An automatic net laying device for a coal mine rock bolter

A bolt drilling rig, automatic technology, applied in the installation of bolts, shaft equipment, mining equipment, etc., can solve the problems of poor safety, low efficiency, high strength, etc., and achieve the effect of improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

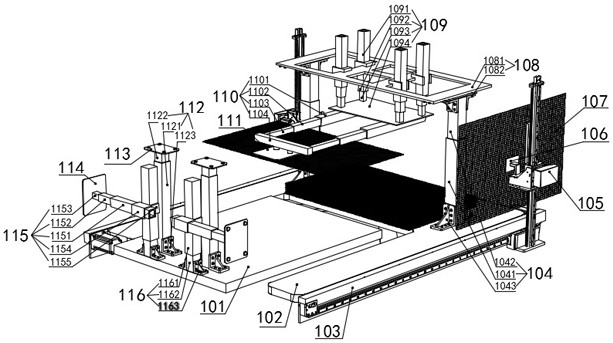

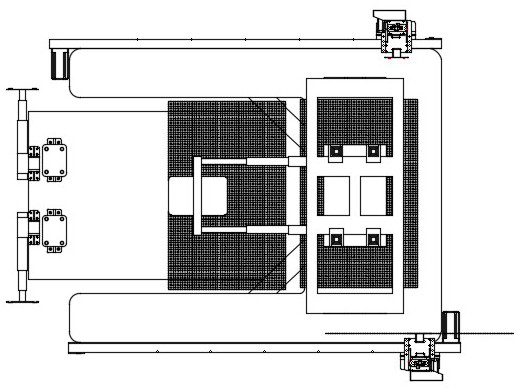

[0022] refer to Figure 1 to Figure 5 The technical solution of the present invention will be further elaborated in conjunction with the embodiments.

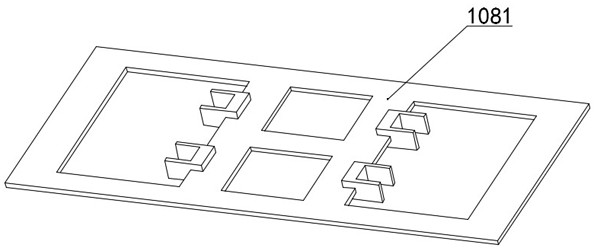

[0023] This embodiment provides an automatic net-laying device for a rock bolter used in coal mines, including a bolter 101, a bolter 102, a belt conveying mechanism 103, a sleeve structure 104, a vertical lifting mechanism 105, and a magnetic chuck 106. Anchor net 107, bracket 108, sleeve structure 2 109, telescopic manipulator 1 110, magnetic sucker 2 111, sleeve structure 3 112, magnetic sucker 3 113, magnetic sucker 4 114, telescopic manipulator 2 115, sleeve Structure 4:116.

[0024] The bolter 102 is a U-shaped structure, and the internal space can accommodate the bolter 101; the anchor bolter 102 and the bolter 101 are all provided with displacement sensors to ensure that the bolter 102 and the bolter 101 In the process of walking, the two sides do not touch the roadway, which improves safety, and a distance sensor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com