Soil slope geogrid laying and mounting method

A geogrid and installation method technology, applied in excavation, soil protection, infrastructure engineering and other directions, can solve the problems of low laying efficiency, large artificial physical strength consumption, damage to the angle and structure of the slope, etc., to avoid loosening of the slope. The effect of collapse, stable and rapid laying, and protection of soil slopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

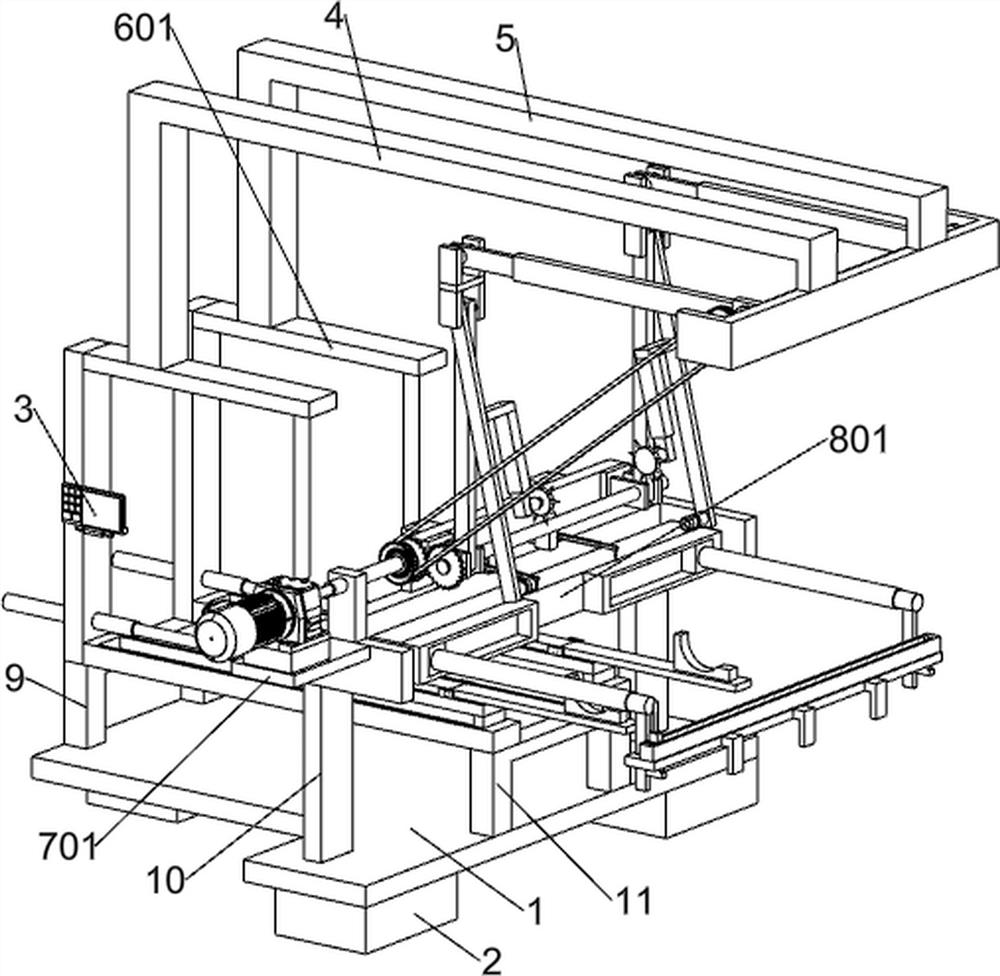

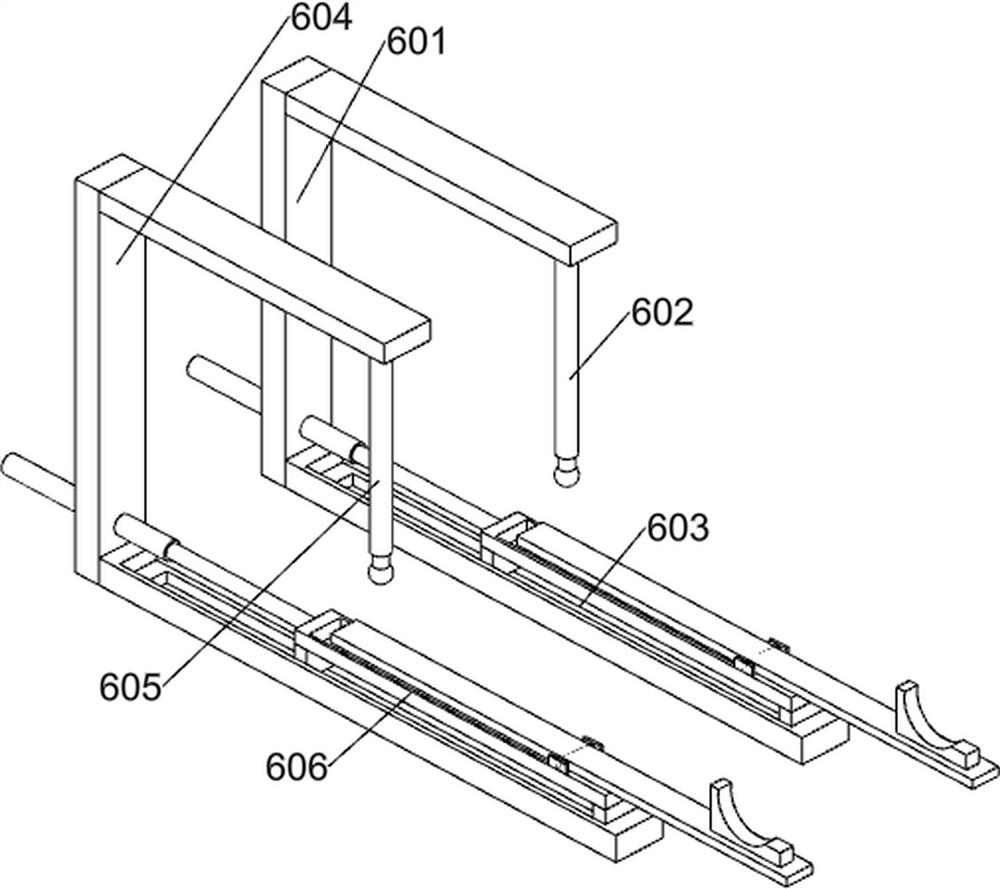

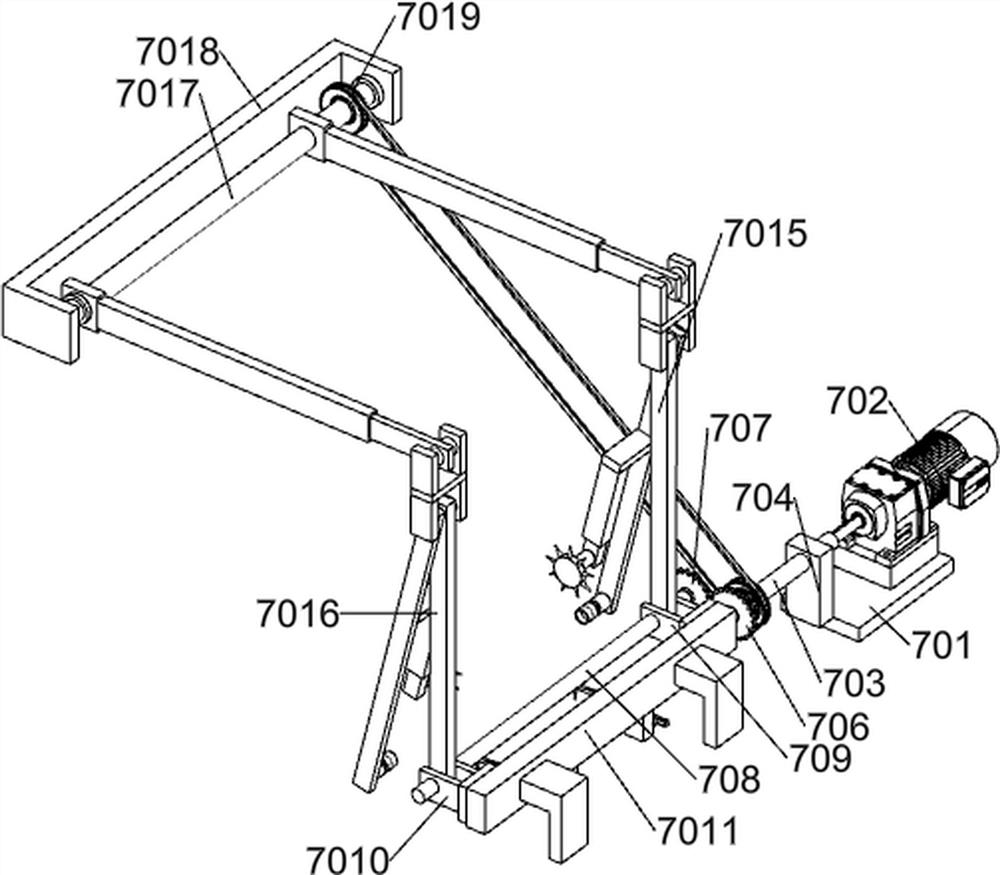

[0041] A method for laying and installing geogrids on soil slopes, such as Figure 1-2 As shown, the method for laying and installing the soil slope geogrid adopts the following processing equipment. The processing equipment includes a mounting frame plate 1, an embedded mounting bottom block 2, a real-time control panel 3, a first connecting frame 4, and a second connecting frame 5. Lay down the laying system, slope protection system, first outrigger 9, second outrigger 10 and third outrigger 11; install the bottom of the rack plate 1 and connect the bottom block 2 with bolts; install the rack plate 1 The top is welded with the first leg 9; the top of the installation frame plate 1 is welded with the second leg 10; the top of the installation frame plate 1 is welded with the third leg 11; one side of the first connecting frame 4 is connected with a lowering Laying system; one side of the second connecting frame 5 is connected with a lowered laying system; the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com