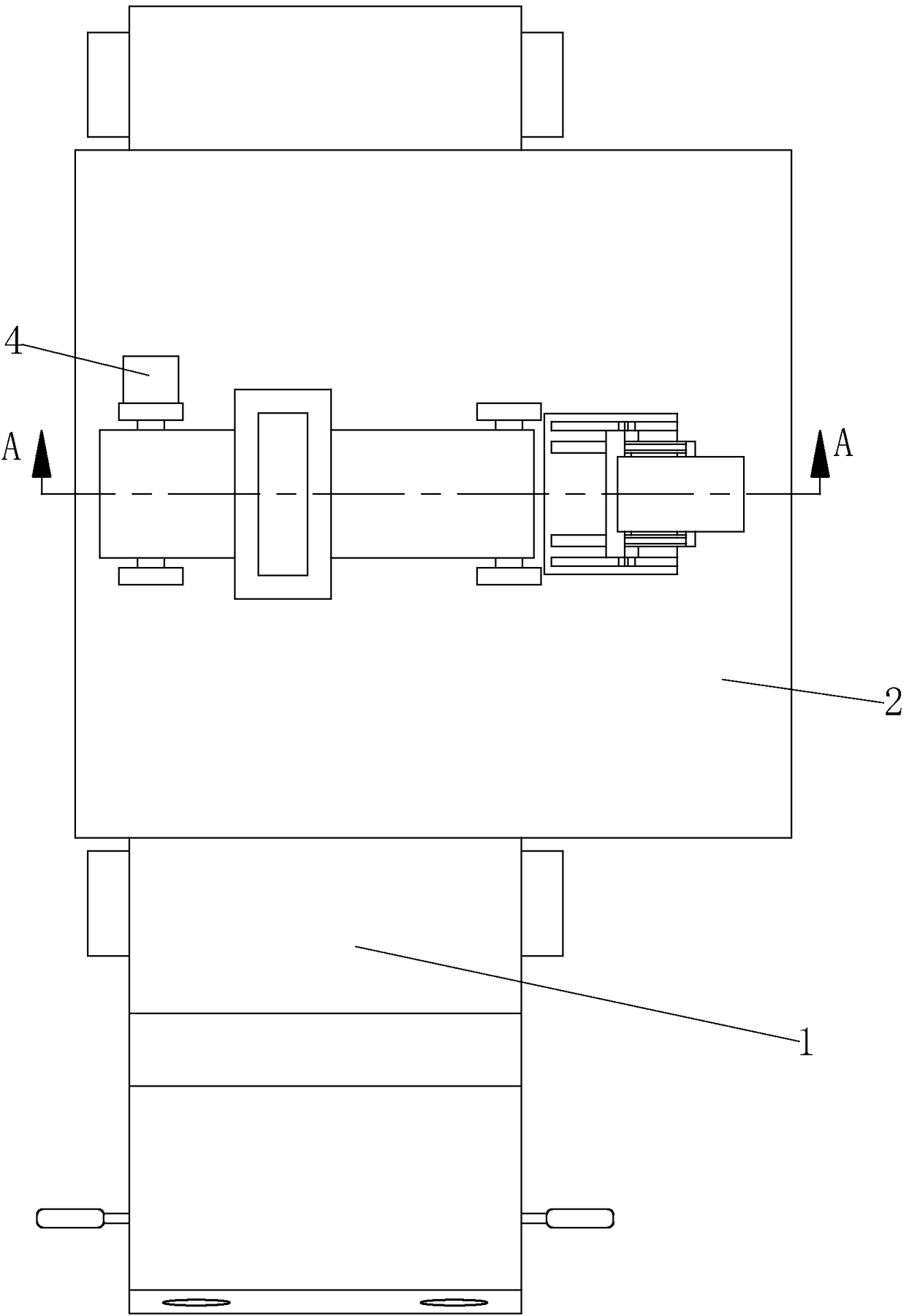

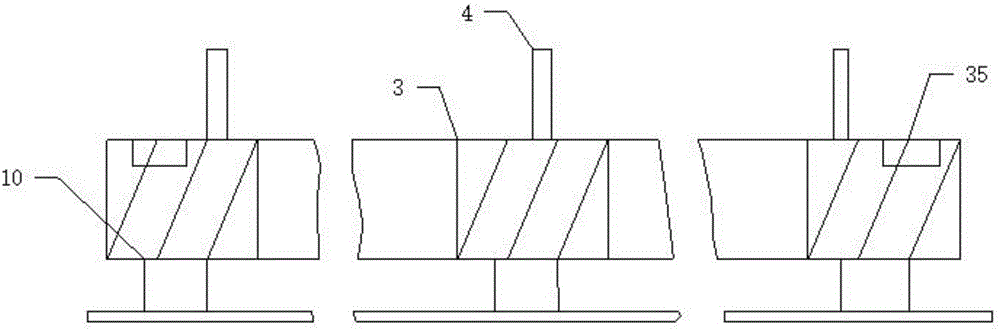

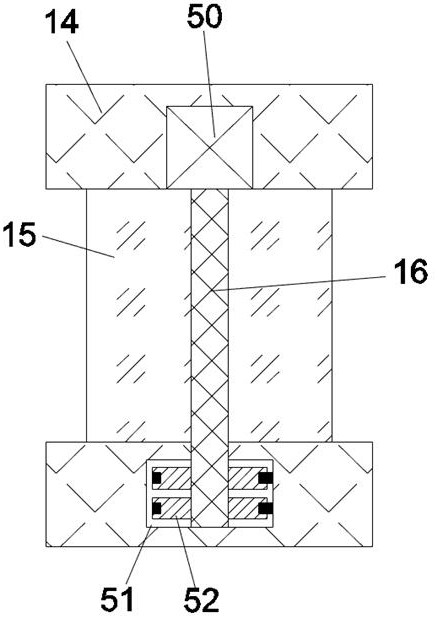

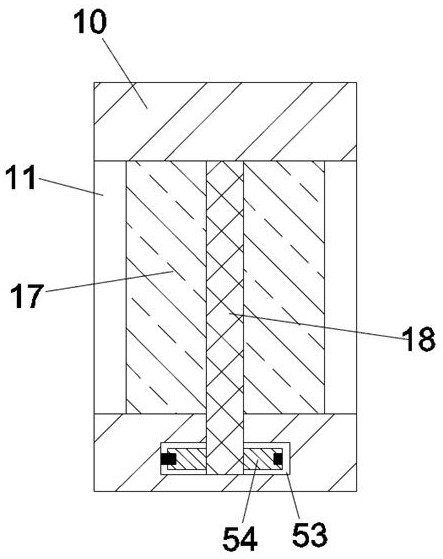

Double-armed floor tile laying robot system having all-round moving function

InactiveCN109227565ARealize automatic layingSimple structureBuilding constructionsManipulatorLaser rangingRobotic systems

The invention provides a double-armed floor tile laying robot system having an all-round moving function. In the system, a robot main base is a rigid platform, and double-freedom-degree moving wheels,a mechanical tile laying arm, a mechanical mortar spraying arm, an electric control system, a floor tile fixing platform and a laser range finder are arranged on the robot main base. The floor tile fixing platform is used for placing and fixing floor tiles. The laser range finder measures angles and positions of floor tiles needing to be laid and sends measurement values to the electric control system. Each double-freedom-degree moving wheel comprises the freedom degrees of axial rotation and radial rotation. The electric control system controls the double-freedom-degree moving wheels to perform axial and / or radial rotation according to the received measurement values, controls the mechanical mortar spraying arm to spray mortar to the ground and controls the mechanical tile laying arm tomove floor tiles to the positions for laying. The double-armed floor tile laying robot system is quick and convenient to operate, can quickly move to a floor tile laying site, perform mortar sprayingthrough the mechanical mortar spraying arm and lay floor tiles on the surface of mortar through the mechanical tile laying arm.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

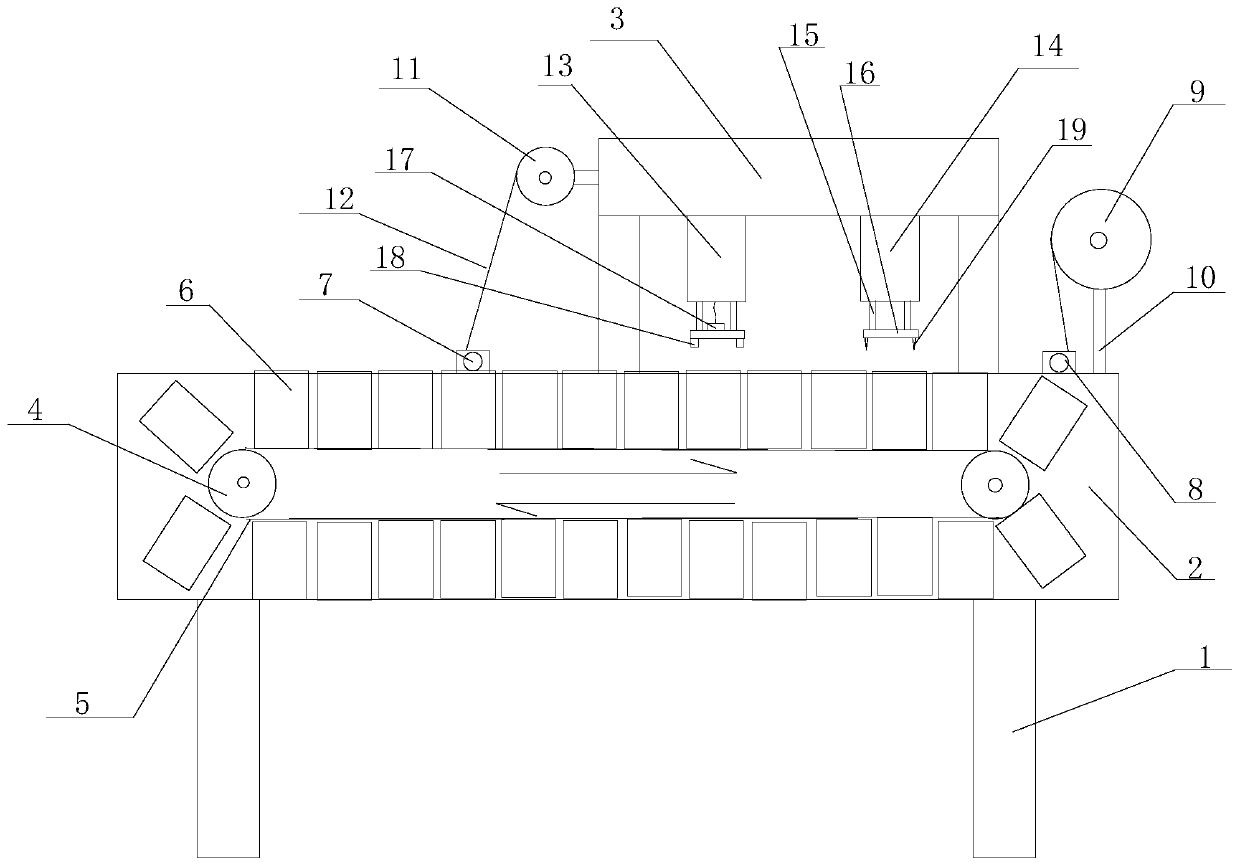

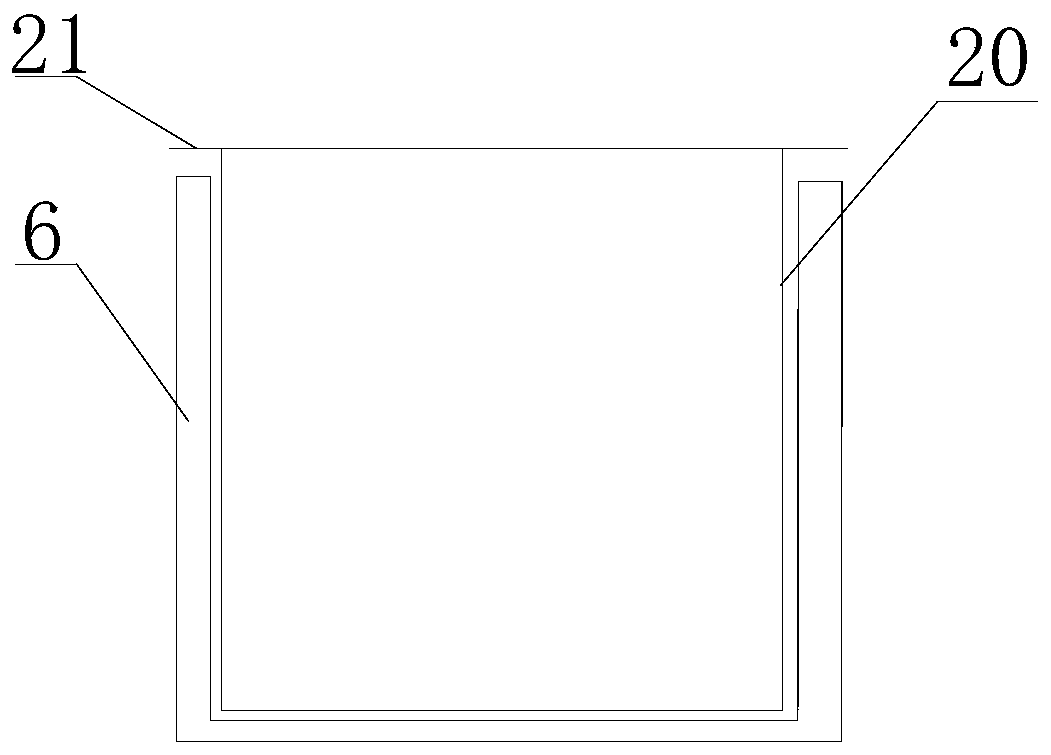

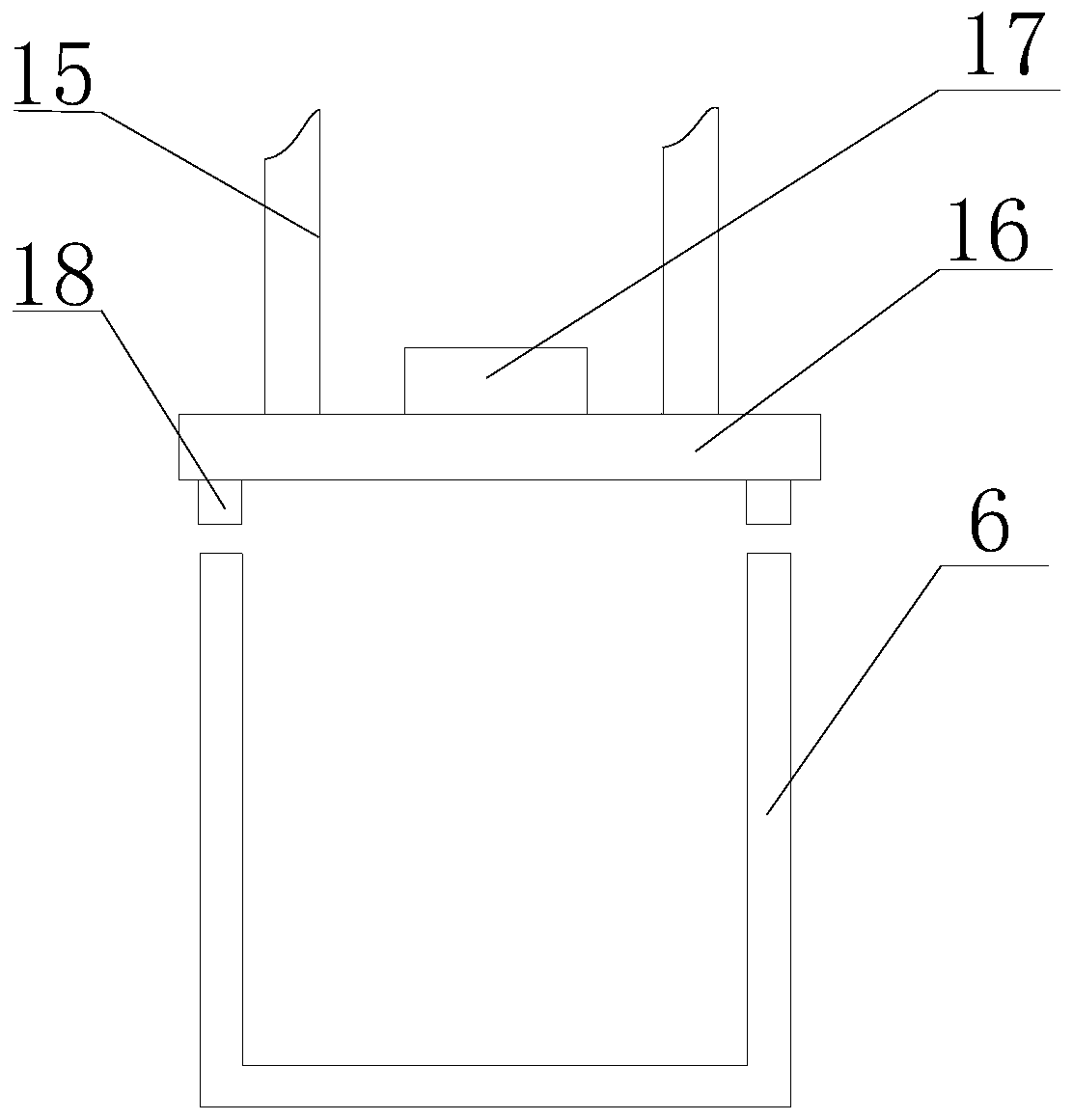

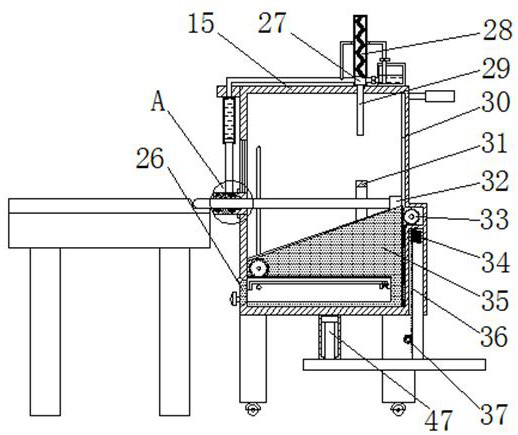

Paving apparatus for kerbstone

InactiveCN108330788ARealize automatic layingGuaranteed stabilityRoads maintainenceAutomotive engineeringHorizontal transmission

The invention relates to a paving apparatus used for kerbstone. The paving apparatus comprises a vehicle body, an loading plate is fixedly arranged at the vehicle body, a conveyer belt is arranged ata left part on the loading plate, and a storage bin is arranged over the left part of the conveyer belt; and the paving apparatus is arranged at a right side of the conveyer belt. The paving apparatuscomprises a polished rod and a small suspension bracket fixedly at the loading plate, a motor is arranged at the small suspension bracket, a leading screw is connected with the motor, and the leadingscrew realizes threaded connection with a pedestal which is vertically cooperated with the polished rod in a sliding mode. Under co-effect of body driving, horizontal transmission of the conveyer belt, transmission elevating of leading screw nuts and a bearing rack, automatic paving of a row of kerbstones on road is realized, and paving stability can be effectively guaranteed.

Owner:陈善兰

Soil slope geogrid laying and mounting method

ActiveCN113565100ARealize automatic layingAvoid loose collapse problemsClimate change adaptationExcavationsSoil scienceGeogrid

The invention relates to the field of geogrids, in particular to a soil slope geogrid laying and mounting method. The soil slope geogrid laying and mounting method aims to solve the technical problems. According to the technical scheme, the soil slope geogrid laying and mounting method uses the following machining equipment comprising a lowering and laying system, a slope surface protection system, a first supporting leg frame, a second supporting leg frame and a third supporting leg frame, and the lower part of a mounting rack plate is in bolt connection with an embedded mounting bottom block. According to the soil slope geogrid laying and mounting method, automatic laying of the soil slope surface is achieved, a supporting structure is formed for the slope surface before laying, so that direct contact friction between the slope surface and a geogrid in the laying process is avoided, the situation that the geogrid rubs against a slope to damage the structure of the slope is prevented, and the effects of stable and rapid laying and soil slope protection are achieved.

Owner:新疆佳宇建设有限公司

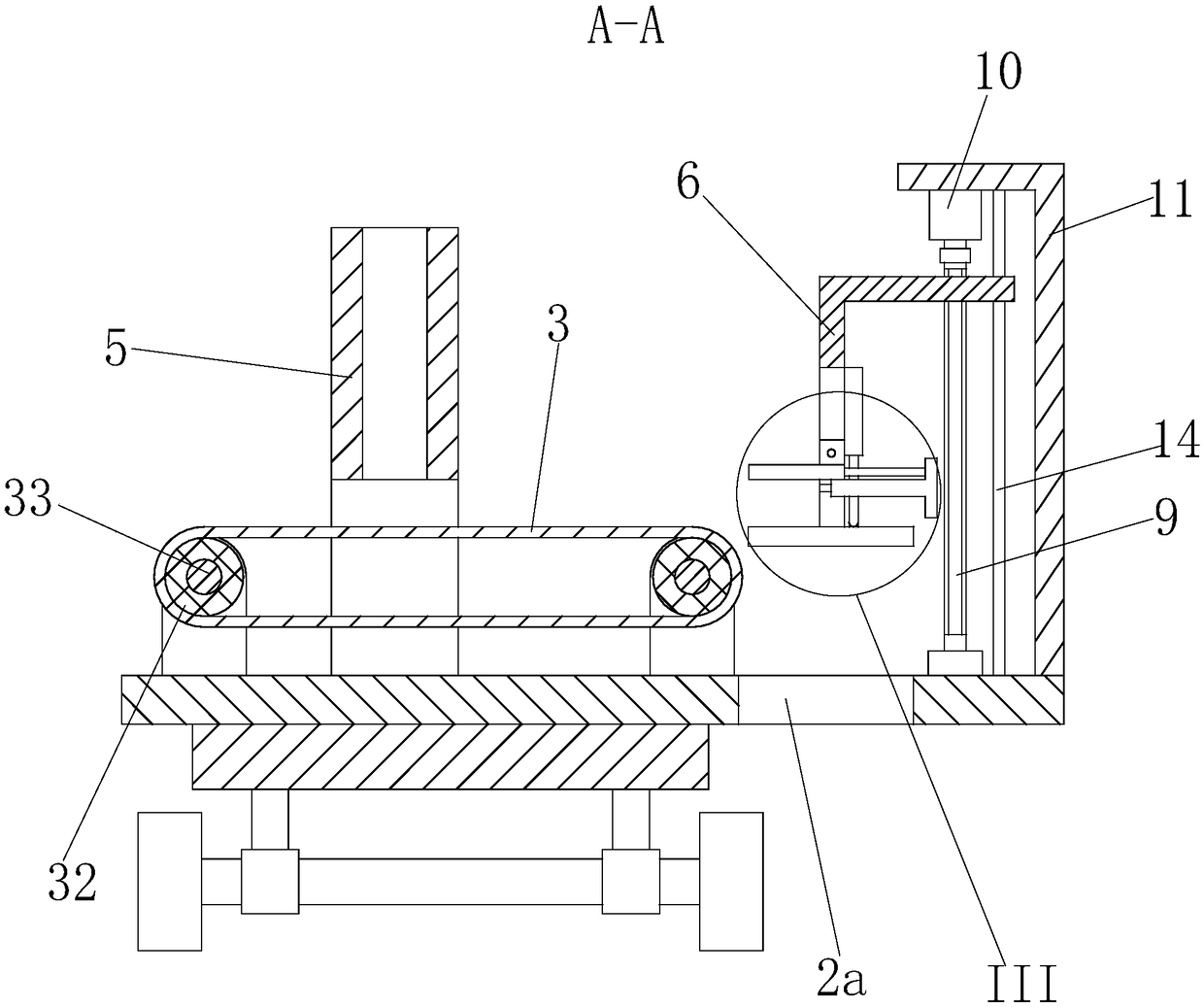

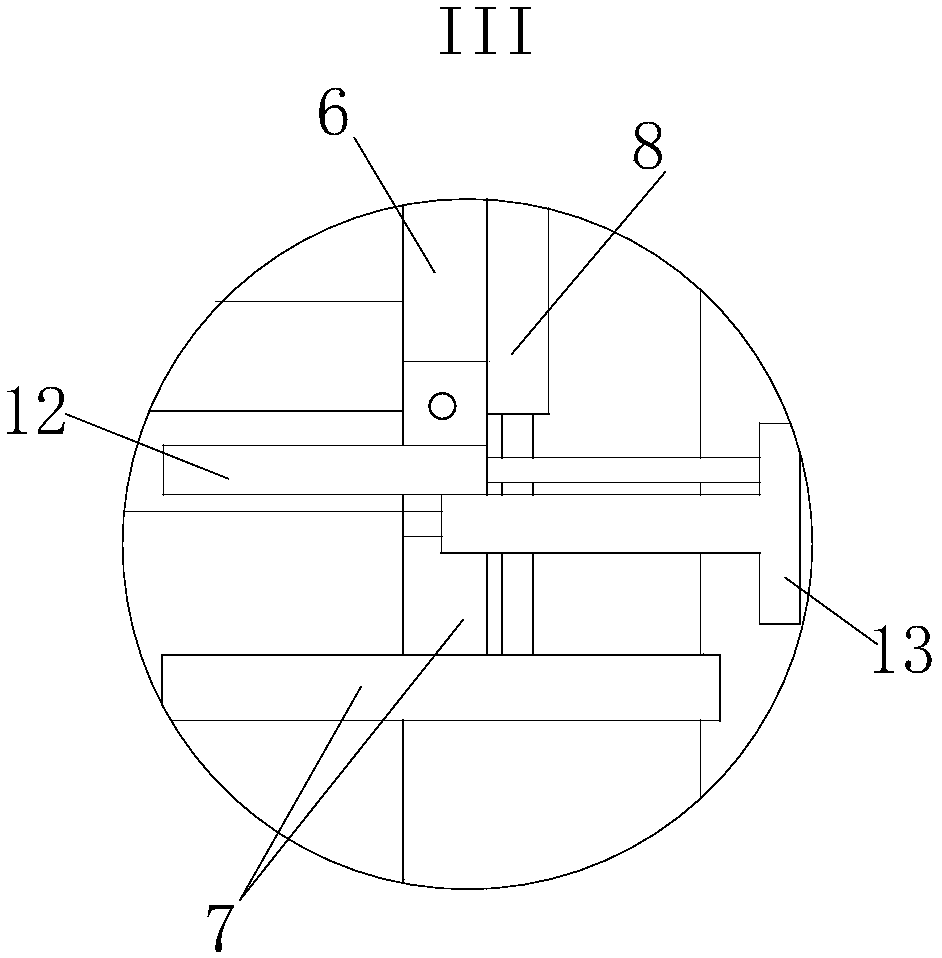

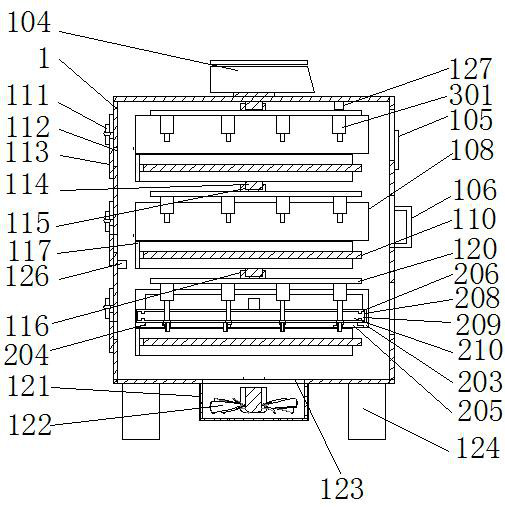

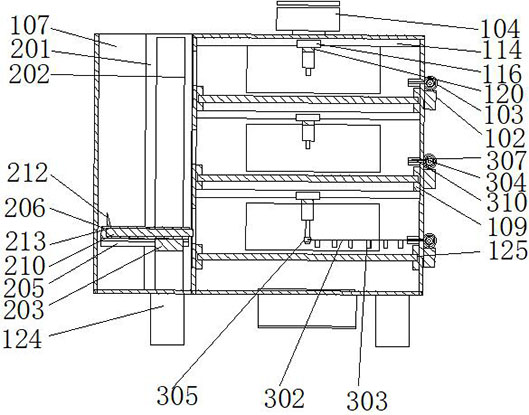

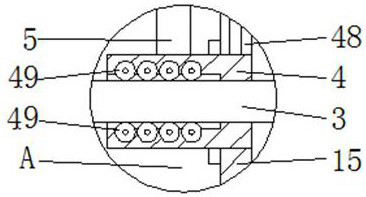

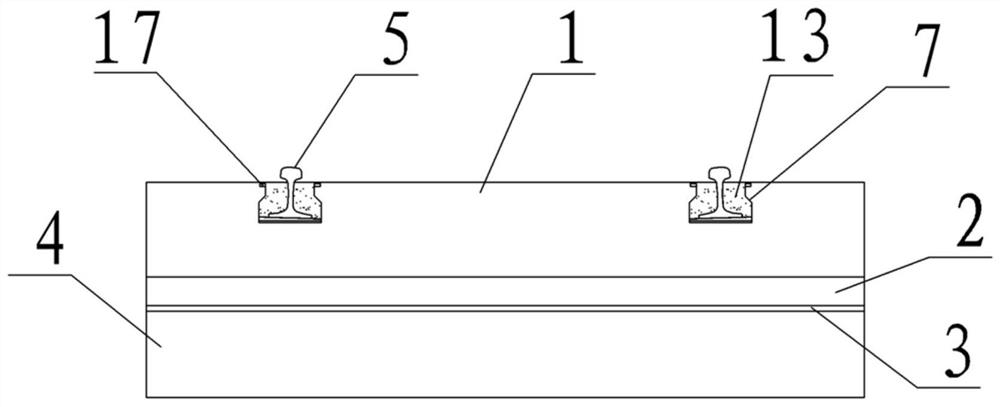

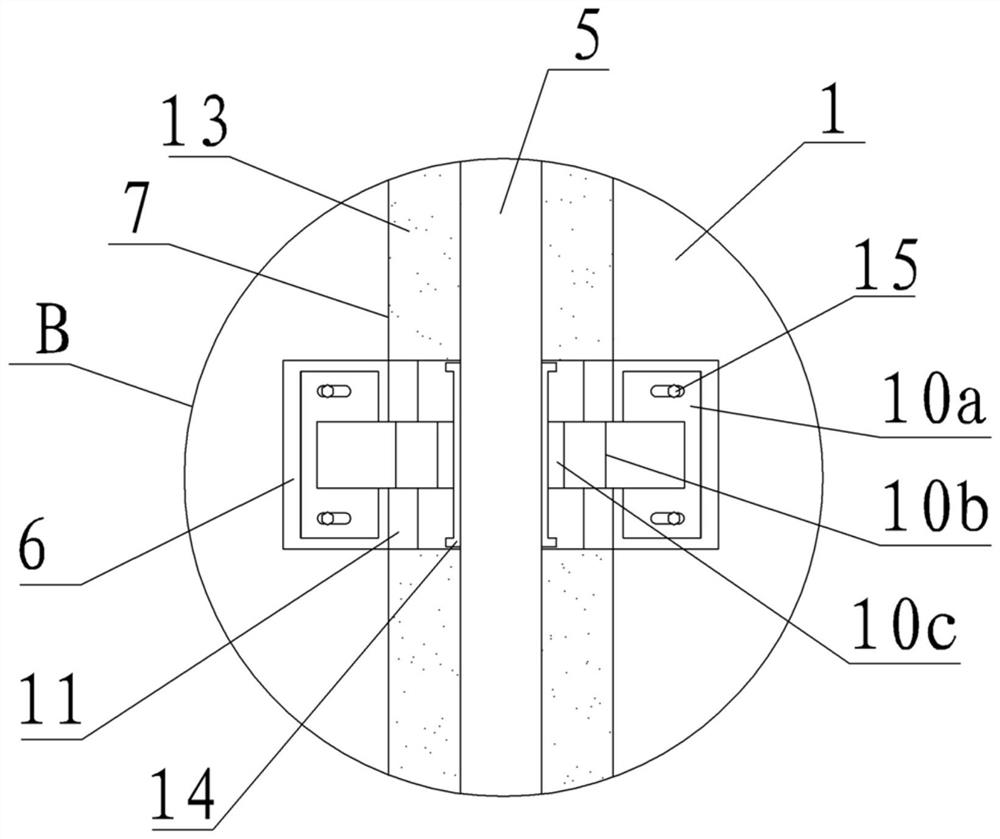

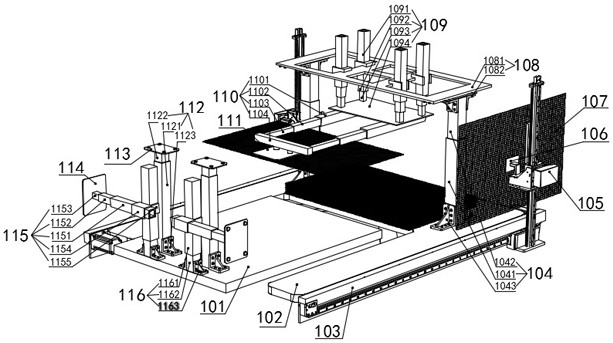

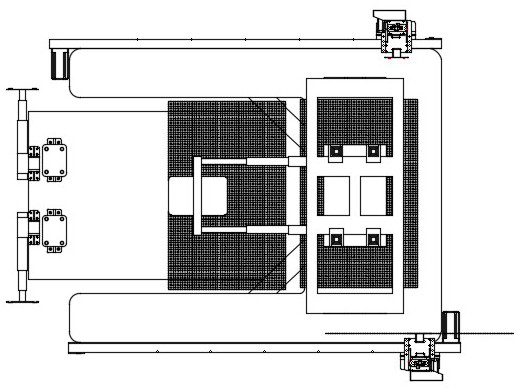

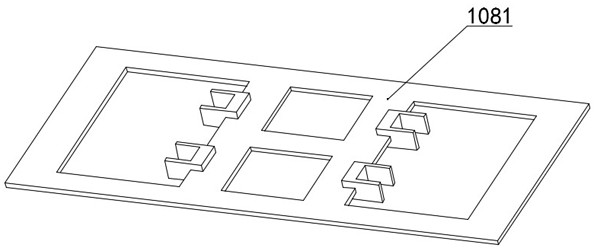

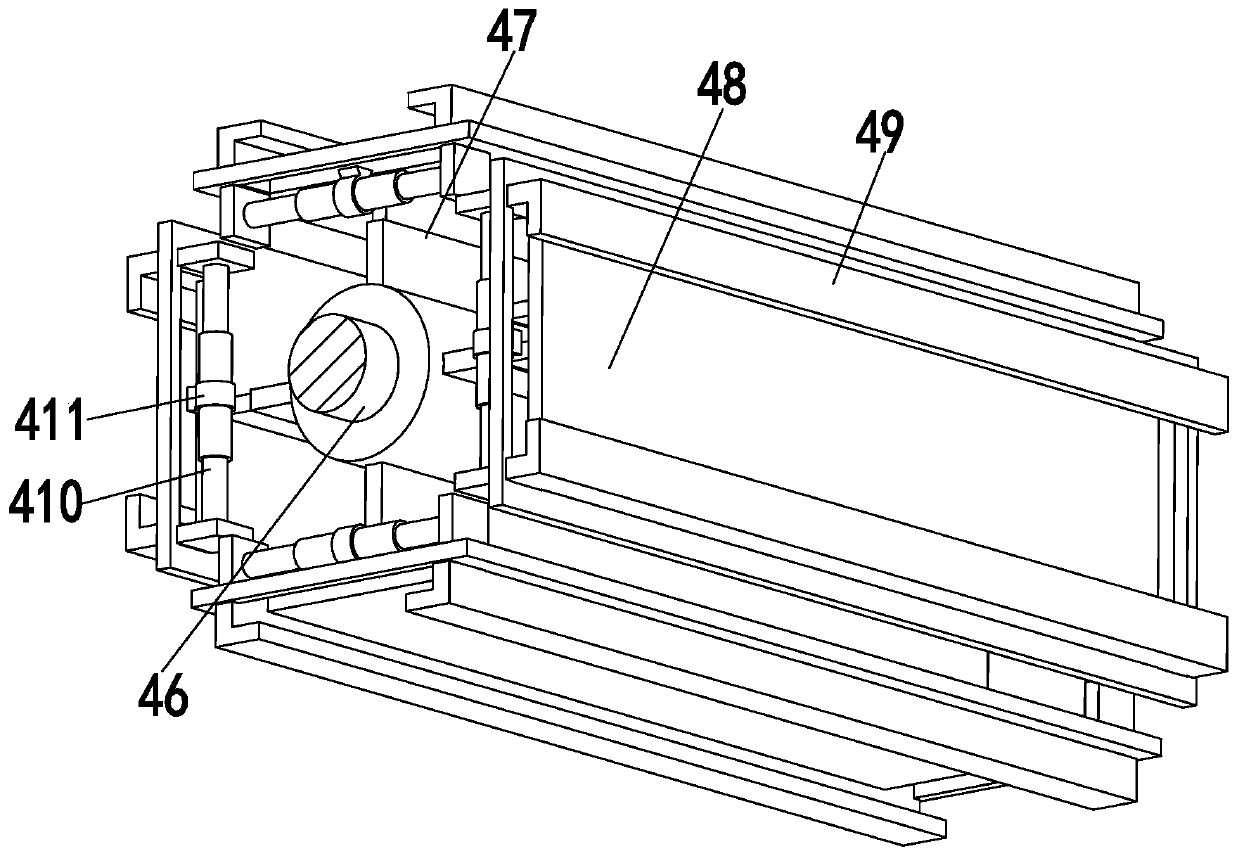

Laminated board hot-pressing equipment with automatic material laying device

InactiveCN109129764AFit tightlyRealize automatic layingPlywood pressesLamination ancillary operationsHot pressEngineering

Owner:天津涵霖科技发展有限公司

Landscaping machine

InactiveCN108330791AReduce labor intensity and labor costsImprove work efficiencyRoads maintainenceEngineeringLandscaping

The invention relates to a landscaping machine which comprises bottom boards, walking wheels, an installation frame, a grabbing device and a laying device. The walking wheels are installed at the lower ends of the bottom boards, the installation frame is installed at the upper ends of the bottom boards, square holes are symmetrically formed in the front end and the rear end of the installation frame, the grabbing device and the laying device are sequentially installed on the installation frame from left to right, the grabbing device comprises carrying mechanisms and compression mechanisms, each compression mechanism comprises a height adjusting air cylinder, a lifting frame, a guide rail, a push board, compression air cylinders, compression blocks, drive branched chains and an installationboard, and the laying device comprises a guide mechanism and a compaction mechanism. The landscaping machine can solve the problems that labor cost is high, labor intensity is large, work efficiencyis low, and laid bricks are likely to incline in the existing square brick laying process, the function that the square bricks are automatically laid can be achieved, and the landscaping machine has the beneficial effects of being low in labor cost, small in labor intensity, high in work efficiency, flexible in adjustment, high in laying straightness and the like.

Owner:丁佐琳

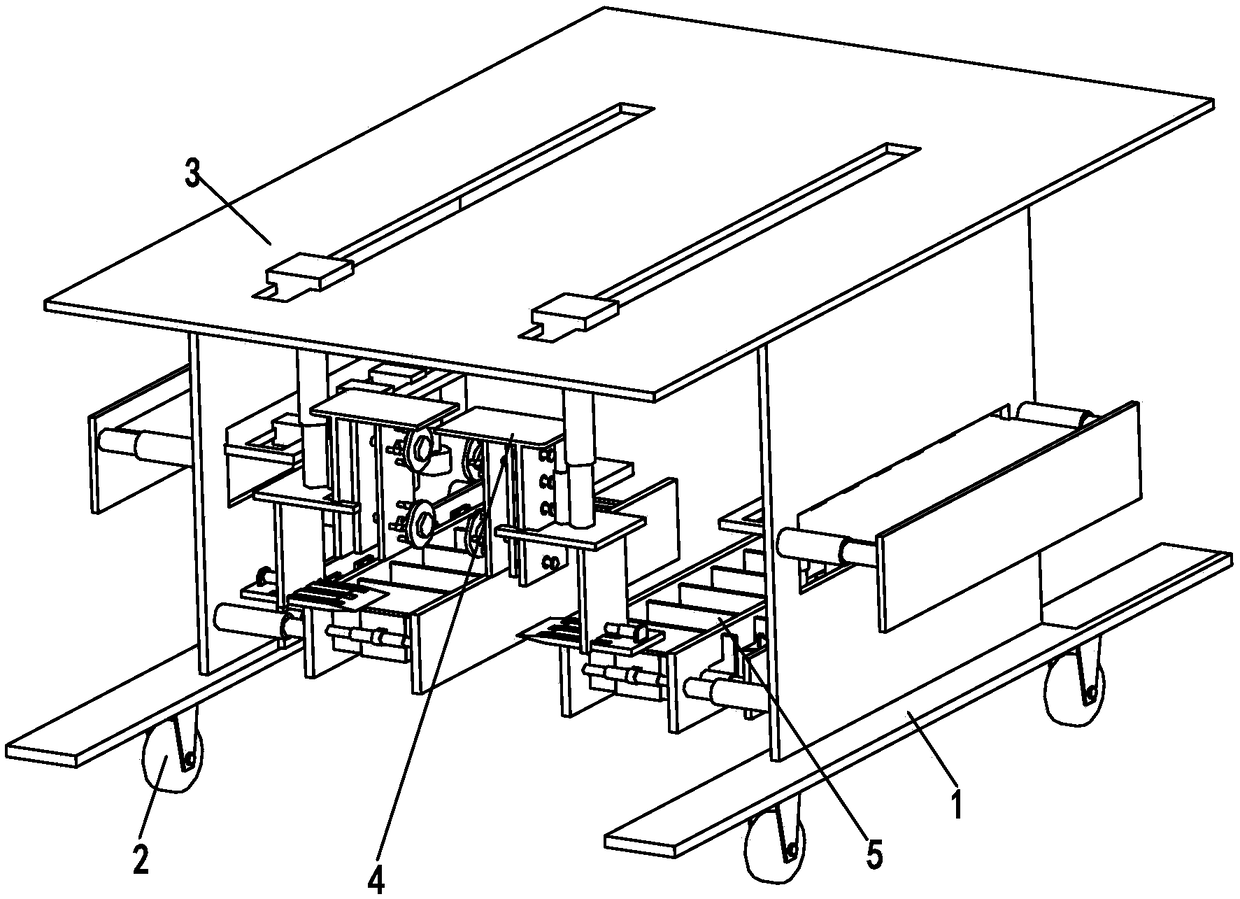

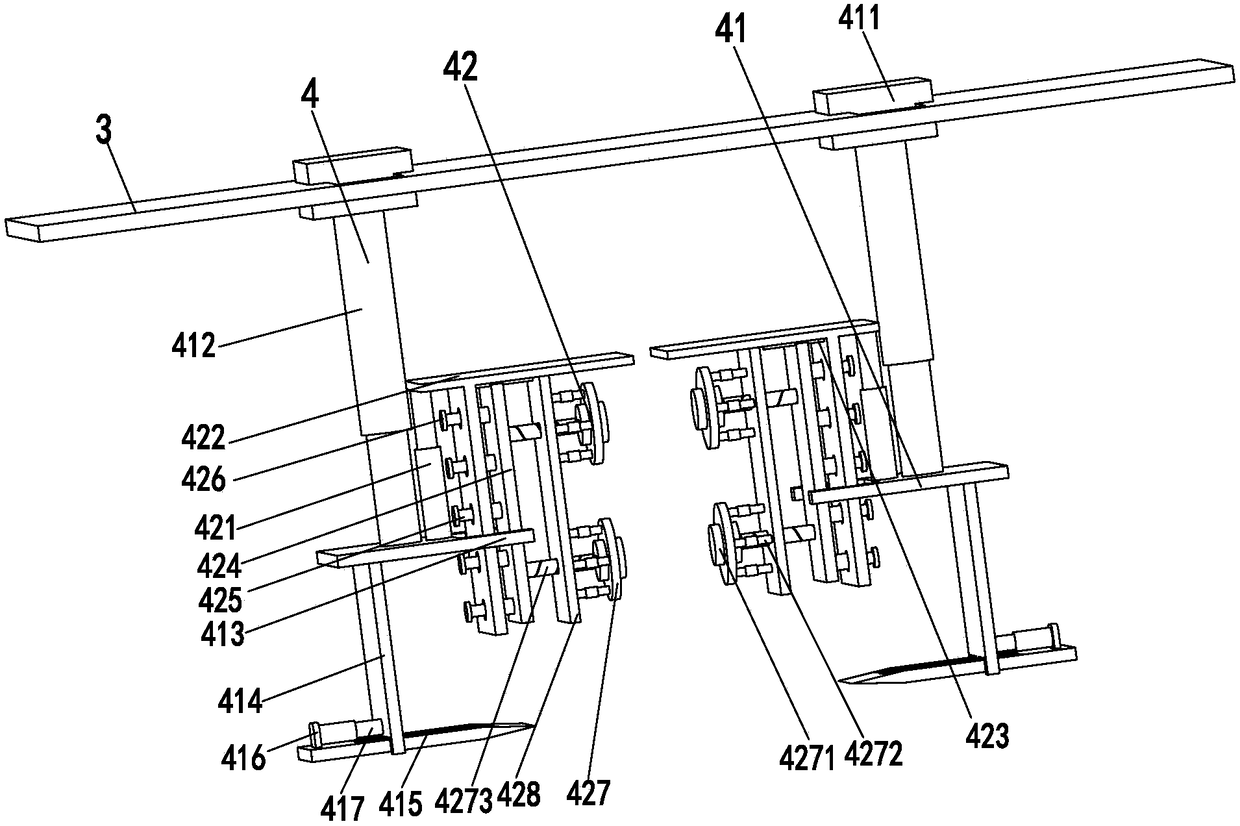

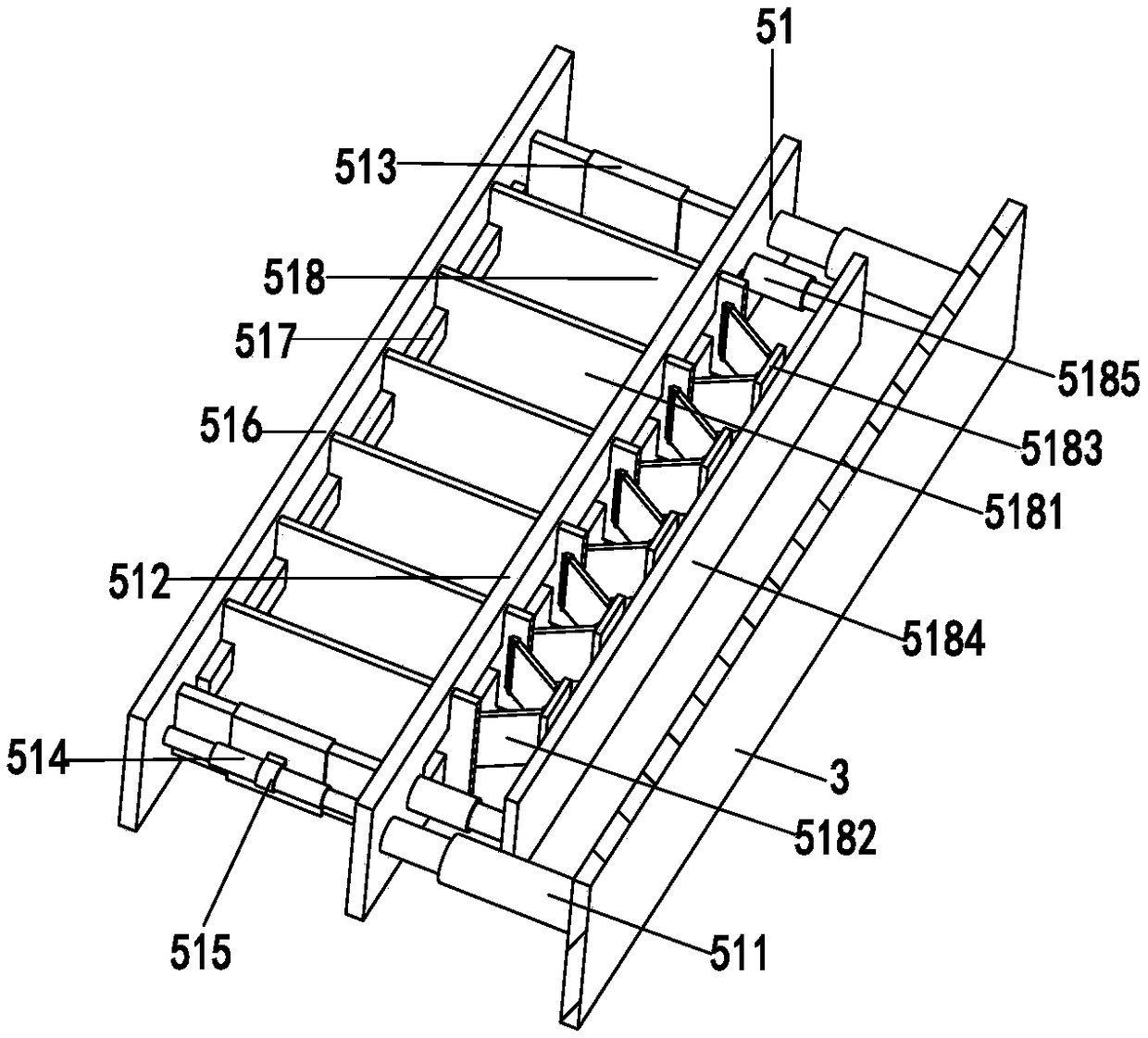

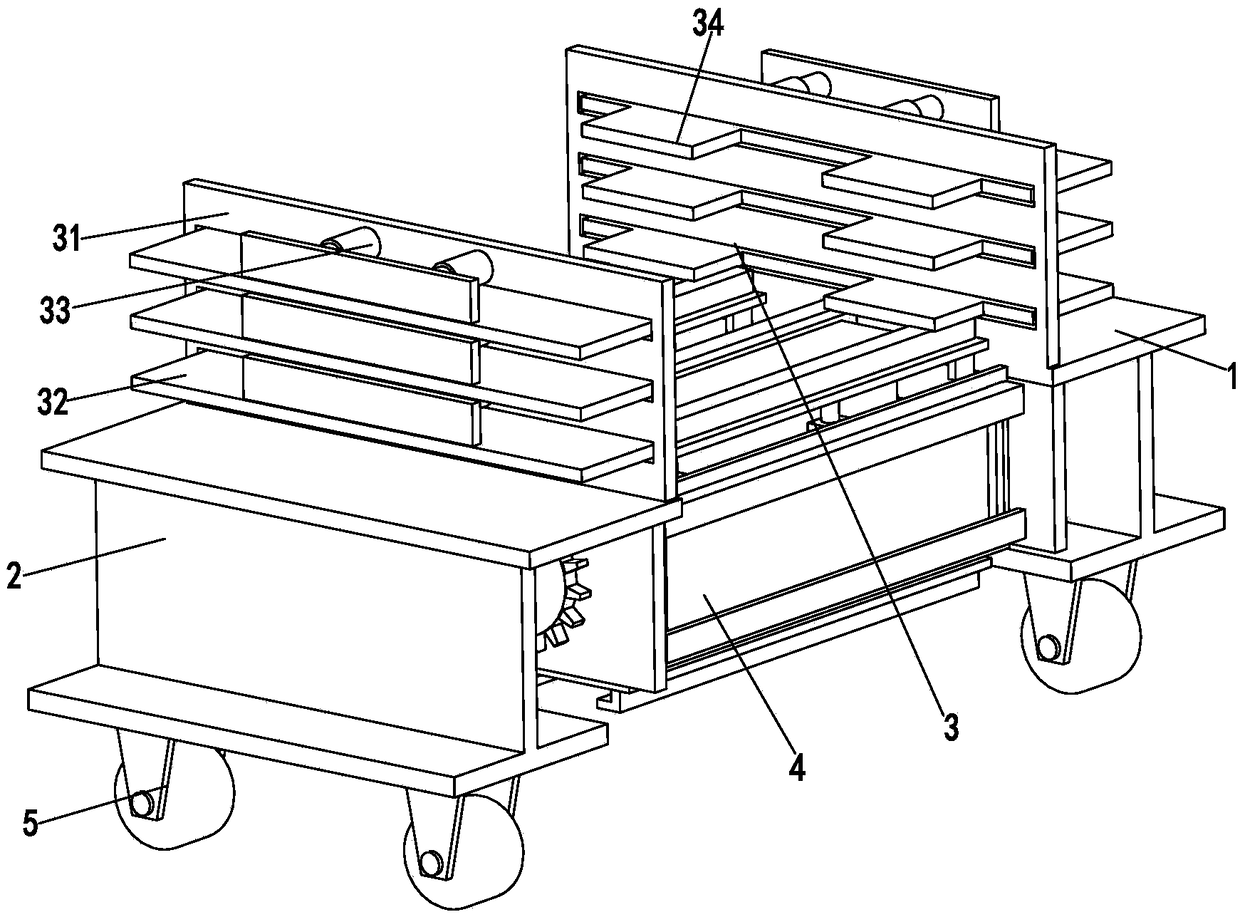

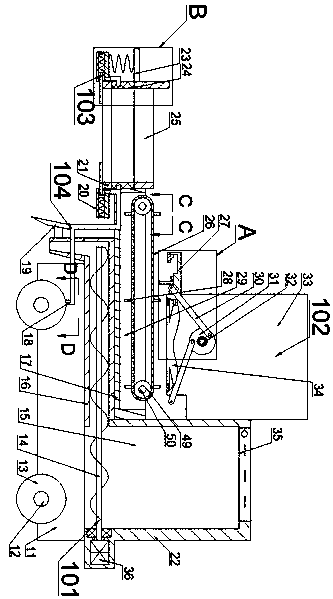

Sleeper automatic laying robot for railway emergency rescue and disaster relief

ActiveCN109281237ARealize automatic layingIncrease labor costRailway track constructionEmergency rescueEngineering

The invention relates to a sleeper automatic laying robot for railway emergency rescue and disaster relief. The sleeper automatic laying robot comprises two base plates, working frames, storing frames, a laying device and traveling wheels; the two base plates are arranged in a bilateral symmetry mode, and the working frames are mounted at the lower ends of the base plates; the traveling wheels aremounted at the lower ends of the working frames, and the storing frames are mounted at the upper ends of the base plates; the laying device is mounted between the two base plates, and the storing frames comprise mounting plates, adjusting frames, adjusting air cylinders and placing plates; and the laying device comprises a vertical plate, a rotating plate, a rotating motor, a mounting frame, a rotating gear, a rotating tube, a telescopic supporting plate, a bearing plate, a fixing plate, a fixing electric push rod and a fixing ring. The problems that in the existing process of sleeper layingfor railway emergency rescue, the labor cost is high, the working efficiency is low, the work continuity is poor, and large equipment works difficultly can be solved, the function of automatic layingon a sleeper can be achieved, and the sleeper automatic laying robot has the advantages of being low in labor cost, high in working efficiency, high in work continuity, small in size and the like.

Owner:胡佳威

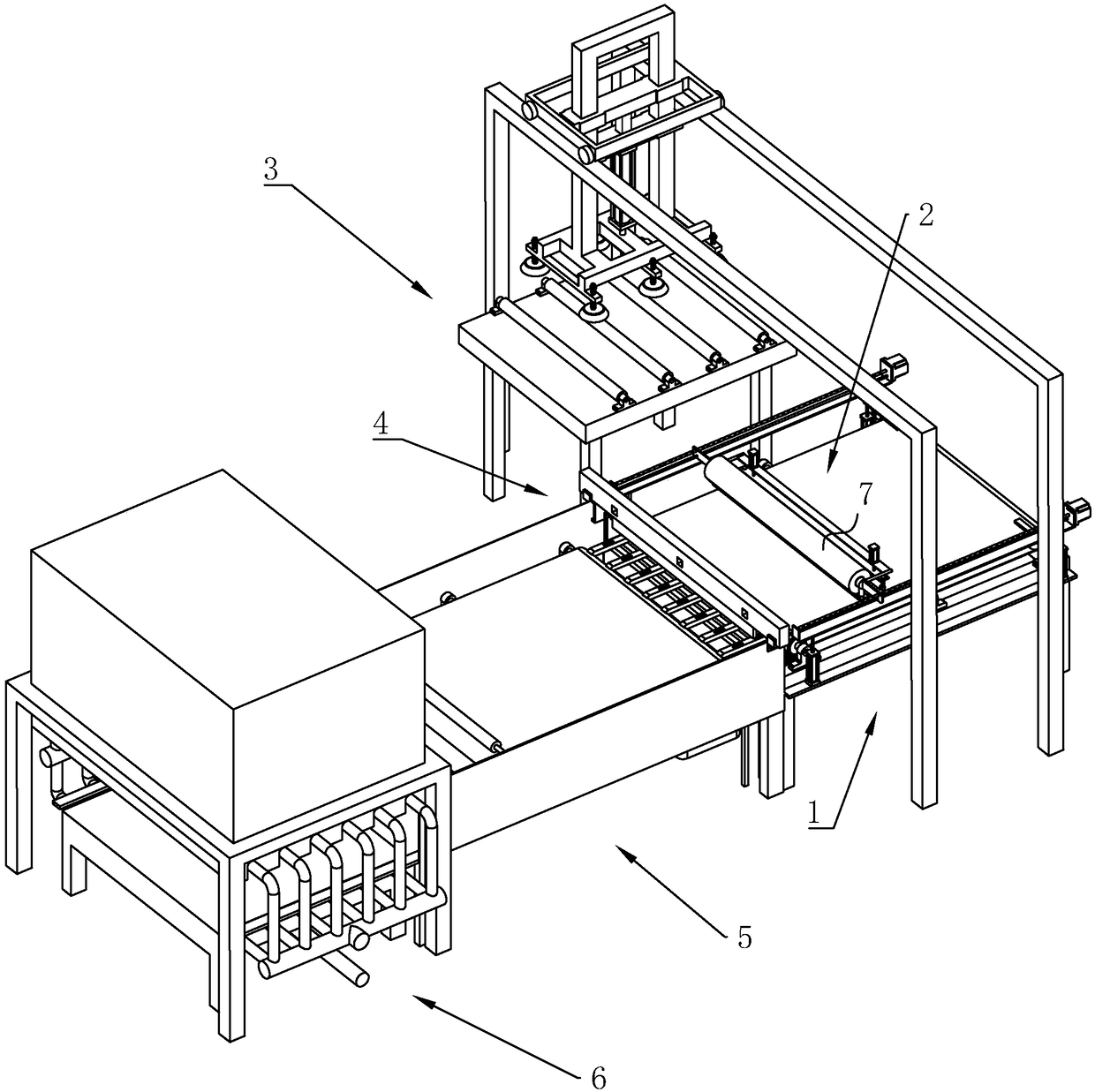

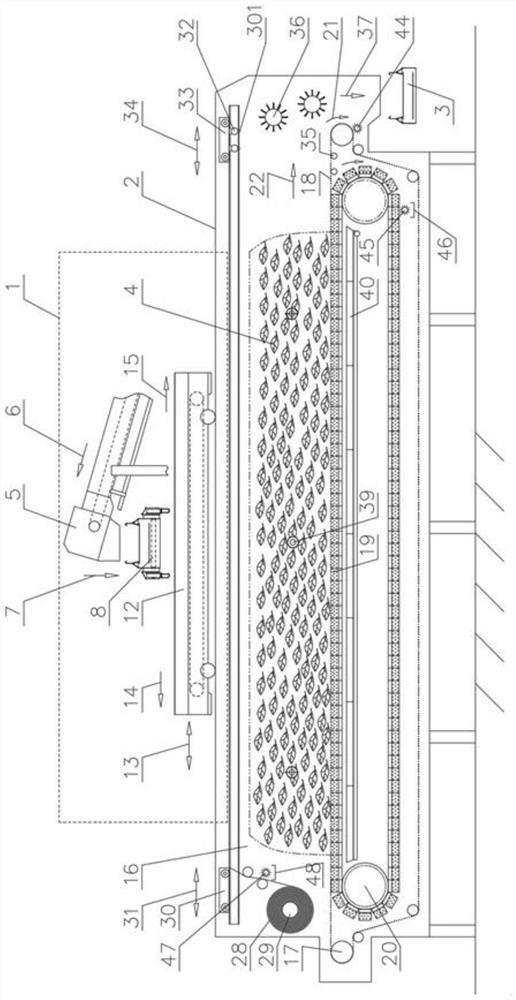

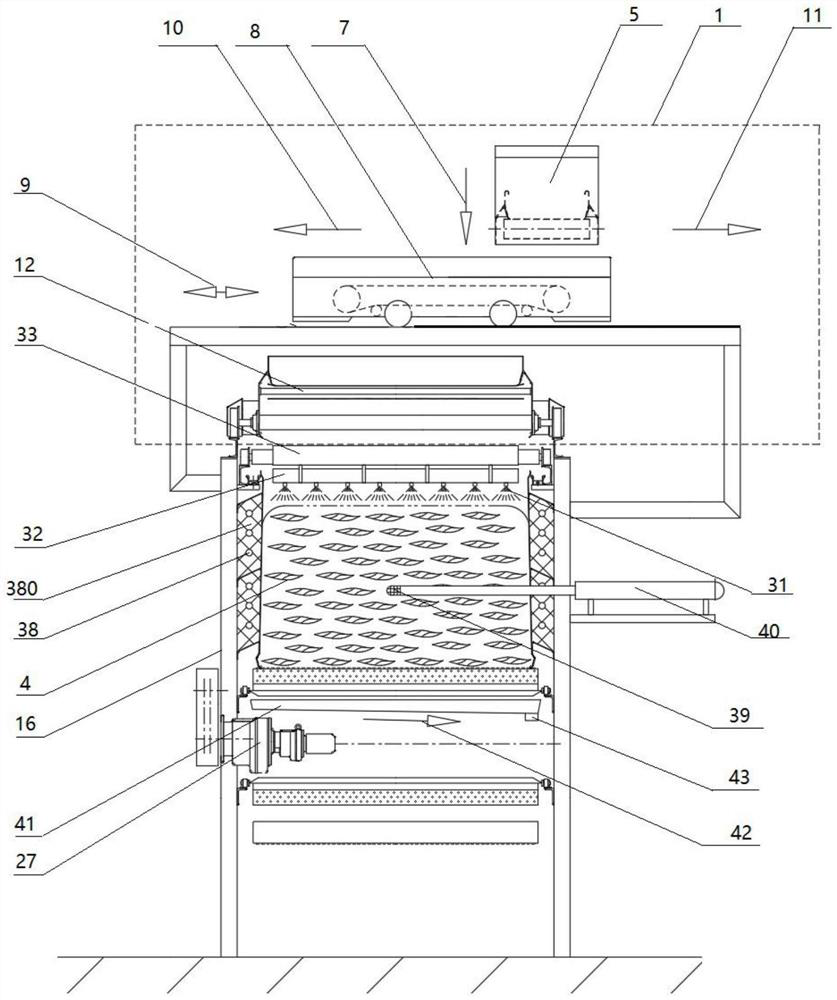

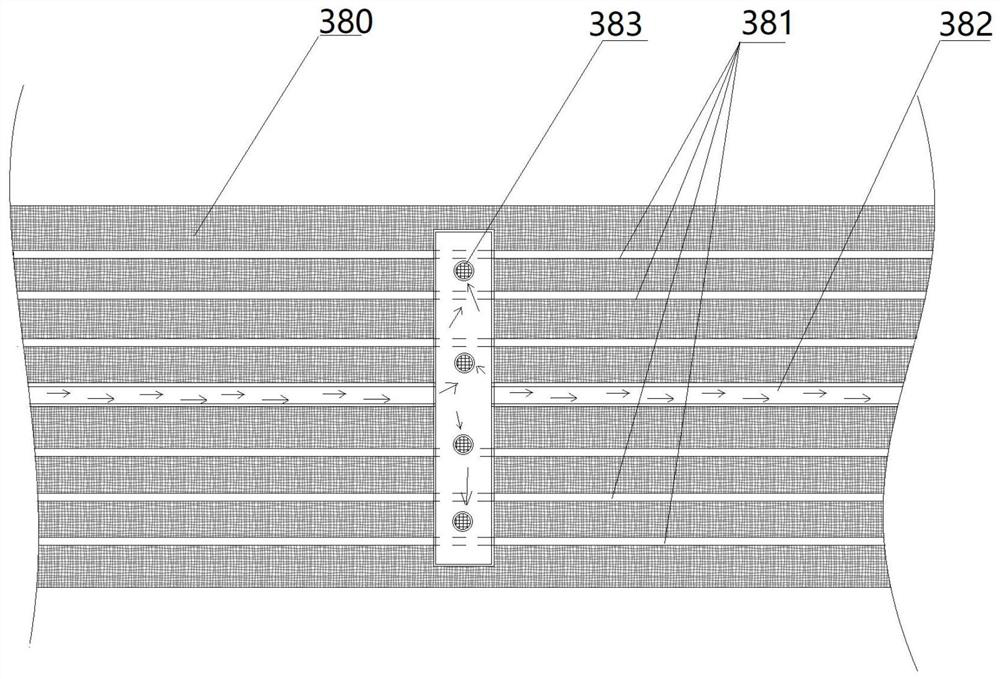

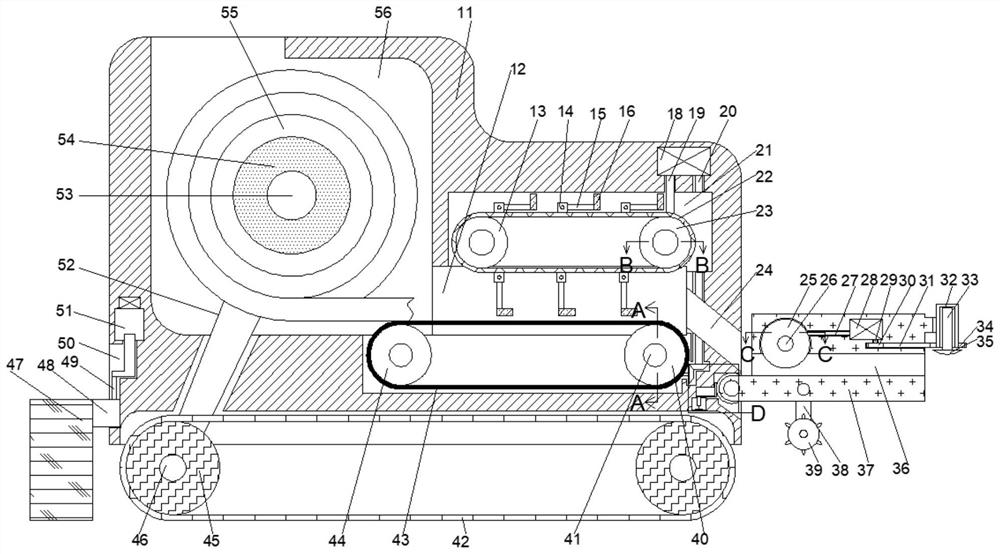

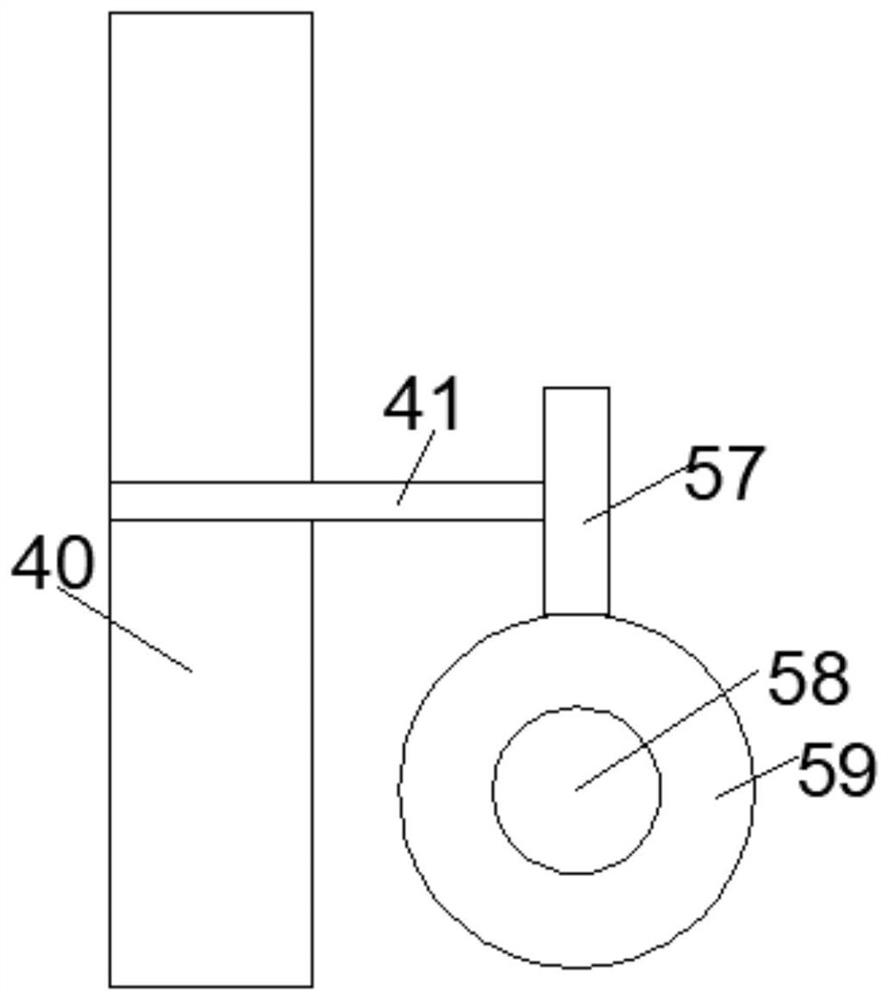

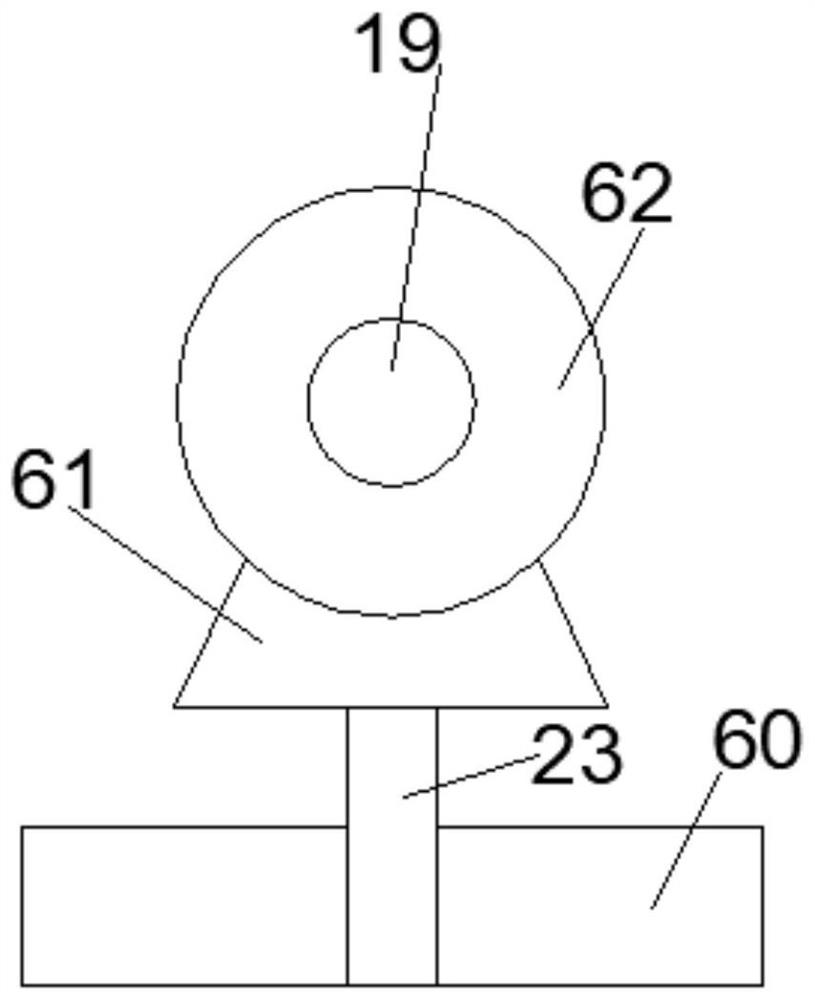

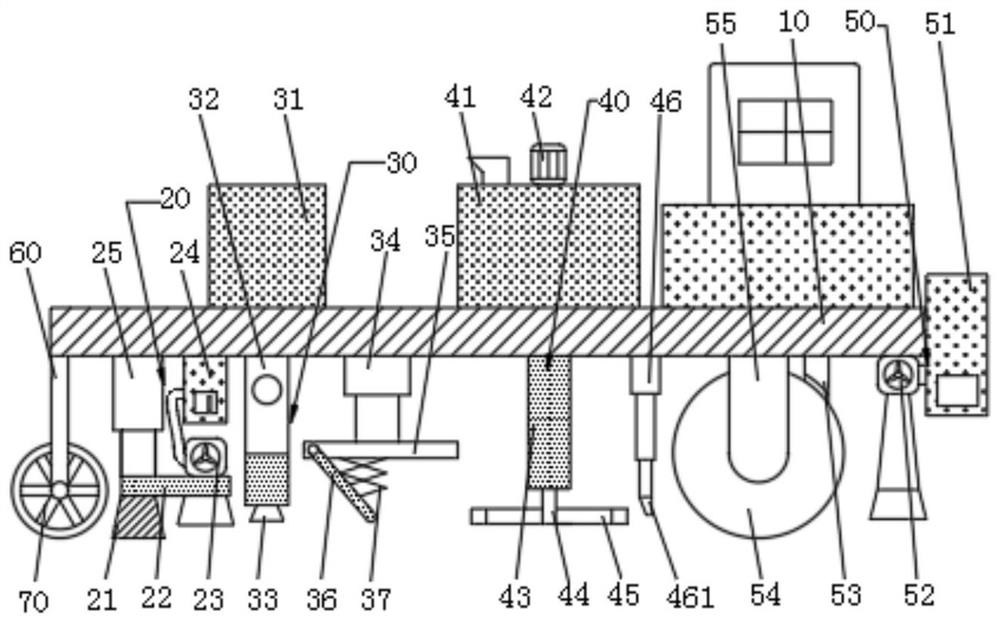

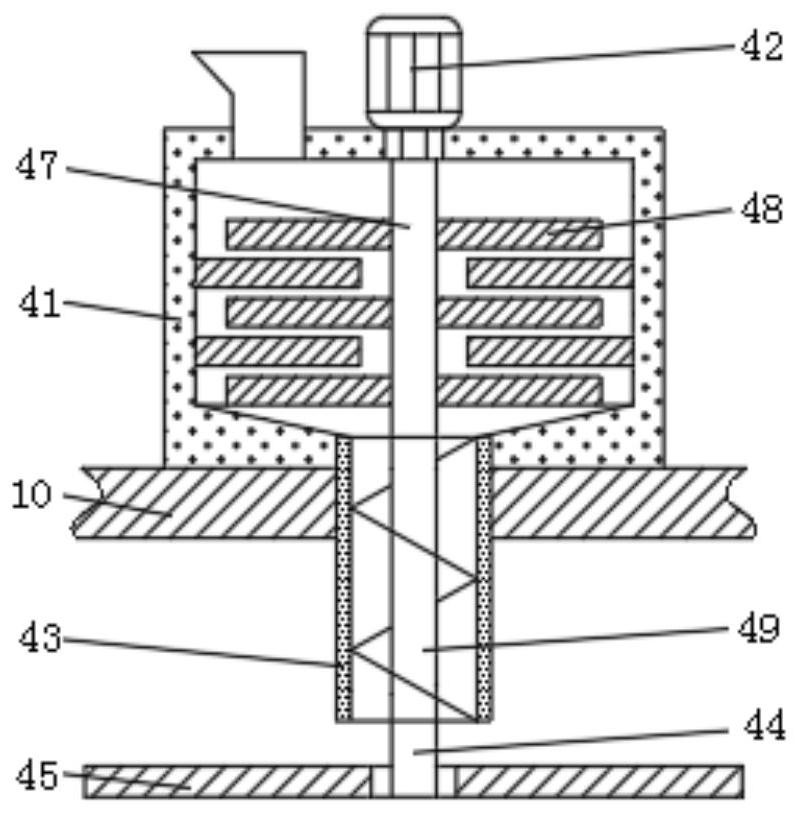

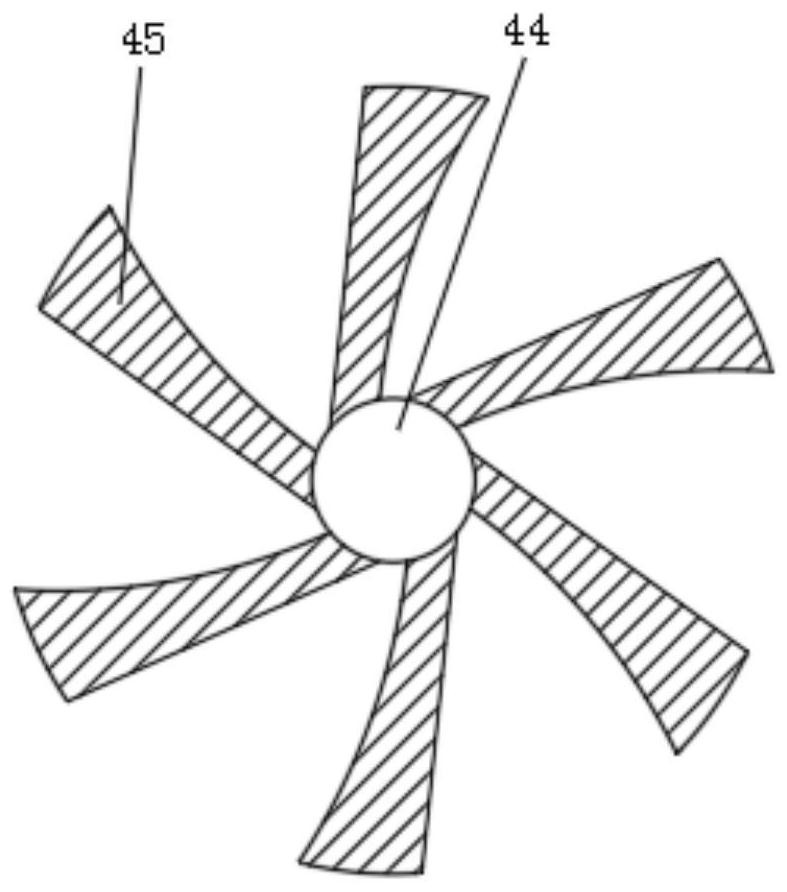

Tea leaf pile fermentation device and method based on automatic splicing movable material bearing table

PendingCN112913940AHigh degree of automationFully automatedPre-extraction tea treatmentAgricultural engineeringMoisture absorption

The invention discloses a tea leaf pile fermentation device and method based on an automatic splicing movable material bearing table. Automatic pile fermentation of tea leaf materials is realized through cooperative work of a material spreading system, a pile fermentation system and discharging conveying equipment. The pile fermentation process is completed in a pile fermentation bin, and the bottom of the bin is an automatic splicing movable material bearing table which is formed by combining a plurality of material bearing table units. Each material bearing table unit is made of concrete blocks, earthenware, battens or bamboo boards with certain thickness, the internal structure is relatively loose, a survival space can be provided for beneficial bacteria needed by pile fermentation, and the functions of heat preservation, humidity control, moisture absorption and the like are achieved. The tea leaves are subjected to pile fermentation on the material bearing table, the advantages of a traditional pile fermentation method can be played, and a feasible solution is provided for achieving automation of the pile fermentation process. By adopting the pile fermentation method, the tea materials do not fall to the ground, and the product is clean and sanitary and has good purity; the pile fermentation process is fully automatic, and the labor intensity is greatly reduced; and the key links are digitally controlled, so that the product quality is better guaranteed.

Owner:KUNMING SHIPBUILDING EQUIP

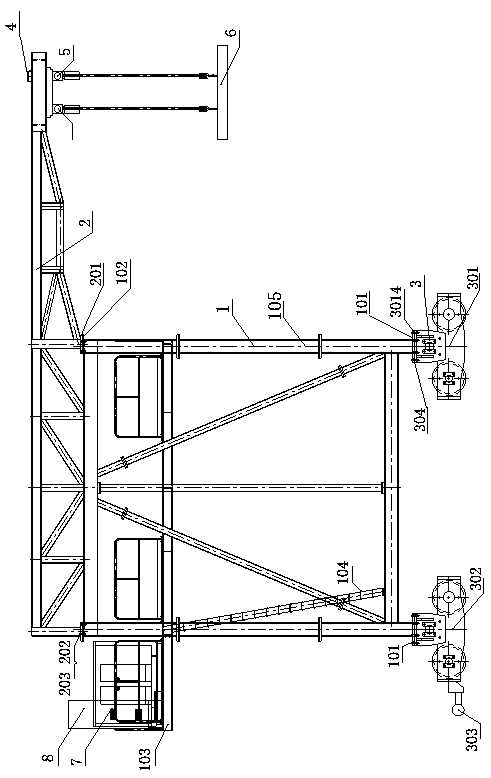

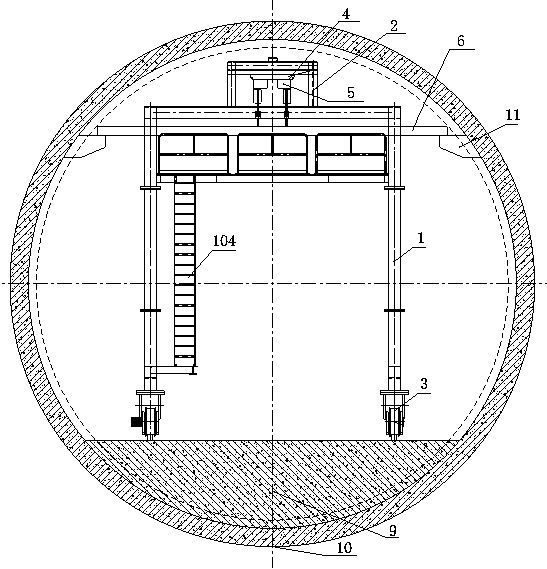

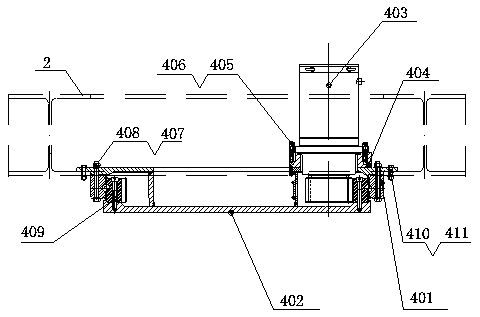

Flue plate laying machine applicable to large-diameter flue plate and laying method thereof

ActiveCN110985091AImprove laying efficiencyImprove construction safetyMining devicesTunnel/mines ventillationProcess engineeringEngineering

The invention discloses a flue plate laying machine applicable to a large-diameter flue plate and a laying method thereof, and solves the problems that in the prior art, operation of a flue plate laying device and tunneling cannot be performed simultaneously and the working efficiency is low. The flue plate laying machine comprises an active trailer, wherein a hoisting frame is arranged on the active trailer, a rotary system is arranged on the hoisting frame, a hoisting system for hoisting the flue plate is arranged on the rotary system, the rotary system can drive the hoisting system to rotate, and the rotary system and the hoisting system are connected with a power-control system on the active trailer. According to the flue plate laying machine applicable to the large-diameter flue plateand the laying method thereof, the flue plate is lifted up through the hoisting system, when the lifting height of the flue plate is higher than that of a flue plate supporting base, the rotary system rotates the flue plate by 90 degrees, the trailer is driven to move back and forth through a wheel pair driving device, the flue plate is placed at a target position, and efficient laying of the flue plate is realized.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

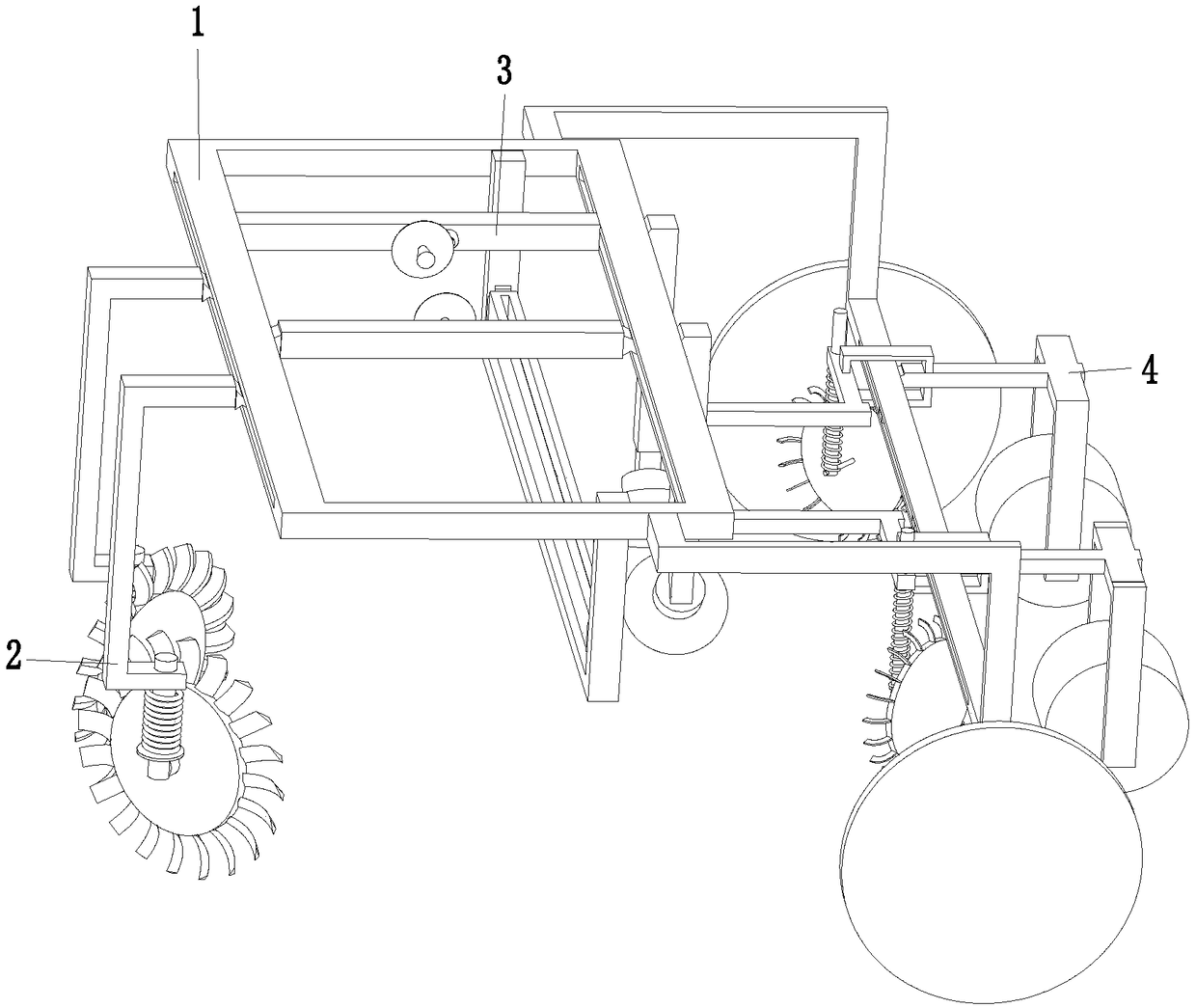

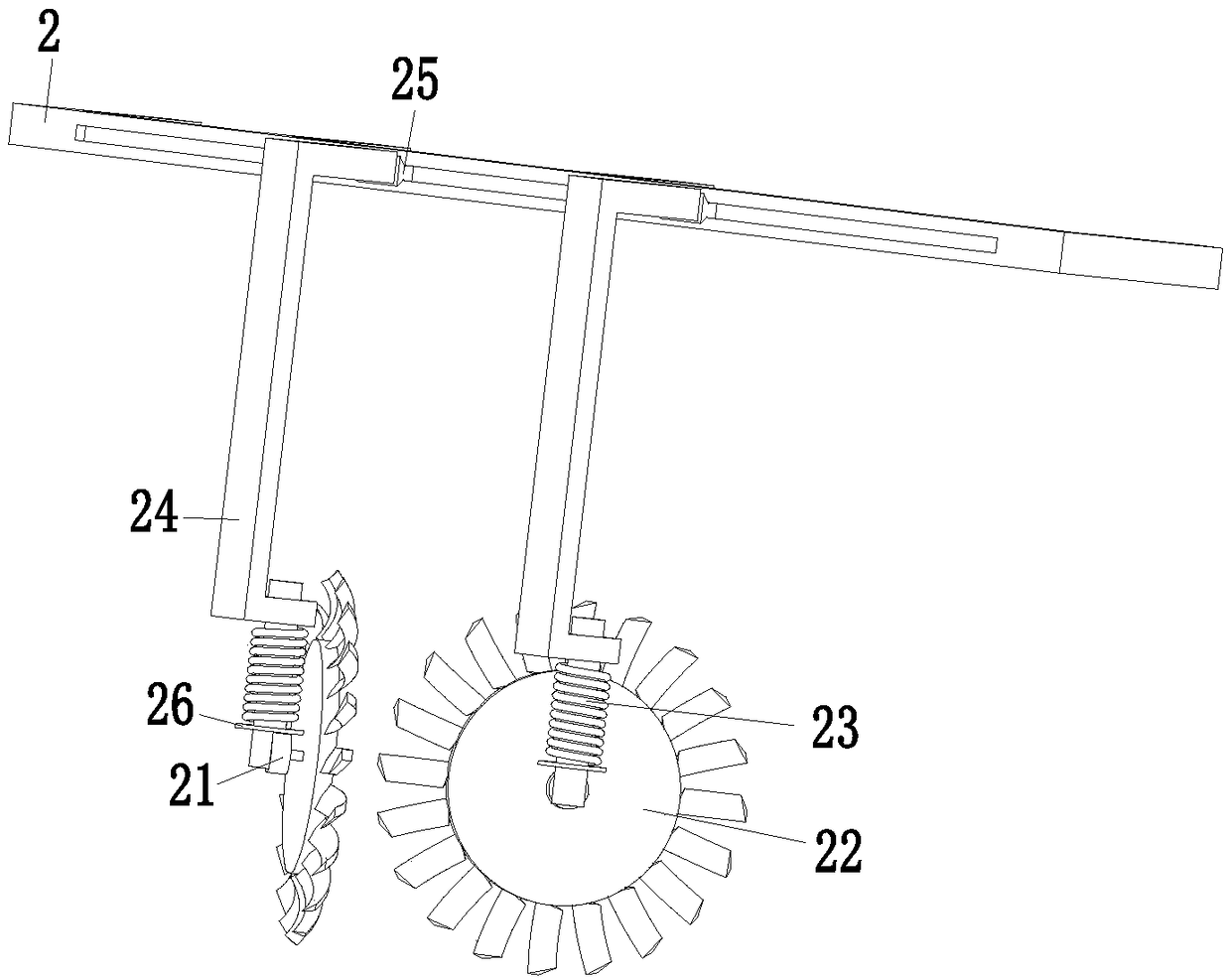

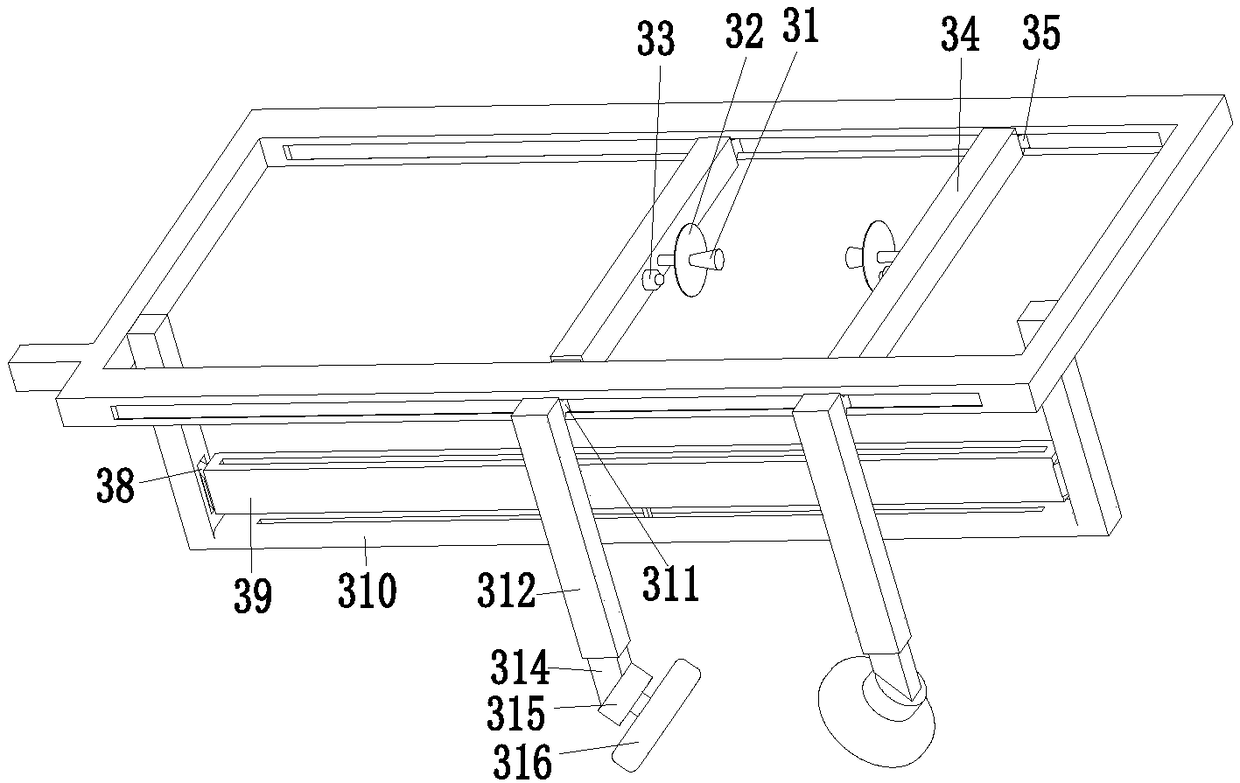

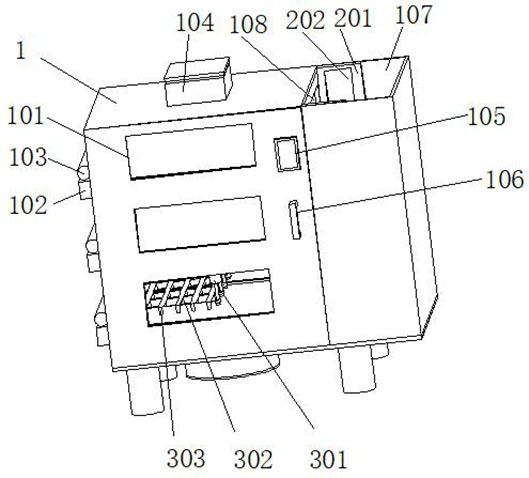

Mulching film laying device for agricultural cultivation and agricultural cultivation mulching film laying method

ActiveCN109287348ARealize automatic layingReduce compactionPlant protective coveringsAgricultural engineeringPlastic mulch

The invention relates to a mulching film laying device for agricultural cultivation and an agricultural cultivation mulching film laying method. The mulching film laying device comprises a bottom frame, two chiseling mechanisms, a laying device and a compacting device. The two chiseling mechanisms are installed on the left end face of the bottom frame. The laying device is installed on the inner side face of the middle of the bottom frame. The compacting device is installed on the right side face of the lower end of the laying device. The problems that an existing mulching film machine cannotmake the two lateral sides of a mulching film well fit the ground, the tightness inconsistency of the laid mulching film can be directly affected by the shaking of the mulching film machine and the lateral sides of the mulching film cannot be compacted after the mulching film is laid can be solved, and the functions of automatically laying the mulching film and compacting the lateral sides of themulching film can be realized.

Owner:柏乡县慧谷春禾农业科技有限公司

Intelligent silkworm breeding equipment

The invention discloses intelligent silkworm breeding equipment, and relates to the technical field of agriculture. The intelligent silkworm breeding equipment comprises a shell, wherein a square hole and a leaf feeding opening are formed in the two sides of the shell respectively, and a baffle is fixedly connected to one side of the shell; a leaf feeding mechanism is fixedly connected to the interior of the baffle and comprises supporting columns, and second electric sliding grooves are formed in the inner walls of the supporting columns; and the second electric sliding grooves are slidably connected with fixing plates, the tops of the fixing plates are provided with third electric sliding grooves, the third electric sliding grooves are internally and slidably connected with second electric sliding blocks, and the tops of the second electric sliding blocks are fixedly connected with first leaf feeding plates. According to the intelligent silkworm breeding equipment, through the arrangement of the leaf feeding opening, the supporting columns, the first leaf feeding plates and second leaf feeding plates, the first leaf feeding plates and the second leaf feeding plates feed mulberry leaves from the leaf feeding opening through up-down movement of the supporting columns, so that automatic feeding is achieved, the feeding time is saved, and therefore the working efficiency is improved.

Owner:平昌县鑫平蚕业有限公司

Gypsum line surface film laminating machine

The invention provides a gypsum line surface film laminating machine. The gypsum line surface film laminating machine is applied to film laminating of a gypsum line surface protective film and comprises a plurality of gypsum line film laminating brackets and a film pulling device, wherein the plurality of gypsum line film laminating brackets are erected, stacked and arranged; and the film pullingdevice walks back and forth along the length direction of the film laminating brackets and pulls the protective film to cover a plurality of gypsum lines. The gypsum lines are stacked and placed on the film laminating brackets, the film pulling device is controlled to walk along the length direction of the gypsum lines when one layer of gypsum line is placed, the protective film is pulled to coverthe surface of the gypsum line, the gypsum line is placed continuously, the film pulling device is controlled to return along the length direction of the gypsum line, stacking of the gypsum lines cooperates with reciprocating walking of the film pulling device, and one layer of protective film is pulled to cover the adjacent two layers of gypsum lines after multiple layers of gypsum lines are placed, so that automatic film laminating of the protective films among the plurality of gypsum lines which are stacked and transported is completed. Through the film laminating brackets and the film pulling device, automatic paving of the protective films is realized, the labor intensity is reduced and effective protection on the gypsum lines is realized.

Owner:宁波万立杰普顺装饰材料有限公司

Steel wool ball packaging box plastic film sealing device

InactiveCN109775053AIncrease productivityRealize automatic layingWrapper twisting/gatheringProduction lineMedium enterprises

The invention provides a steel wool ball packaging box plastic film sealing device. A containing box is installed on a conveyer belt. A pressure roll and a guide roll are installed at the two ends ofa machine frame and at the positions above the upper edge of a conveying device, the pressure roll is used for tightly pressing packaging film to a packaging box, and the guide roll is used for rolling up cut waste film. The waste film is guided by the guide roll to be conveyer to a waste film coiling device. The waste film coiling device is fixedly installed on a coiling bracket support fixedly installed on the machine frame. A fixed frame is provided with a sealing film roll, a sealing air cylinder and a cut-off air cylinder respectively. Because the conveyer belt and the containing box areadopted for being used in cooperation, the steel wool ball packaging box to be sealed can be produced in a production line manner; and the steel wool ball packaging box plastic film sealing device canseal steel wool ball packaging boxes with plastic film efficiently, and is high in efficiency, obviously reduced in labor cost, and quite applicable to small and medium enterprises.

Owner:鄂州宝丰金属棉技术股份有限公司

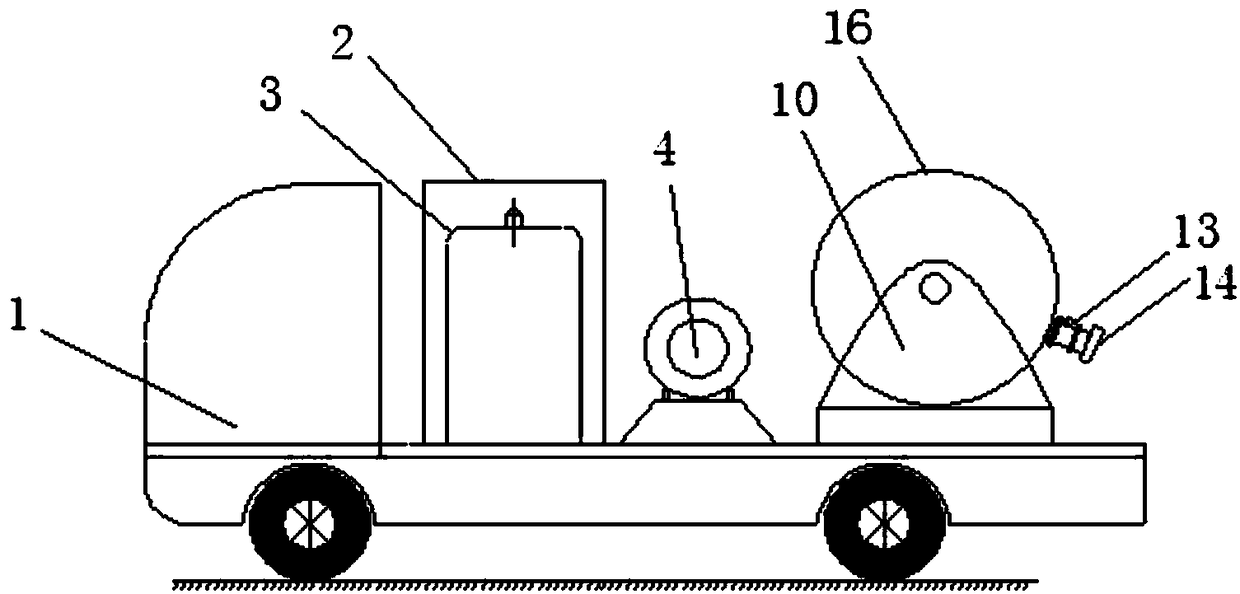

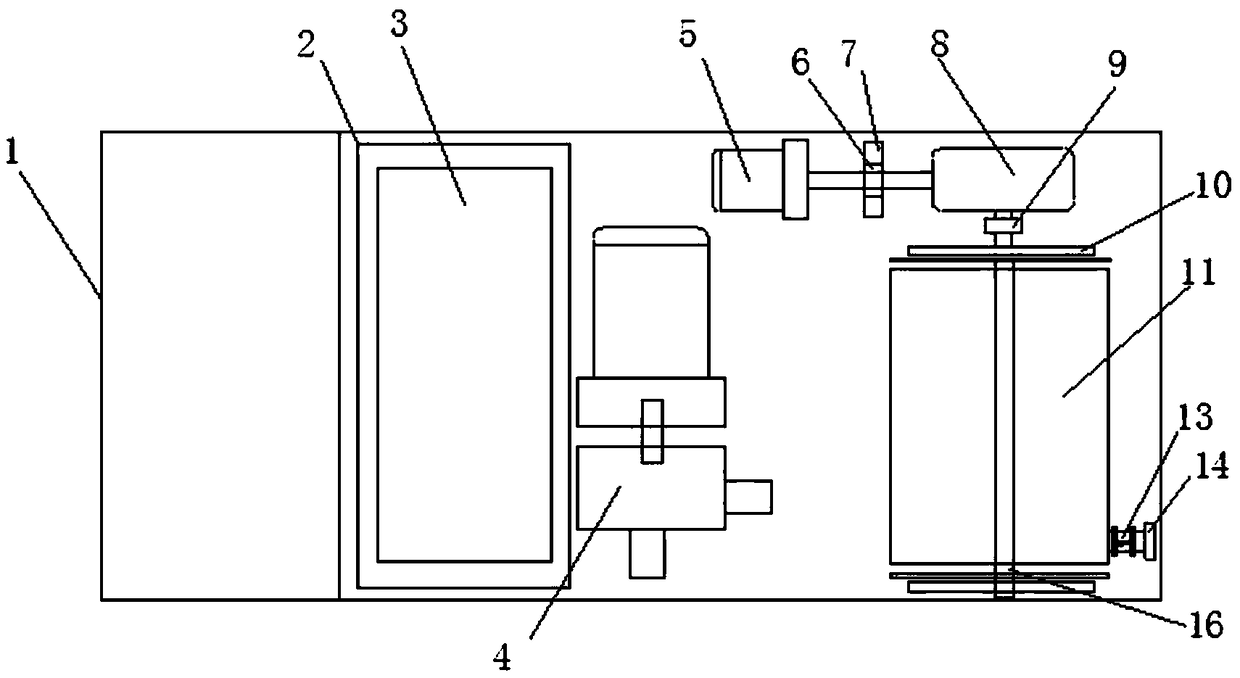

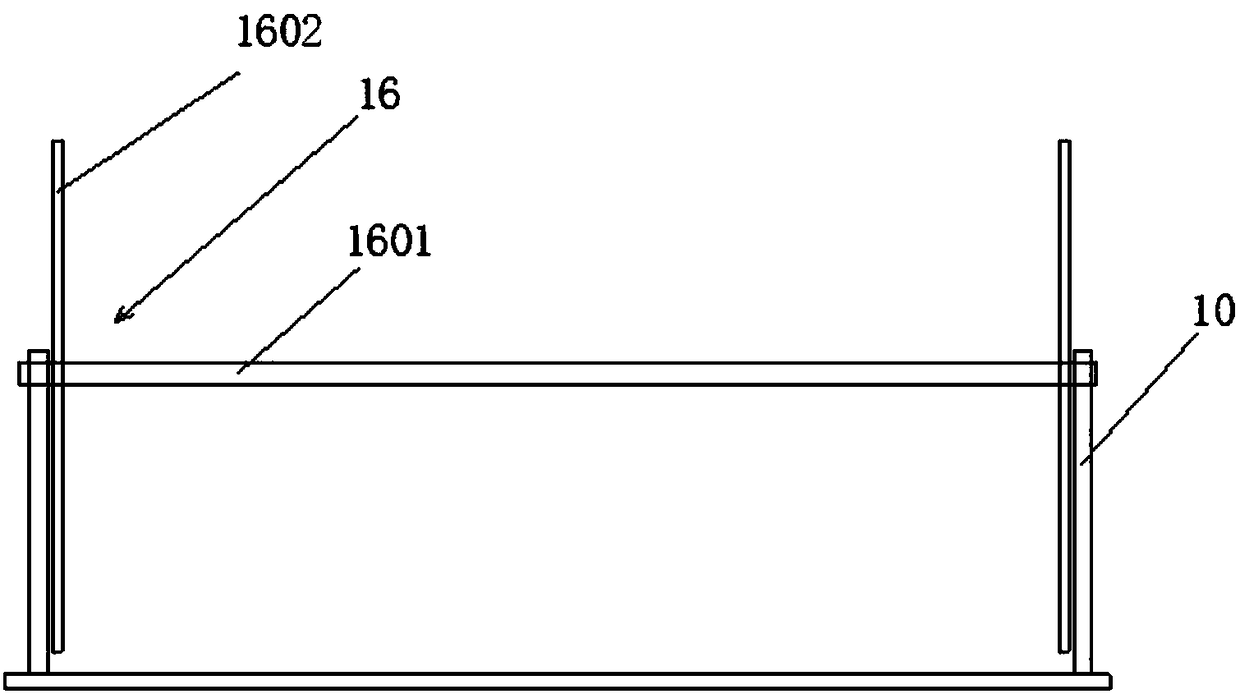

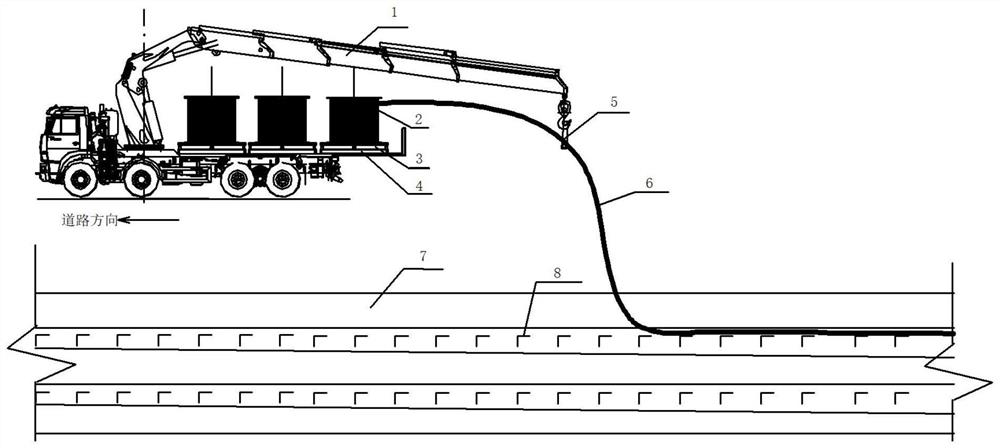

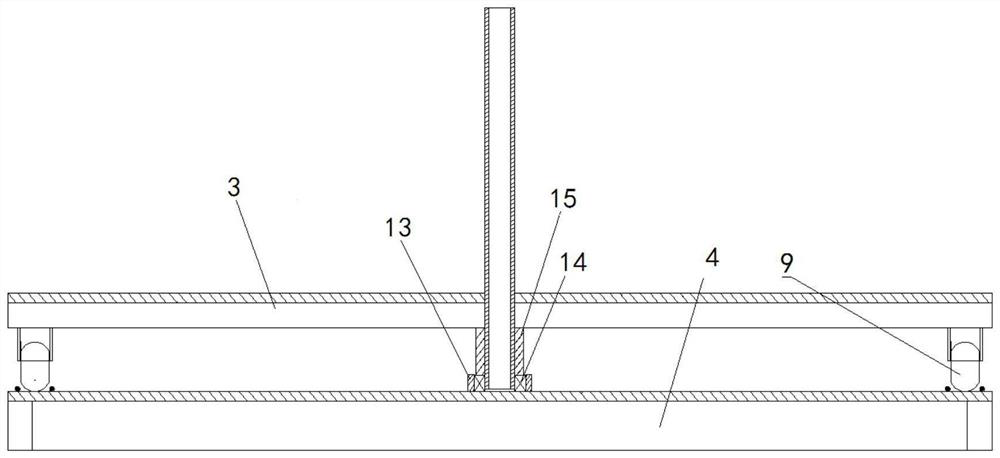

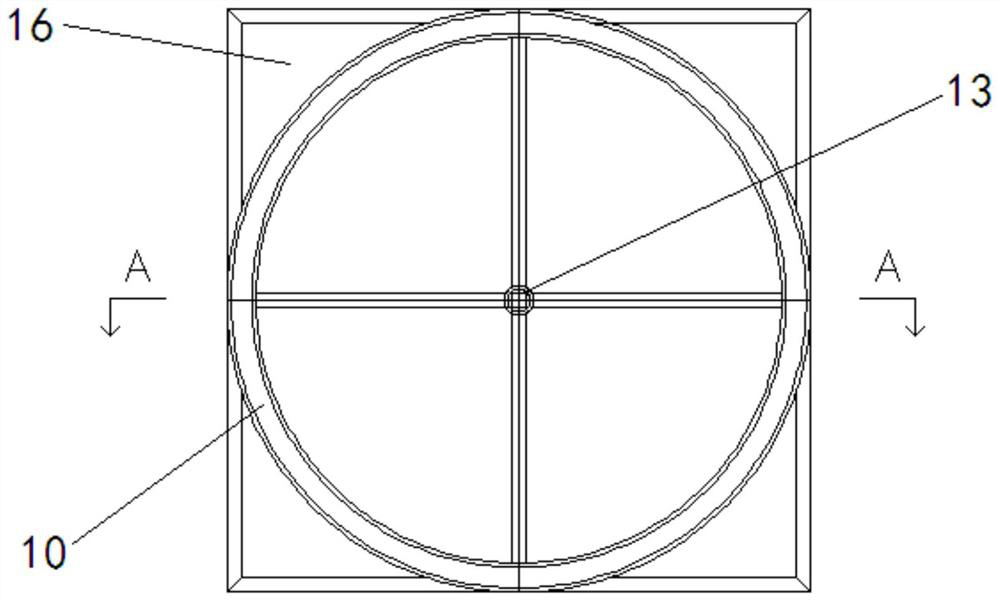

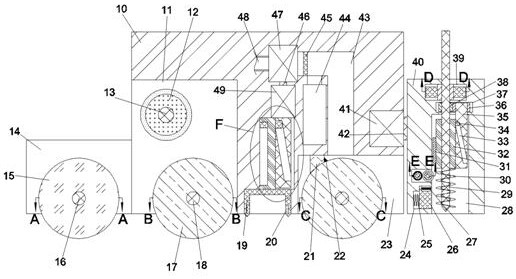

Movable emergency flood drainage and water storage device

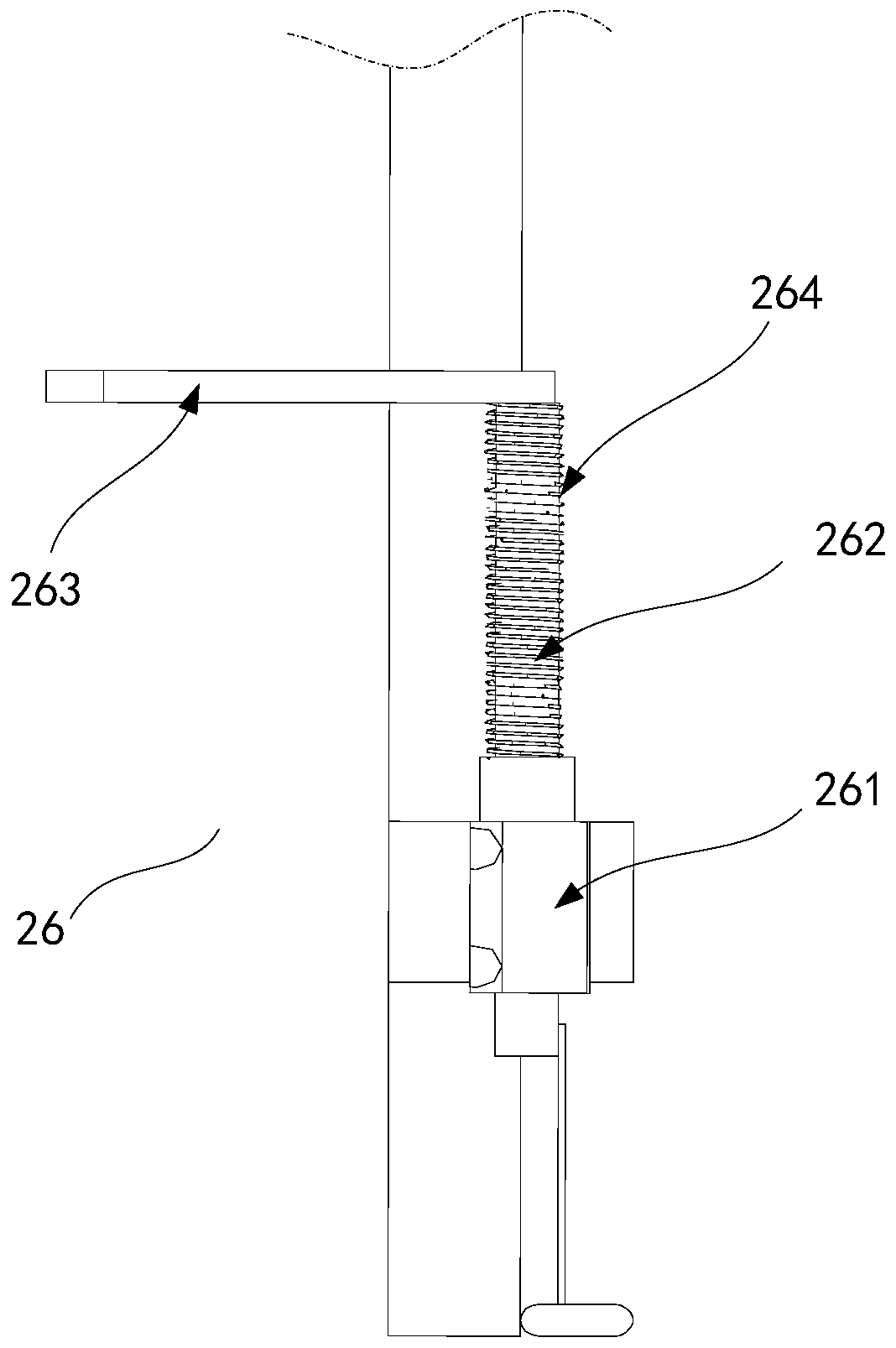

PendingCN108867804AEasy to produceReady for useSewerage structuresSewage drainingWater storageReduction drive

The invention discloses a movable emergency flood drainage and water storage device. The device comprises a frame system, the frame system is provided with an electromechanical box, an electric waterpump and electric winding equipment, the electromechanical box is internally provided with a diesel power generator for providing electric power, the electric winding equipment comprises a motor, a speed reducer and a reel, the reel comprises a roller and rolling plates arranged at the two ends of the roller, and the roller is provided with hook pieces; the motor is connected with the speed reducer through a first coupler, and the roller is connected with the speed reducer through a second coupler; a flexible water tank is rolled in the reel, one end of the flexible water tank is provided withbuckle belts fixedly connected with the hook pieces, and the other end of the flexible water tank is provided with a pipe connecting port connected with a water outlet of the electric water pump. Thedevice is mainly used for solving the problem of water accumulation in a city, can be moved to a flood area with deep accumulated water in the city for temporary water storage and flood relief duringuse and placed in a warehouse when not working, does not occupy urban construction land and is suitable for emergency flood drainage of the water accumulation area in the city.

Owner:TIANJIN UNIV

Quick and automatic lifting-free bed sheet replacing device for patient

The invention discloses a quick and automatic lifting-free bed sheet replacing device for a patient, and belongs to the field of medical nursing equipment. The device comprises a main box body and a liftable trapezoidal seat, the upper end face of the trapezoidal seat is an inclined plane, the upper end face of the trapezoidal seat is slidably connected with an insertion plate, and the main box body is provided with a first driving mechanism for driving the trapezoidal seat to ascend; the outer side of the main box body is provided with a limiting mechanism used for preventing the insertion plate from rising and an unlocking mechanism used for relieving the blocking effect of the limiting mechanism; a bed sheet storage cavity is formed in the trapezoidal seat, and an outer U-shaped plate and an inner U-shaped plate which are used for clamping one side of a clean bed sheet are arranged in the trapezoidal seat; the outer U-shaped plate and the inner U-shaped plate are driven to stretch out from the lower portion of the insertion plate, and one side of the clean bed sheet can be pulled to the position between a sickbed and a patient; and under the action of a positioning rod and a fourth spring, the outer U-shaped plate can displace relative to the inner U-shaped plate, so that clamping of the clean bed sheet can be automatically released. The device is convenient to operate and high in working efficiency, a patient does not need to be moved, and a motor does not need to be used.

Owner:THE FIRST AFFILIATED HOSPITAL OF WANNAN MEDICAL COLLEGE YIJISHAN HOSPITAL OF WANNAN MEDICAL COLLEGE

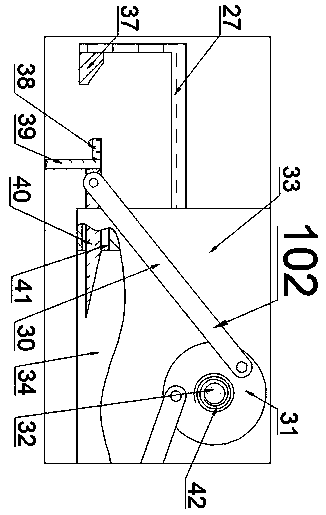

Sidewalk granite plate laying device

InactiveCN111236020ARealize automatic layingReduce labor intensityRoads maintainenceStructural engineeringGas supply

The invention discloses a sidewalk granite plate laying device. The device comprise a carrier vehicle which are internally provided with two bilaterally symmetrical wheel axles; the wheel axles extendforwards and backwards to penetrate through the carrier vehicle; two wheel axles which are symmetrical front and back are fixedly connected to the wheel axles; a cement laying device is arranged on the upper side of the carrier vehicle; the cement laying device is used for storing and laying cement; the carrier vehicle is provided with a stone plate storage device located on the upper left side of the cement laying device. The stone plate storage device is used for storing and supplying stone plates; a stone plate laying device is arranged on the lower left side of the stone plate storage device; the stone plate laying device is used for laying stone plates, a fixed-distance air supply device is arranged on the end face of the front side of the carrier vehicle, the fixed-distance air supply device provides airflow needed for laying the stone plates for the stone plate laying device, automatic stone plate laying can be achieved, the labor intensity of workers is reduced, and the laborcost is reduced.

Owner:嵊州摩天自动化设备有限公司

Road curb laying device for road construction

ActiveCN108342956BRealize automatic layingGuaranteed stabilityRoads maintainenceStructural engineeringBrush device

The invention relates to a curbstone laying implement used for highway construction. The curbstone laying implement comprises a vehicle body, a carrying board is fixedly arranged on the vehicle body,a conveyor belt is arranged on the left portion of the carrying board, and a storage box is arranged above the left portion of the conveyor belt. A cement loading box is arranged above the middle portion of the conveyor belt; a material taking brushing device is arranged above the right portion of the conveyor belt; and a laying device is arranged on the right side of the conveyor belt. Belt wheels are connected to the left side and the right side of the conveyor belt, each belt wheel is connected with a belt shaft installed on the carrying board through a bearing seat, and the belt shaft on the left side is connected with a motor; and an opening is formed between the upper end of the conveyor belt and the right side wall of the storage box. Under the common effect of traveling of the vehicle body, horizontal conveyance of the conveyor belt, striding type brushing of brushes, transmission lifting of a lead screw nut and a carrying frame, a row of curbstones can be automatically laid ona highway, small faces of every two adjacent curbstones can be connected through brushed cement, the curbstone laying stability is guaranteed, and laying is relatively firm.

Owner:WUHU LANREN INTELLIGENT TECH

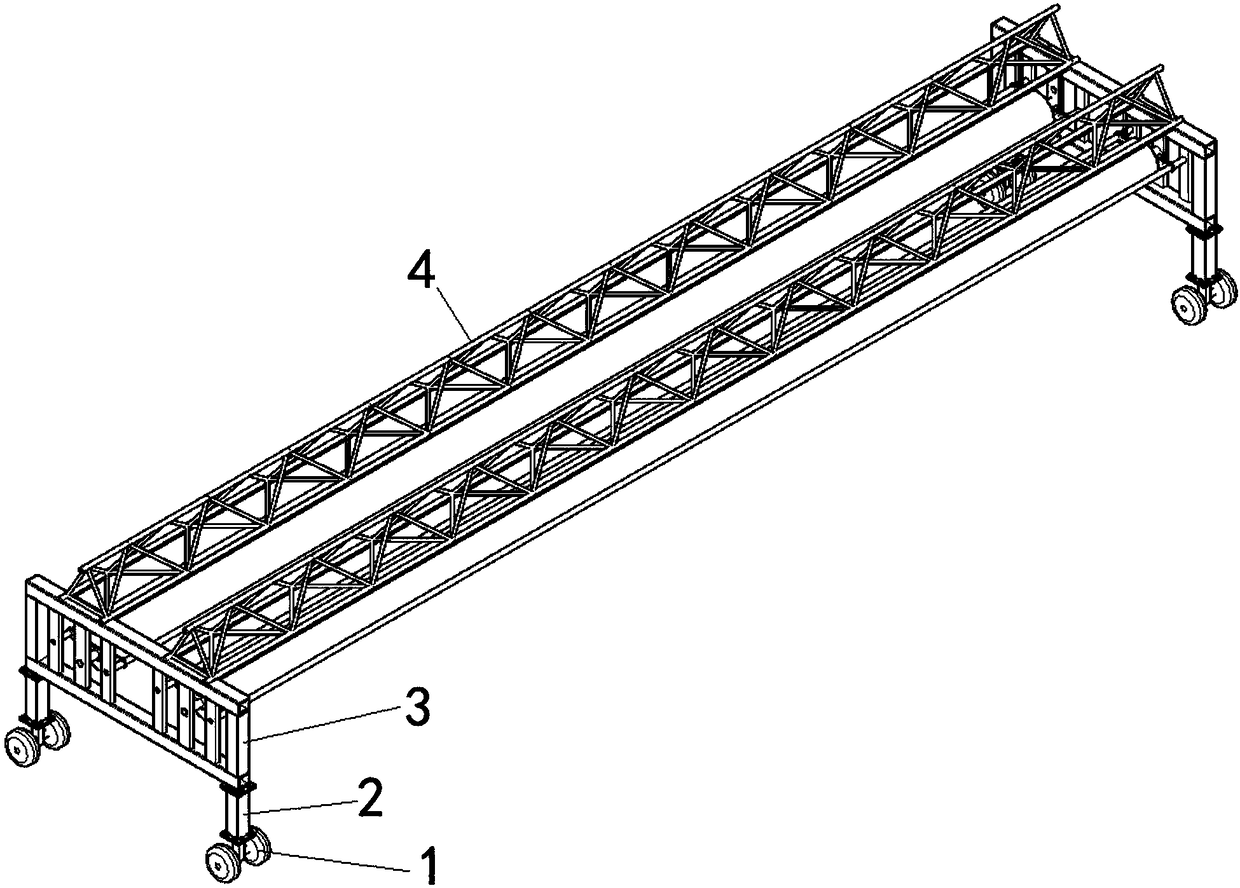

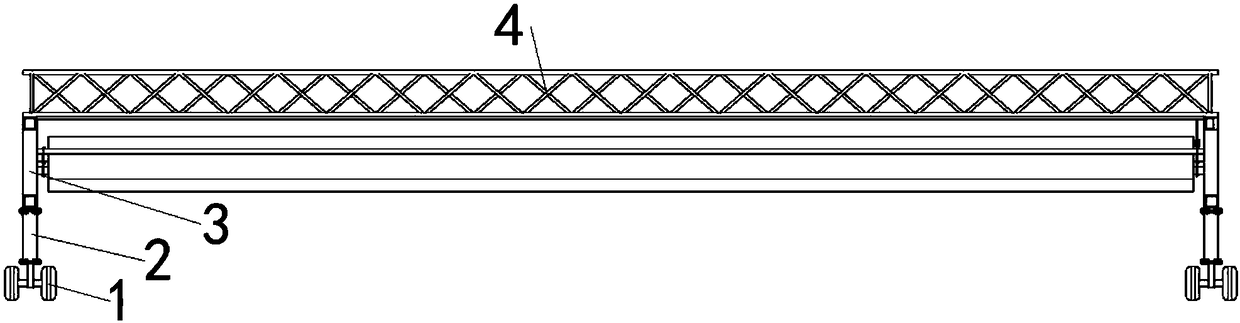

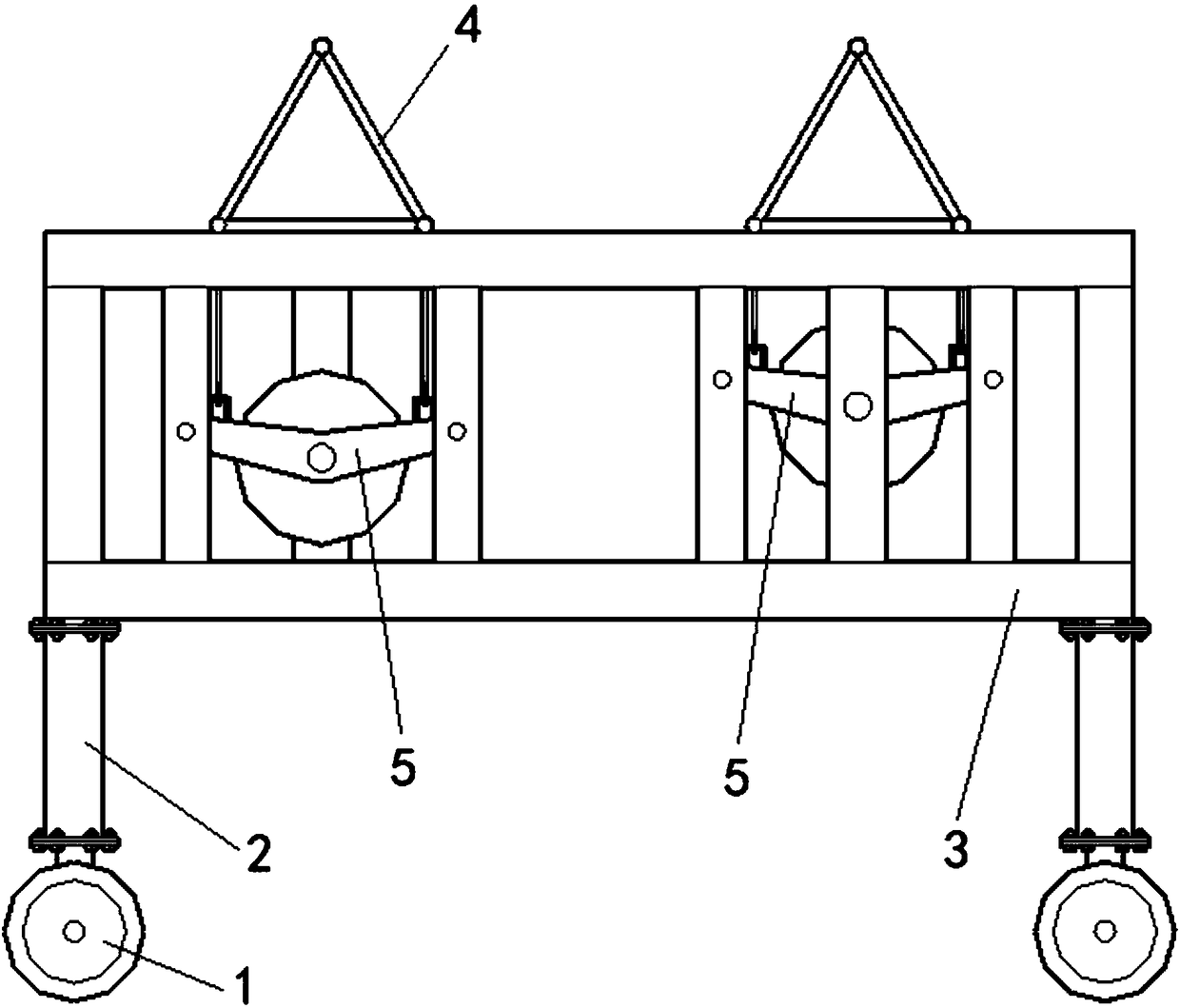

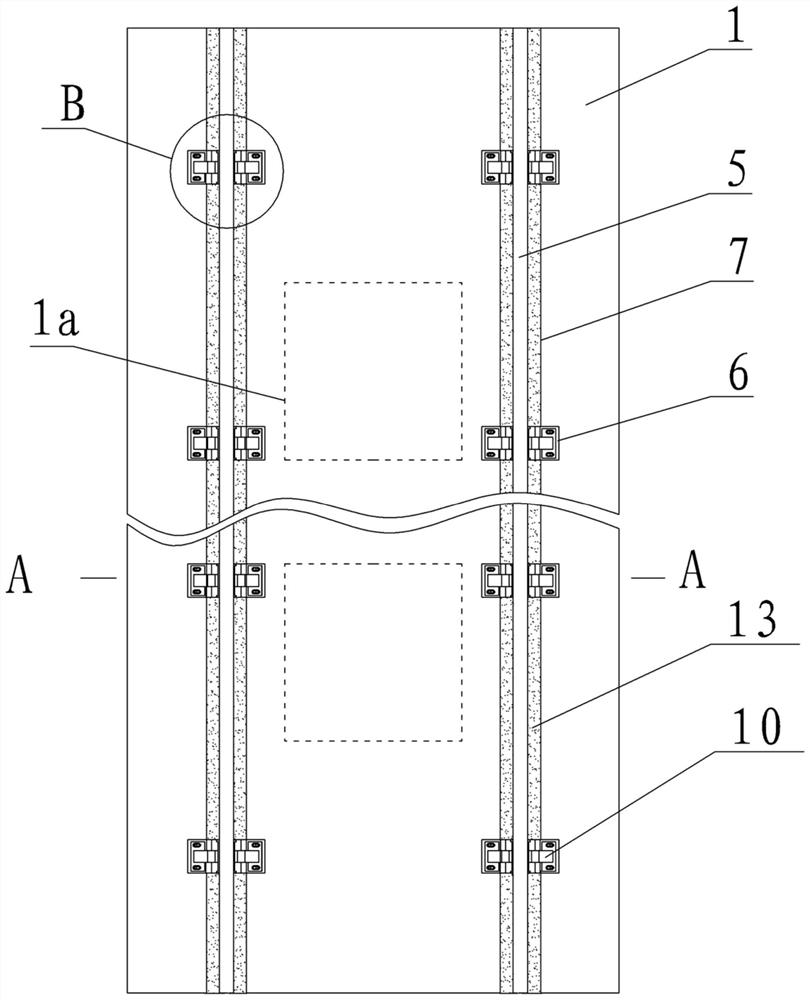

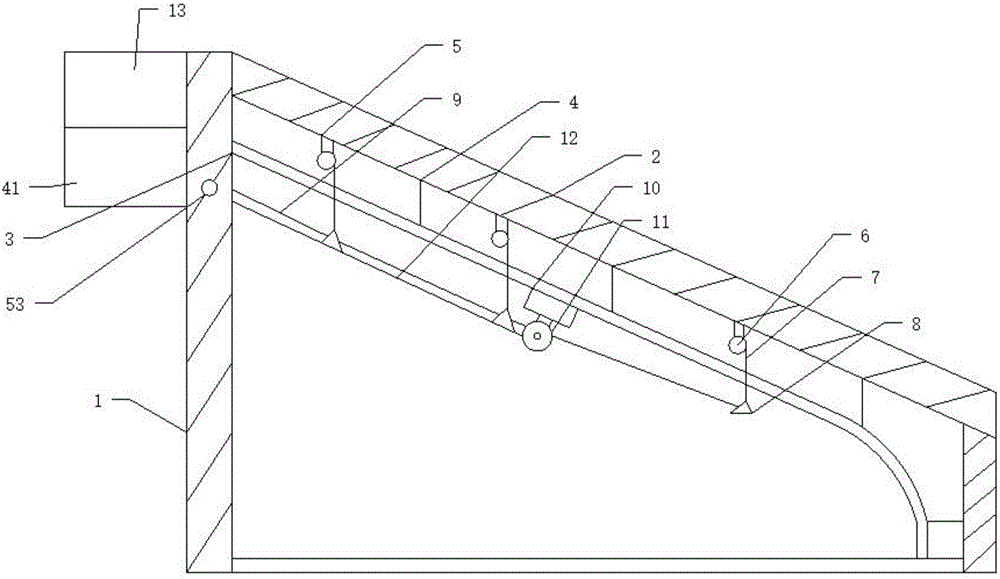

Thermal insulation material laying device for concrete face pouring surface

ActiveCN108360468ARealize the laying operationRealize automatic layingEarth-fill damsRock-fill damsThermal insulationEngineering

The invention discloses a thermal insulation material laying device for a concrete face pouring surface. The thermal insulation material laying device comprises a left support and a right support which are the same in structure and are arranged in parallel. The left support comprises a supporting frame and rolling wheels, and the rolling wheels are arranged on the bottom of the supporting frame. The left support and the right support are connected through two trusses which are arranged in parallel. The lower portions of the trusses are provided with a coiled material installation main shaft, and the end portions of the coiled material installation main shaft are rotationally connected to the left support and the right support. By means of the thermal insulation material laying device, twothermal insulation materials can be installed at the same time, the thermal insulation materials synchronously ascend along with bin position pouring under the traction of the external force, and automatic laying of the coiled thermal insulation materials can be achieved. The laying work of the thermal insulation materials can be achieved at a large span bin position and a slope, manual material carrying and coiled material laying on the slope are avoided, the working efficiency is improved, the manual labor intensity on the slope is reduced, and potential safety hazards are reduced.

Owner:SINOHYDRO BUREAU 5

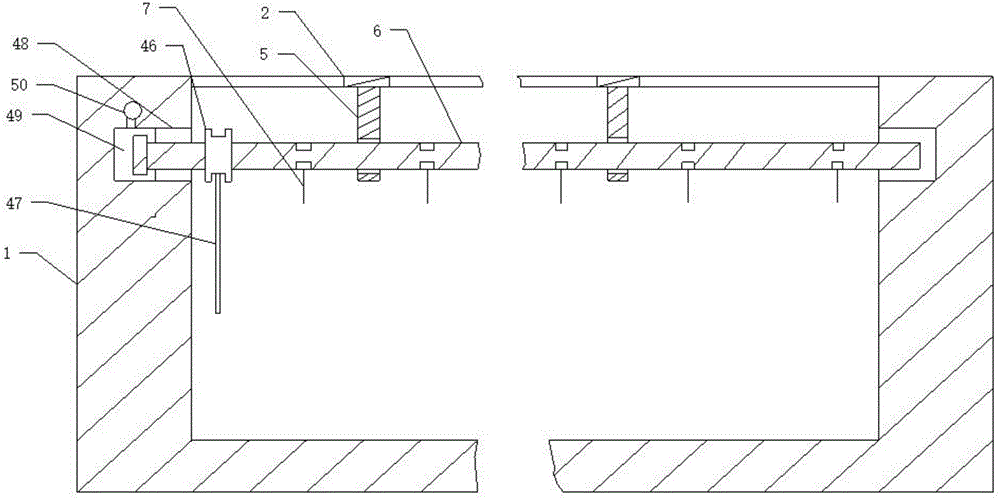

Embedded track structure of high-speed railway

An embedded track structure of a high-speed railway comprises a base and a track plate on the base, and is characterized in that the track plate is formed by prefabricating reinforced concrete, and aheight adjusting base plate, an elastic base plate and a steel rail are arranged in two track bearing grooves in the track plate from bottom to top; track adjusting grooves are longitudinally formed in the track bearing grooves at equal intervals; track adjusting pieces on the two sides of the steel rail in the track adjusting grooves are fixed to the bottoms of the track adjusting grooves throughanchor bolts; damping blocks are embedded between the front hammers of the track adjusting pieces and the rail webs of the steel rails; polyurethane filling bodies are filled between the track bearing grooves outside the track adjusting grooves and the steel rails; the bottom surface of the track plate is connected with a cast-in-place self-compacting mortar layer; and protrusions on the top faceof the self-compacting mortar layer are matched with grooves in the bottom face of the track plate, and an isolation layer is arranged between the bottom face of the self-compacting mortar layer andthe prefabricated base. The track structure can greatly reduce environmental noise, and reduce corrugation of steel rails and maintenance of anchor bolts, and track maintenance is convenient and low in cost; and batch and mechanical production and automatic laying of the tracks can be realized, so that the high-speed railway lines are convenient and quick to lay.

Owner:CHINA RAILWAYS CORPORATION +1

Pesticide atomization machine capable of paving heat preservation film in agricultural greenhouse

ActiveCN106818307ARealize automatic layingAchieve sprayingClimate change adaptationGreenhouse cultivationGreenhouseAgricultural engineering

The invention discloses a pesticide atomization machine capable of paving a heat preservation film in an agricultural greenhouse. Side-by-side supporting beams are correspondingly connected with a row of corresponding sliding beams; a slider capable of sliding on each sliding beam is arranged on each of the side-by-side sliding beams; the side-by-side sliders are correspondingly connected with a winding drum; a rotatable fifth rotating shaft is arranged in an inner cavity of the winding drum; the fifth rotating shaft drives an inner heat preservation film to be curled; the side-by-side supporting beams are further connected with at least four correspondingly arranged second supporting frames; a rotatable first rotating shaft is connected to each of the side-by-side second supporting frames; the first rotating shafts are connected with a row of corresponding first connection pipes; the end part of each of the first connection pipes is connected with an atomization suction disk. The sliders can drive sliding of the rotary drum, so that automatic paving of the inner heat preservation film can be further realized; meanwhile, the atomization suction disk sprays pesticide after atomizing the pesticide, so as to prevent injury to a human body due to the pesticide.

Owner:金寨县御叶农产品销售有限公司

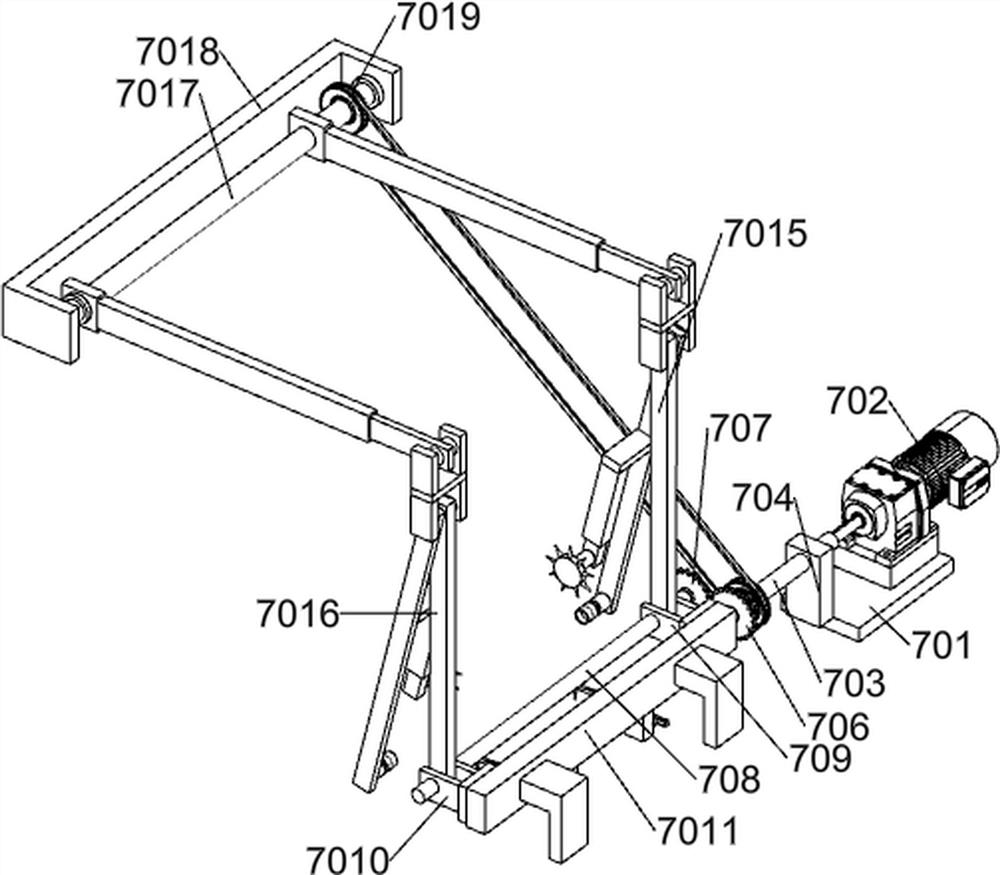

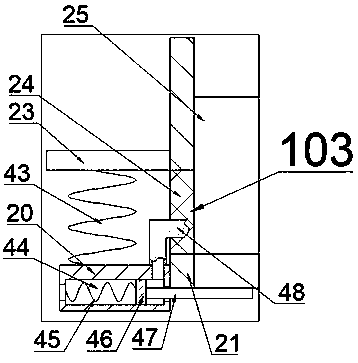

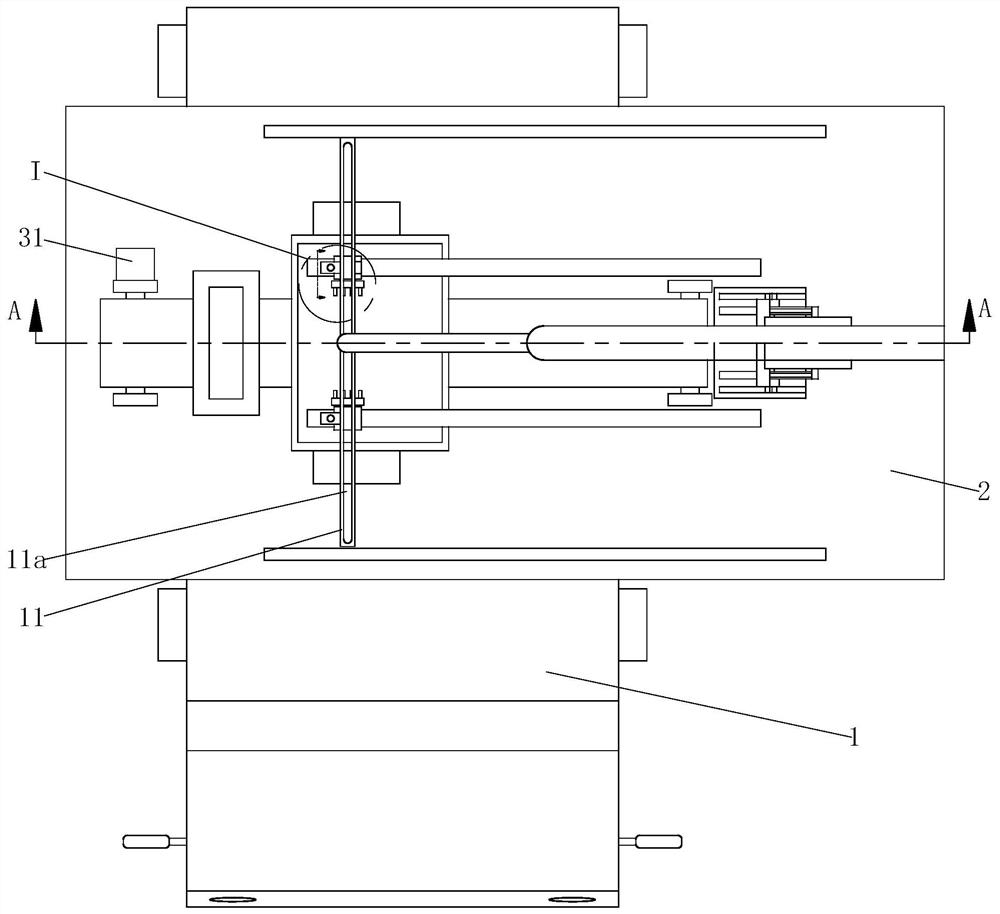

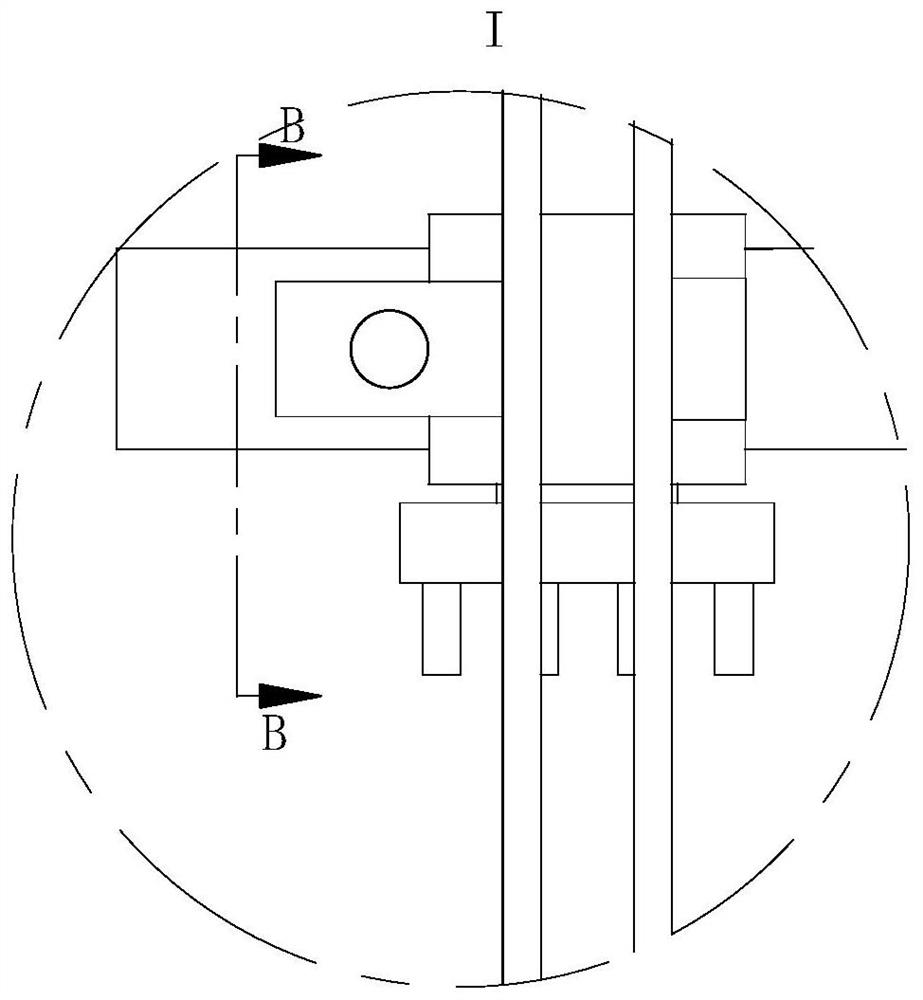

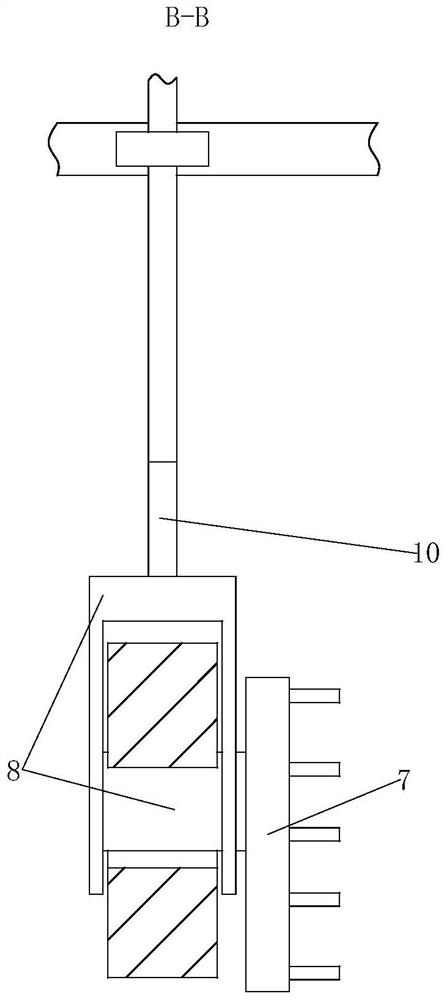

An automatic net laying device for a coal mine rock bolter

ActiveCN110454204BRealization of automatic layingRealize automatic layingUnderground chambersTunnel liningMining engineeringMesh reinforcement

The invention belongs to the technical field of anchor bolt support equipment for coal mines, and particularly relates to an automatic mining net-laying device for an anchor bolt drill rig. The problems of low efficiency, high labor intensity, harsh working environment and poor safety of an existing anchor bolt support method are solved. The automatic mining net-laying device includes an anchor bolt drill rig, an anchor net car, a belt conveying mechanism, a first sleeve structure, a vertical lifting mechanism, a first magnetic suction cup, an anchor net, a bracket, a second sleeve structure,a first telescopic mechanical arm, a second telescopic mechanical arm and a fourth sleeve structure. The top anchor net is grabbed by lifting and lowering the second sleeve structure, the top anchor net is sent to a third magnetic suction cup on an anchor bolt car through the first telescopic mechanical arm, the vertical lifting mechanism sucks the side anchor net through the first magnetic suction cup, the side anchor net is sent to a fourth magnetic suction cup of the anchor bolt drill rig through the belt conveying mechanism, and the automatic laying of the top anchor net and the side anchor net is realized. The automatic mining net-laying device realizes the automatic laying of steel meshes and improves the laying efficiency of the steel meshes.

Owner:TAIYUAN UNIV OF TECH

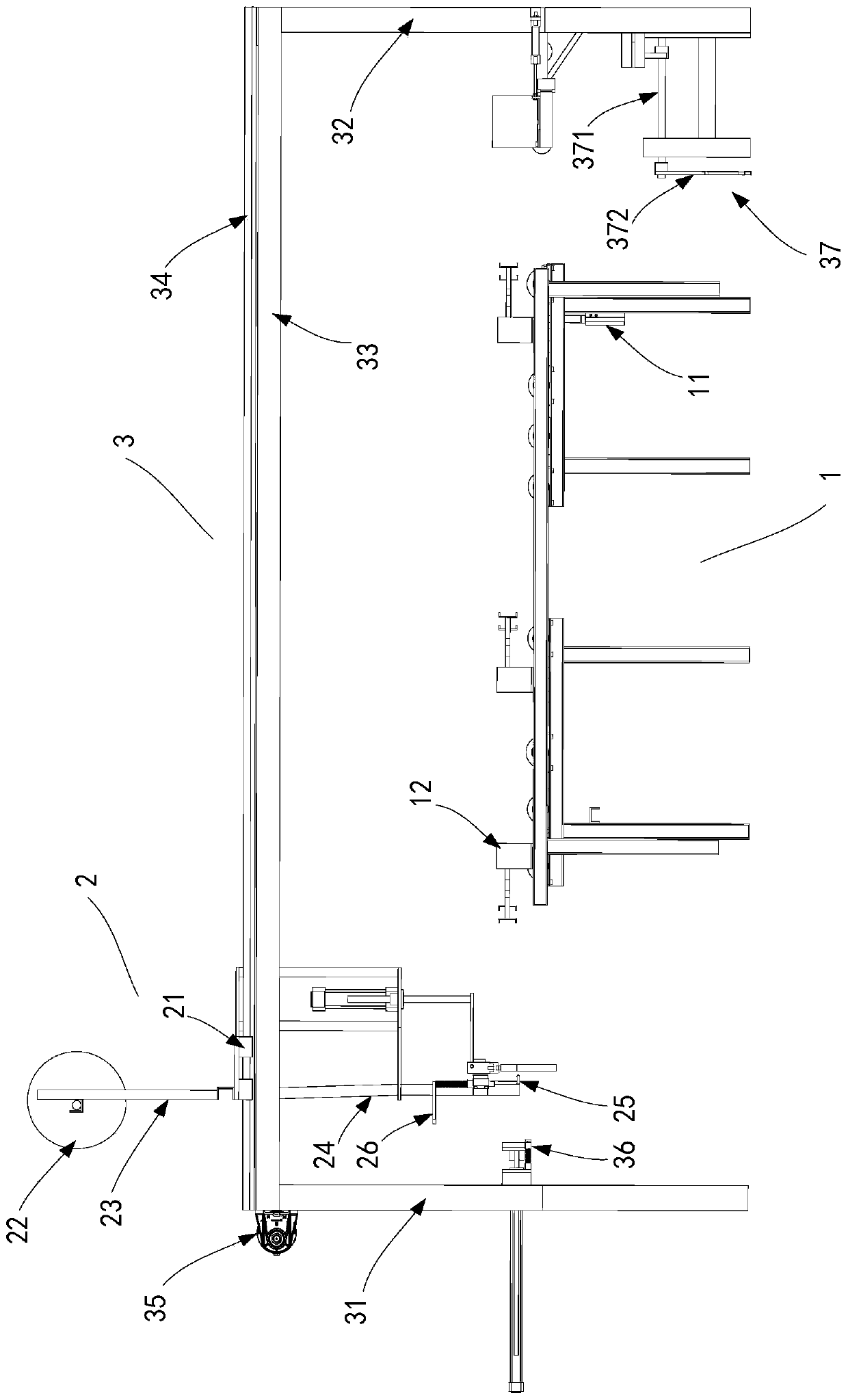

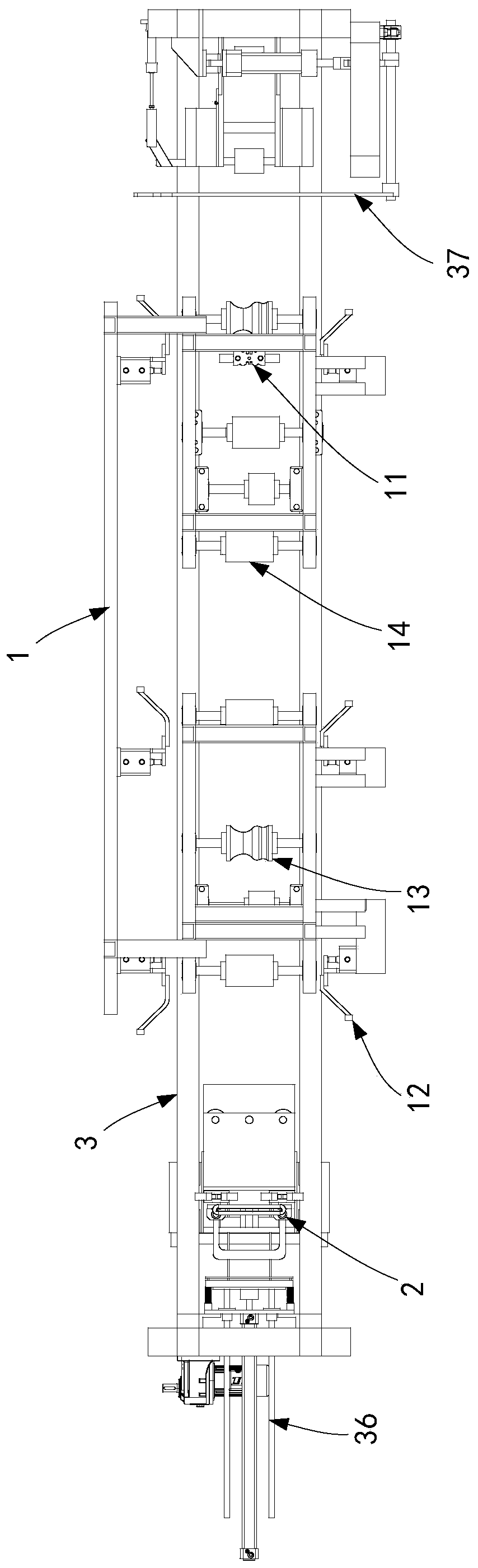

Long-distance large-diameter cable laying system and method under complex terrain

PendingCN114476815ANot easy to damageAvoid the problem of real-time rotation adjustment positionFilament handlingApparatus for laying cablesStructural engineeringElectric cables

The invention discloses a long-distance large-diameter cable laying system and method under complex terrains, and belongs to the technical field of power transmission and transformation engineering, the long-distance large-diameter cable laying system comprises a vertical cable laying device, the vertical cable laying device comprises a base and a rotating support, the base and the rotating support are horizontally arranged, a guide rail is arranged at the top of the base, and rollers are fixedly arranged at the bottom of the rotating support; the rollers are arranged in the guide rails; the upper end of the rotating shaft exceeds the top of the rotating support to support the cable reel, the lower end of the rotating shaft is connected with the base, and a positioning sleeve is arranged between the rotating shaft and the base to quickly position the rotating support.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Agricultural machine capable of automatically finishing planting preparation of mulching film cultivation technology

InactiveCN112273117ARealize automatic layingReduce the impactSpadesPloughsHydraulic cylinderAgricultural science

The invention discloses an agricultural machine capable of automatically finishing planting preparation of a mulching film cultivation technology. The agricultural machine comprises a shell, power fixing blocks which are symmetrical front and back are fixedly arranged on the end face of the left side of the shell, a laying cavity with a downward opening is formed in the end face of the left side of the shell, and a dust collection cavity with a downward opening is formed in the end face of the right side of the shell; and a perforating cavity with a downward opening is formed in the bottom endface of the shell, a hydraulic cylinder is fixedly arranged on the end face of the right side of the shell, and a hydraulic rod extending rightwards is in power connection with the end face of the right side of the hydraulic cylinder. According to the agricultural machine, automatic mulching film laying is achieved, mulching film perforating is automatically completed in the laying process, efficiency and rapidness are achieved, mulching film fragments are automatically collected after perforating is completed, the influence of ground fragments on soil is reduced, drilling and soil looseningare conducted on soil below perforated mulching films, subsequent crop planting and automatic agricultural production are facilitated, the automation degree of the agricultural machine is greatly improved, and the production efficiency is improved.

Owner:魏振存

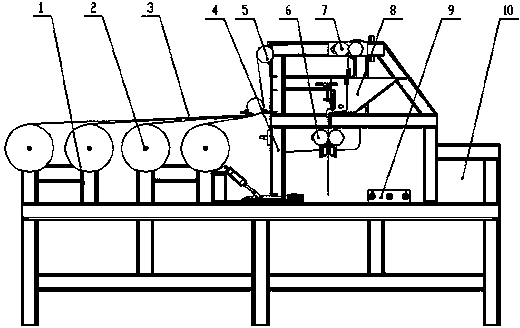

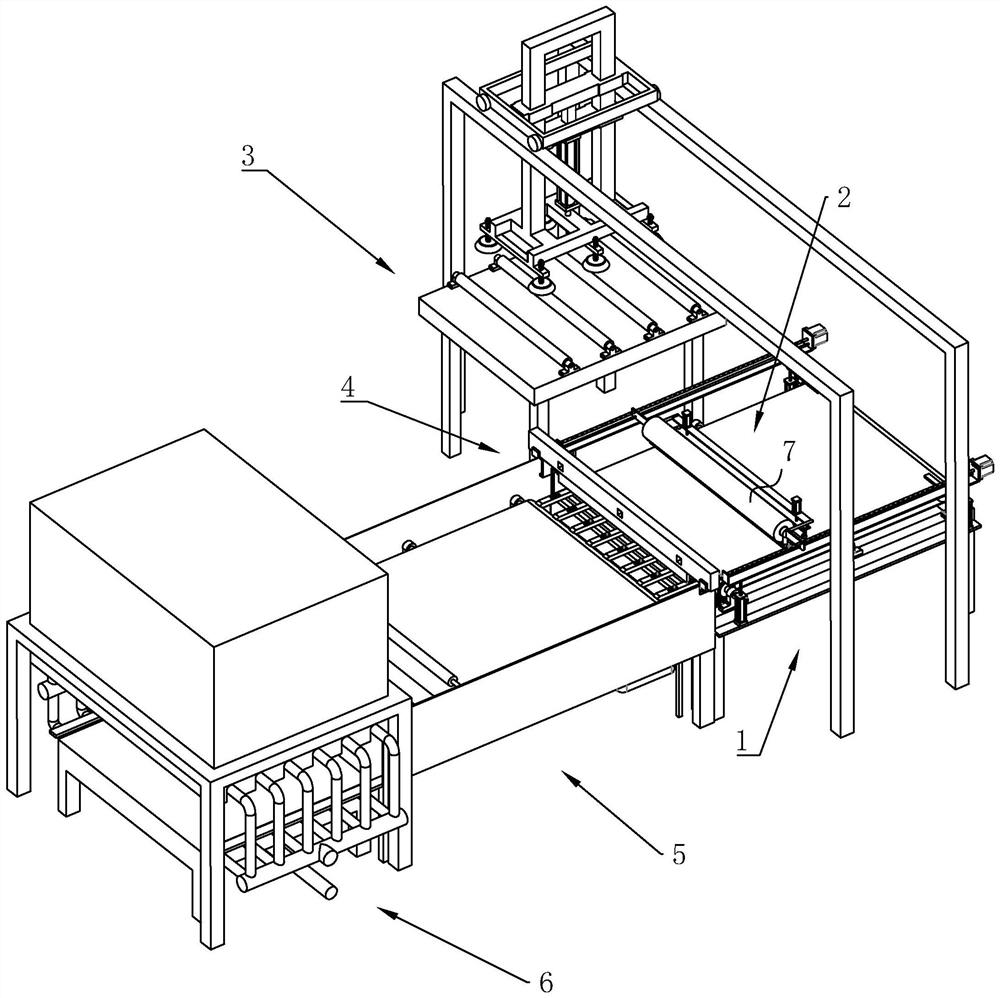

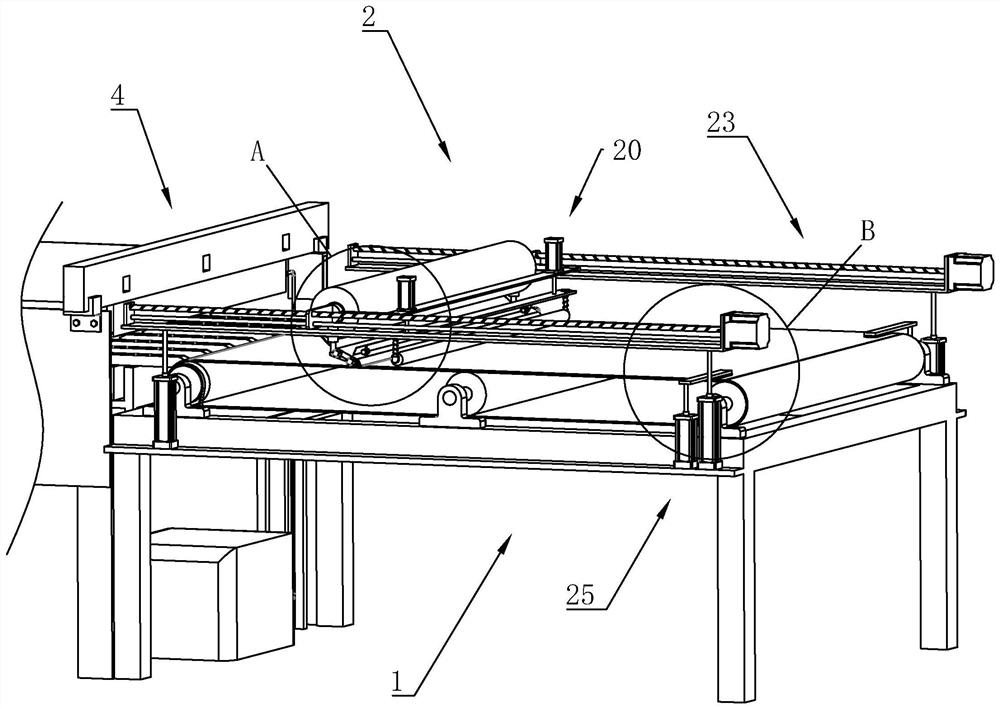

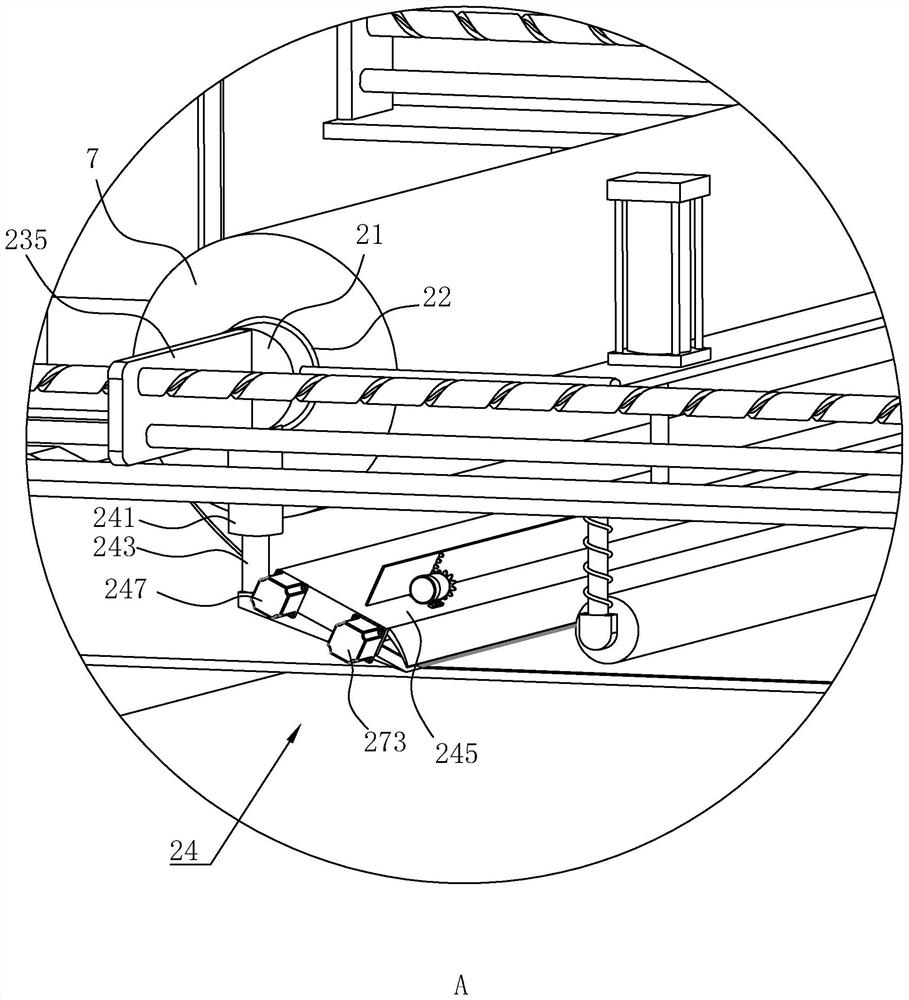

Cloth mixing spreading machine for novel wall material production line

InactiveCN103754690AHigh degree of automationSpread evenlyUnfolding thin materialsLoading/unloadingProgrammable logic controllerTextile

The invention discloses a cloth mixing spreading machine for a novel wall material production line, and belongs to the technical field of spreading machines. The cloth mixing spreading machine comprises cloth rolls, cloth feeding embossing rolls, power cloth feeding rolls, an open feed bin, a cloth shearing mechanism, a star spreading device and a PLC (programmable logic controller) control module. The open feed bin and the cloth feeding embossing rolls are arranged below the power cloth feeding rolls in sequence. The cloth shearing mechanism is arranged below the cloth feeding embossing rolls. The open feed bin and the star spreading device are communicated with a delivery pipe. The cloth rolls, the cloth feeding embossing rolls, the power cloth feeding rolls, the cloth shearing mechanism and the star spreading device are all connected with a PLC. During working, cloth rolled on the cloth rolls penetrates the power cloth feeding rolls, the open feed bin, the cloth feeding embossing rolls and the cloth shearing mechanism sequentially to fit a mould plate subjected to spreading of the star spreading device, and the cloth is sheared off by the cloth shearing mechanism. The cloth mixing spreading machine for the novel wall material production line is capable of realizing automatic spreading, high in automation degree, also capable of regulating spreading amount and spreading speed, and uniform in spreading by means of PLC control.

Owner:ZHAOYANG PNEUAMTIC HYDRAULIC MECHANICAL EQUIP JIANGSU

Mounting equipment for laying lawn

InactiveCN113099961ARealize automatic layingUniform outputHops/wine cultivationTurf growingRotational axisAgricultural engineering

The invention discloses mounting equipment for laying lawn. The mounting equipment comprises a rack, wherein a storage cavity with an upward opening is formed in the rack, a rotating shaft is rotationally arranged in the storage cavity, tooth profiles capable of being meshed are arranged on the rear side of the rotating shaft, a collecting disc is fixedly arranged on the rotating shaft, turf winds around the outer end of the collecting disc, and a transmission cavity is formed in the right end of the storage cavity in a communicating mode. According to the mounting equipment for laying the lawn, automatic laying of the turf can be achieved, the ground treatment time when the lawn is mounted by people is shortened, then physical strength consumed before laying is reduced, the laying efficiency is improved, uniform output of the turf is kept through an abutting block, and therefore, the situation that the turf is broken due to uneven stress in the mounting process and then the use experience is affected is avoided.

Owner:南京欣喜思家具有限公司

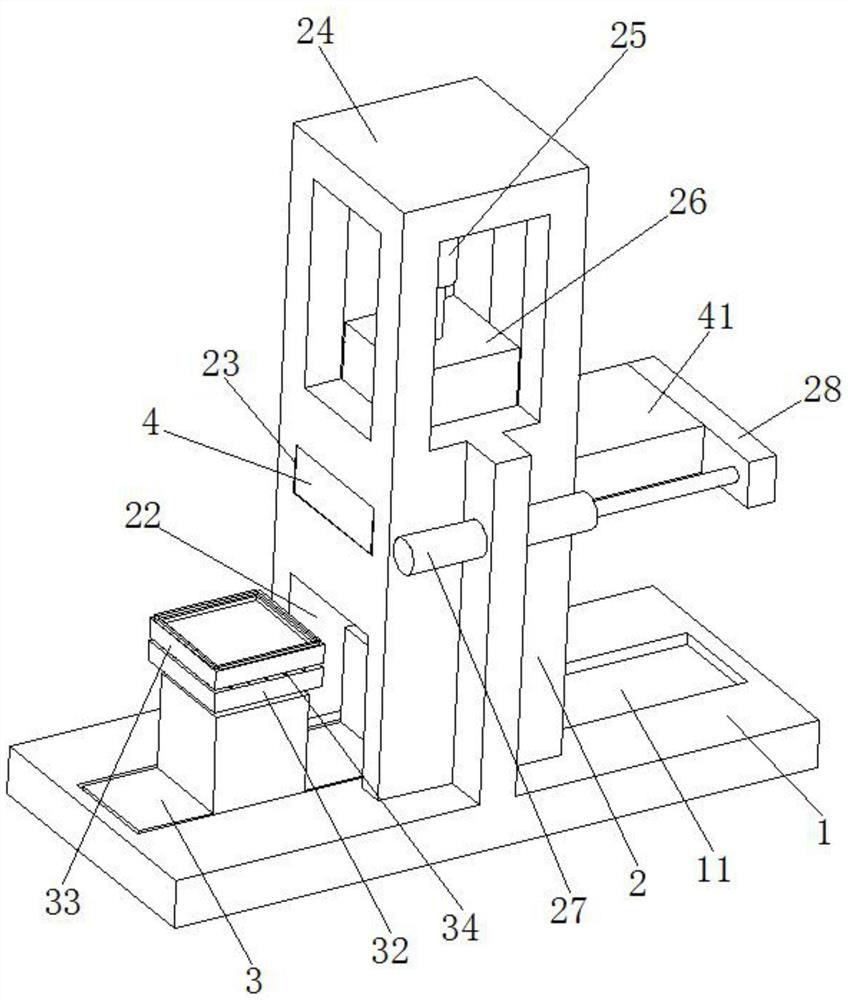

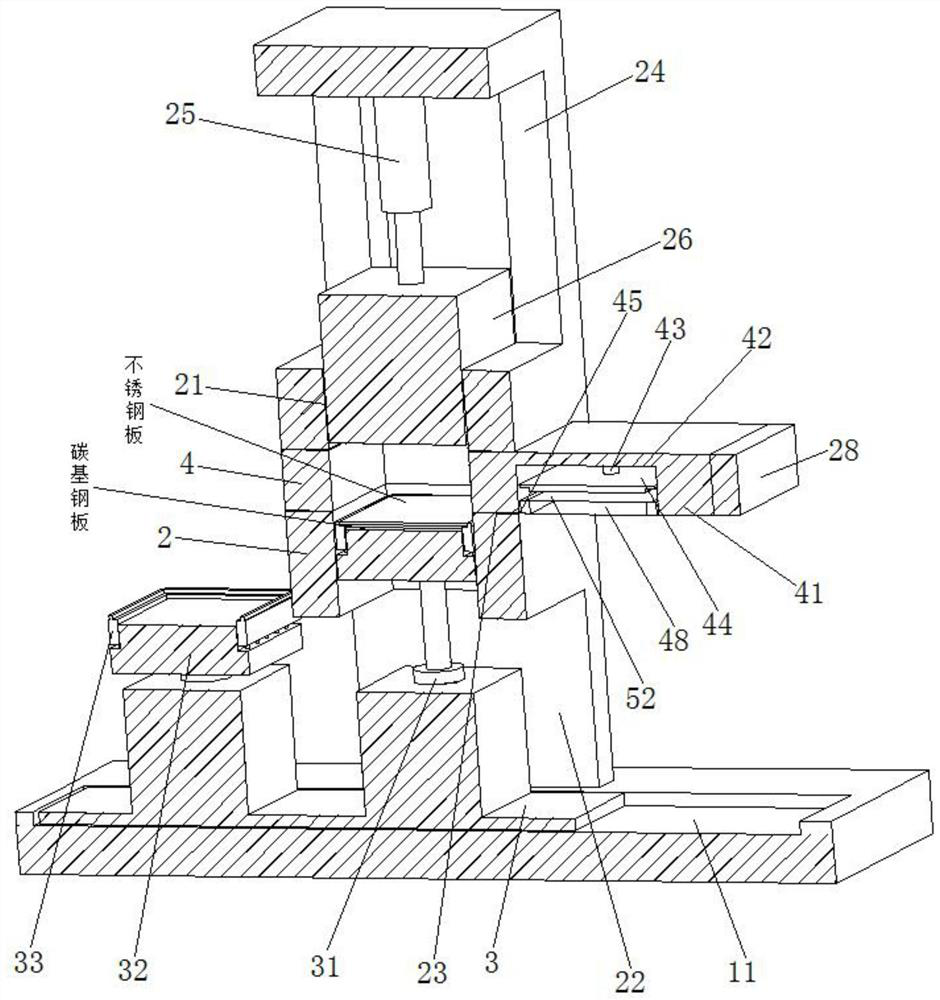

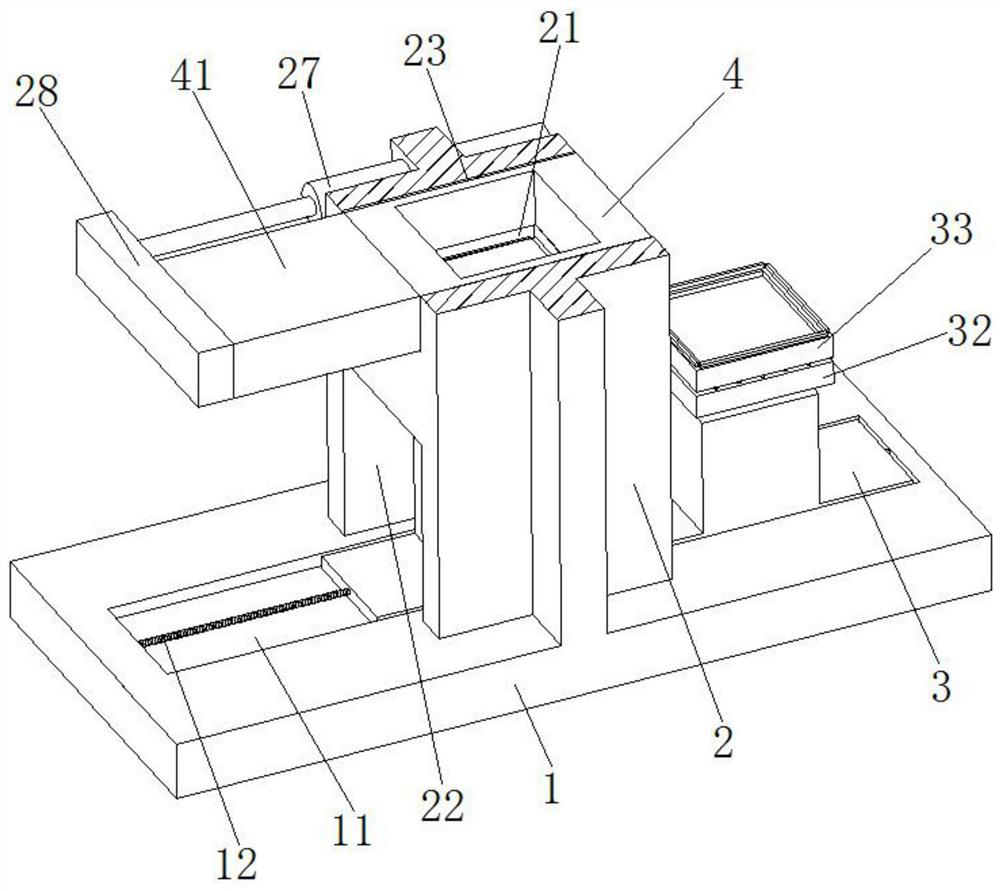

Stainless steel composite plate automatic forming equipment

ActiveCN113369665AEvenly distributedIncrease productivityWelding/soldering/cutting articlesMetal working apparatusStructural engineeringSS - Stainless steel

The invention relates to the field of stainless steel plate production, in particular to stainless steel composite plate automatic forming equipment. The equipment comprises a base, a fixing frame of a rectangular structure is arranged on the base, a first through groove of a rectangular structure is vertically formed in the fixing frame, a second through groove and a third through groove are horizontally formed in the fixing frame, the two ends of the first through groove, the two ends of the second through groove and the two ends of the third through groove all penetrate through the fixing frame, the second through groove and the third through groove communicate with the first through groove, the bottom of the third through groove communicates with the base, a sliding groove is formed in the position, located below the second through groove, of the base, a movable frame is slidably installed in the sliding groove, the movable frame is inserted in the second through groove, first air cylinders are symmetrically arranged on the movable frame, and bottom plates of inverted-T-shaped structures are arranged at the output ends of the first air cylinders. A stainless steel plate and a carbon steel base plate can be rapidly positioned and separated, meanwhile, explosive can be automatically laid on the positioned stainless steel plate, and the equipment is suitable for popularization.

Owner:DONGGUAN CITY YUEGANG STAINLESS STEEL PROD

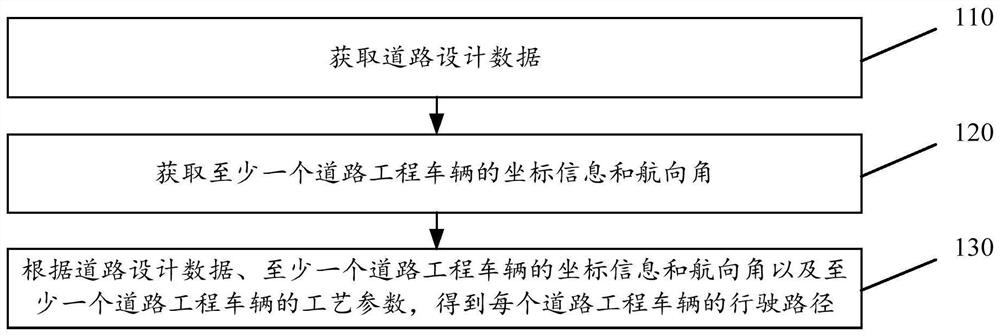

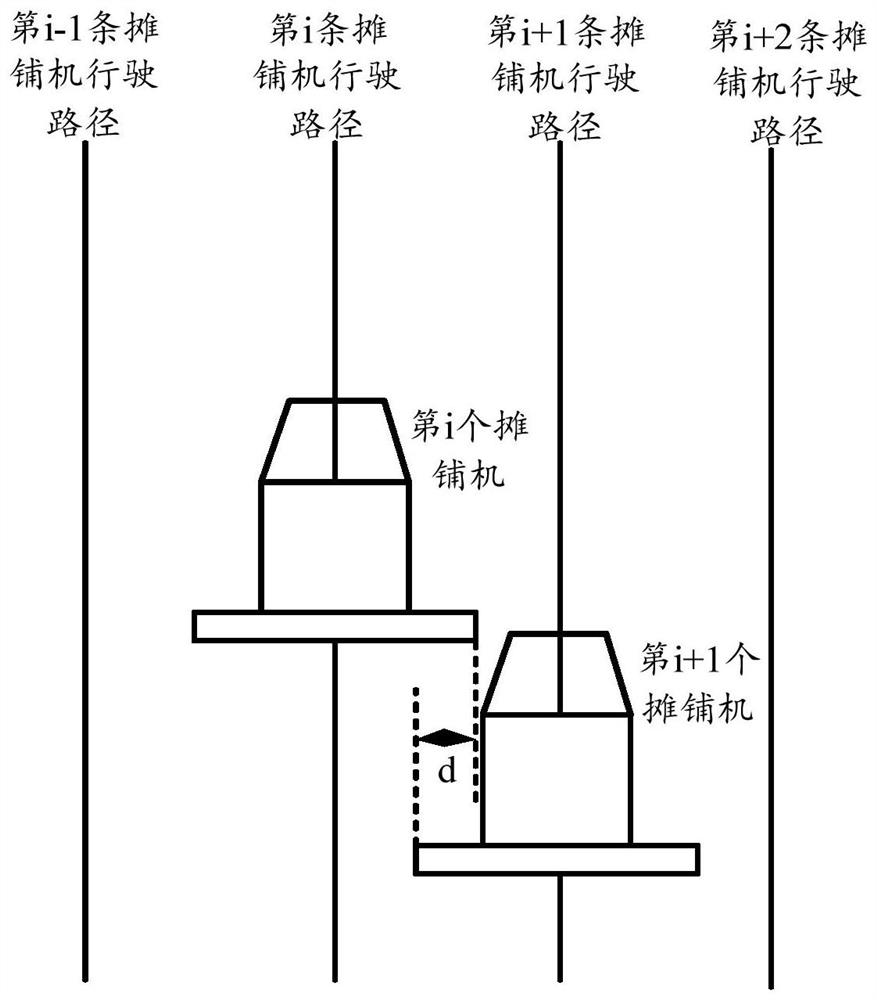

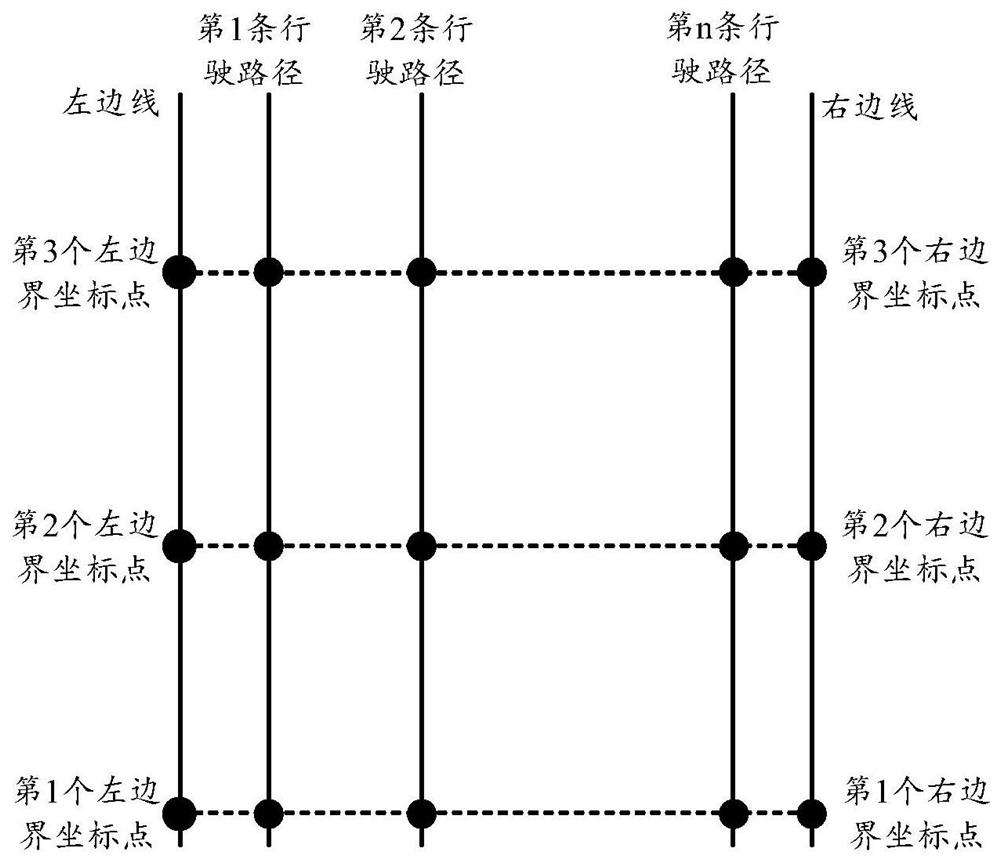

Road engineering vehicle, path planning method and system of road engineering vehicle and storage medium

ActiveCN113008257AAutomated compactionReduce demandInstruments for road network navigationRoad engineeringTransport engineering

The invention provides a road engineering vehicle, a path planning method and system of the road engineering vehicle,and a computer readable storage medium. According to the road engineering vehicle, the path planning method and system of the road engineering vehicle and the storage medium, the road design data, coordinate information and course angles of the road engineering vehicle, and technological parameters of the road engineering vehicles are obtained, so that a construction region range can be determined according to a road left line and a road right line of a to-be-laid road; the path width of each road engineering vehicle and the relative distance between the adjacent road engineering vehicles are determined according to process parameters, and the initial position information and the initial advancing direction of each road engineering vehicle are determined according to the coordinate information and the course angles of the road engineering vehicle, so that the driving path of each road engineering vehicle is accurately determined; and therefore, accurate intelligent path planning is achieved, automatic road laying is achieved, the construction efficiency and precision can be improved, and the labor cost and the requirement for professional drivers can be greatly reduced.

Owner:HUNAN SANY INTELLIGENT CONTROL EQUIP

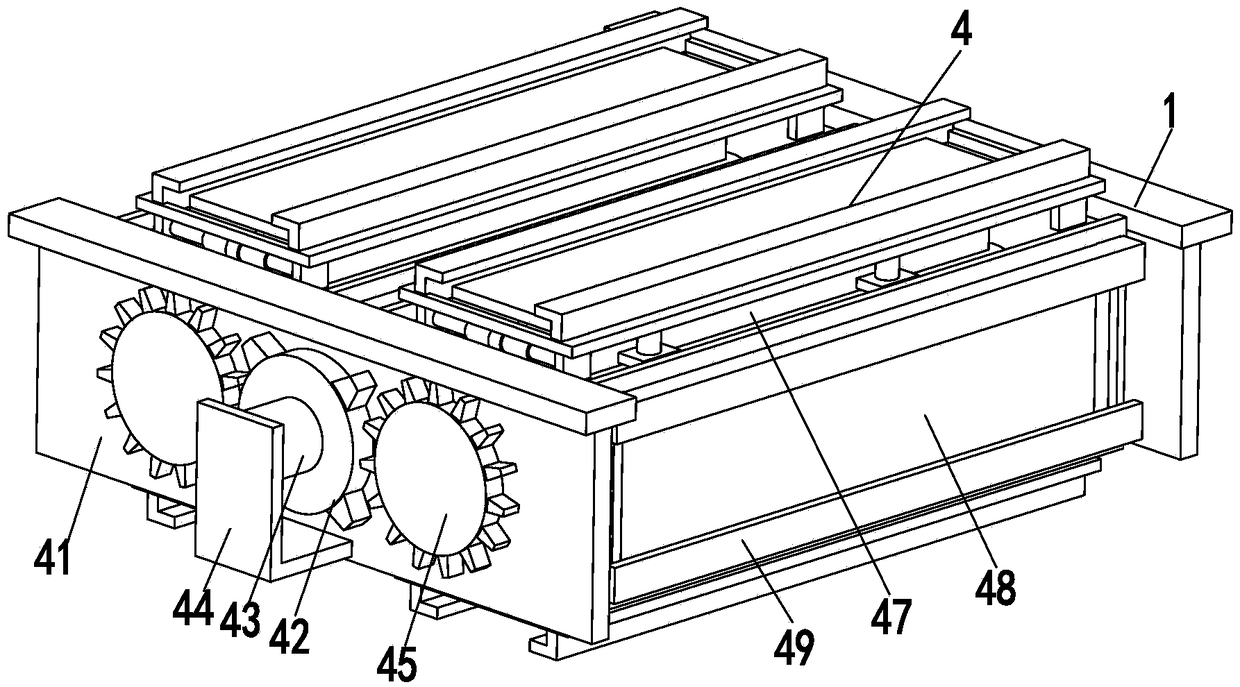

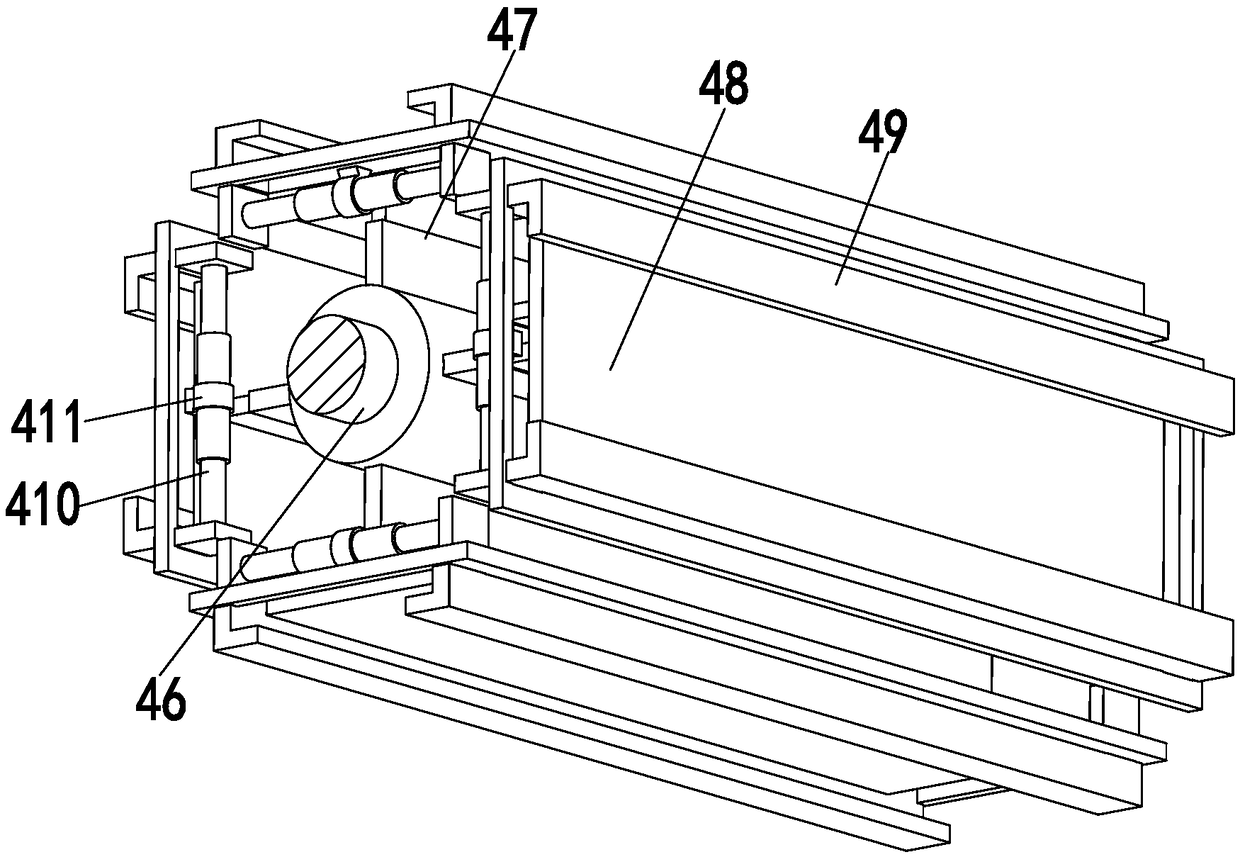

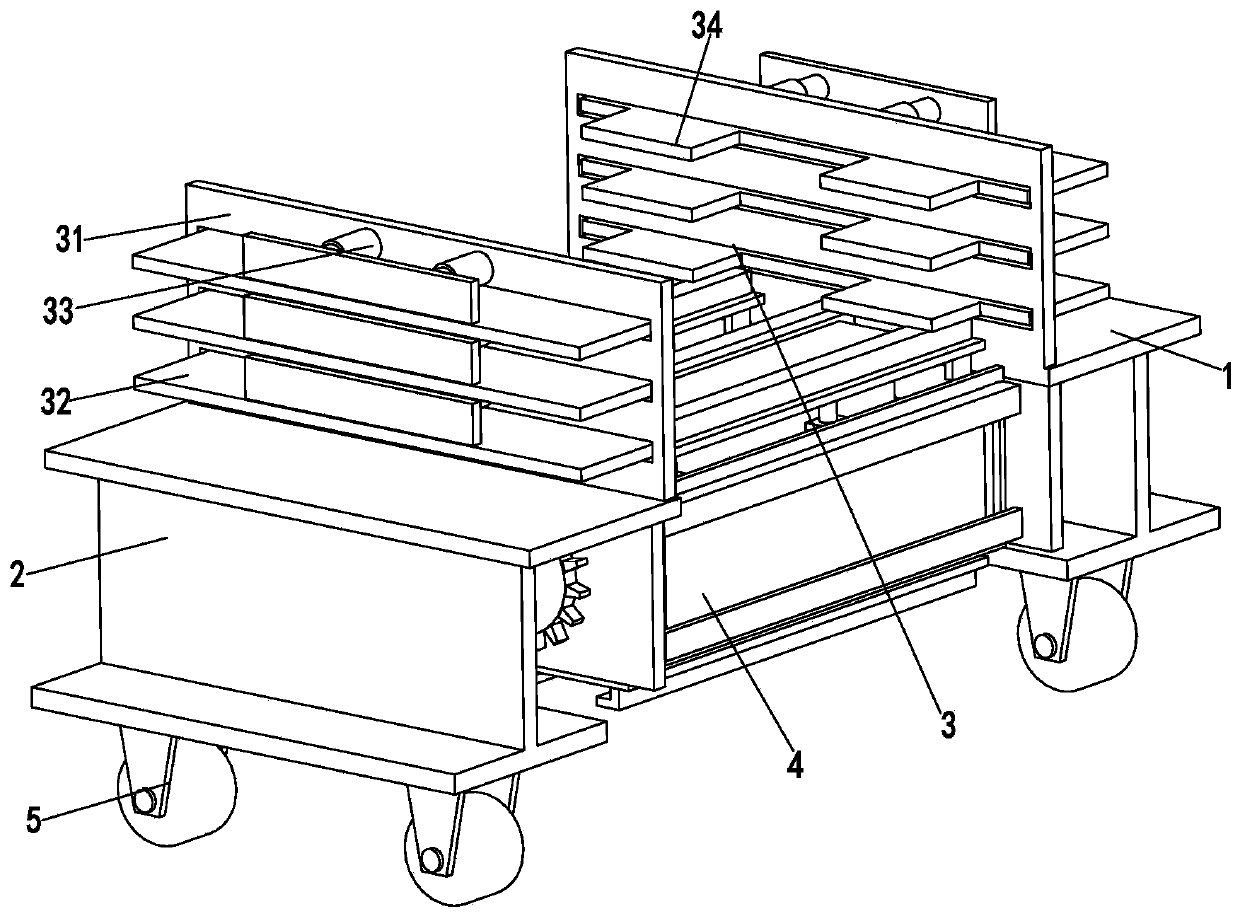

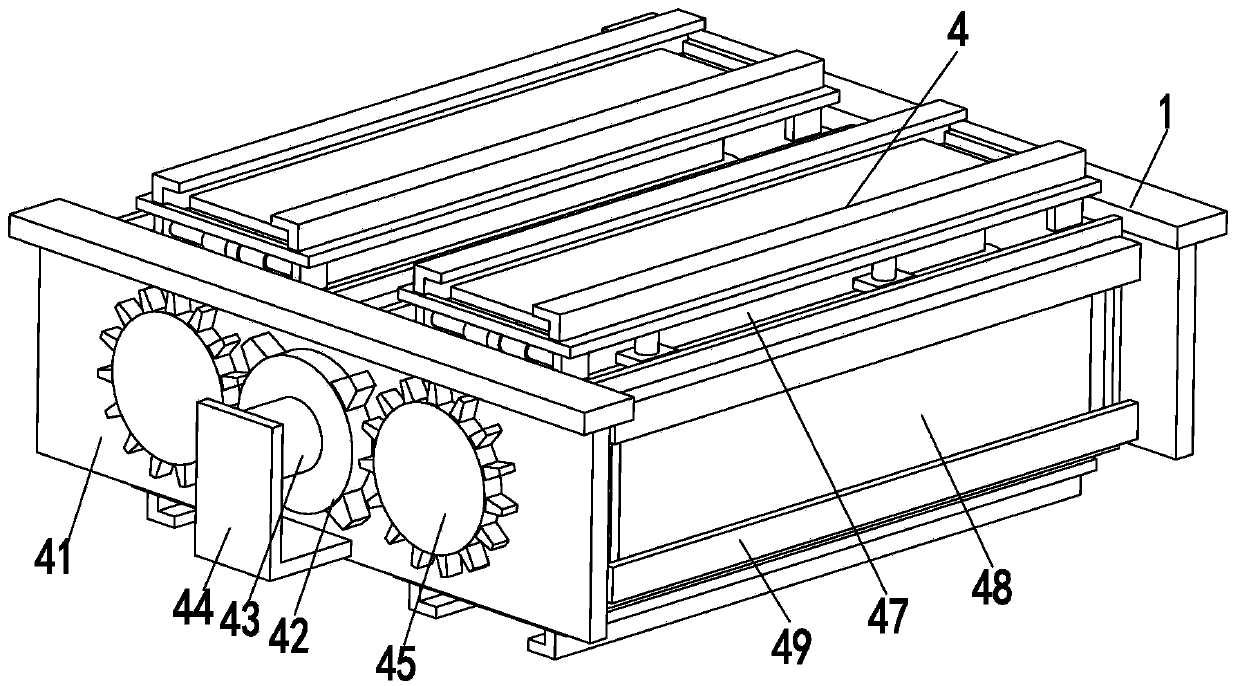

A railway sleeper automatic laying robot for disaster relief

ActiveCN109281237BRealize automatic layingIncrease labor costRailway track constructionEmergency rescueGear wheel

The invention relates to a sleeper automatic laying robot for railway emergency rescue and disaster relief. The sleeper automatic laying robot comprises two base plates, working frames, storing frames, a laying device and traveling wheels; the two base plates are arranged in a bilateral symmetry mode, and the working frames are mounted at the lower ends of the base plates; the traveling wheels aremounted at the lower ends of the working frames, and the storing frames are mounted at the upper ends of the base plates; the laying device is mounted between the two base plates, and the storing frames comprise mounting plates, adjusting frames, adjusting air cylinders and placing plates; and the laying device comprises a vertical plate, a rotating plate, a rotating motor, a mounting frame, a rotating gear, a rotating tube, a telescopic supporting plate, a bearing plate, a fixing plate, a fixing electric push rod and a fixing ring. The problems that in the existing process of sleeper layingfor railway emergency rescue, the labor cost is high, the working efficiency is low, the work continuity is poor, and large equipment works difficultly can be solved, the function of automatic layingon a sleeper can be achieved, and the sleeper automatic laying robot has the advantages of being low in labor cost, high in working efficiency, high in work continuity, small in size and the like.

Owner:胡佳威

Asphalt pavement anti-slip treatment device

The invention discloses an anti-slip treatment device for asphalt pavement, which comprises a car body, a cleaning device, a glue spreading device and a material spreading device are arranged under the car body, a collecting device is arranged on the side of the car body, and a support rod is fixedly connected under the car body to support the The bottom end of the rod is provided with a roller, and the spreading device includes a cylinder body, which is installed on the car body, and a motor is fixedly installed on the cylinder body, and one end of the motor shaft is fixedly connected to a rotating rod, and the rotating rod is fixedly connected to the inner wall of the cylinder body. The fins are scattered, the cylinder body is fixedly connected with a discharge pipe, the lower end of the rotating rod is fixedly connected with a screw rod, the screw rod is located in the discharge pipe, the lower end of the screw rod is provided with a connecting rod, and the lower end of the connecting rod is fixedly connected with a rotating blade. A first air cylinder is fixedly installed on the bottom, and a first scraper is fixedly connected to the piston rod end of the first air cylinder. The invention realizes the automatic laying of anti-skid particles, and the laying is even and smooth.

Owner:李绍森

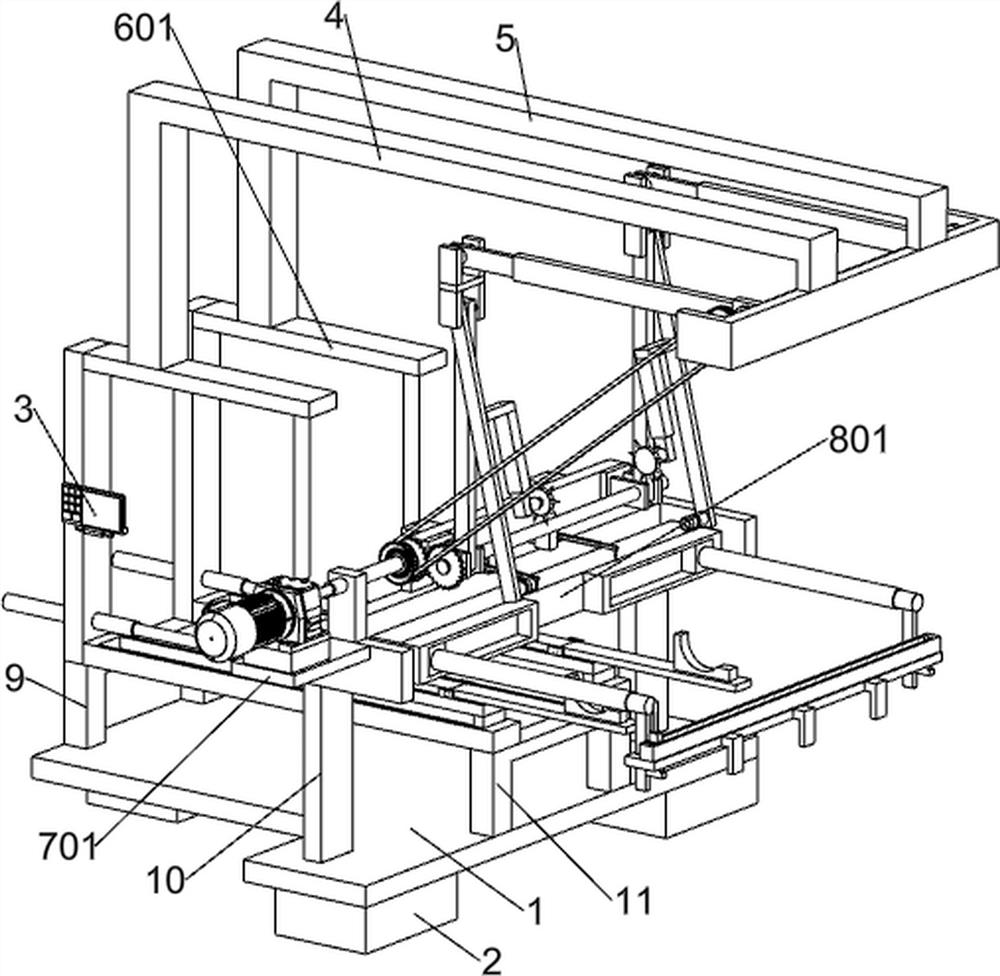

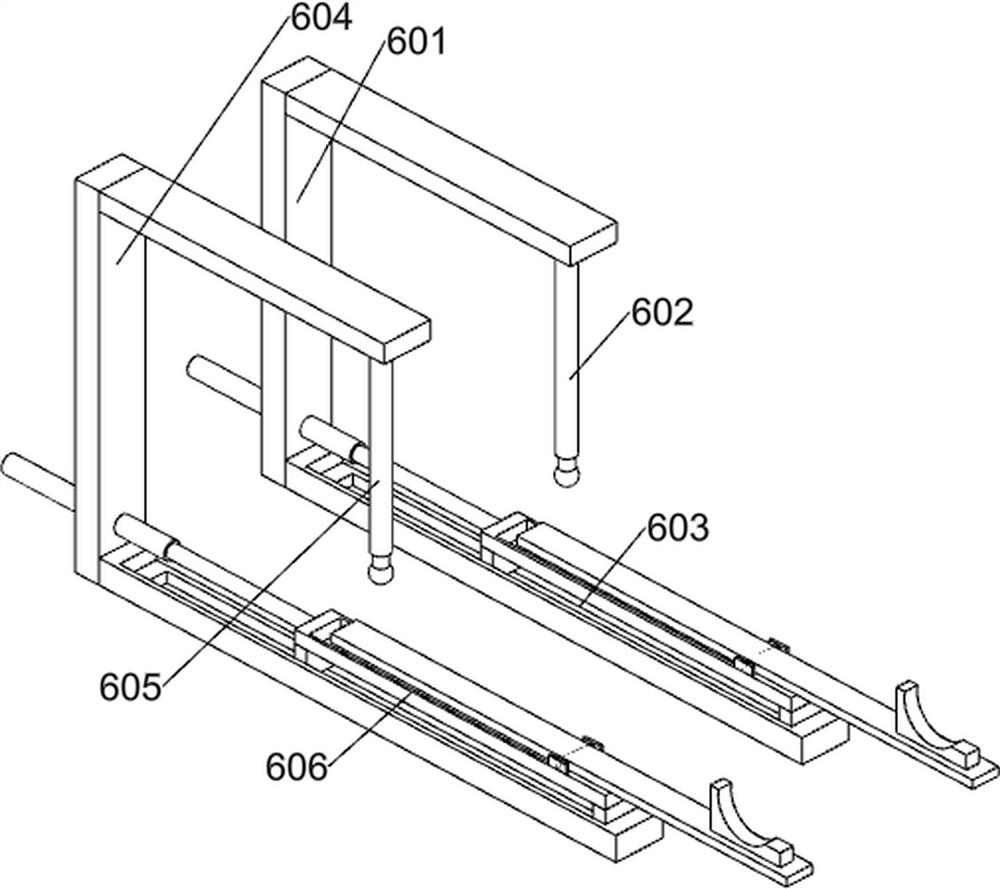

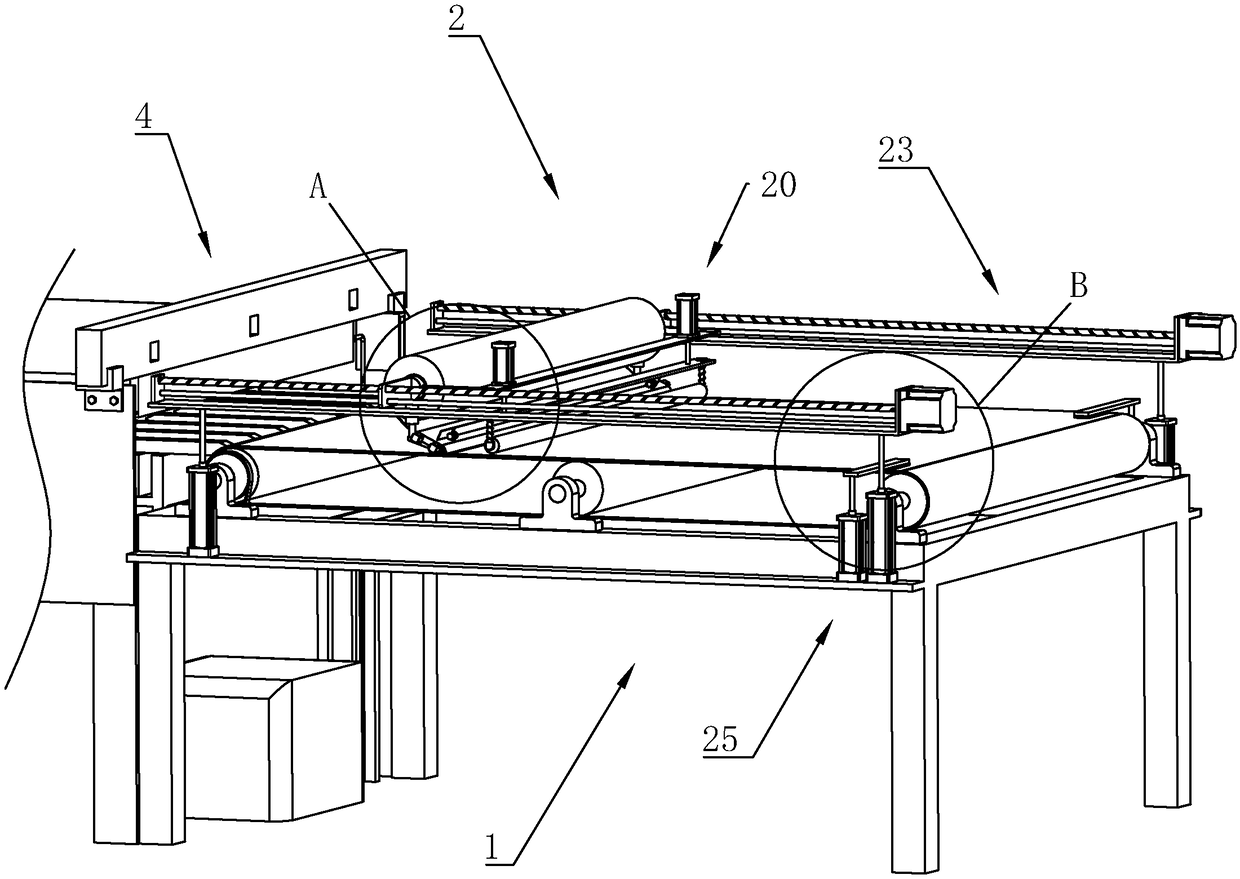

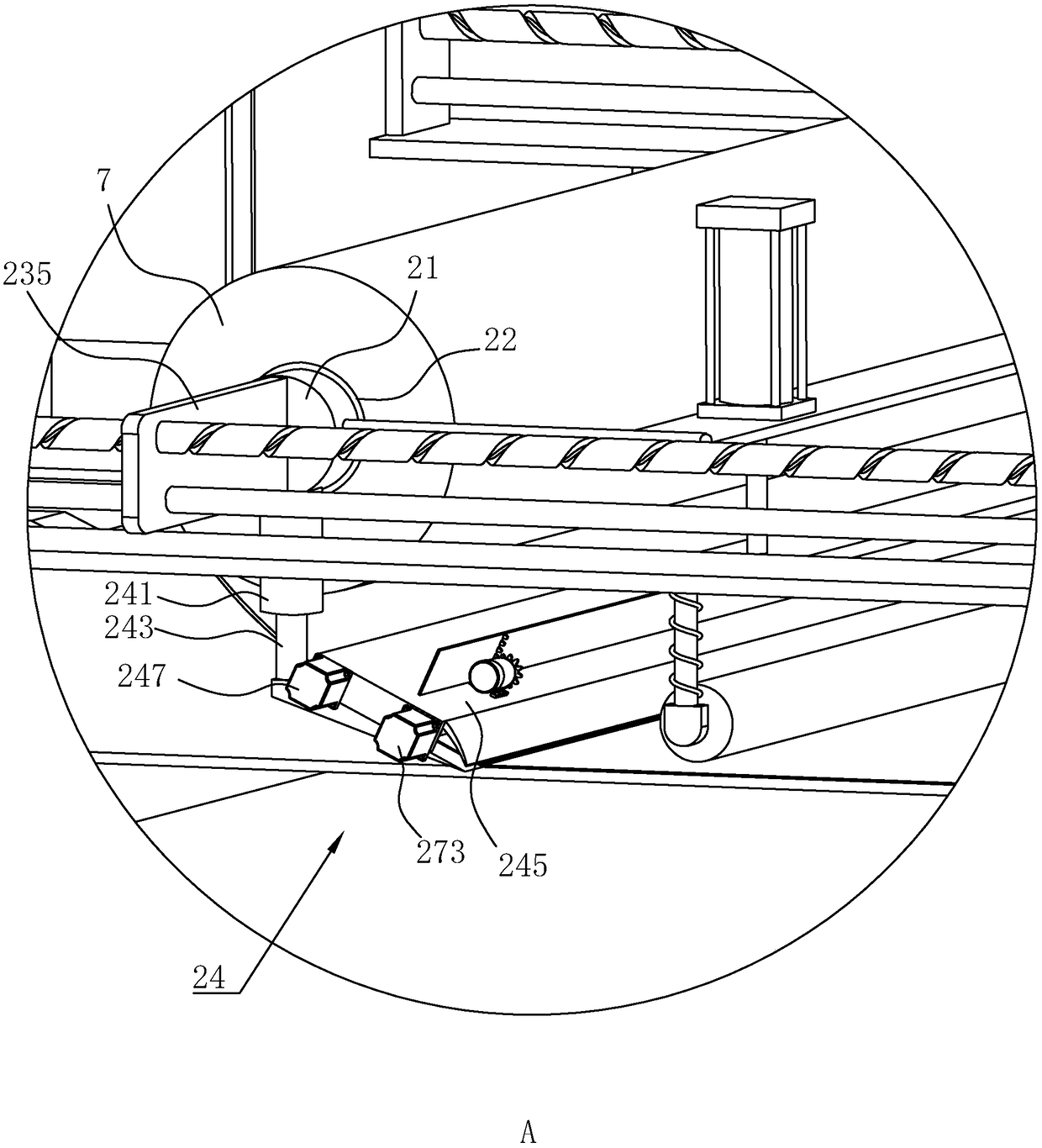

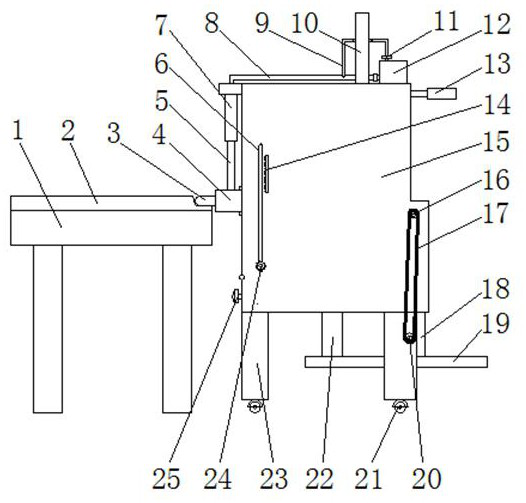

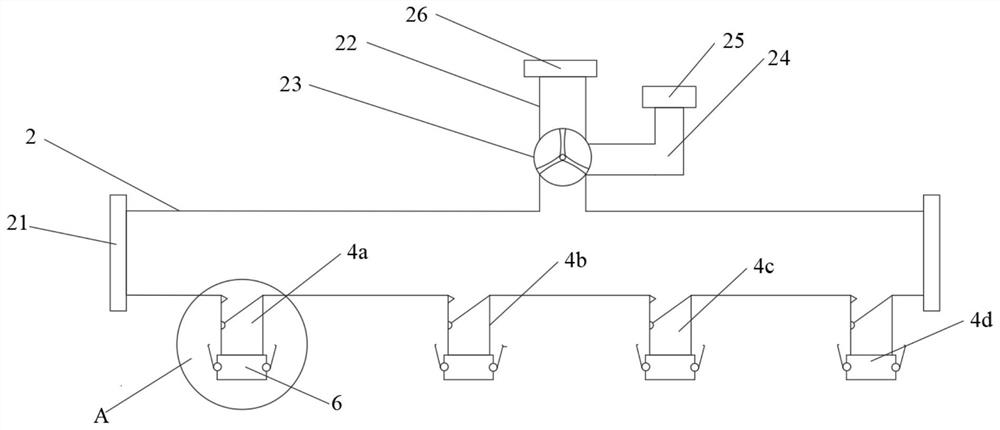

A veneer hot-pressing equipment with an automatic laying device

InactiveCN109129764BRealize automatic layingWork automaticallyPlywood pressesLamination ancillary operationsStructural engineeringConveyor belt

The invention discloses laminated board hot-pressing equipment with an automatic material laying device. According to the technical scheme, the equipment comprises a discharging conveying belt, the discharging conveying belt is provided with an automatic material laying device used for spreading decorative fabric, the automatic material laying device comprises a supporting shaft which is horizontally arranged above the discharging conveying belt, the peripheral surface of the supporting shaft is rotationally connected with a decoration fabric, and the two ends of the supporting shaft are provided with a driving mechanism for driving the supporting shaft to slide above the discharging conveying belt and used for laying the decorative fabric, and a guide cutting mechanism which is fixedly connected with the supporting shaft and used for guiding the decorative fabric and cutting the decorative fabric is arranged below the supporting shaft; and a positioning assembly for fixing the end part of the decorative fabric is further arranged on the discharging conveying belt. The laminated board hot-pressing equipment with the automatic material laying device has the advantages that the automatic material laying device is provided, so that the decorative fabric is laid more automatically, the labor consumption is reduced, and the hot-pressing efficiency of the laminated board is improved.

Owner:天津涵霖科技发展有限公司

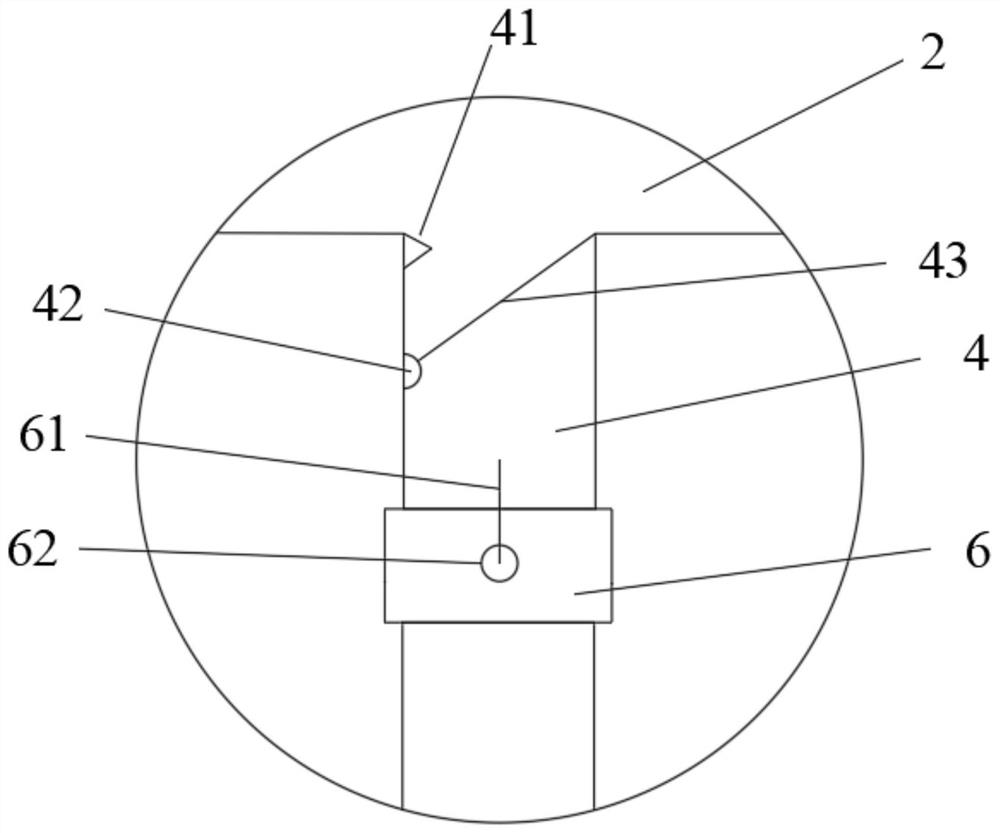

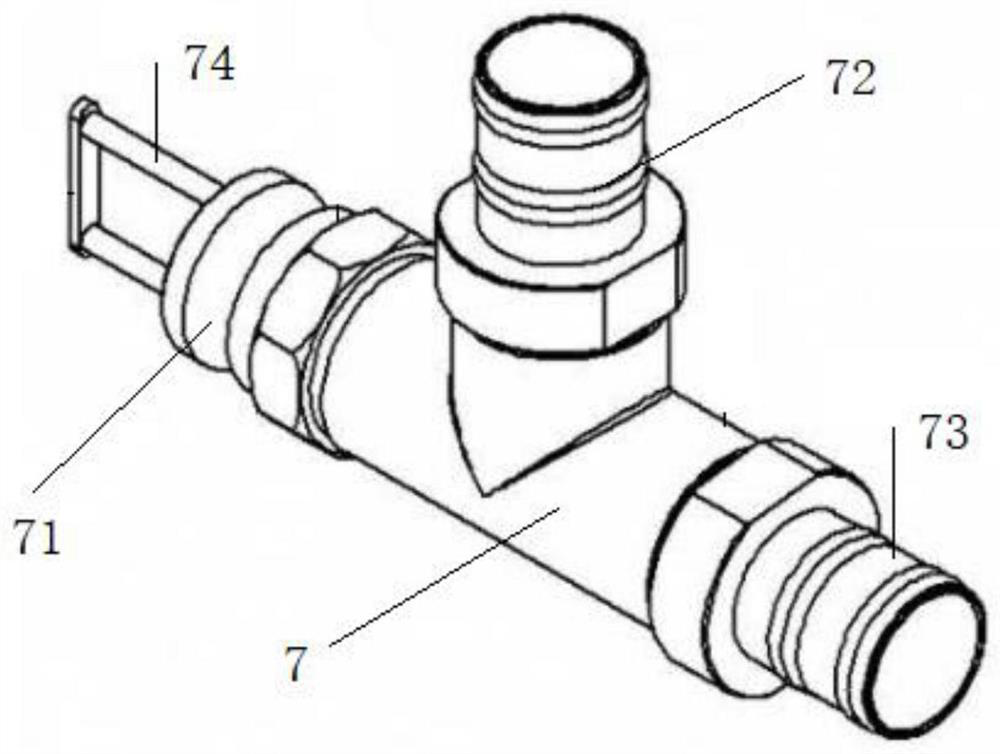

Fire hose quick connecting device and automatic laying system

PendingCN112691325AIncrease the lengthPrevent backflowFire rescueStructural engineeringMechanical engineering

The invention discloses a fire hose quick connecting device and an automatic laying system. The device comprises a water outlet cavity pipe and clamping sleeves, wherein a water outlet pipe is installed on the upper wall of the water outlet cavity pipe; a plurality of water supply connectors are installed on the lower wall of the water outlet cavity pipe; the clamping sleeves are fixedly connected with the water supply connectors; and reversing assemblies are arranged between the water supply connectors and the water outlet cavity pipe. The system comprises a tank body, water hoses, tee joints, locking mechanisms, hose pressing boxes and the fire hose quick connecting device, wherein the water outlet cavity pipe is installed on the upper portion in the tank body; the tee joints are clamped to the water supply connectors through the clamping sleeves; the locking mechanisms and the hose pressing boxes are both installed in the tank body; the water hoses sequentially penetrate through the hose pressing boxes and the locking mechanisms to be connected with the next tee joint; and the locking mechanisms control clamping rods on the clamping sleeves to rotate up and down around clamping seats. The automatic laying system can conveniently realize quick laying of the water hoses, is easy to operate and high in laying efficiency, can be widely applied to fire rescue work of fire fighting trucks, large enterprises and the like, improves the rescue efficiency, and reduces the loss caused by delayed fire rescue.

Owner:郑雪琴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com