A veneer hot-pressing equipment with an automatic laying device

A material laying device and hot pressing equipment technology, which is applied in the field of veneer manufacturing, can solve problems affecting the adsorption and heat pressing efficiency of veneers, and achieve a tight fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

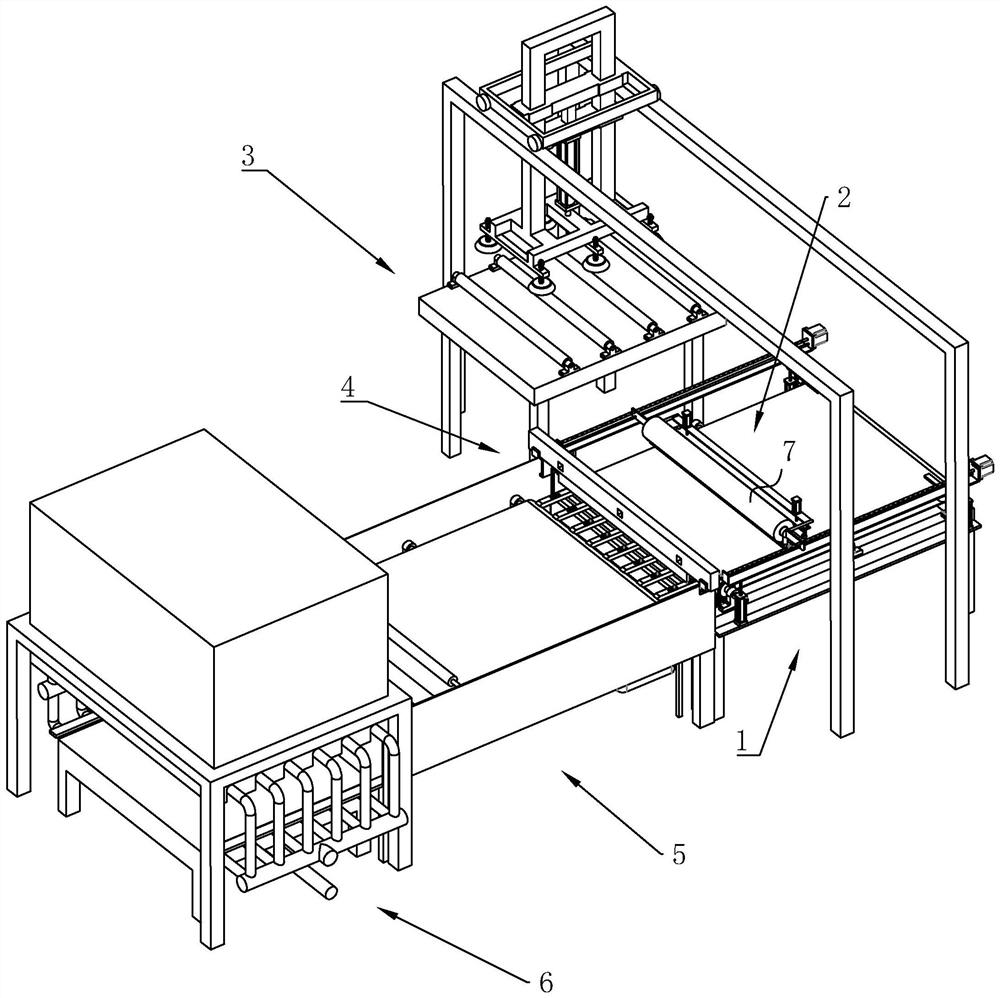

[0037] A veneer hot pressing equipment with an automatic laying device, such as figure 1 As shown, it includes a discharge conveyor belt 1, an automatic material laying device 2 for laying decorative fabrics 7 is arranged above the discharge conveyor belt 1, and a veneer transfer device 3 for transmitting veneers is arranged beside the discharge conveyor belt 1, and the discharge conveyor belt The transmission tail of 1 is provided with an electrostatic adsorption device 4 that mutually adsorbs the veneer and the decorative fabric 7, and the side of the electrostatic adsorption device 4 away from the discharge conveyor belt 1 is provided with a hot-pressed transmission rack 5 that accepts the adsorbed veneer. A heat press 6 is provided on the side of the transmission rack 5 away from the discharge conveyor belt 1 .

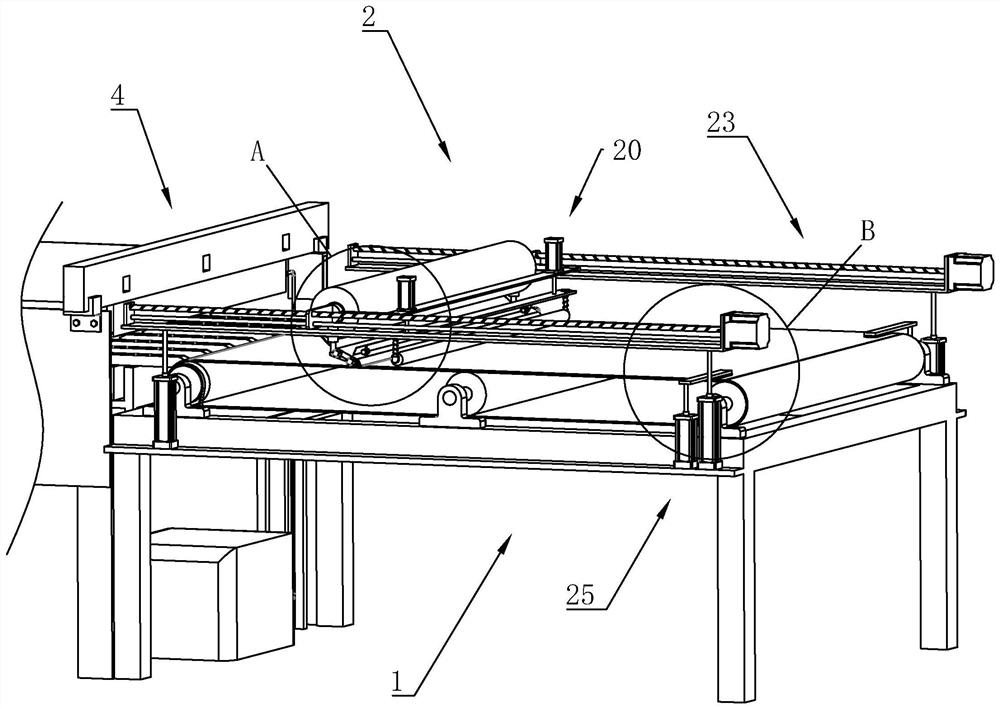

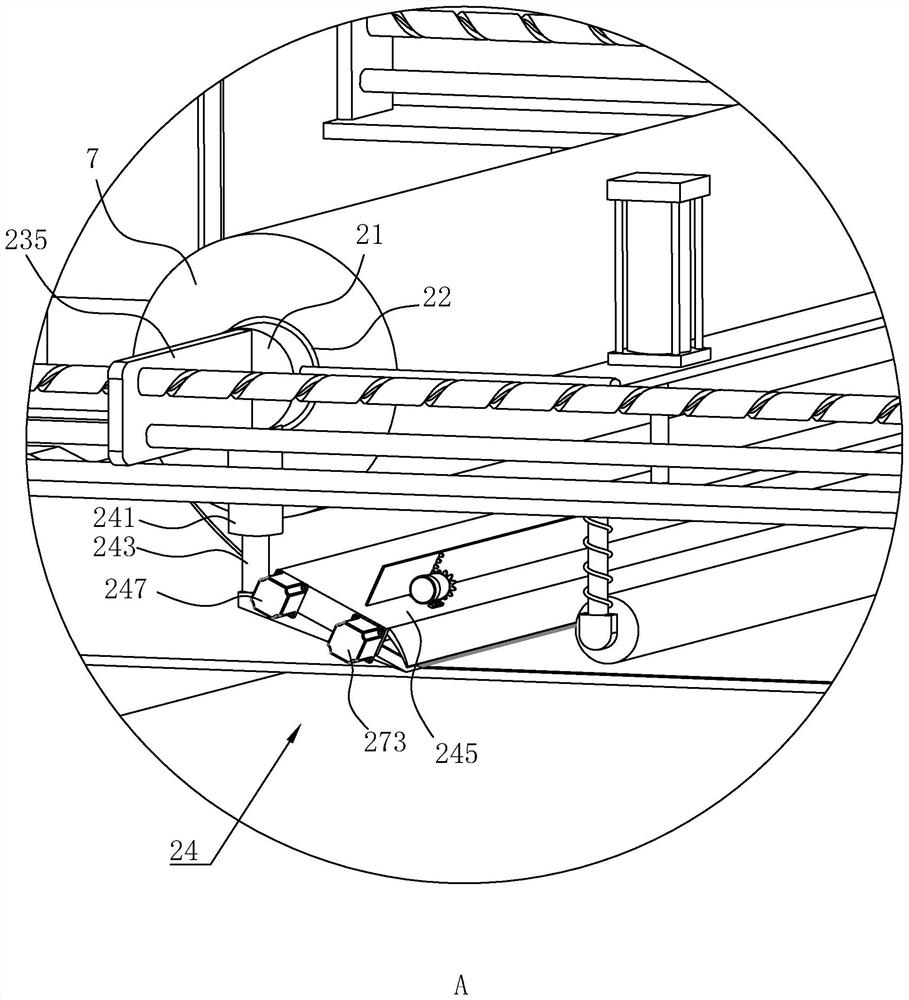

[0038] Such as figure 2 and image 3 As shown, the automatic material laying device 2 includes a support shaft 21 horizontally arranged above the discharge con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com