Automatic cable laying equipment and method

A technology for laying equipment and cables, which is applied in the field of automatic cable laying equipment, which can solve the problems of restricting the shipbuilding industry, limited construction space, harsh working environment, etc., and achieve the effect of avoiding manual laying, easy operation, and satisfying volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

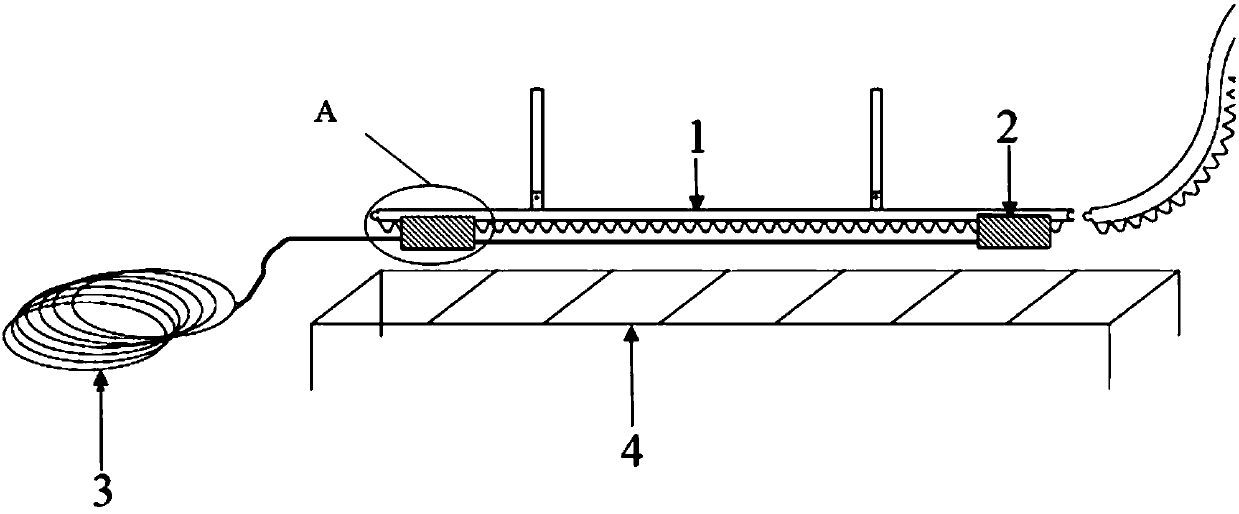

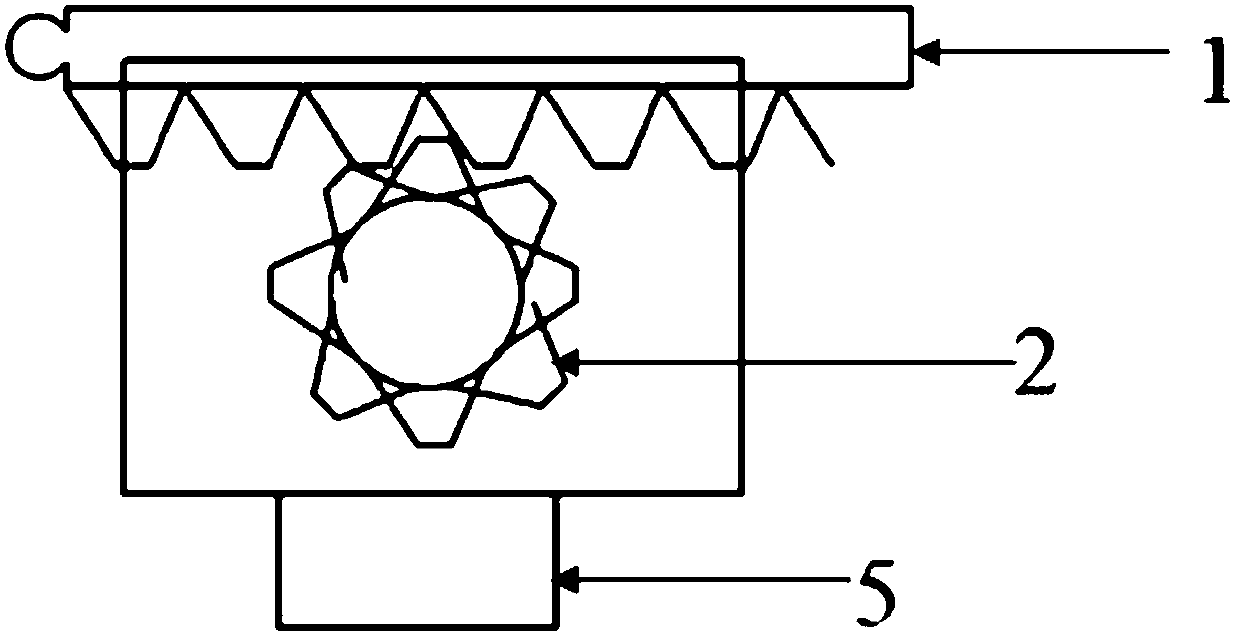

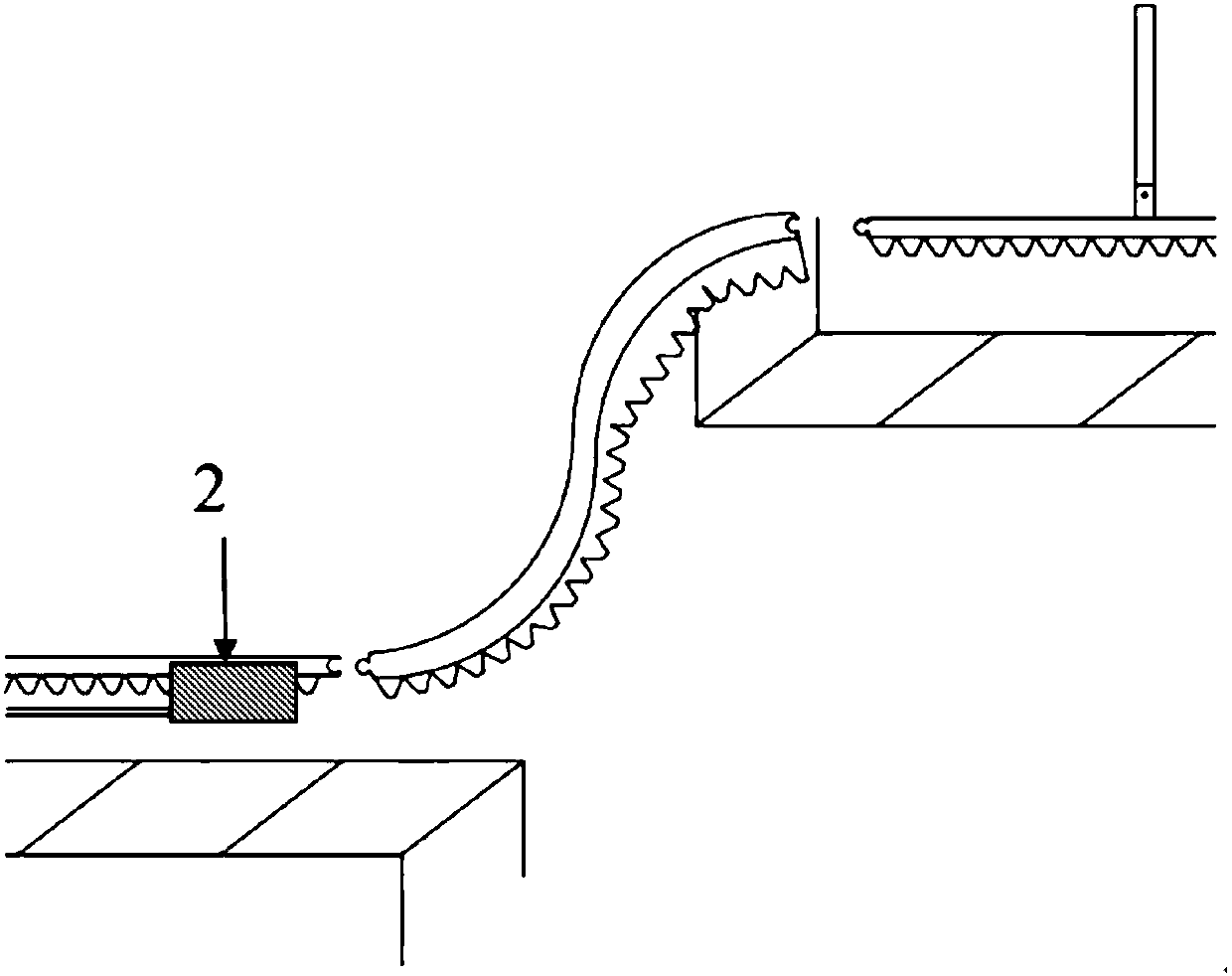

[0040] Please refer to Figures 1 to 3 As shown, the first embodiment of the present invention is: an automatic cable laying equipment, including at least two traction motors 2, cable guide rails 1, cable clamps 5 and a control system, the output shaft of the traction motor 2 is provided with a traction gear , the lower surface of the cable guide rail 1 is provided with a rack; the rack is meshed with the traction gear, the cable clamp 5 is installed below the traction motor 2, and the cable clamp 5 is connected to the control system connected; the cable guide rail 1 is composed of a plurality of guide rail segments, one end of the guide rail segment is provided with a groove, and the other end is provided with a protrusion matching the groove. The end of the cable guide 1 is provided with a limiting device. The guide rail section includes a straight guide rail section and an elbow guide rail section. The elbow-shaped guide rail section is S-shaped. The laying equipment als...

Embodiment 2

[0041] Embodiment 2 of the present invention is: an automatic cable laying equipment, including at least two traction motors 2, cable guide rails 1, cable clamps 5 and a control system, the output shaft of the traction motor 2 is provided with a traction gear, the The lower surface of the cable guide rail 1 is provided with a rack; the rack is meshed with the traction gear, the cable clamp 5 is installed below the traction motor 2, and the cable clamp 5 is connected to the control system; The cable guide rail 1 is composed of a plurality of guide rail sections, one end of the guide rail section is provided with a groove, and the other end is provided with a protrusion matching the groove. The end of the cable guide 1 is provided with a limiting device. The guide rail section includes a straight guide rail section and an elbow guide rail section. The elbow-shaped guide rail section is S-shaped. The laying equipment also includes a motor mounting plate, which is used for mount...

Embodiment 3

[0042] Embodiment 3 of the present invention is: an automatic cable laying method, comprising the following steps:

[0043] S1. Install the cable guide rail 1 above the peripheral cable bracket 4;

[0044] S2. Control the cable clamp 5 to automatically clamp the cable 3 through the control system, and move forward under the drive of the traction motor 2;

[0045] S3. After the traction motor moves to a designated position, control the cable clamp 5 to release, and the cable 3 falls naturally on the bracket 4 .

[0046] In summary, the present invention provides automatic cable laying equipment and a laying method, which have a wide application range and are easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com