Cloth mixing spreading machine for novel wall material production line

A wall material and production line technology, which is applied in the direction of spreading thin soft materials, thin material handling, loading/unloading, etc., can solve the problems that materials cannot soak into fabrics, restrict production efficiency, and low degree of automation, so as to achieve easy maintenance and Maintenance, good economic and social benefits, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

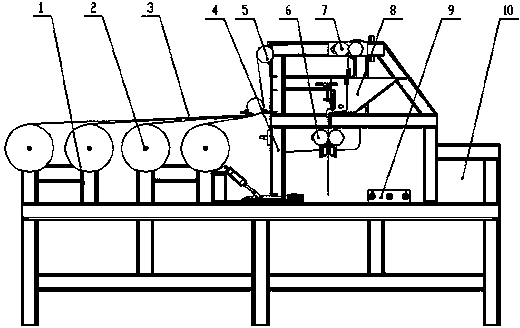

[0022] The present invention will be further described below in conjunction with specific drawings.

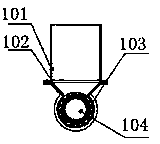

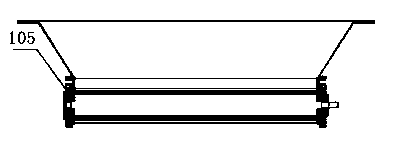

[0023] Such as Figure 1-3 As shown, the cloth mixing paving machine for the new wall material production line includes a machine chassis 1 and a bin frame 4 arranged on the machine chassis 1, and four cloth rollers 2 are arranged on the machine chassis 1. One side of the bin frame 4 is provided with an arc-shaped roller 5 used in conjunction with the cloth roller 2, and a star-shaped material spreading device 10 is provided on the machine chassis 1 on the other side of the bin frame 4; There is a powered lower cloth roller 7, and an opening hopper 8 and a lower cloth flower roller 6 are arranged successively on the material bin frame 4 below the powered lower cloth roller 7; The cloth mechanism 9; the open feed bin 8 and the star-shaped material spreading device 10 are respectively connected with the external feeding pipe; the arc roller 5, the lower cloth flower roller 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com