Automatic bolt mesh laying and connection excavation temporary support device

A temporary support and automatic technology, applied in the direction of temporary shields, mine roof supports, shaft equipment, etc., can solve the problems of roof dropping and hurting people, and the inability to fully utilize the efficiency of high-performance roadheaders, so as to reduce repeated support and realize Timely support and the effect of improving tunneling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

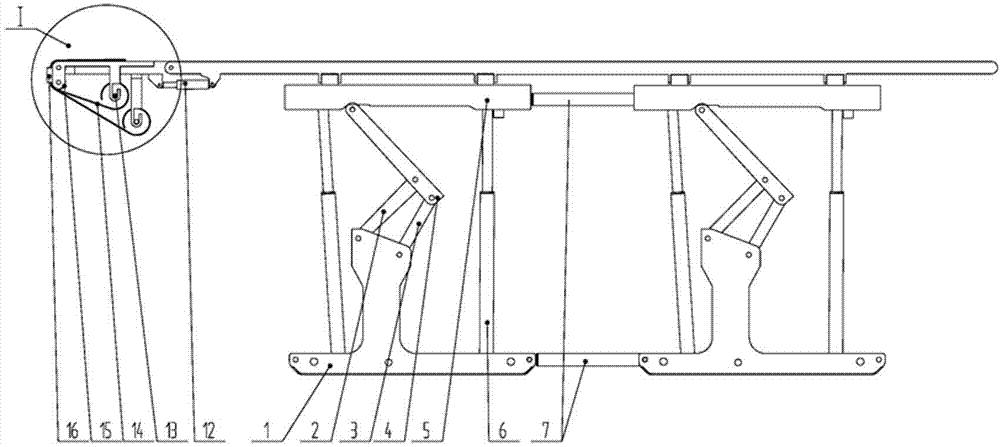

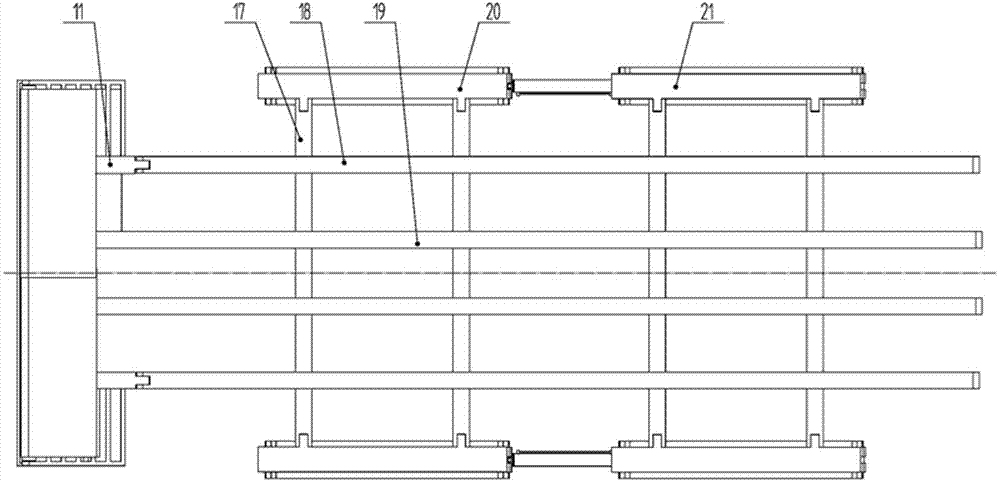

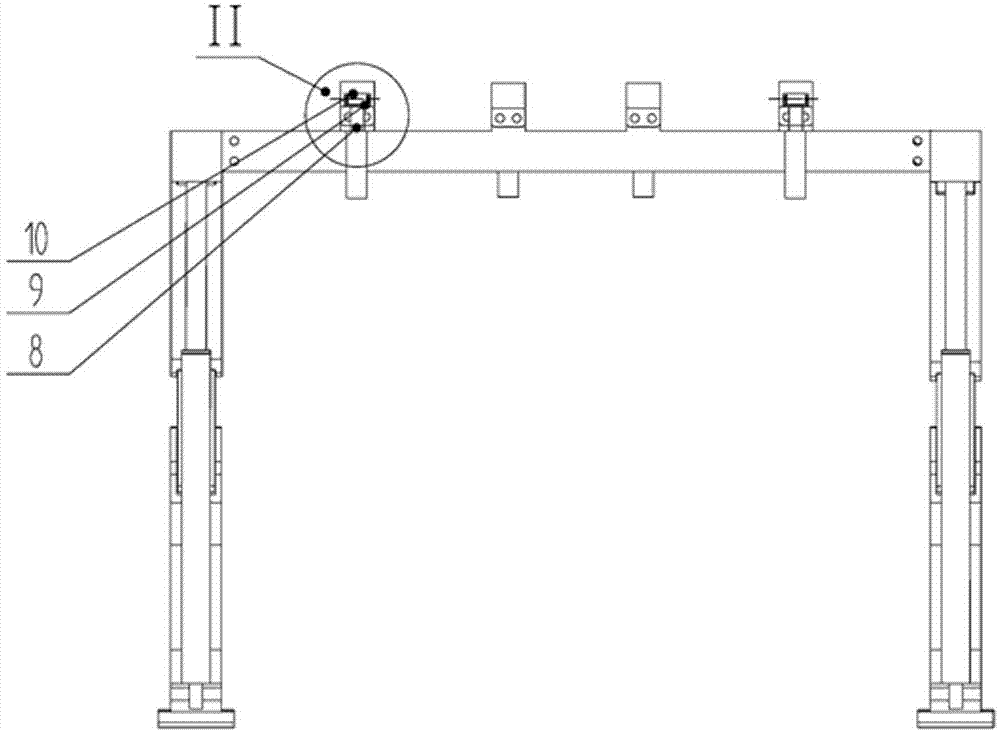

[0030] The temporary support device for automatic laying and networked excavation is mainly composed of front and rear support groups, beams, parallel beams, idlers, push-pull cylinders, rigid frames, rollers, steel rods, rigid frame jacks, lifting cylinders, rollers, roller mounting frames, automatic network device, hydraulic system, etc. The two sets of brackets are respectively composed of two left and right brackets connecting two top beams through two beams, and the beams of each bracket are arranged with parallel beams and supporting rollers. The running beam is mainly used to support the roof, and the idler roller is mainly used to provide rolling friction for the running beam during the forward movement of the bracket. The front end of the beam of the front support group is equipped with rigid frames, rollers, steel rods, automatic net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com