Patents

Literature

31results about How to "Laying to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

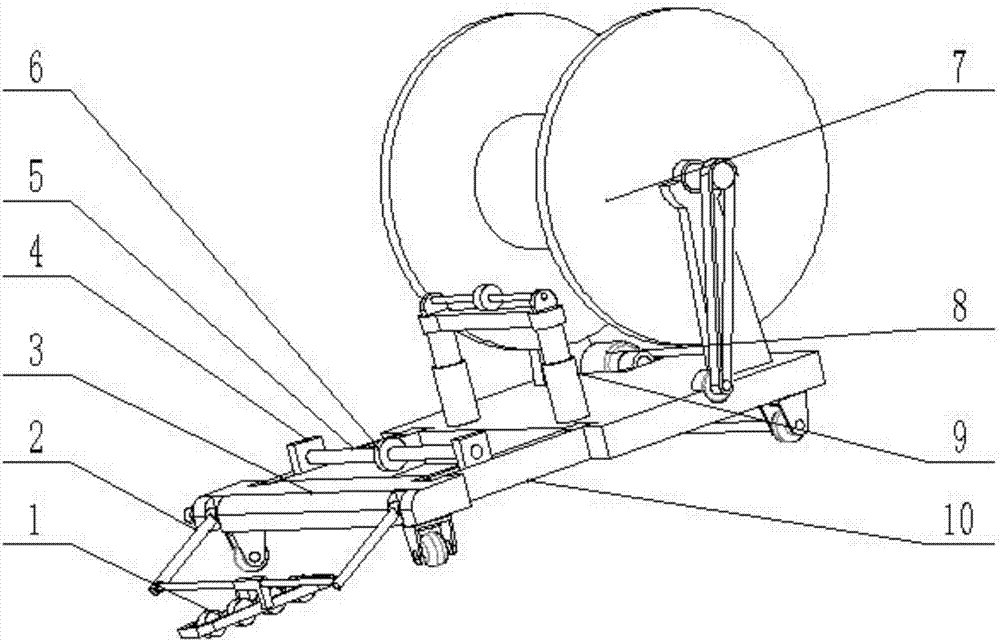

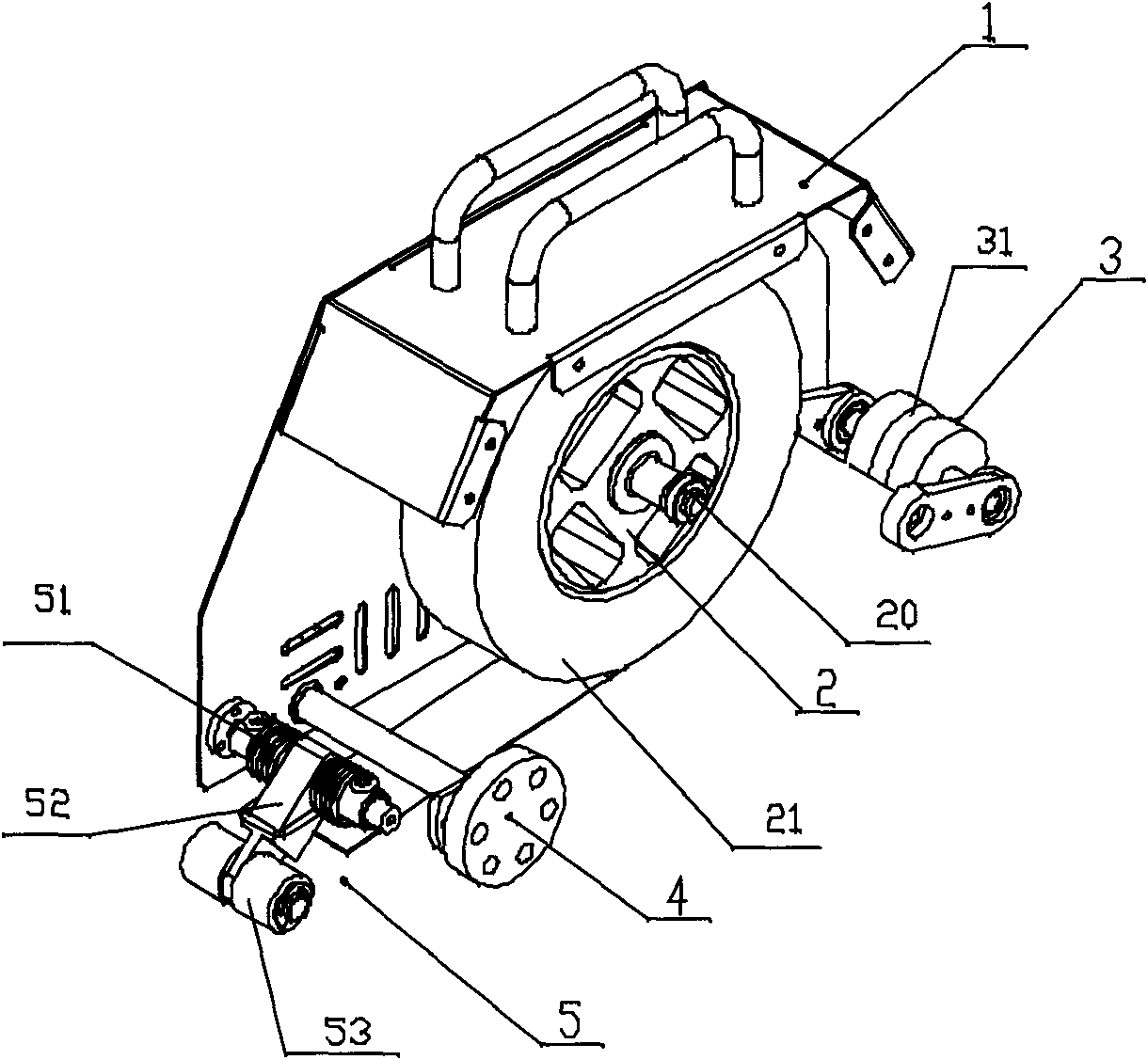

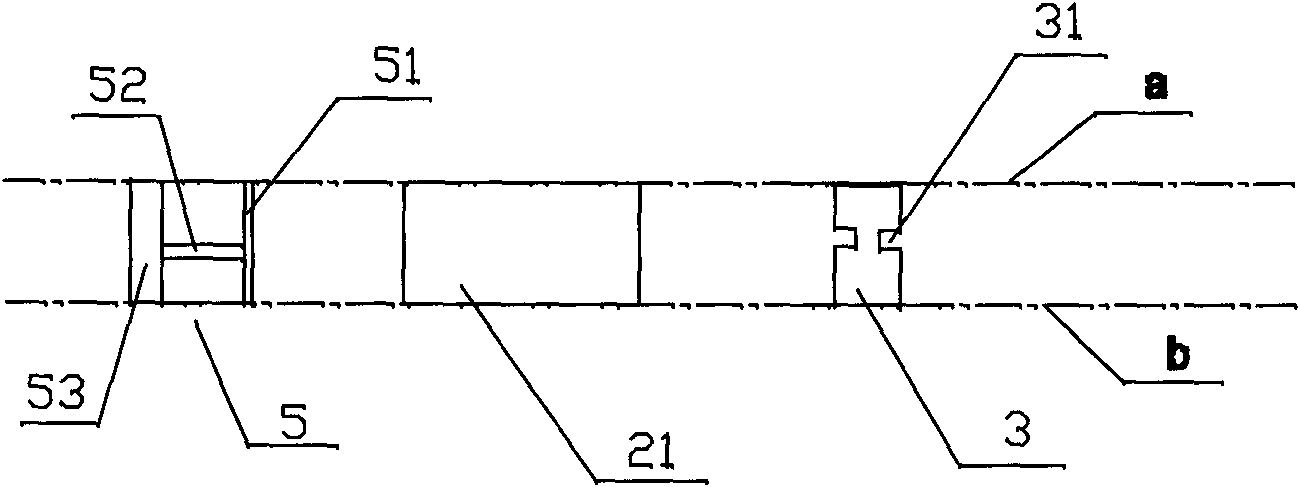

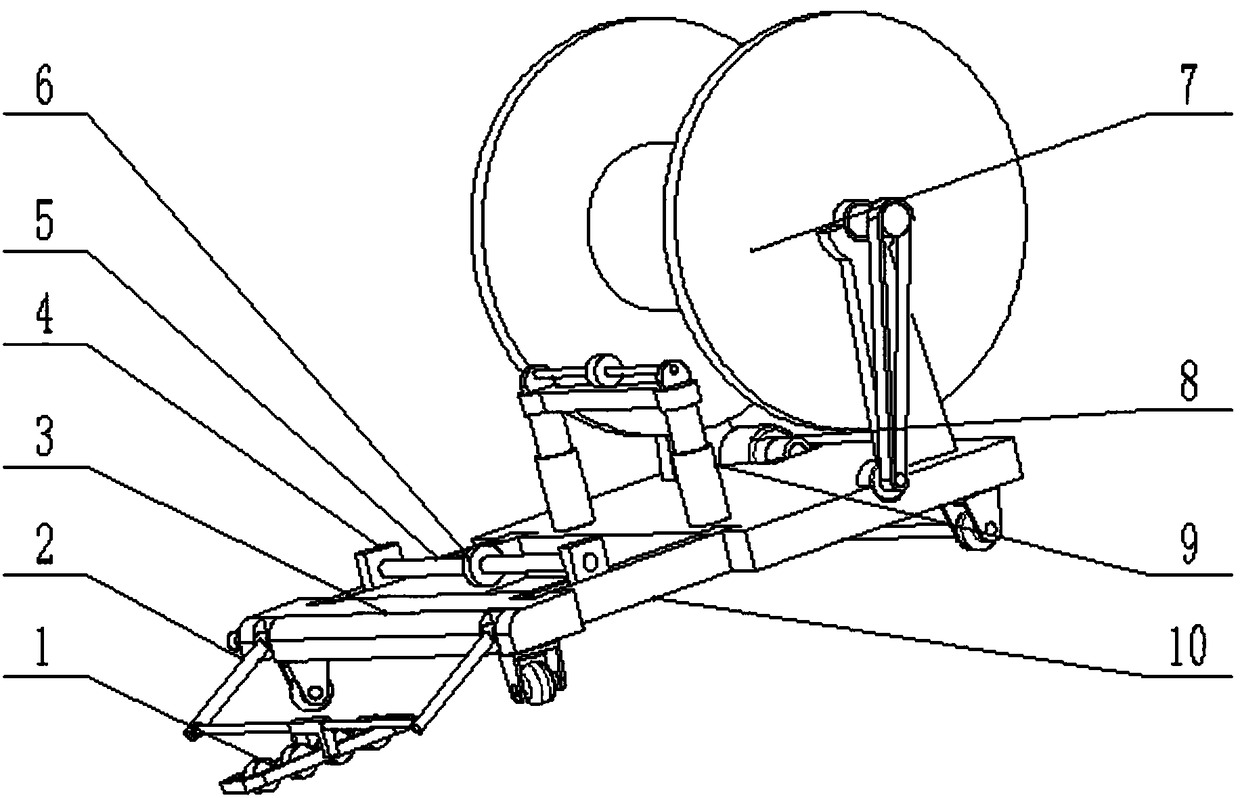

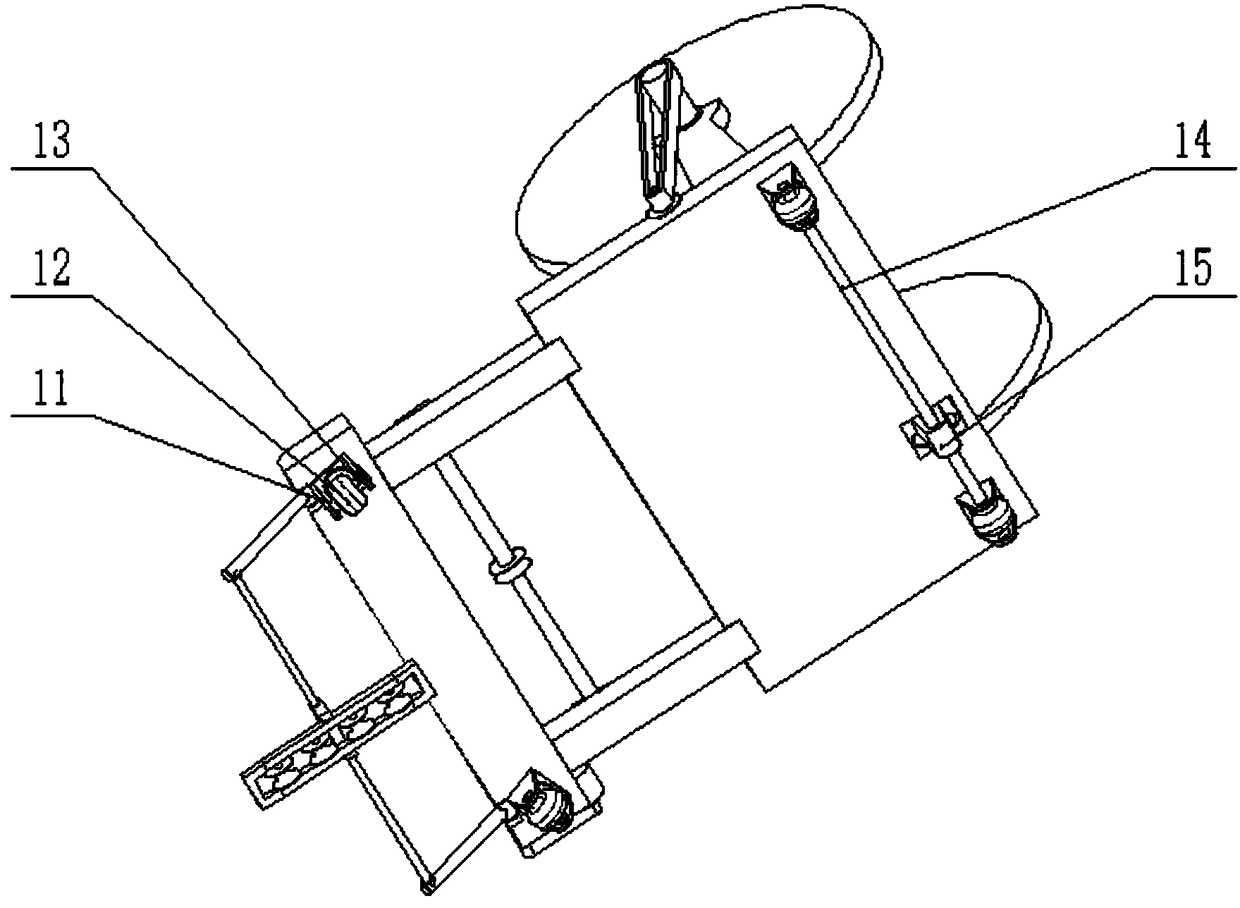

Cable laying device

ActiveCN106972418AStable deliveryLaying to achieveApparatus for laying cablesEngineeringMechanical equipment

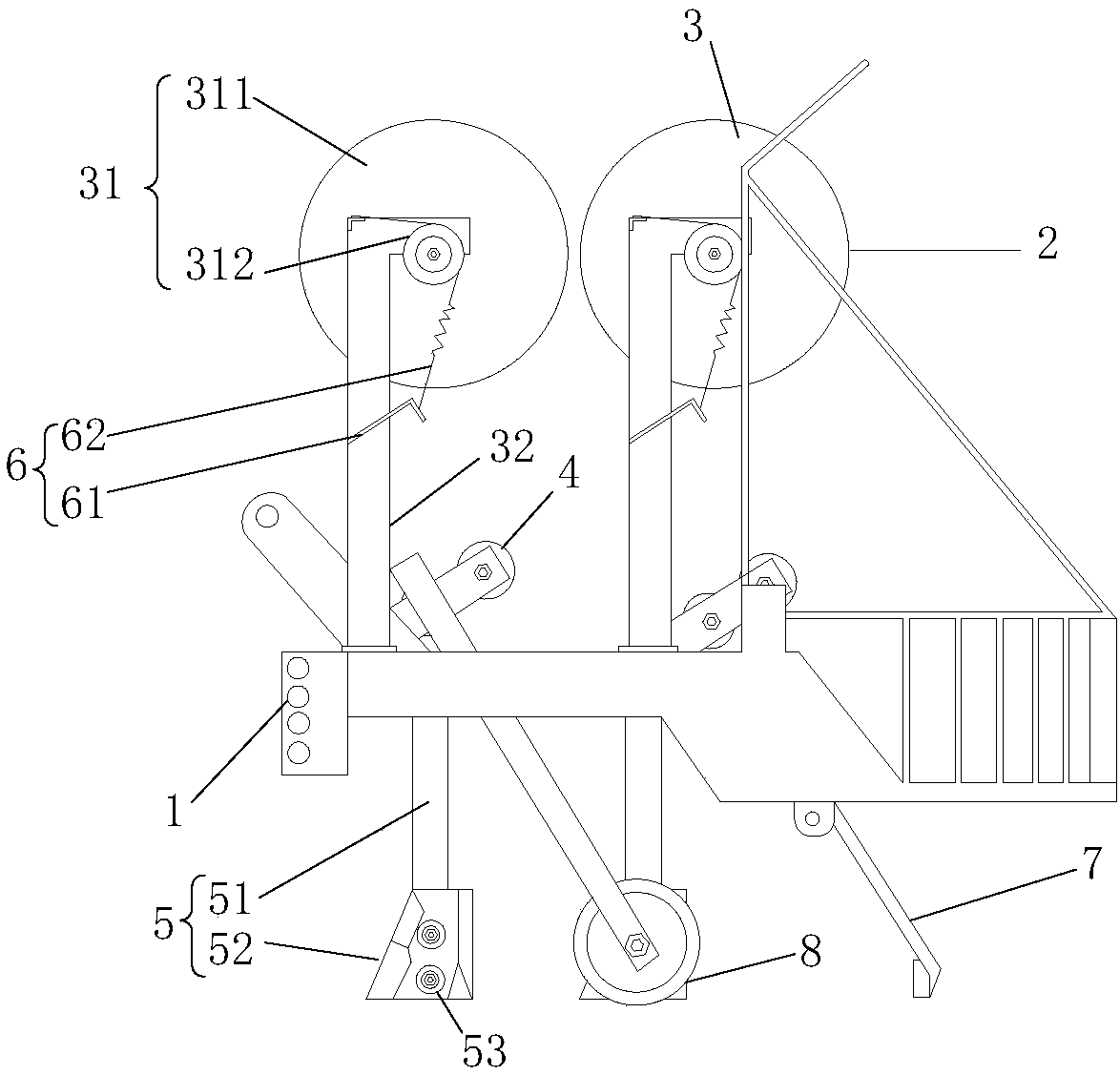

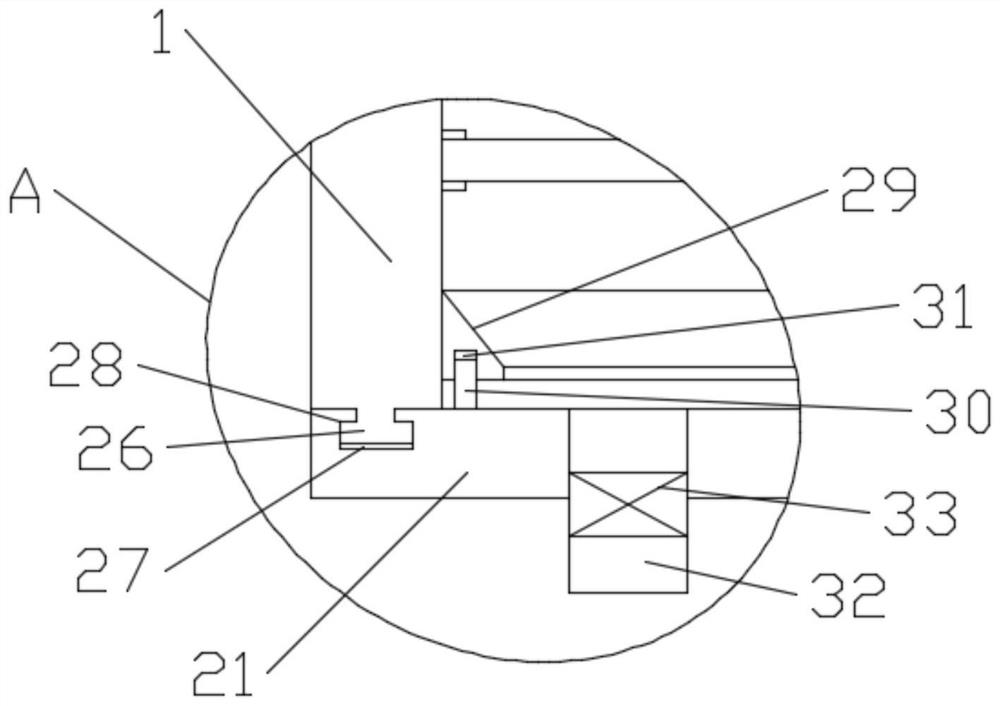

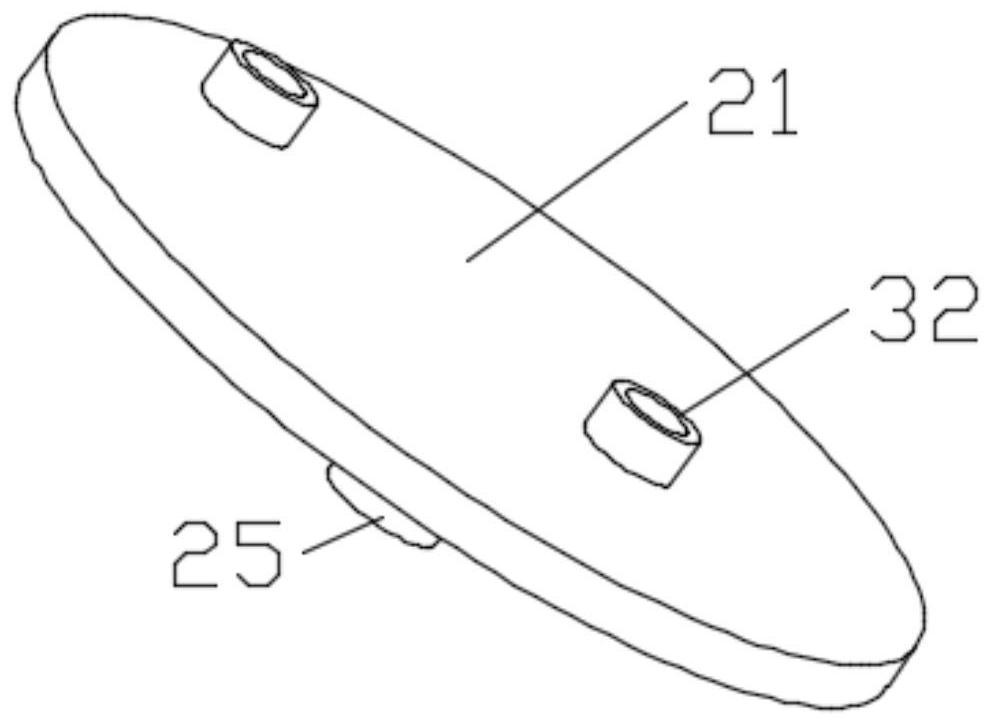

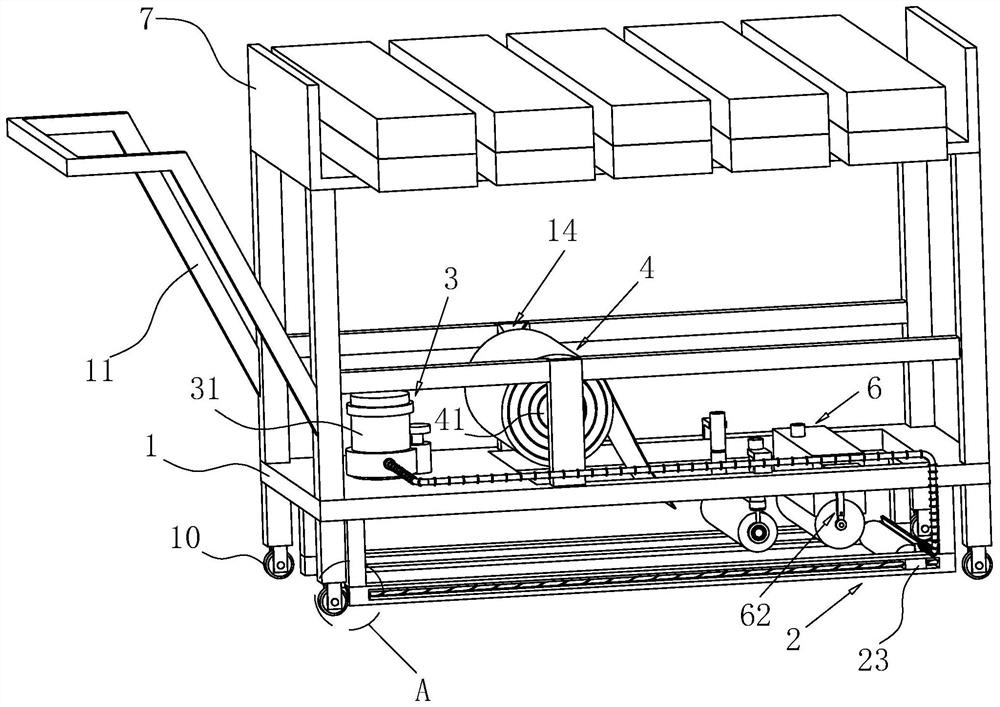

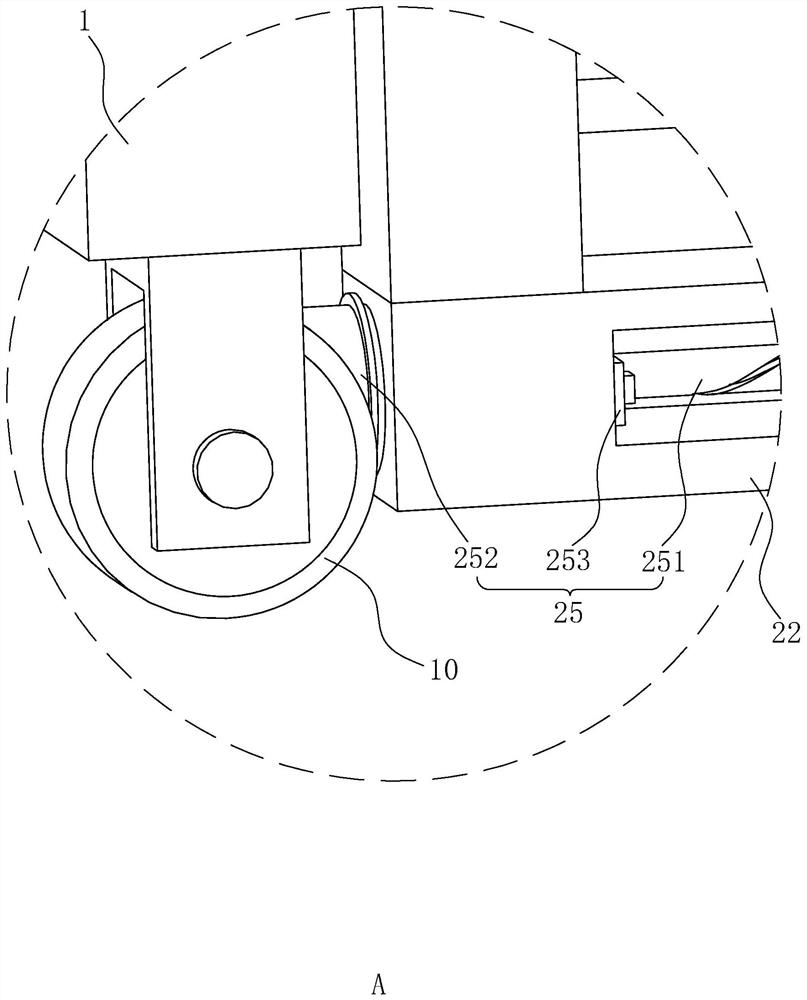

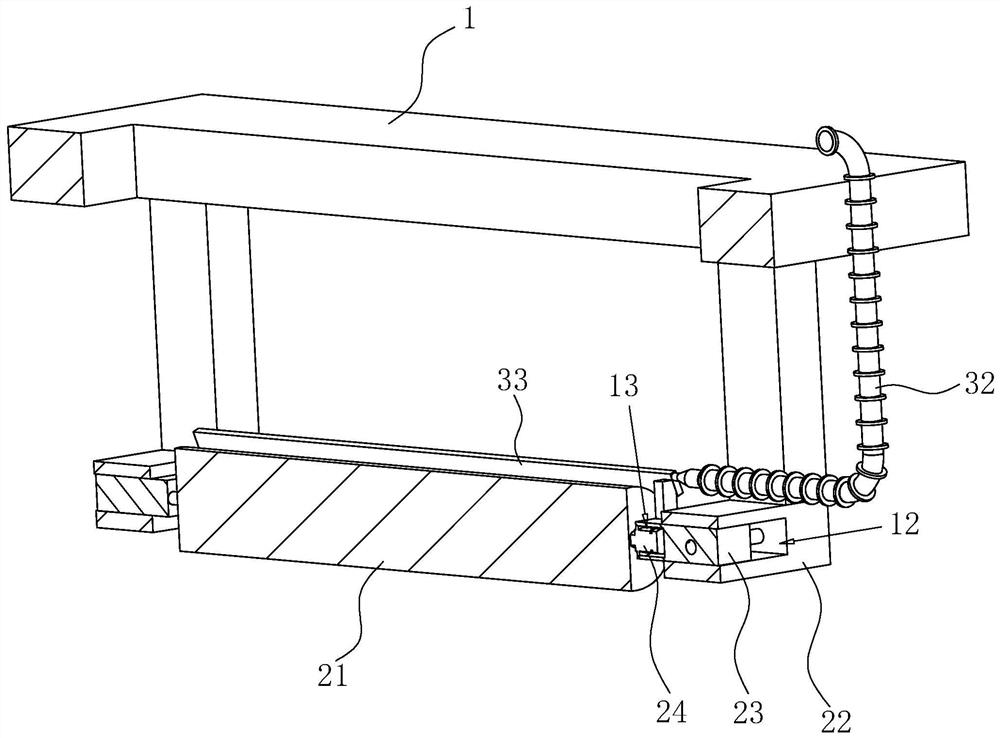

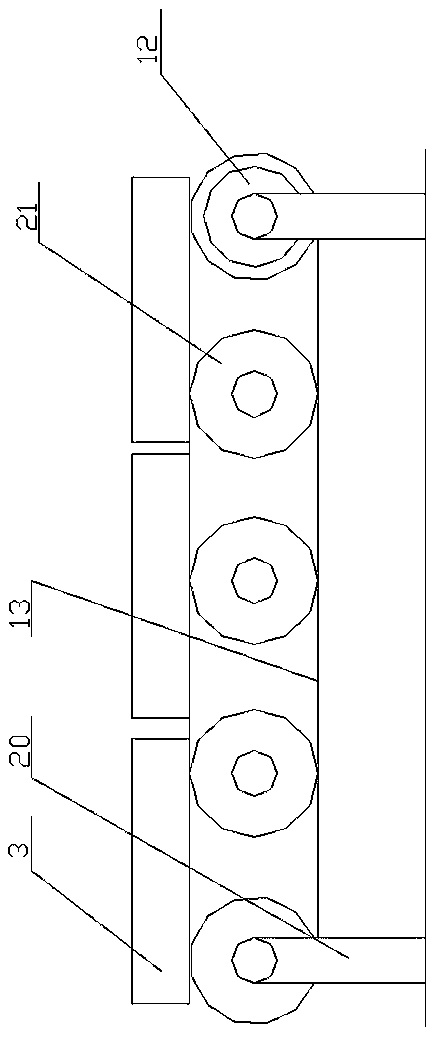

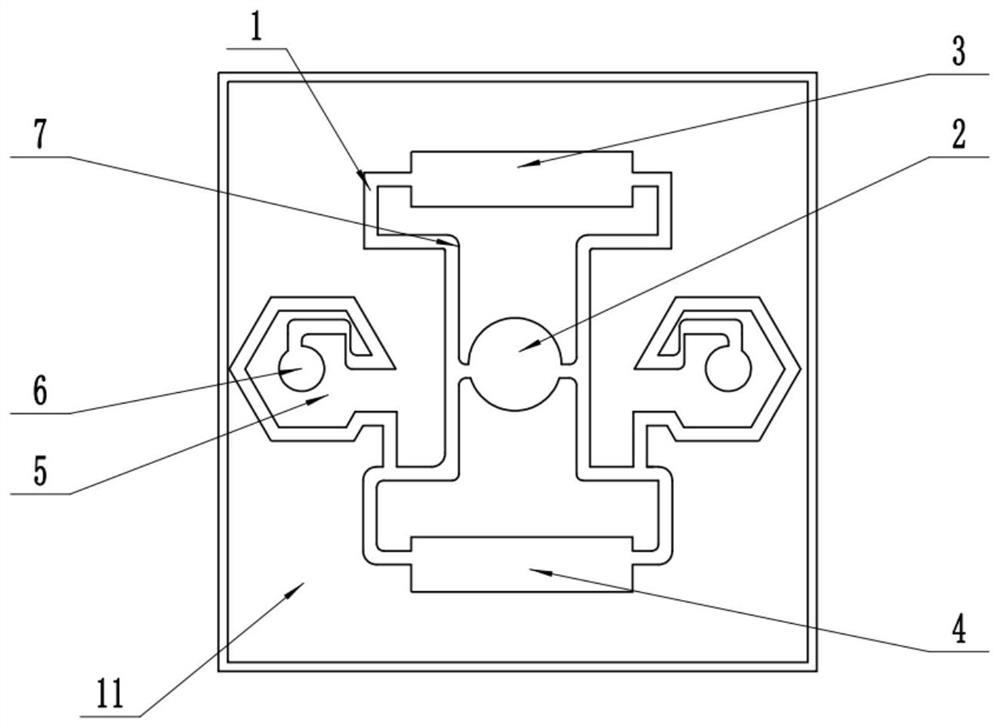

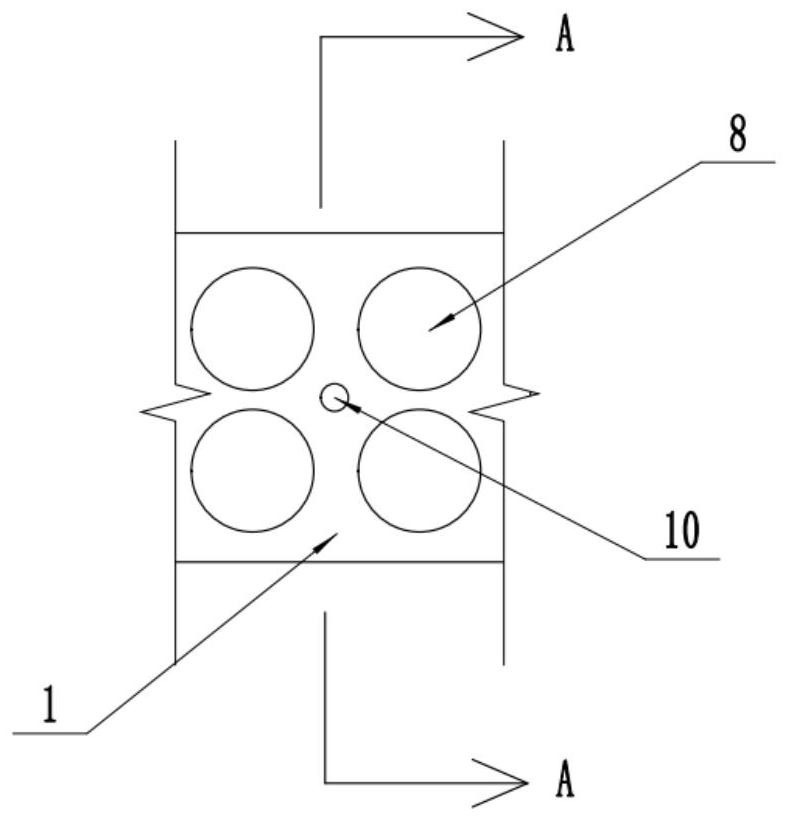

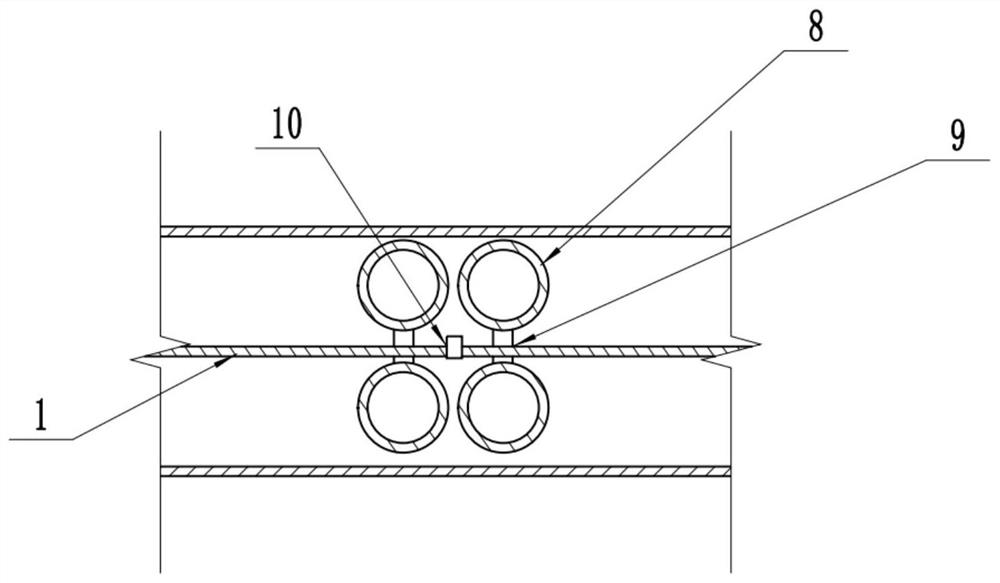

The invention provides a cable laying device, and belongs to the field of construction mechanical equipment. A roller connecting rod is connected with a first base device. The first base device is connected with a cable conveying device through a slideway connecting frame. A slide block is connected with a third connecting shaft. The slide block is arranged in the slideway of the slideway connecting frame. A hydraulic elevating roller device is installed on the cable conveying device. A third motor is installed on the cable conveying device. Vehicle wheels and wheel frames are connected through wheel axles to be installed on the cable conveying device. A fifth connecting shaft is connected with two vehicle wheels to be installed on the cable conveying device. The third motor drives the fifth connecting shaft to rotate through a second belt. A baffle plate is connected with a side connecting plate. A connecting rod frame is installed on the side connecting plate. A first roller is connected on the side connecting plate through a first connecting shaft. The connecting rod frame is connected with the roller connecting rod.

Owner:兴能电力建设有限公司

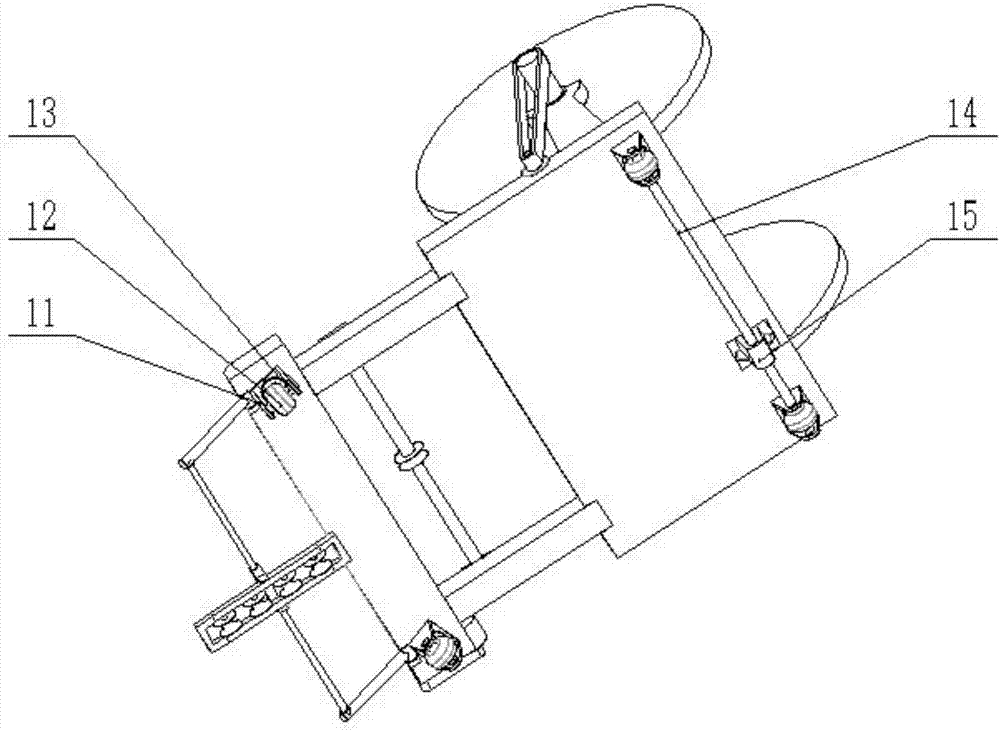

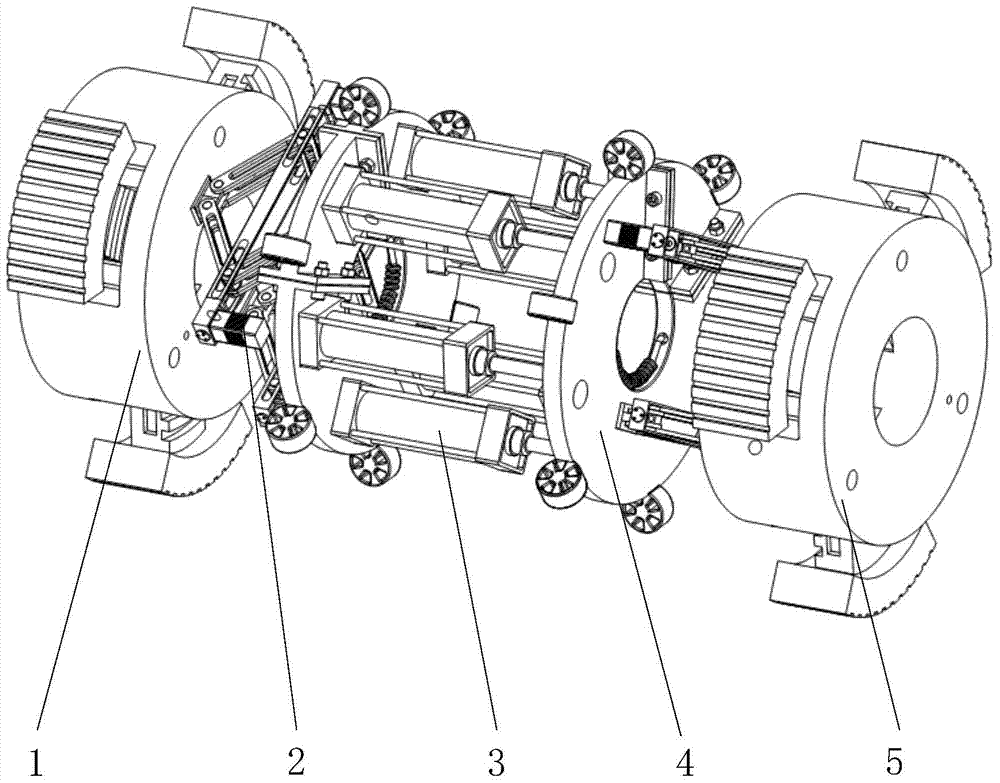

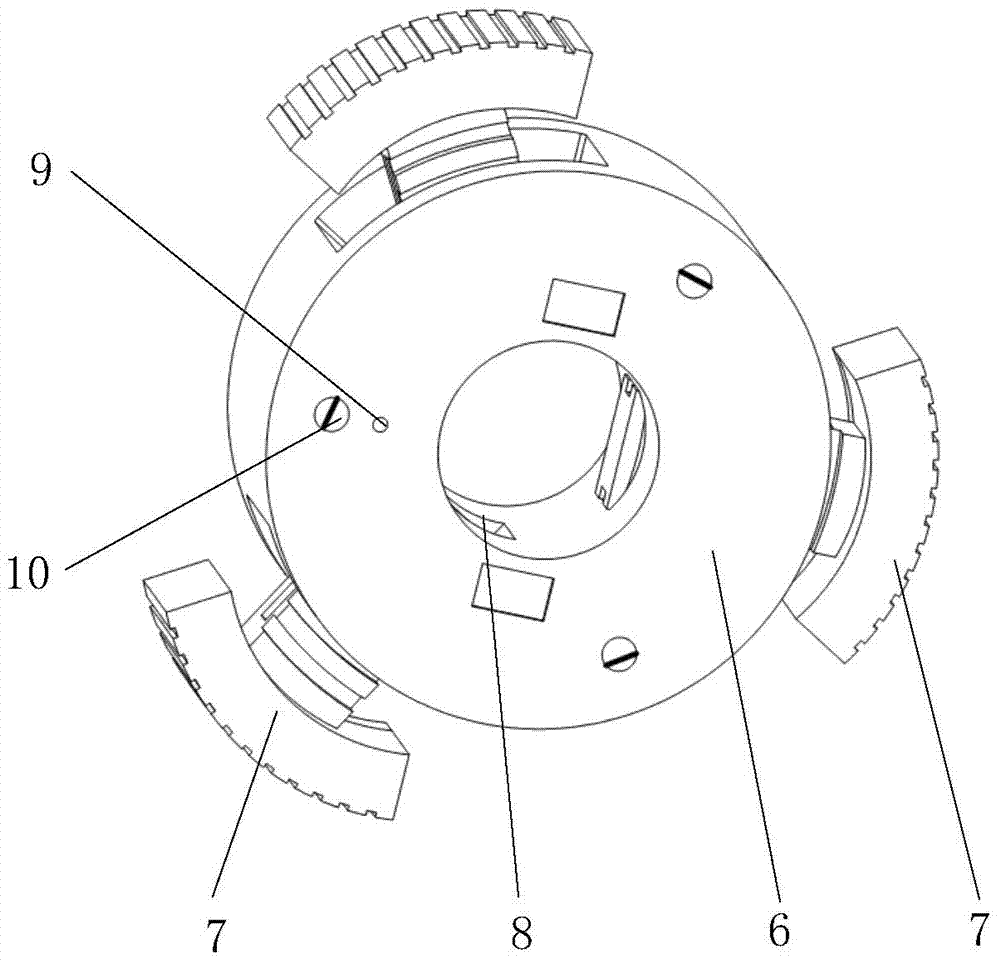

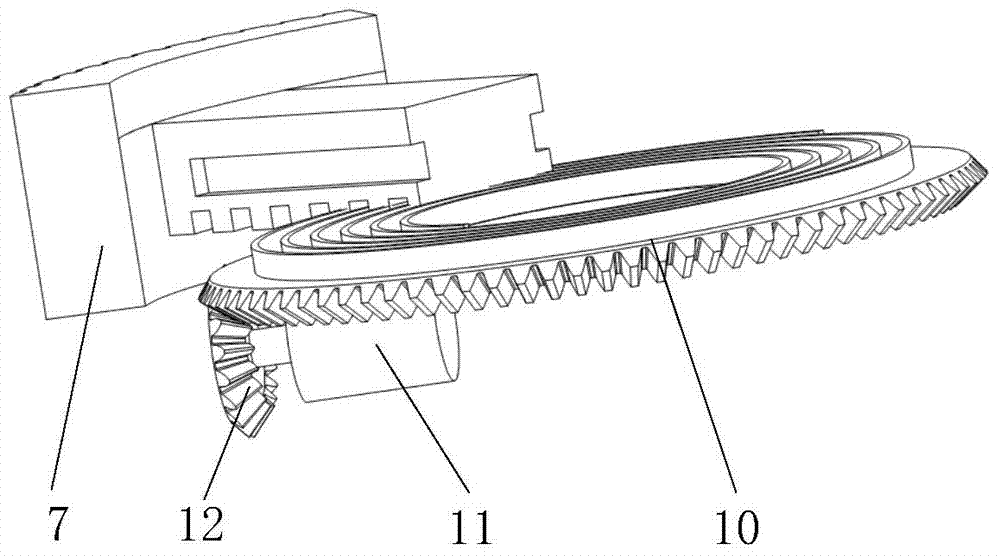

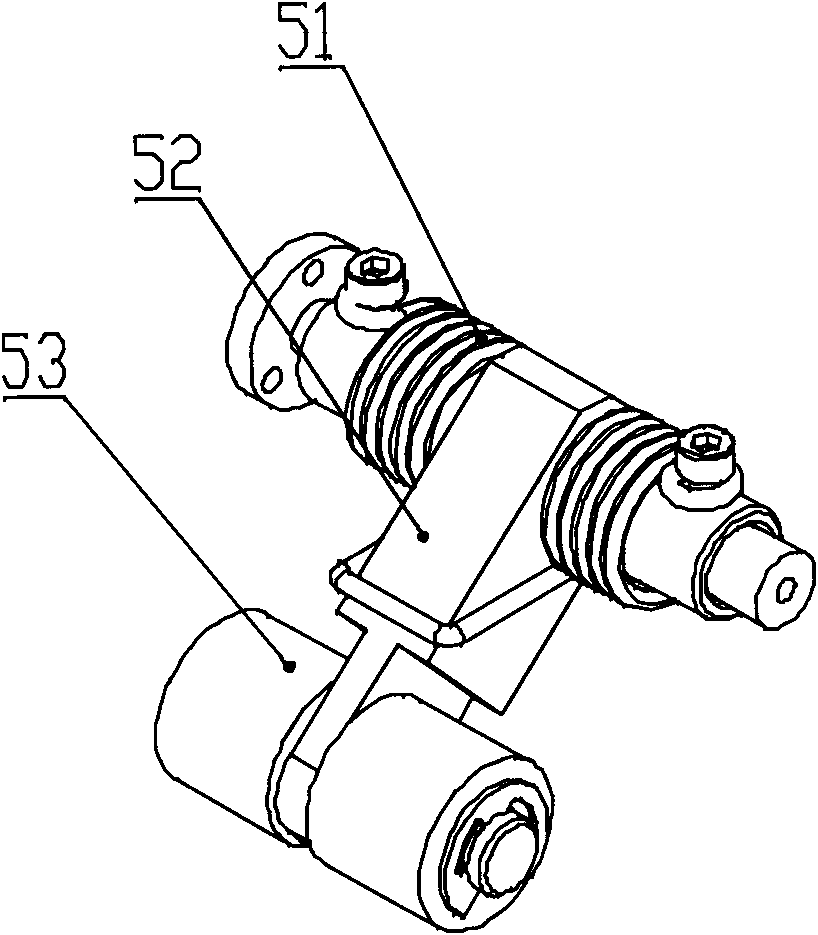

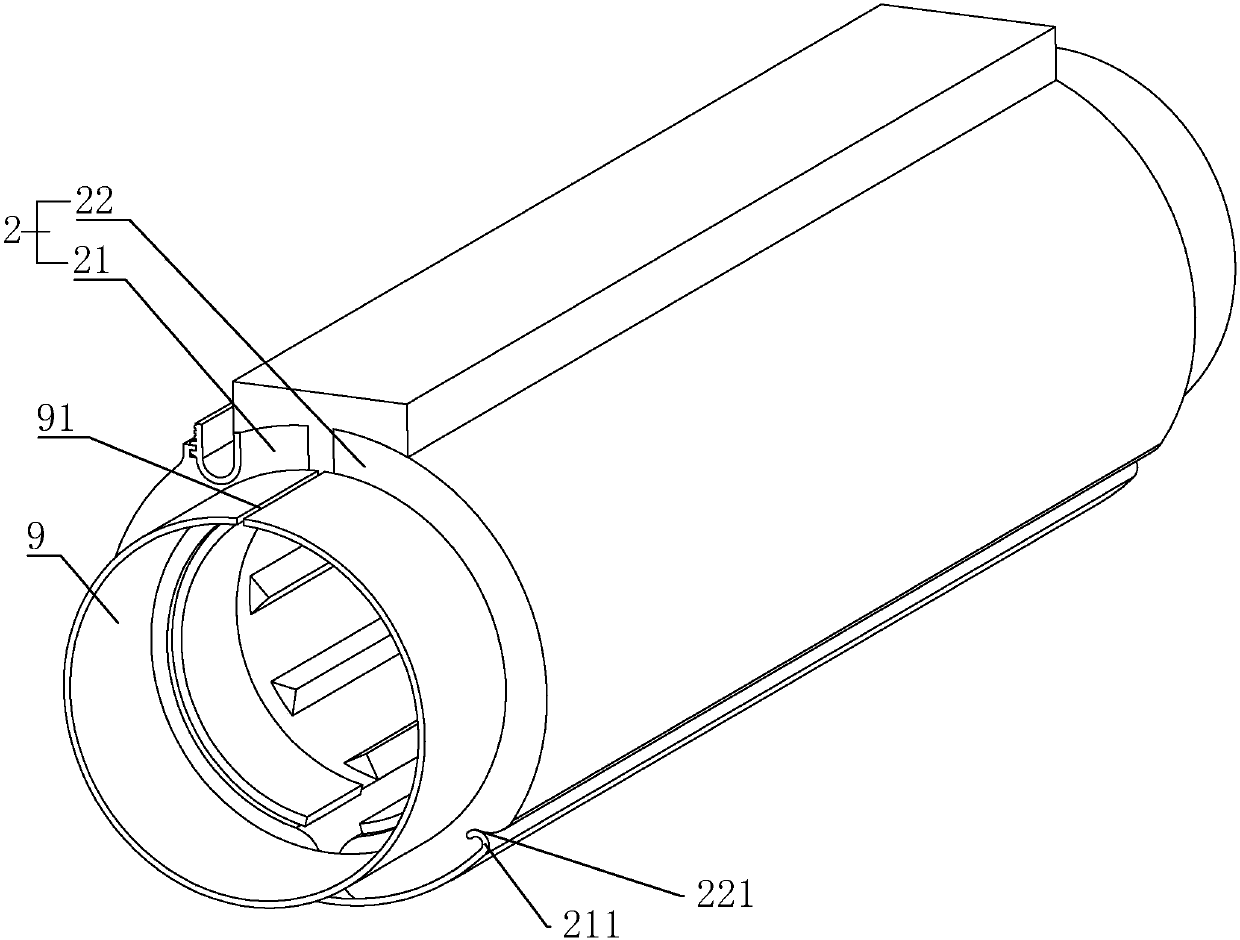

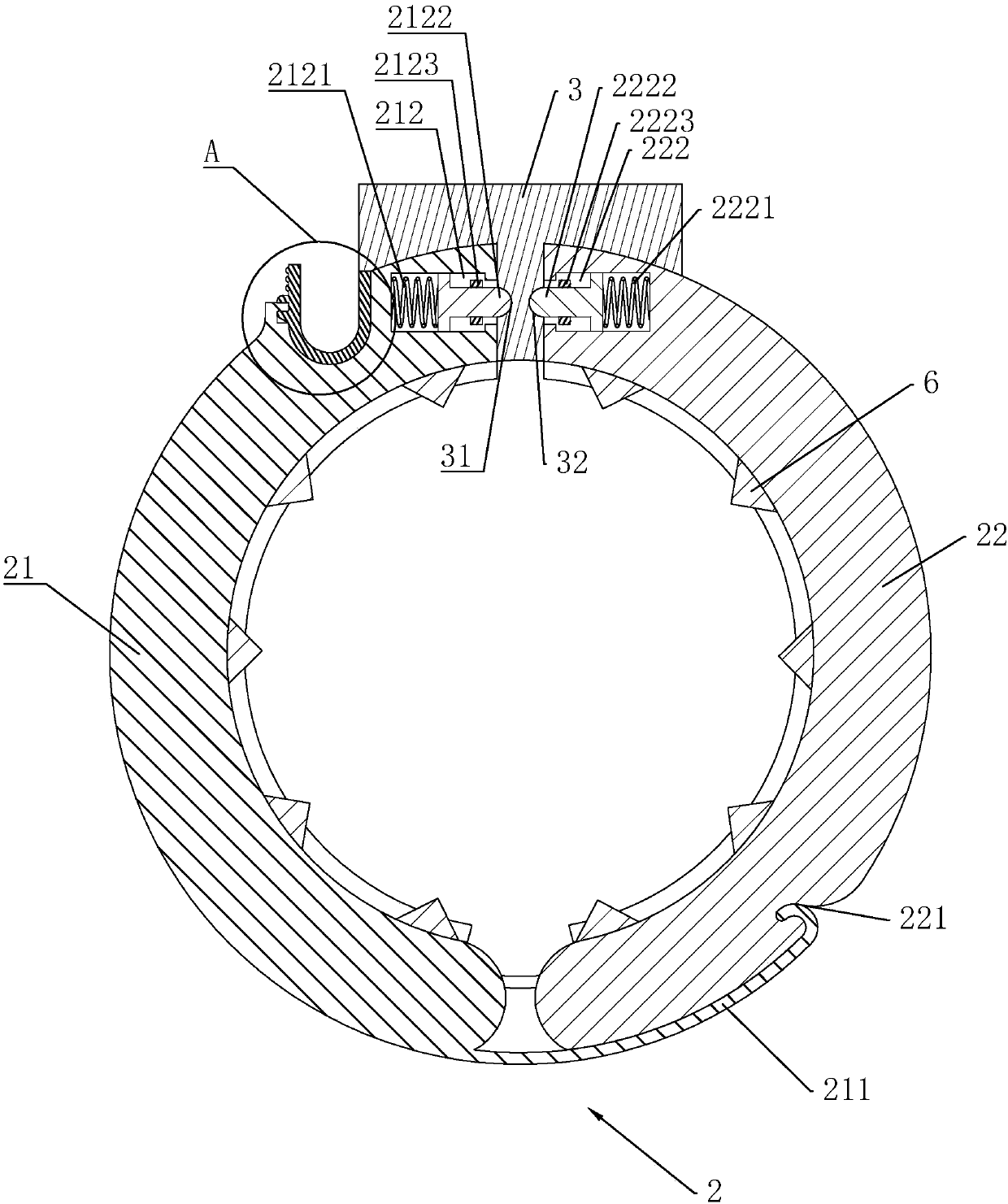

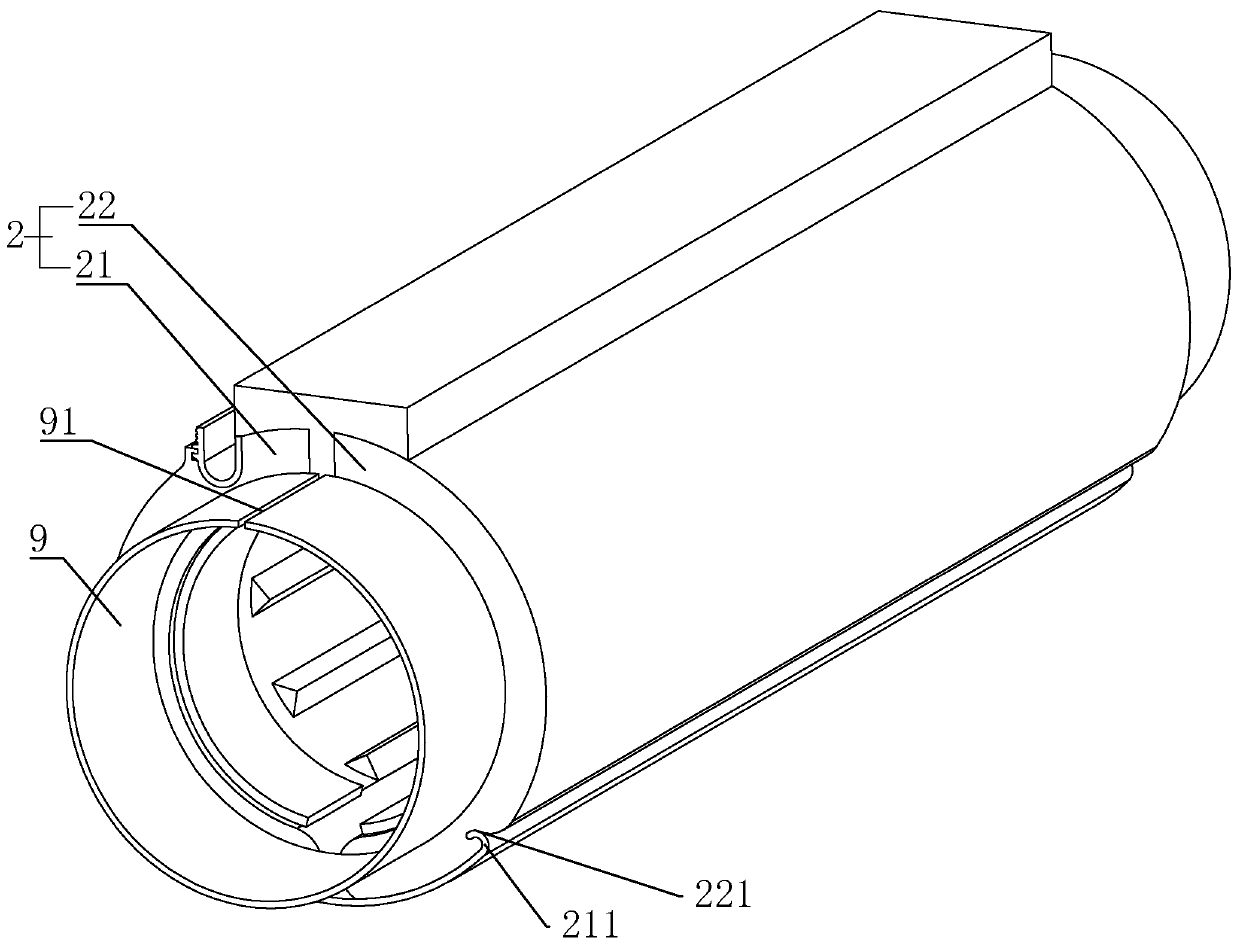

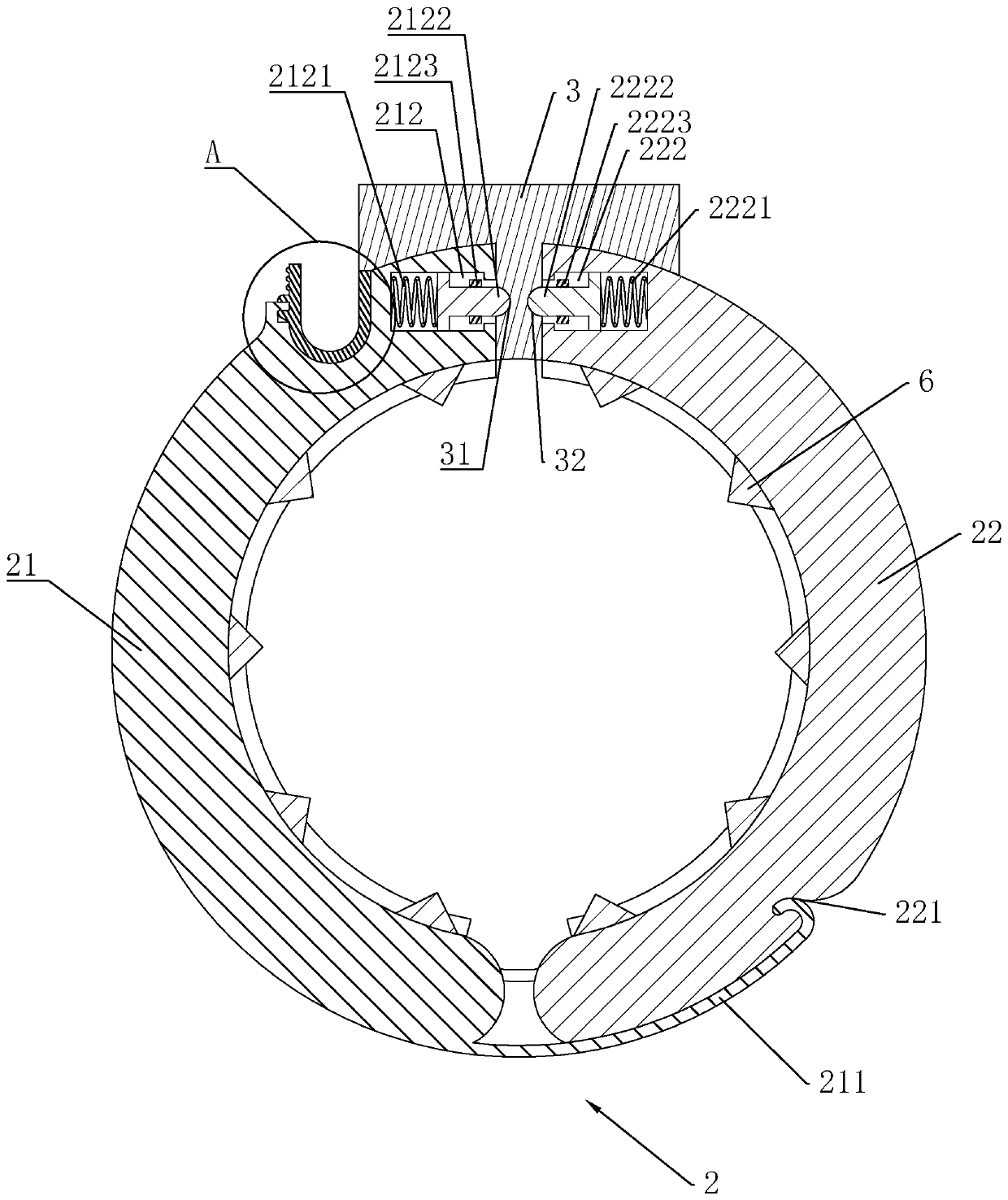

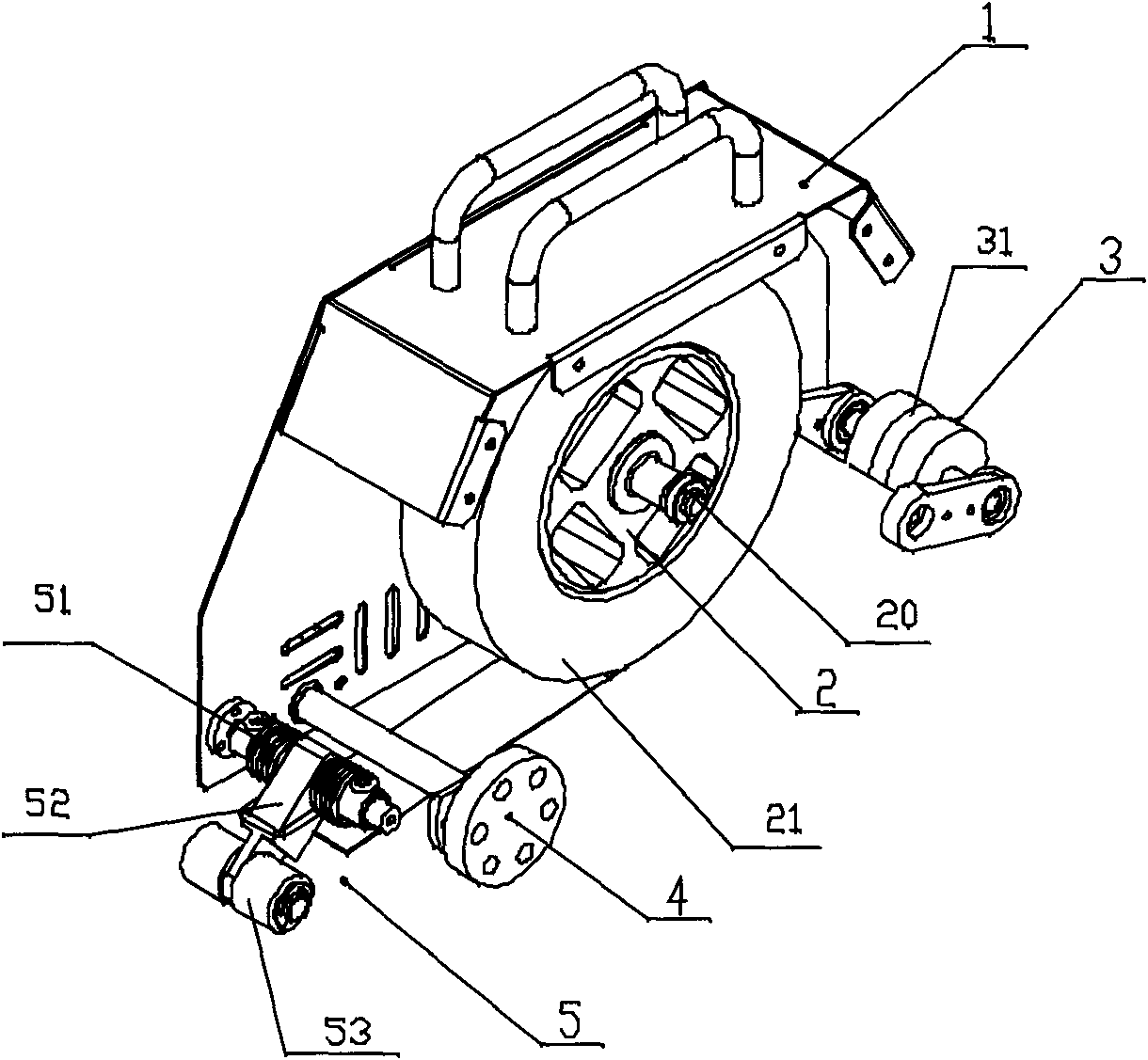

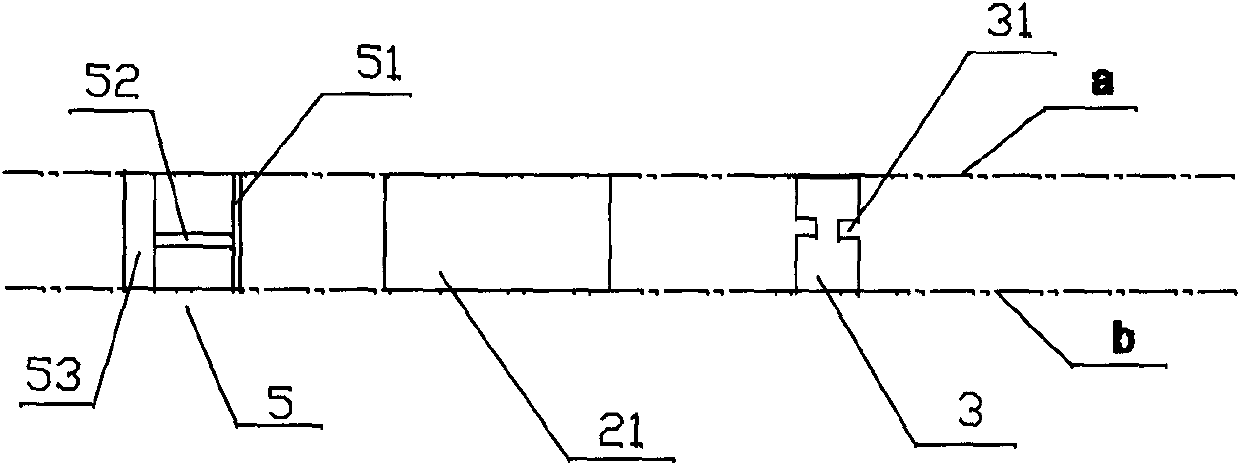

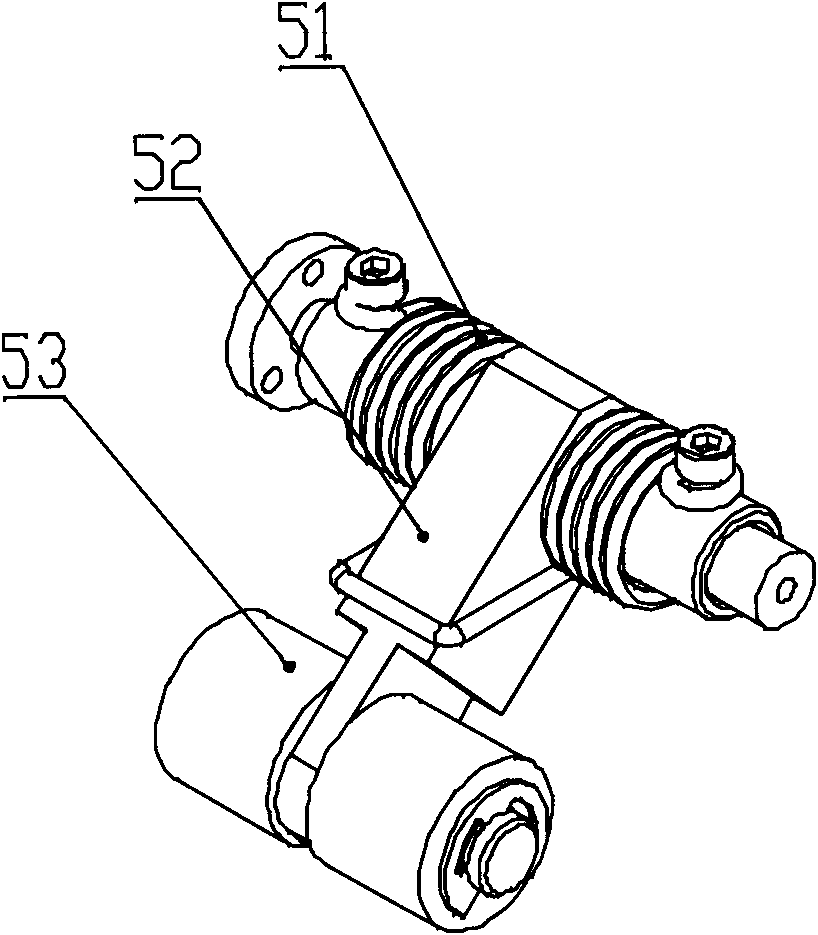

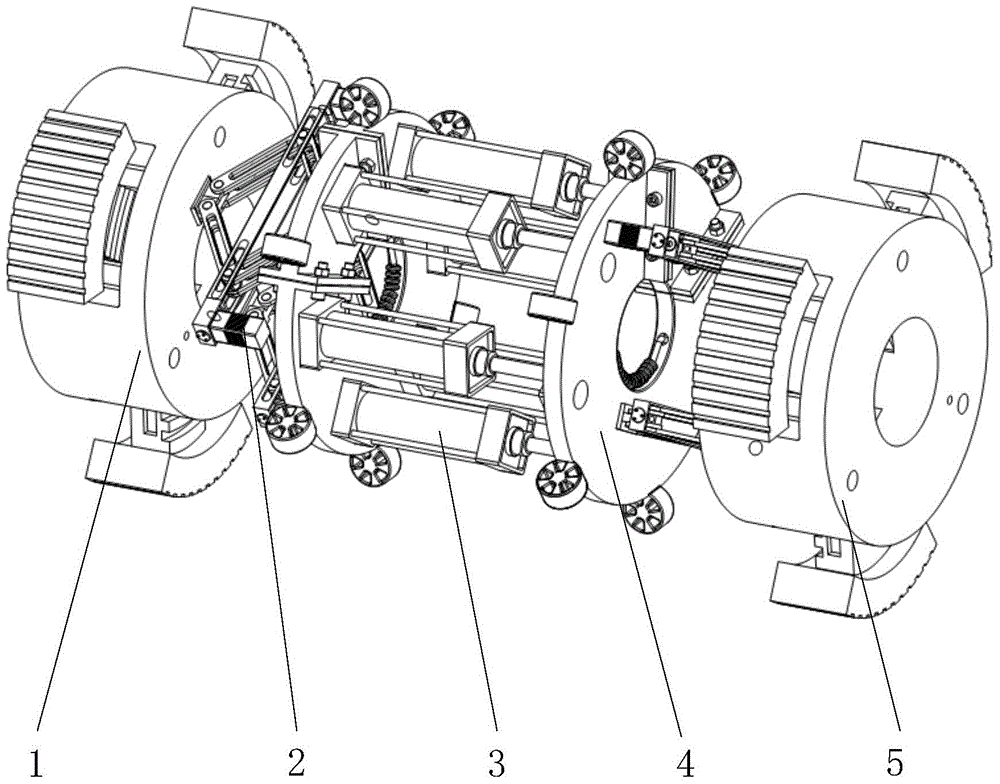

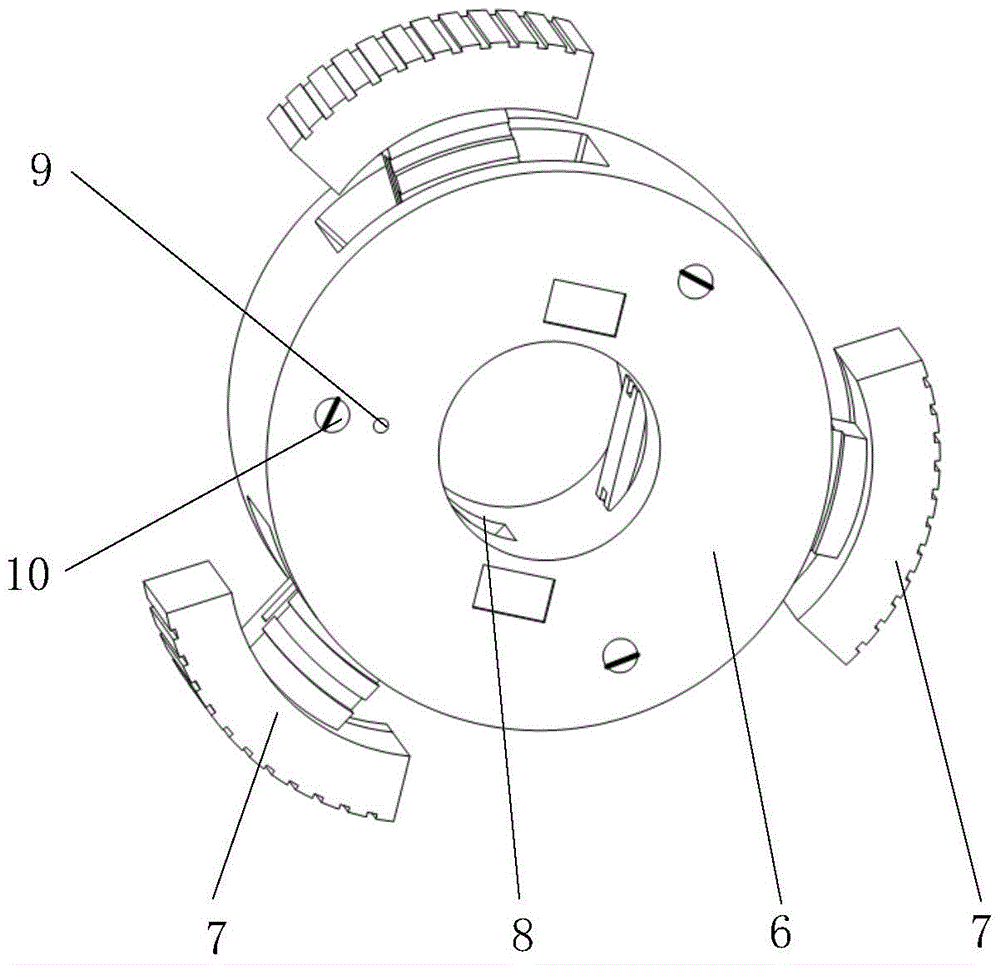

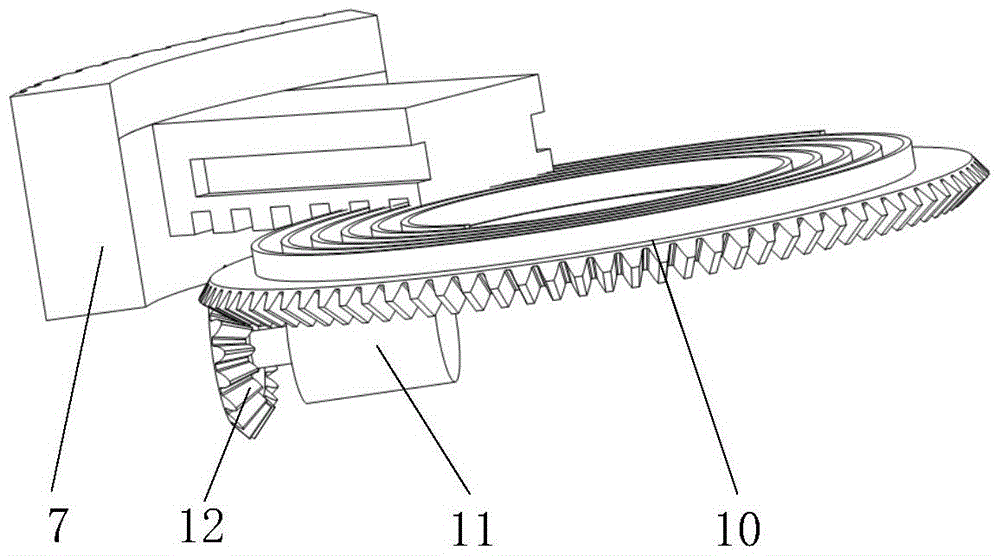

Cable laying robot

ActiveCN104779558AThe process is simple and convenientSimple structureApparatus for laying cablesEngineeringElectrical and Electronics engineering

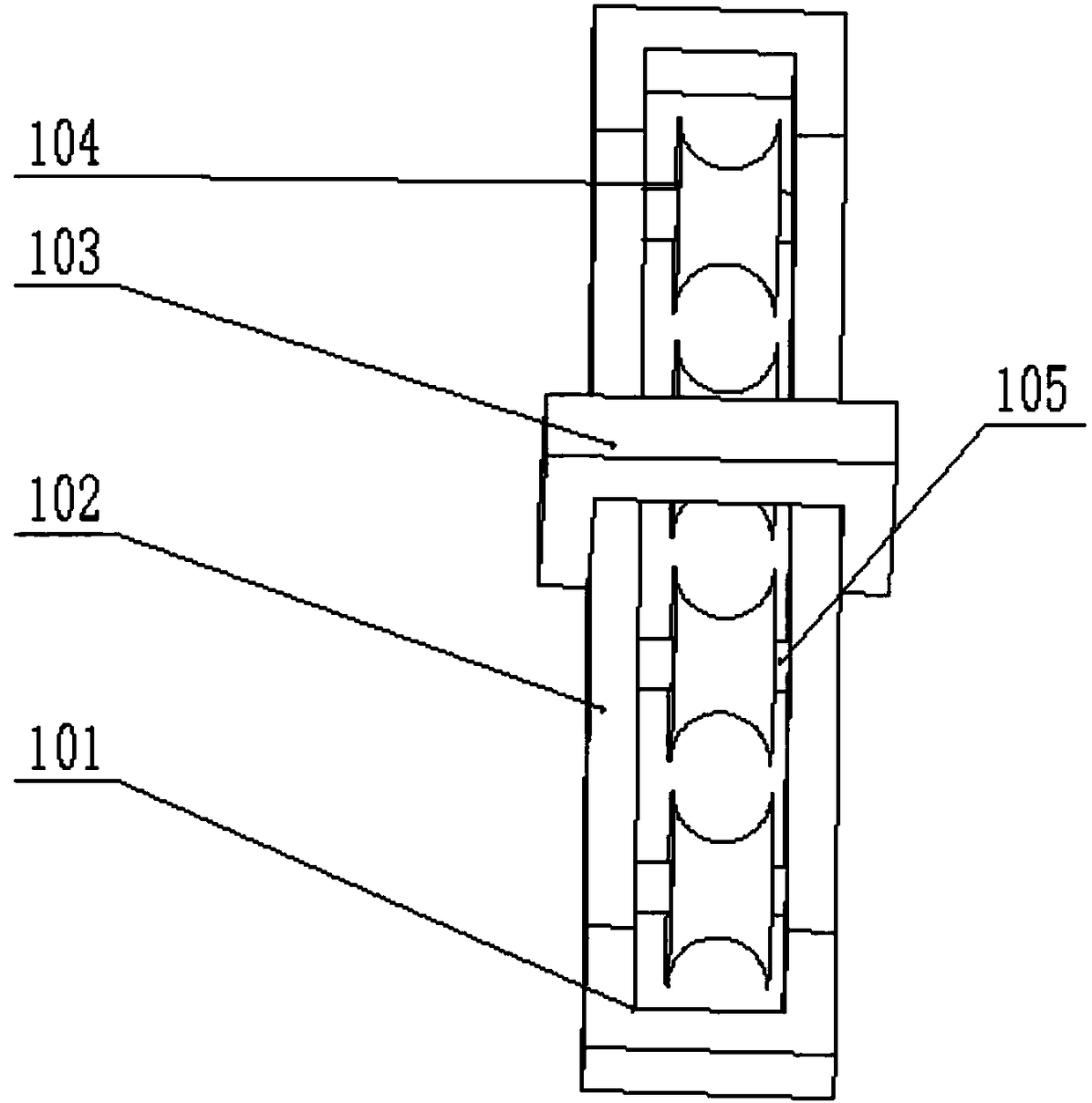

The invention discloses a cable laying robot. The cable laying robot comprises a first top wall mechanism, a first fork shearing push mechanism, a passive type pseudo parallel steering mechanism, a second fork shearing push mechanism and a second top wall mechanism which are connected in sequence, wherein the first top wall mechanism and the second top wall mechanism comprise chuck bodies, top wall supports which are installed on the chuck bodies and can move in an extension mode relative to the radial directions of the chuck bodies and first driving mechanisms, a second driving mechanism used for driving the first fork shearing push mechanism to move in an extension mode relative to the first top wall mechanism is arranged on the first fork shearing push mechanism, the passive type pseudo parallel steering mechanism comprises two subdivision chassis which are arranged oppositely and a steering mechanism, the subdivision chassis are arranged outside a cable in a sleeved mode, and a third driving mechanism used for driving the second fork shearing push mechanism to move in an extension mode relative to the second top wall mechanism is arranged on the second fork shearing push mechanism. The cable laying robot can creep in various pipelines such as a horizontal pipeline, or a vertical pipeline or an inclined pipeline, laying of the cable is achieved, and the cable laying robot cannot be limited by the thickness and the length of the cable.

Owner:WUHAN UNIV OF TECH

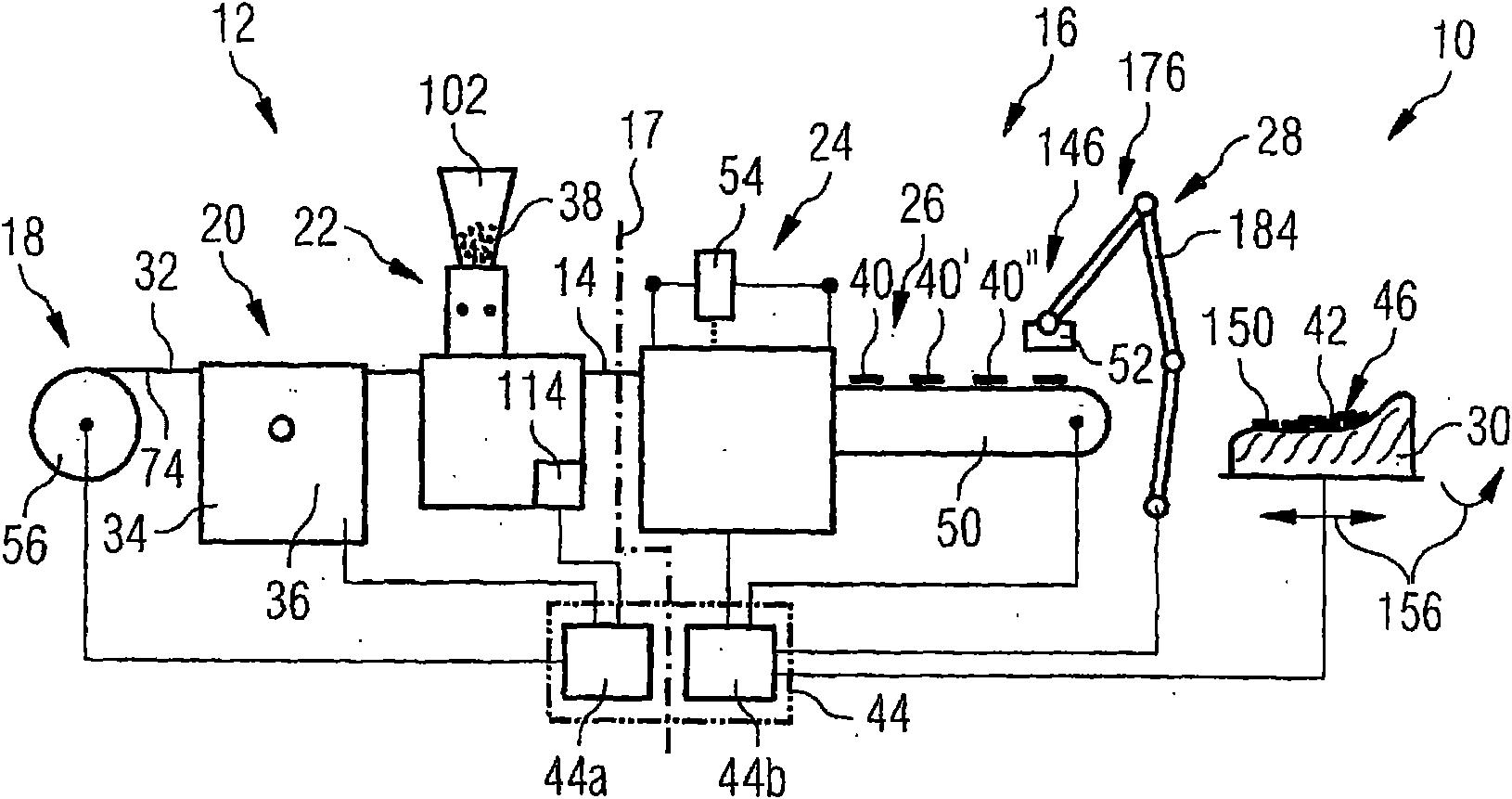

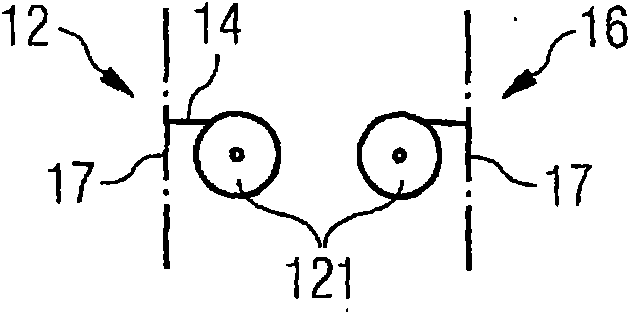

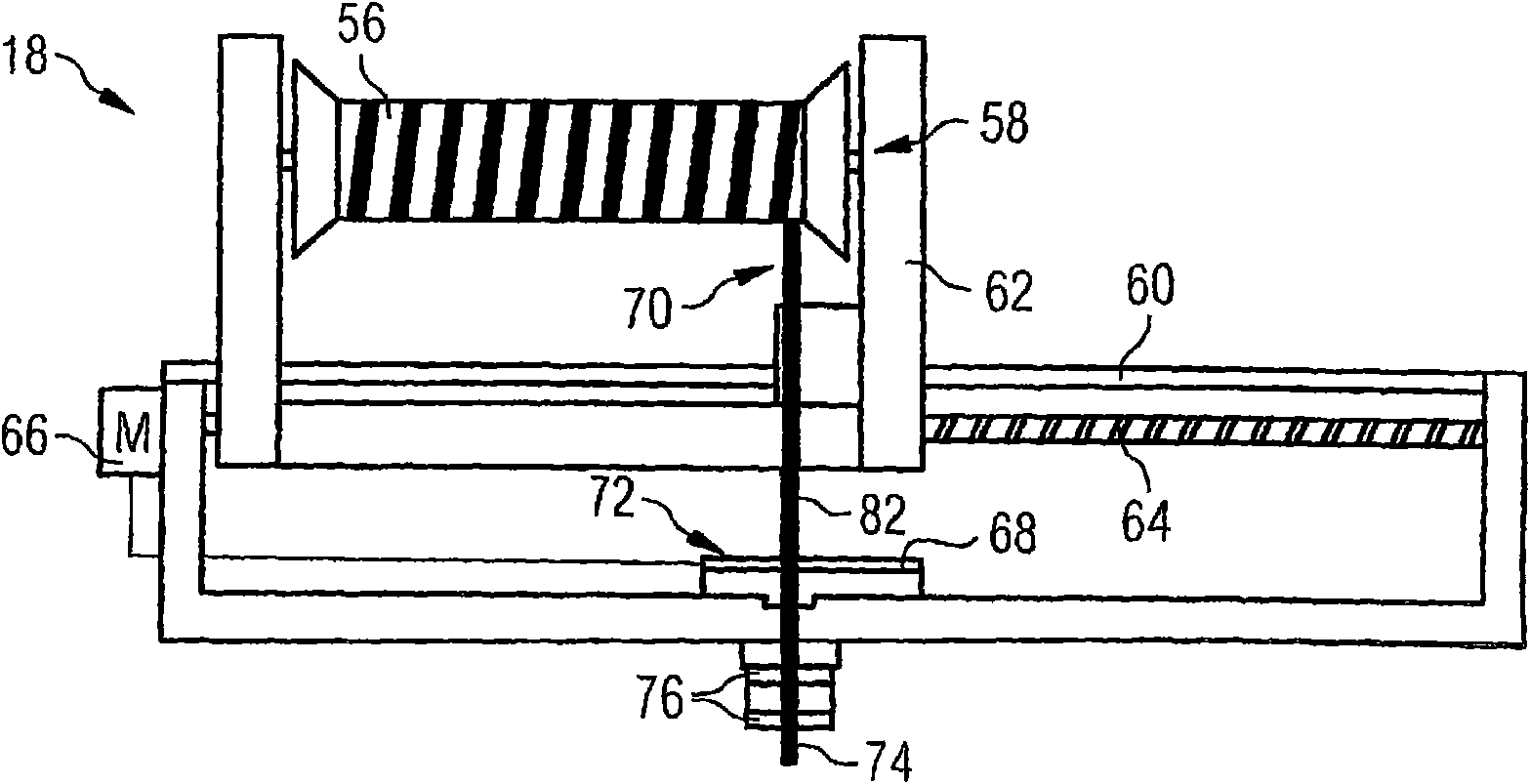

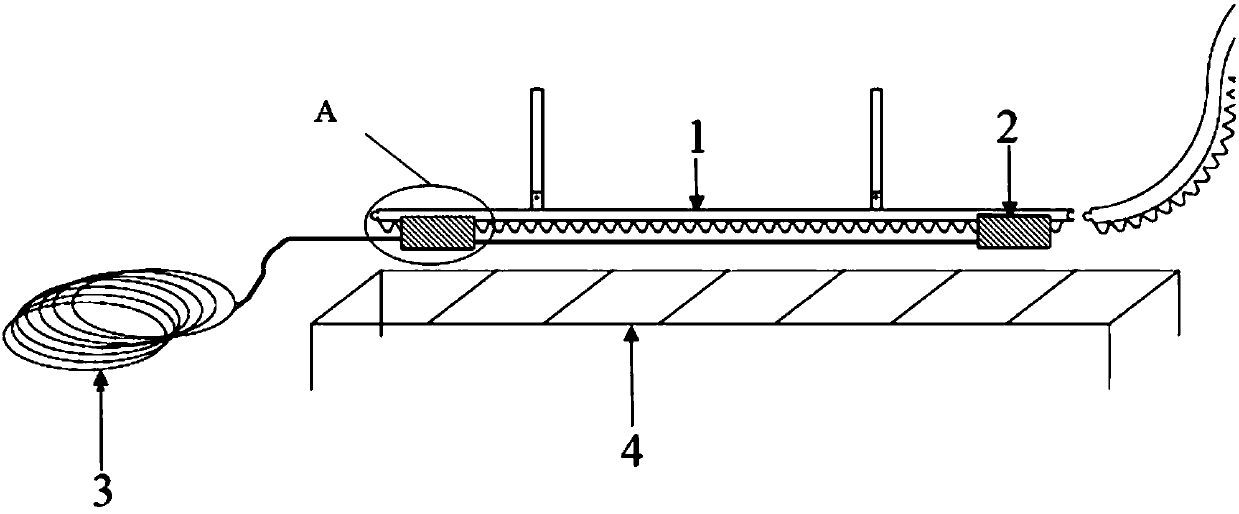

Device and method for laying fibers

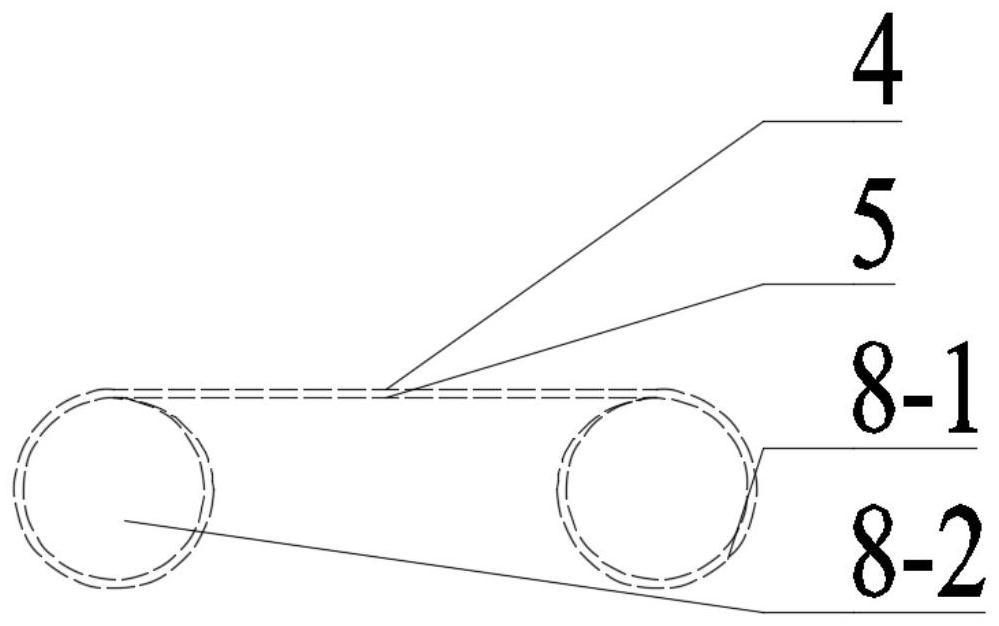

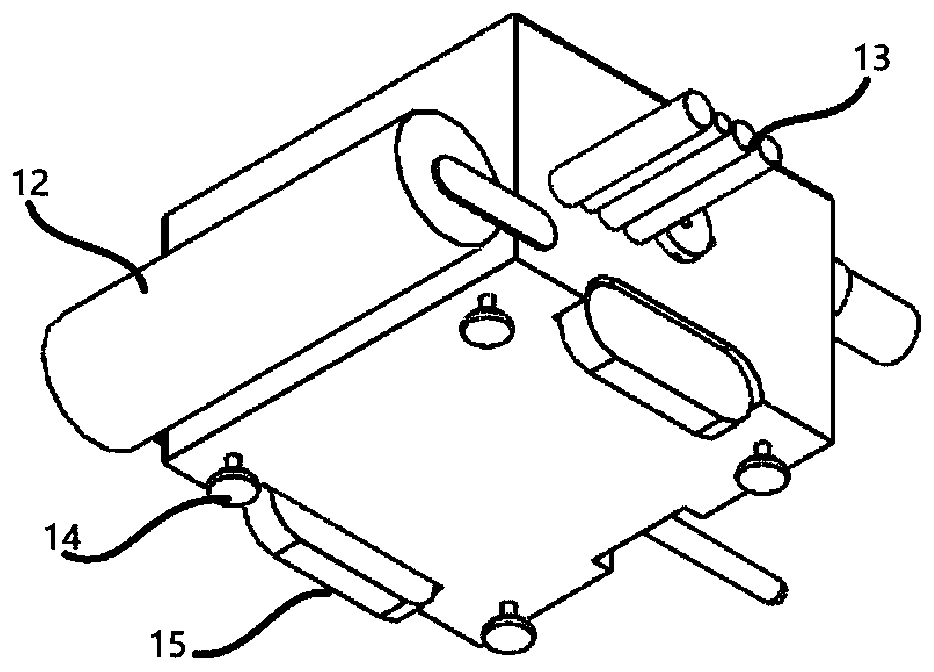

InactiveCN102156339AEasy to carryLaying to achieveThermometers using physical/chemical changesOptical fibre/cable installationFiberIdler-wheel

The invention relates to a device for laying fibers, which comprises a shell, an idler wheel, a gluing module, a limiting module and a compacting module, wherein the idler wheel, the gluing module, the limiting module and the compacting module are all arranged on the shell; the gluing module can rotate around a core shaft and is used for assembling an adhesive tape roll and placing fibers stuck and covered by the adhesive tape; the core shaft is vertical to the moving direction of the device for laying fibers in construction process; the limiting module has a limiting structure which is used for restraining the fibers and positioning the fibers at the position capable of being stuck and covered by the adhesive tape; the compacting module is used for applying force to the adhesive tape sticking and covering the fibers; and the idler wheel is arranged on the bottom of the device for laying fibers and is used for moving the device for laying fibers in a rolling manner. The invention alsoprovides a method for laying fibers. The device and method provided by the invention have the advantages that the construction efficiency is high, the laid fibers are beautiful, the maneuverability is high, the device is portable, and the like.

Owner:FOCUSED PHOTONICS

Spreading device for spreading out fibre filament bundles, and spreading method carried out using same

The invention relates to a spreading device (20) and a spreading method for spreading out fibre filament bundles (32) to form a flat fibre band (14). Problems relating to the material quality of fibrefilament bundles (32) to be spread out are solved by repeatedly exposing the fibre filament bundle (32) to at least one convex spreading edge (80).

Owner:EADS DEUT GMBH

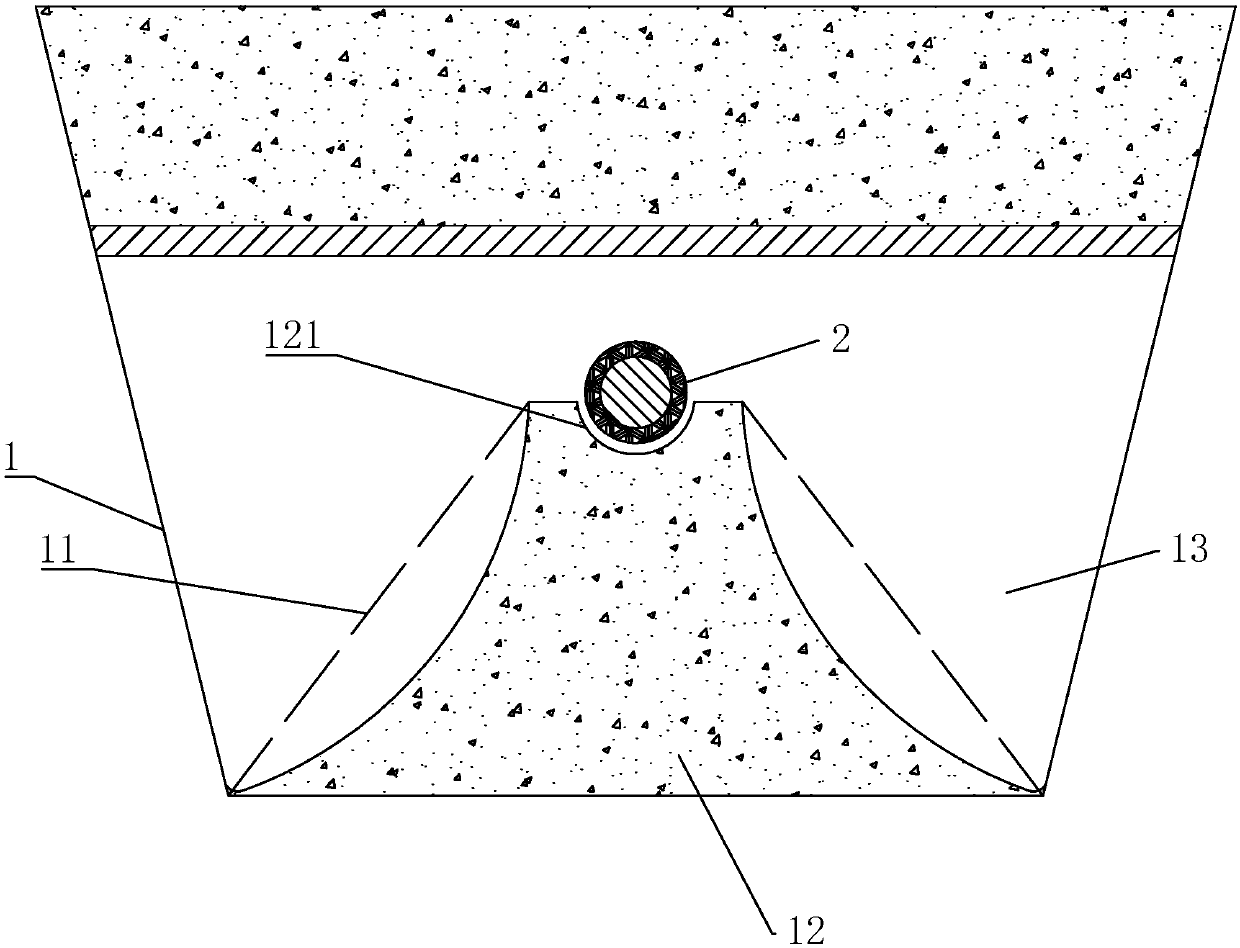

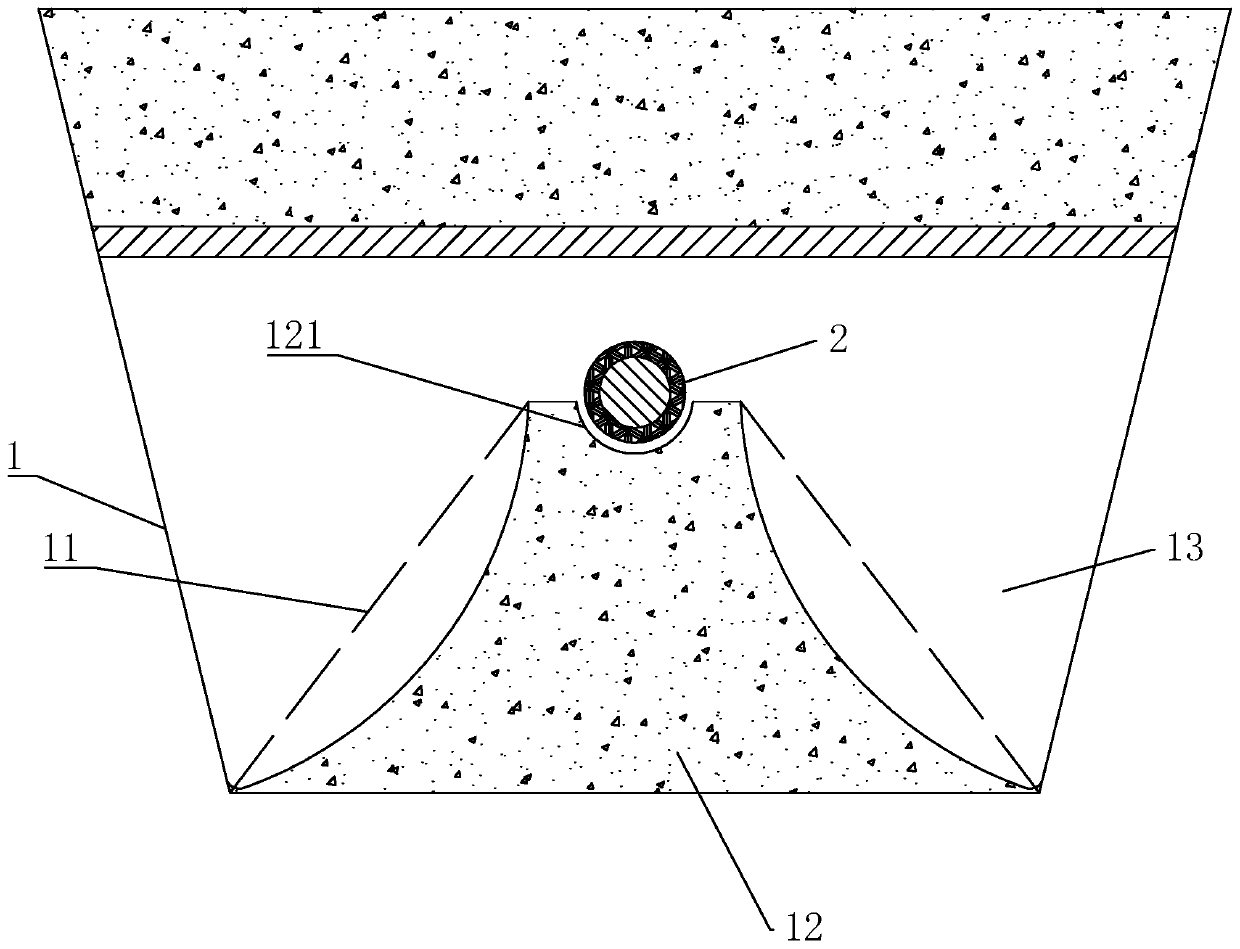

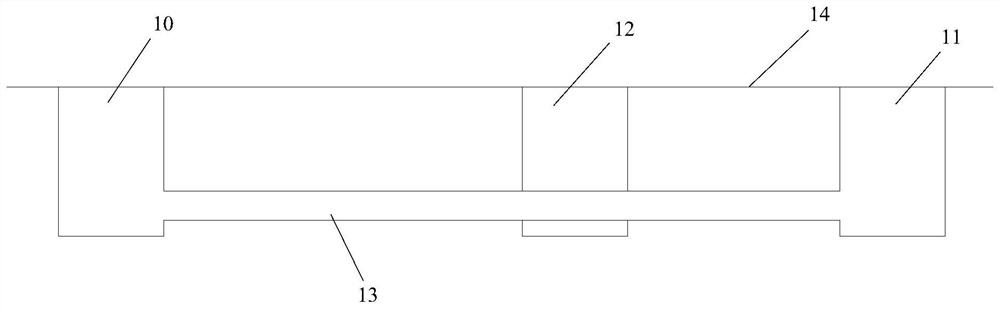

Buried cable laying method and cable protection sleeve special for method

ActiveCN108565785AEnhance storage and drainage capacityExtended service lifeCable installations in underground tubesApparatus for laying cablesDirect-buried cableEngineering

The invention discloses a buried cable laying method and a cable protection sleeve special for the method and belongs to the field of cable laying. According to the buried cable laying method, by improving the water storage and drainage capacity of a cable groove, the cable protection sleeve is not easily in contact with accumulated water, and accordingly the problem is solved that the cable protection sleeve swells and deforms when being soaked in the accumulated water. The buried cable laying method is characterized by comprising the following steps of S1, engineering line repetition measurement of a cable line; S2, disk distribution for a cable; S3, cable laying; S4, backfill of the cable groove; S5, burying of stakes. The third step comprises the following specific processes of 3-1, digging of the cable groove, wherein foundation pits are dug, stacks are formed, rough shaping and fine shaping are conducted, and the cable groove is poured and formed; 3-2, cable laying, wherein manual cable laying is conducted, the cable is laid at one side of the cable groove, and the cable protection sleeve wraps the cable; a specially-assigned person straightens out the cable and puts the cable into the cable groove. The buried cable laying method is suitable for buried cable laying.

Owner:中铁十五局集团电气化工程有限公司

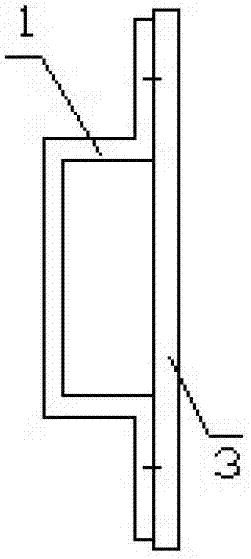

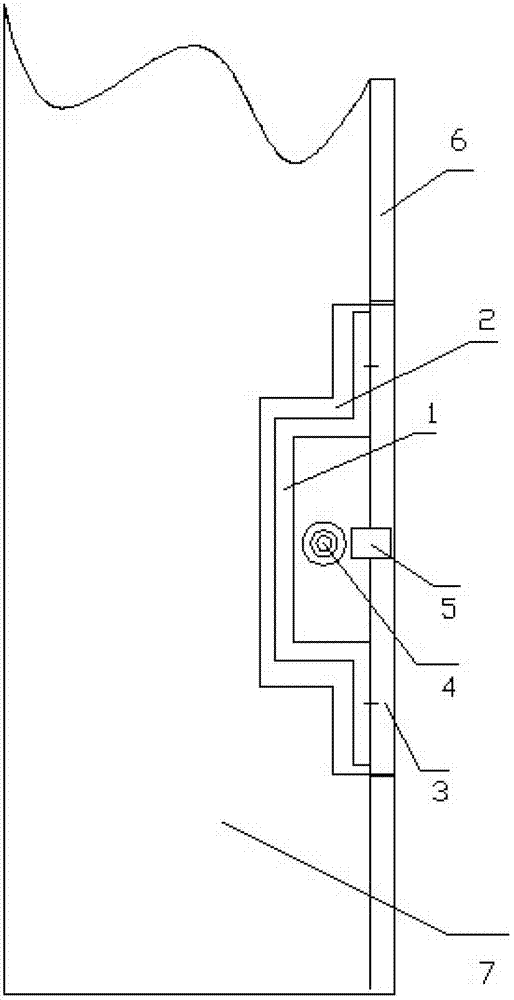

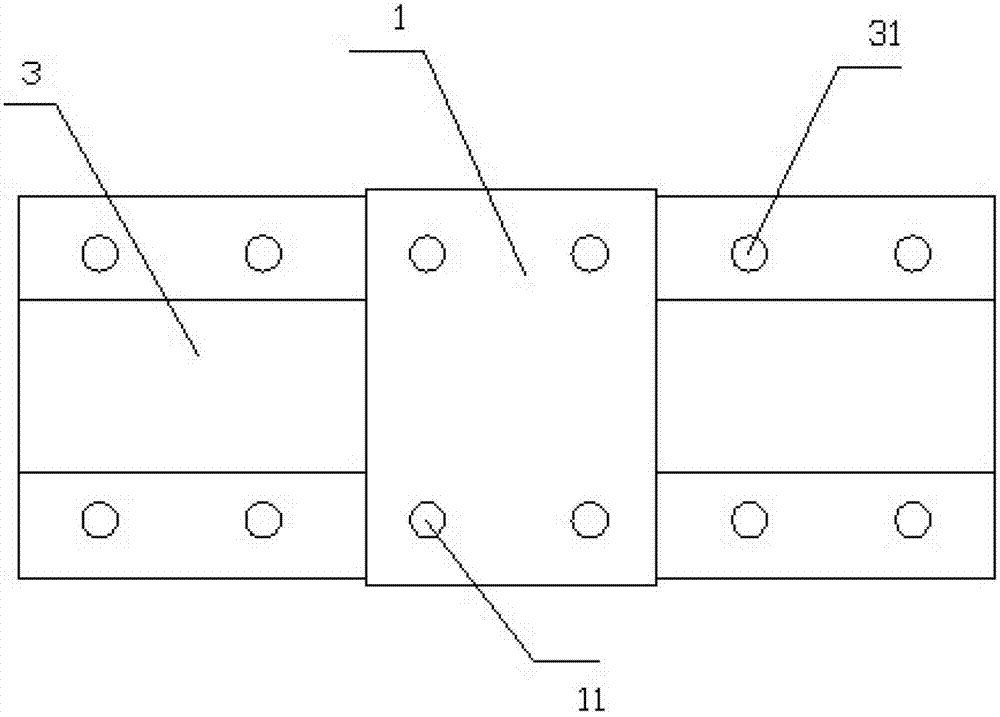

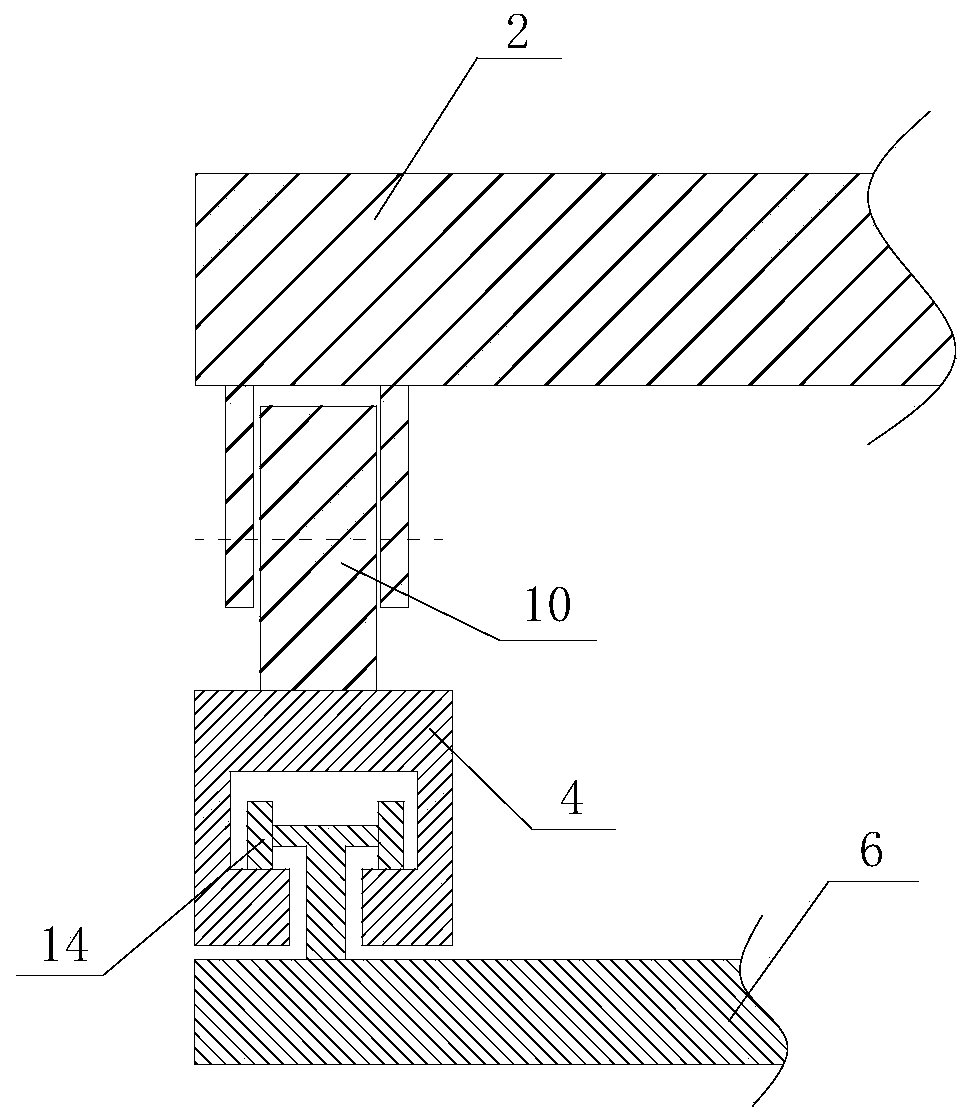

Installation device for wall hidden pipeline

The invention discloses an installation device for a wall hidden pipeline, belonging to the field of an installation device for a pipeline. The installation device comprises a fixed frame and an outer sealing plate which is matched with the fixed frame, wherein a convoluted part is arranged between folding plates on the two sides of the fixed frame; and the fixed frame is connected with the outer sealing plate by the folding plates on the two sides. The installation device has the advantages that: in the using process, a groove which is matched with and is used for installing the fixed frame is presrved or dug in the wall body; the fixed frame is arranged inside the groove for paving the pipeline inside the fixed frame; and the outer sealing plate is used to seal the outer surface of the fixed frame; the pipeline is sealed, so that the outer sealing surface of the outer sealing plate and the outer wall are kept in the same plane. The installation device can directly achieve the pavement of the hidden pipeline; in a maintaining process, the wall and the ground are not needed to be dug, and anti-leakage maintenance for the pipeline can be directly carried out only by opening or taking down the outer sealing plate; and besides, the installation device is economical and practical, and convenient to operate.

Owner:胡智慧 +1

A cable laying device

ActiveCN106972418BStable deliveryLaying to achieveApparatus for laying cablesEngineeringMechanical equipment

Owner:兴能电力建设有限公司

Shallow-buried type drip irrigation laying device

PendingCN109392664ALaying to achieveImprove laying efficiencyClimate change adaptationWatering devicesDrip irrigationEngineering

The invention discloses a shallow-buried type drip irrigation laying device. The device includes a laying frame; at least one set of laying sub-devices is distributed in the width direction of the laying frame; each laying sub-device successively includes a drip irrigation belt erector, a drip irrigation belt guide pulley and a furrow device; each furrow device includes a hollow pipe and a plow head; and the lower end at the internal of each plow head is provided with at least one drip irrigation belt conveying wheel. In the device, drip irrigation belts wound on the drip irrigation belt erectors bypass the guide pulleys to enter the hollow pipes, and the hollow pipes are connected to the plow heads; the drip irrigation belts pass through the hollow pipes to enter the plow heads, wind on the drip irrigation belt conveying wheels, and are laid in channels plowed by the plow heads by passing out of the plow heads under the forward driving action of the device and the downward extruding action of the drip irrigation belt conveying wheels. The device can realize the laying of the drip irrigation belts and enhance the laying efficiency of the drip irrigation belts during travelling.

Owner:NINGXIA YINHE STEEL PLASTIC DRIP IRRIGATION EQUIP

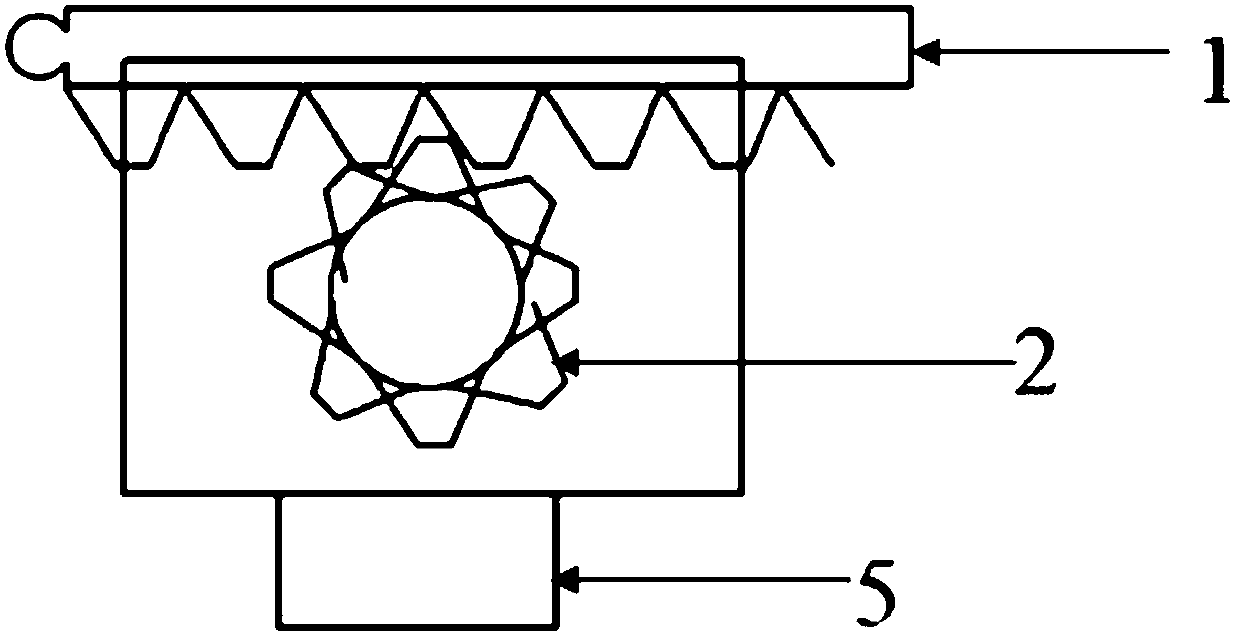

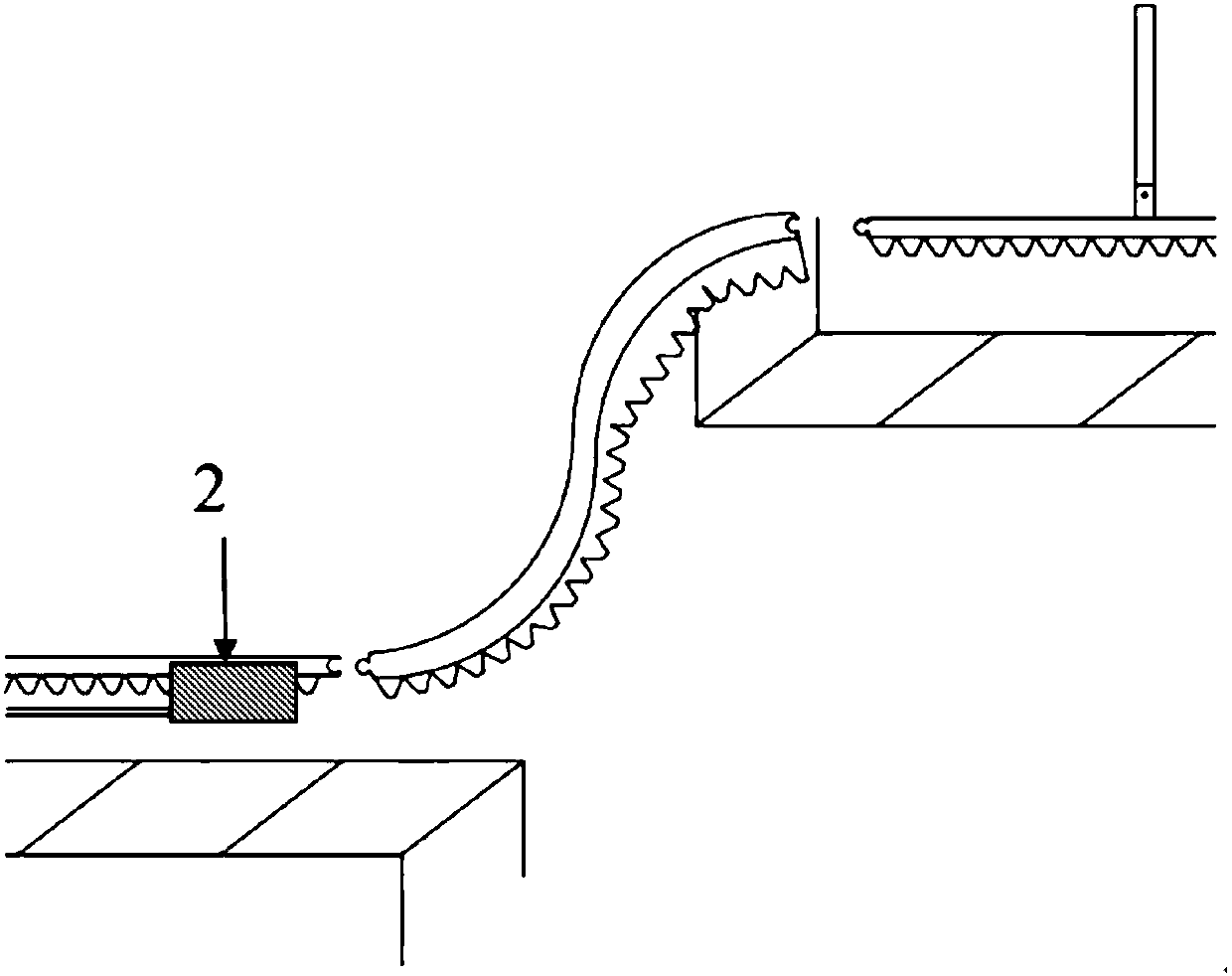

Automatic cable laying equipment and method

InactiveCN107732795AReduce construction costsSimple structureApparatus for laying cablesControl systemEngineering

The invention provides automatic cable laying equipment and method. The automatic cable laying equipment comprises at least two traction motors, a cable guide rail, a cable clamp and a control system,wherein a traction gear is arranged on an output shaft of the traction motor, a rack is arranged on the lower surface of the cable guide rail, the rack is meshed with the traction gear, the cable clamp is arranged below the traction motor, and the cable clamp is connected with the control system; the cable guide rail is composed of a plurality of guide rail sections, a groove is formed in one endof each guide rail section, and the other end of each guide rail section is provided with a protrusion matched with the corresponding groove. The laying method comprises the step of installing the cable guide rail, the step of driving a cable to move through the traction motor, and the step of loosening the cable clamp to make a bracket fall. Compared with the prior art, the automatic laying equipment is of a simple structure, and the laying method has the advantages of being simple and convenient to operate and the like.

Owner:FUJIAN MAWEI SHIPBUILDING

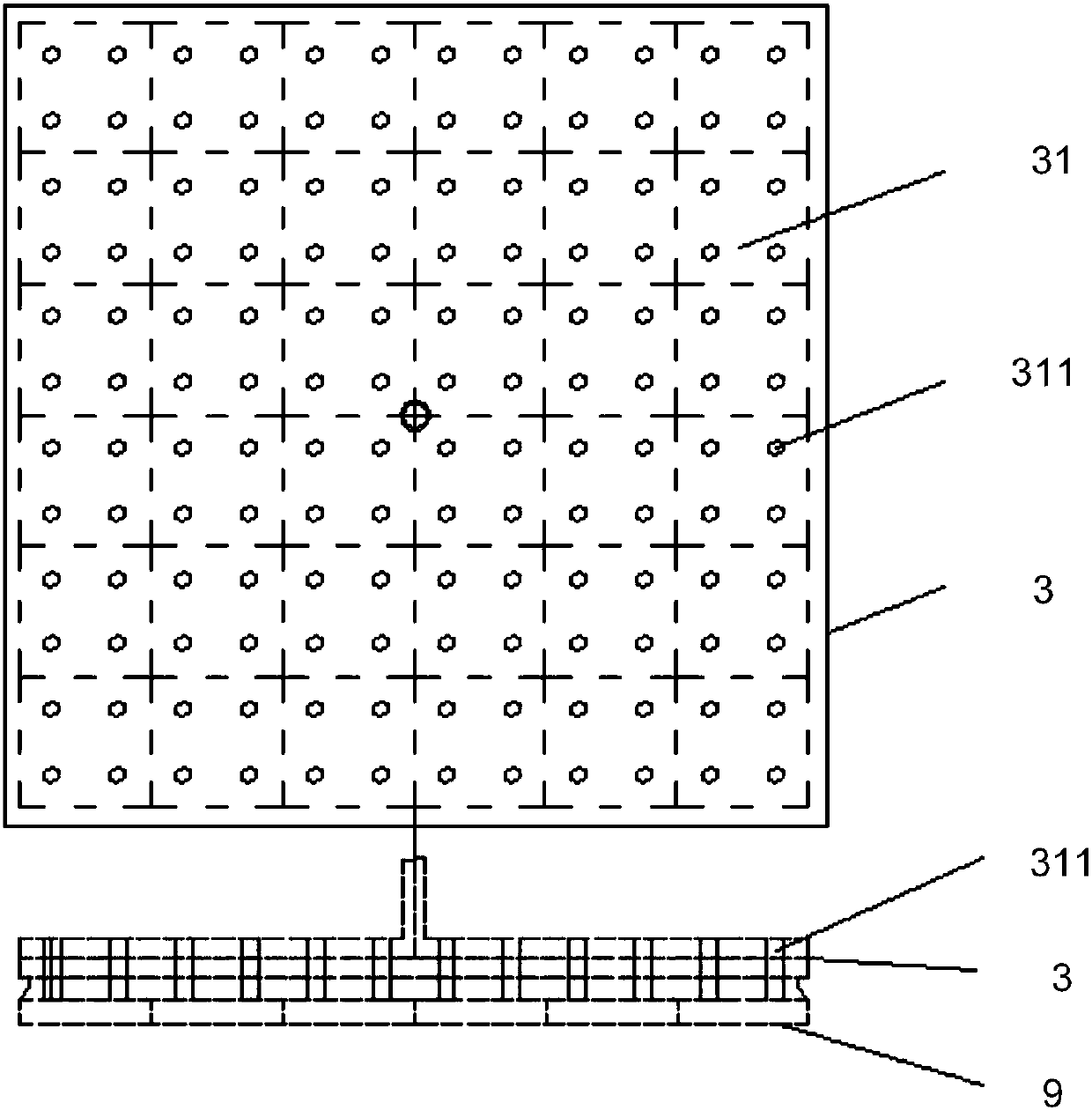

Mono-like seed crystal laying device and equipment

PendingCN107630250ALaying to achieveReduce the chance of collisionPolycrystalline material growthFrom frozen solutionsCrucibleAir pump

An embodiment of the invention discloses a mono-like seed crystal laying device and system. The mono-like seed crystal laying device comprises a controller, a lifting support, a vacuum sucker, an airpump and an air pipeline, wherein the control end of the controller is connected with the drive end of the air pump and the drive end of the lifting support; the output end of the air pump is connected with the input end of the air pipeline; the output end of the air pipeline is connected with an air port of the vacuum sucker; the air port end of the vacuum sucker is connected with the movable endof the lifting support; multiple sucker areas are formed at the bottom of the vacuum sucker, each sucker area corresponds to a seed crystal, and at least one sucker hole is formed in each sucker area; the controller is used for controlling the lifting support to drive the vacuum sucker to lift or drop, so that seed crystal arrays laid in advance are transferred to the bottom of a crucible by thevacuum sucker, and the seed crystal arrays are laid by multiple seed crystals in a seamless manner. According to the embodiment of the invention, the collision probability of corners of the seed crystals is reduced in the seed crystal laying process, the laying quality and efficiency are higher, and the seamless effect is better.

Owner:JINKO SOLAR CO LTD +1

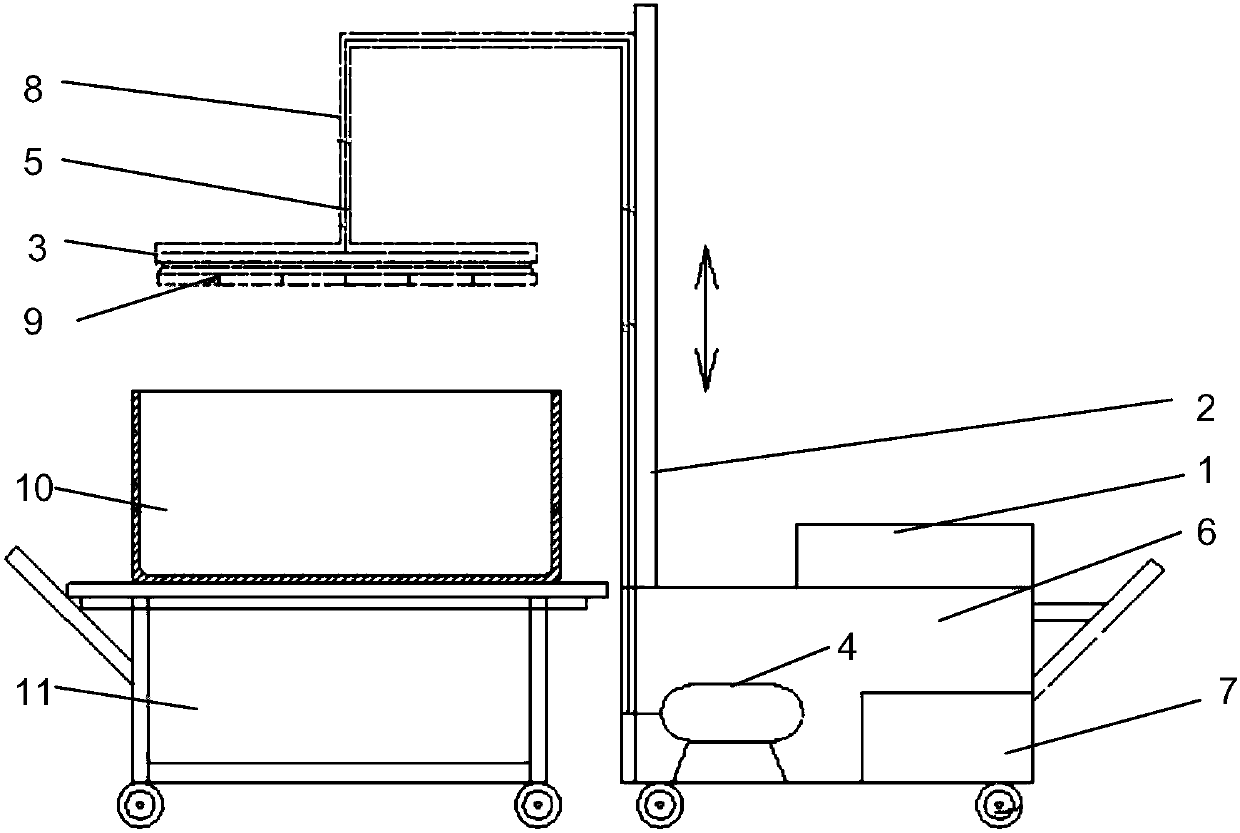

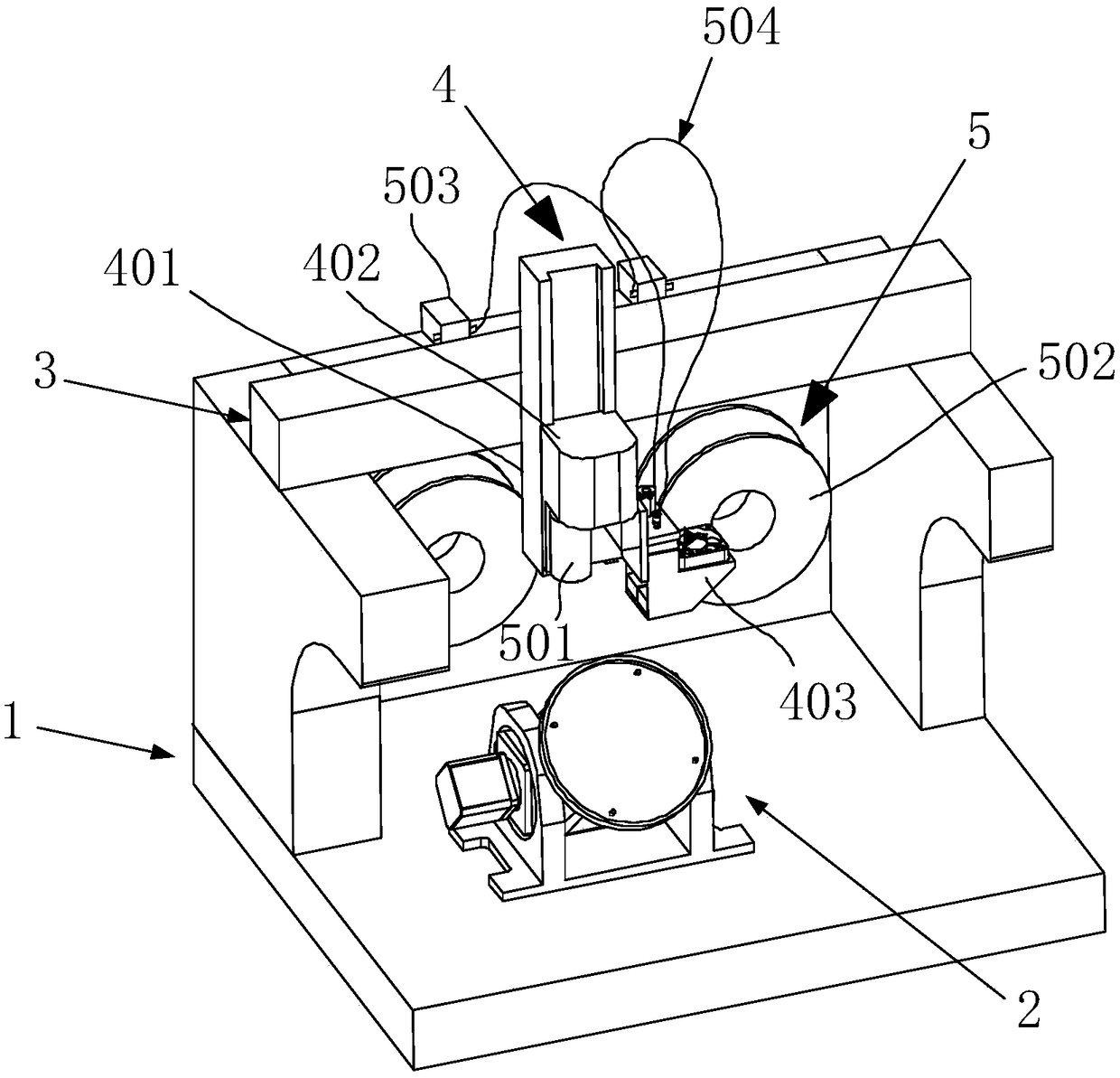

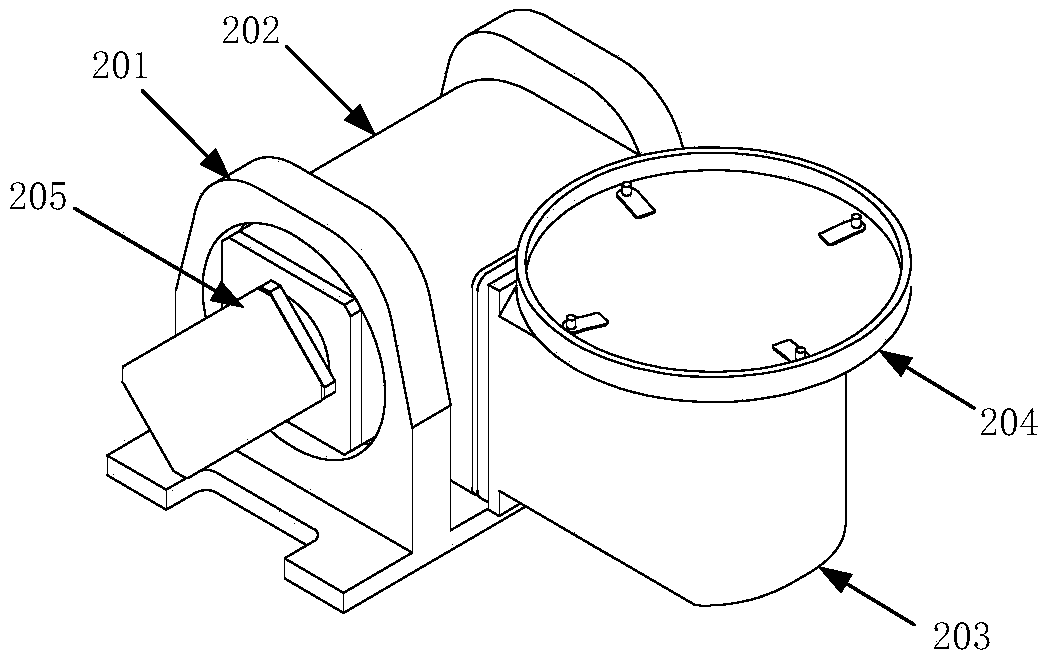

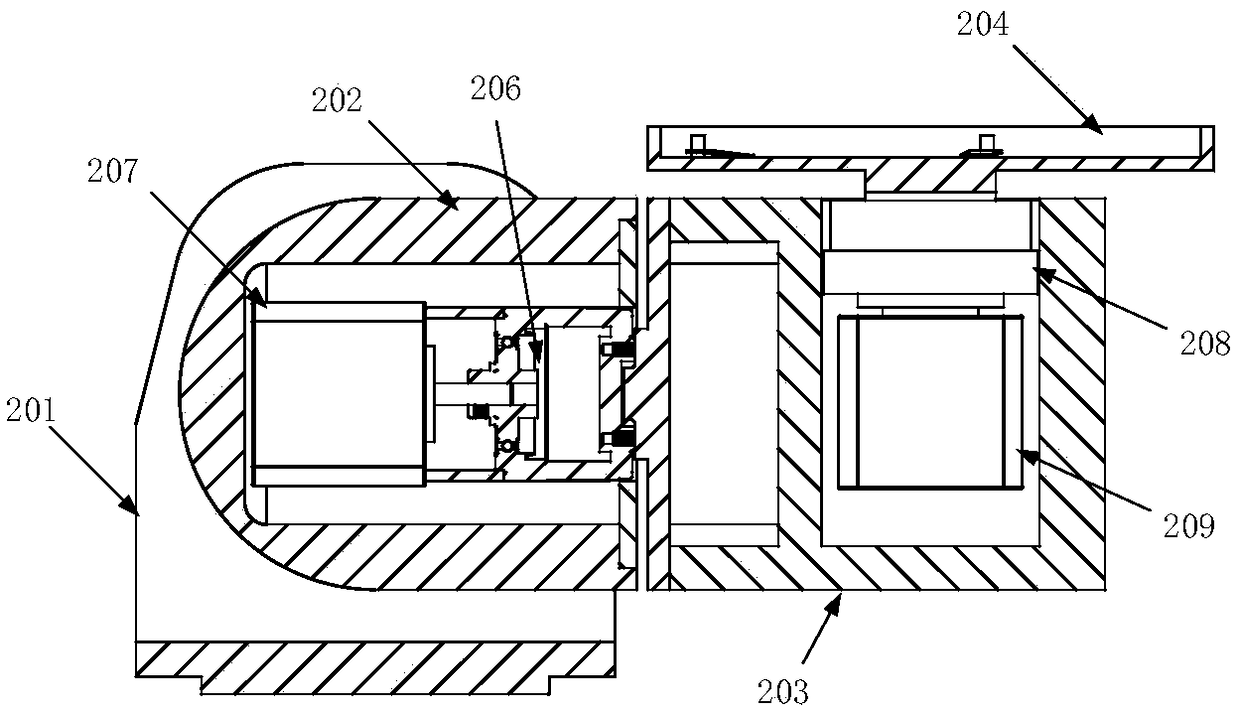

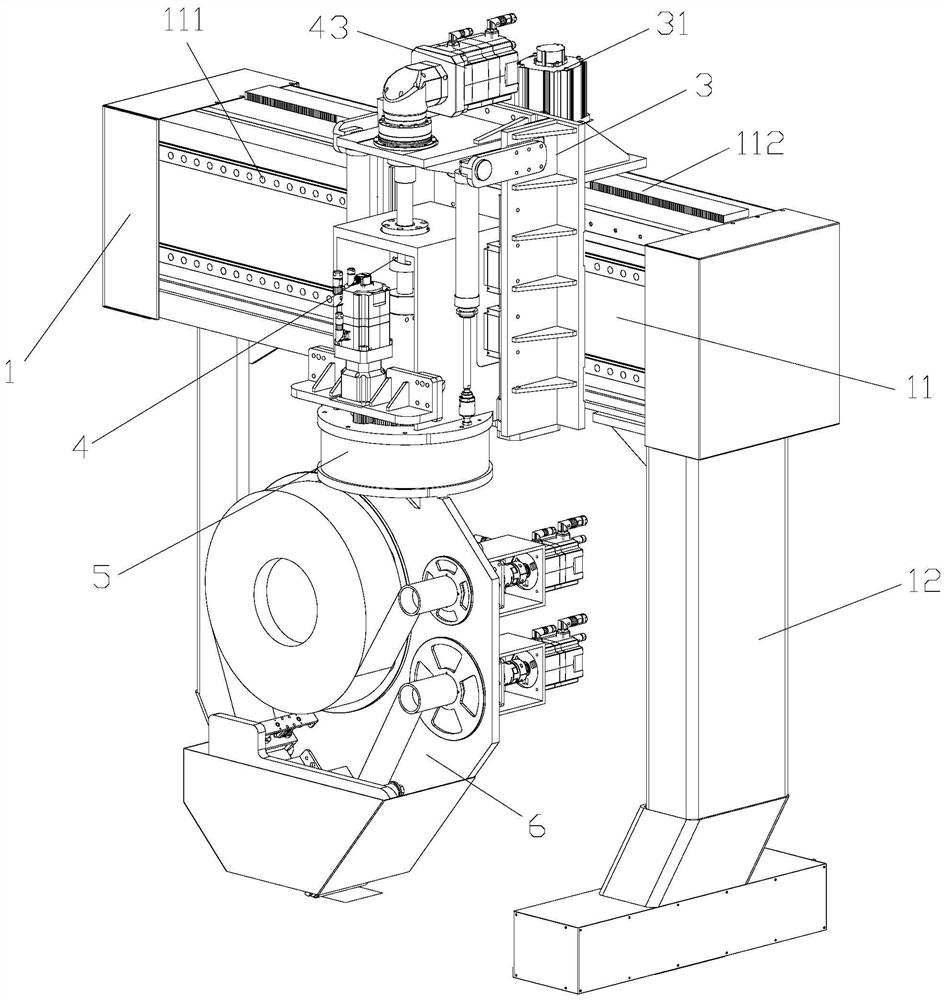

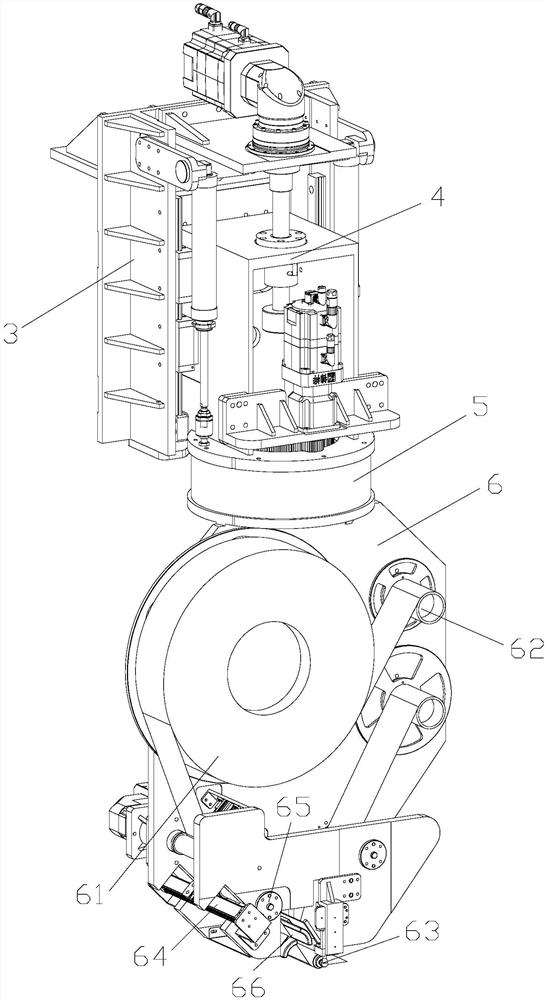

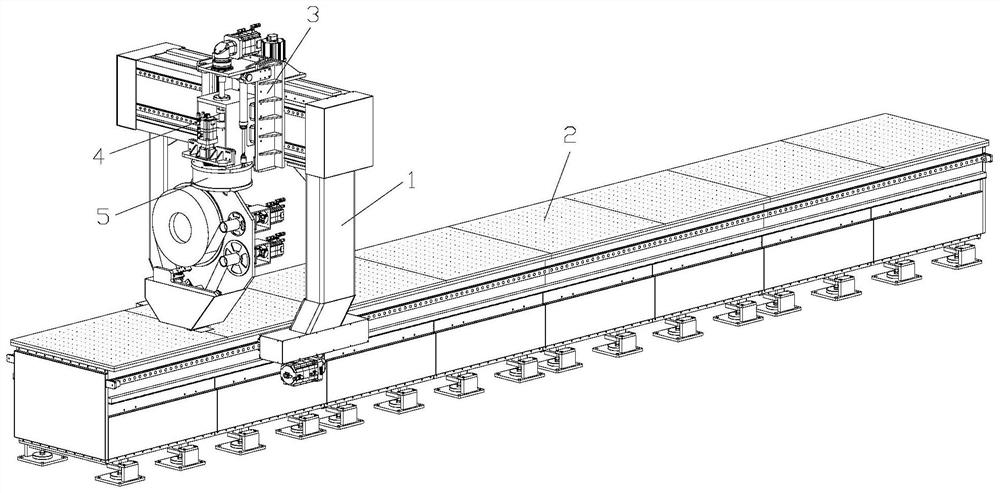

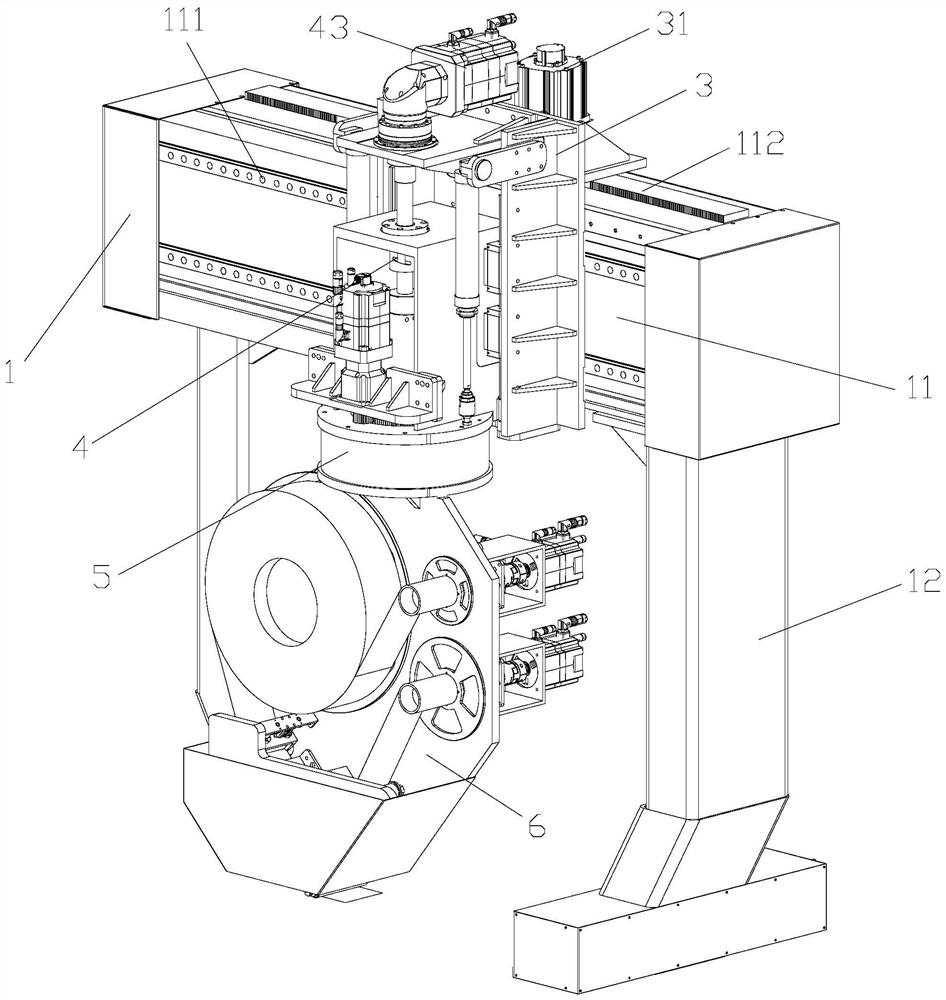

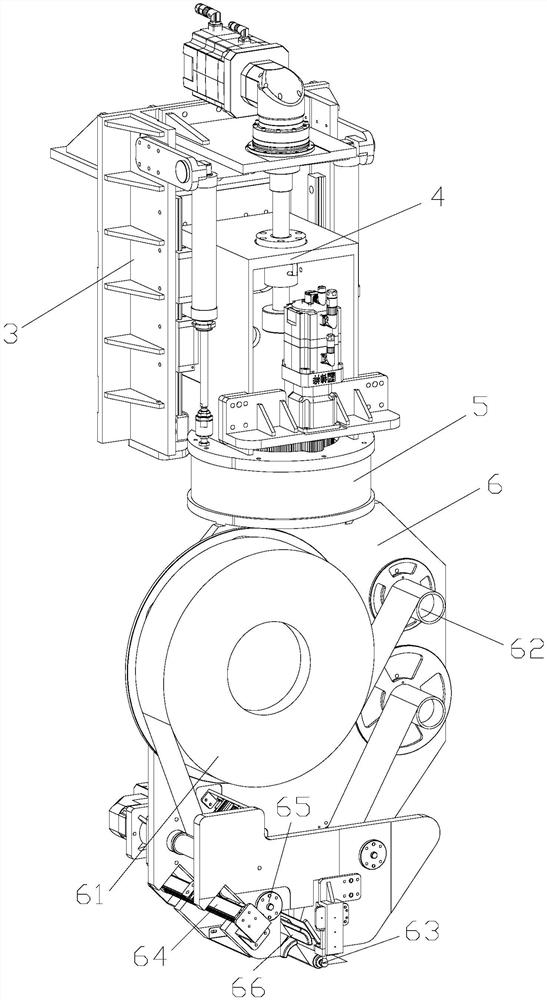

Spatial multi-degree-of-freedom additive manufacturing equipment based on continuous fiber reinforcement

InactiveCN109177161ALaying to achieveAchieve windingAdditive manufacturing apparatus3D object support structuresEngineeringMulti degree of freedom

The invention discloses spatial multi-degree-of-freedom additive manufacturing equipment capable of realizing continuous fiber reinforcement manufacture, and a continuous fiber reinforcement technology is introduced to the field of additive manufacture. The spatial multi-degree-of-freedom additive manufacturing equipment is composed of five parts in total: a base, a turntable, a vertical shaft anda feeding and molding unit; a mobile unit is designed on the base and is combined with the vertical shaft to change a spatial position for a printing head; the turntable is used for changing a spatial posture for a material plate for processing a workpiece; due to the change of relative positions of the printing head and a workbench, spatial multidirectional fiber laying can be realized; the feeding and molding unit comprises the printing head, a wire feeding mechanism and a scroll; and additive manufacture is realized by using a fused deposition technology. Continuous fibers in a spatial multi-dimensional direction can be laid in an additive manufacture process according to the requirements for performances such as appearances and mechanics of parts, and meanwhile, various base materialsare laid, so that all performances of the parts are enhanced.

Owner:BEIHANG UNIV

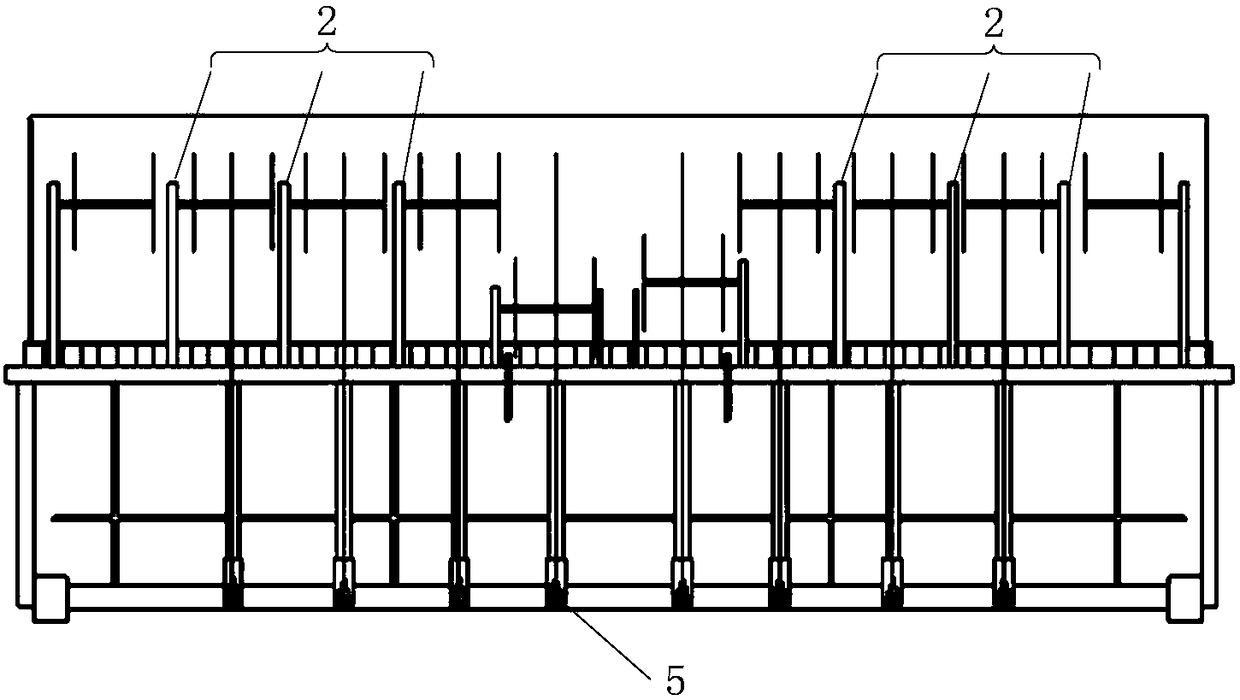

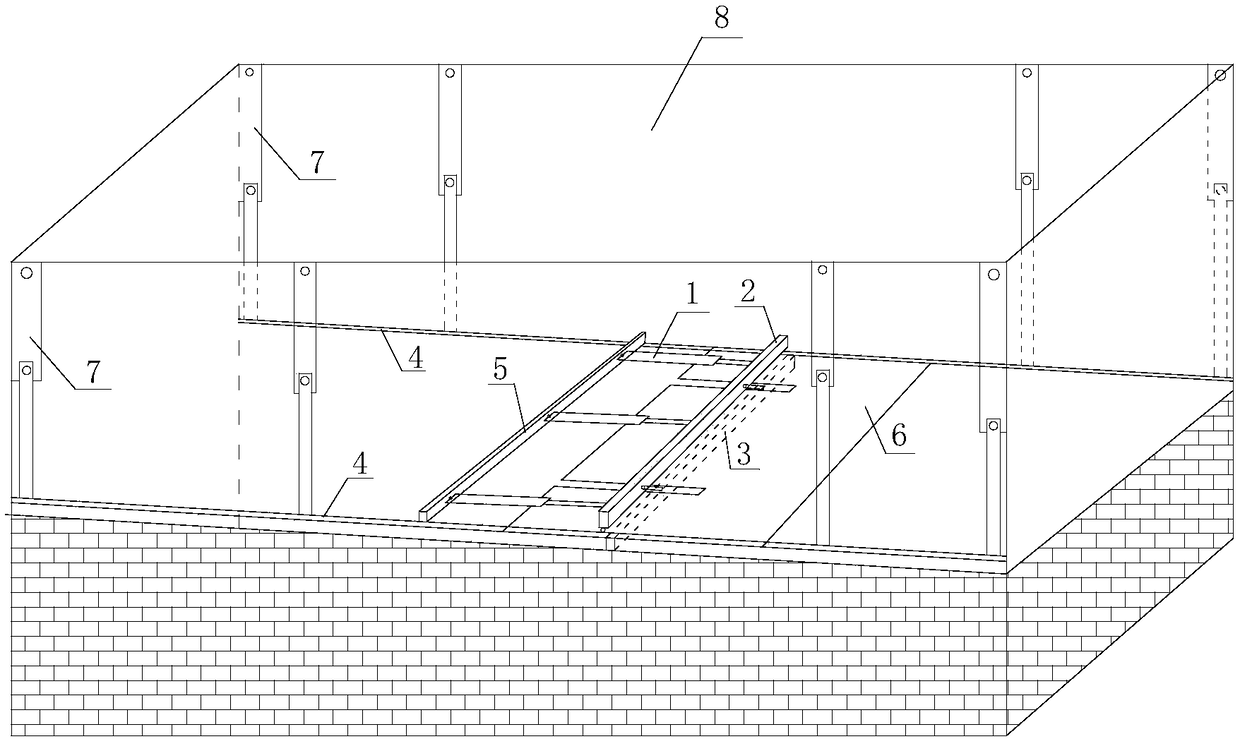

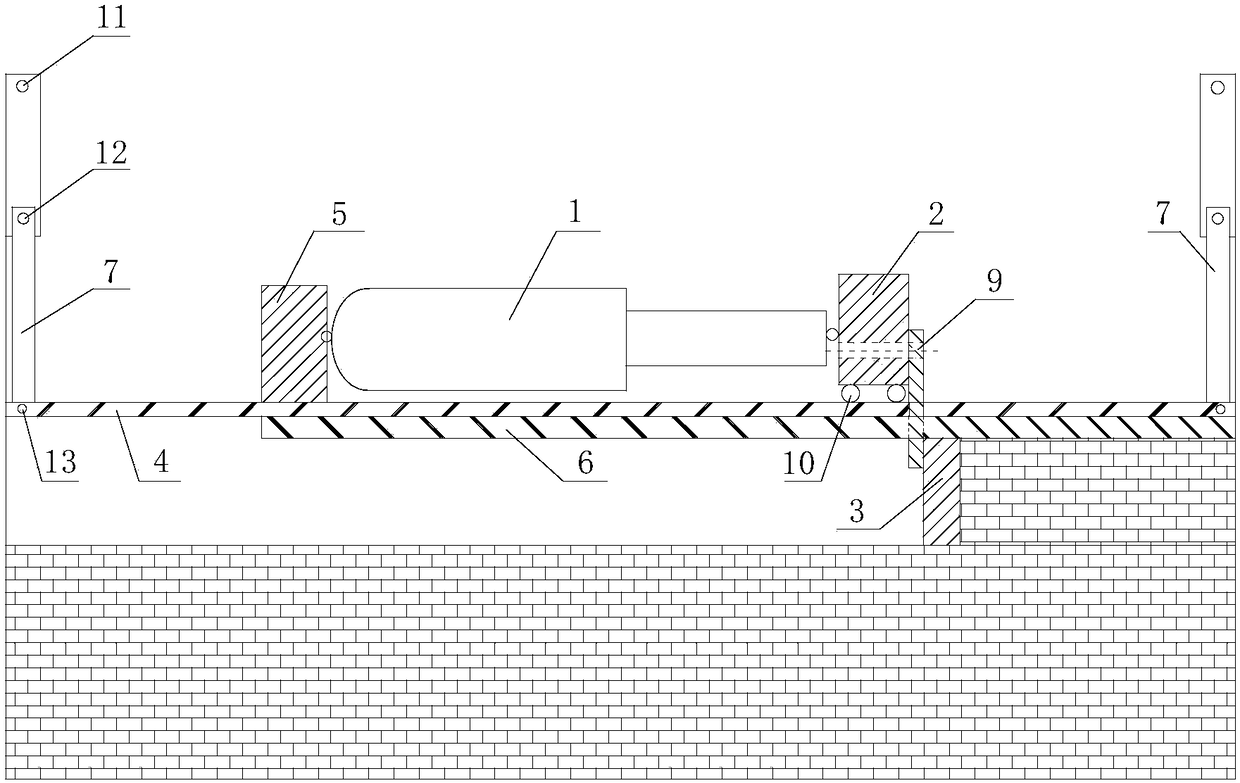

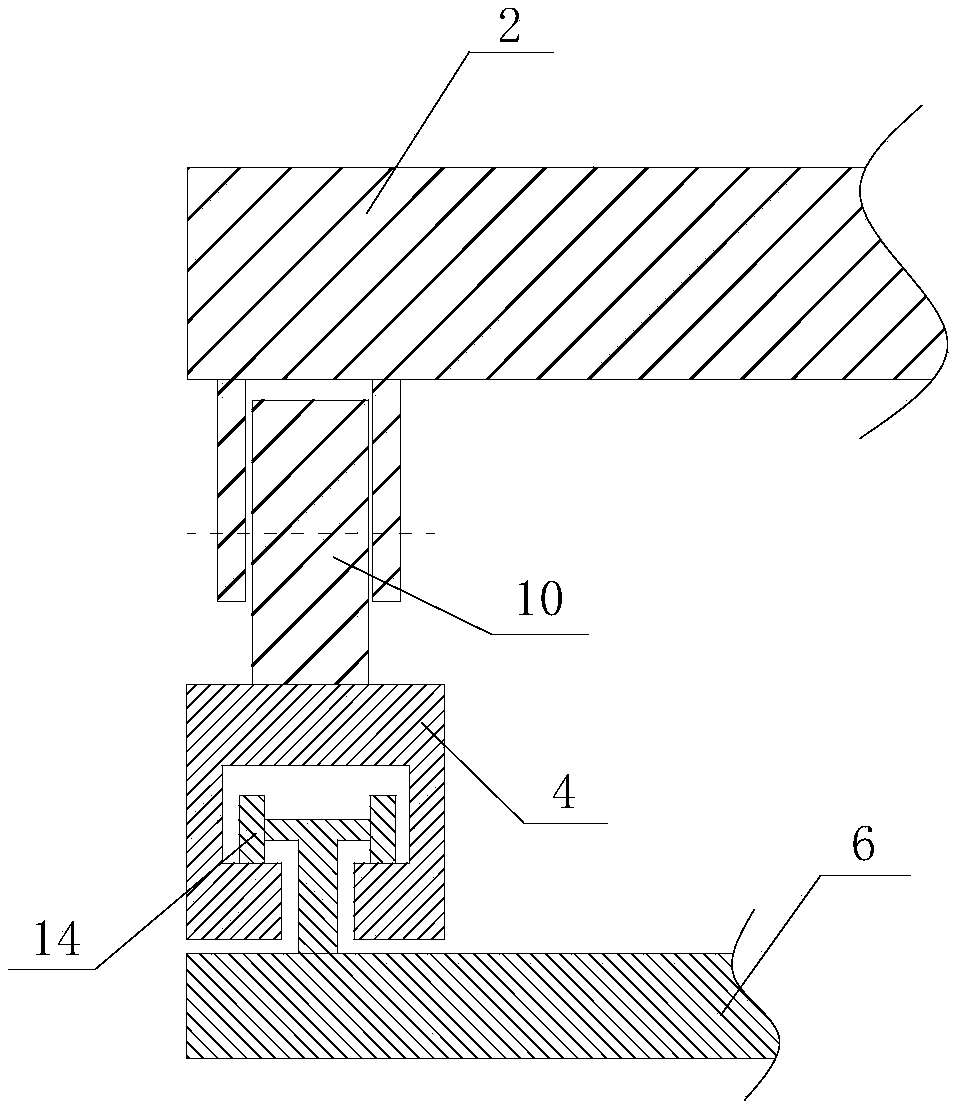

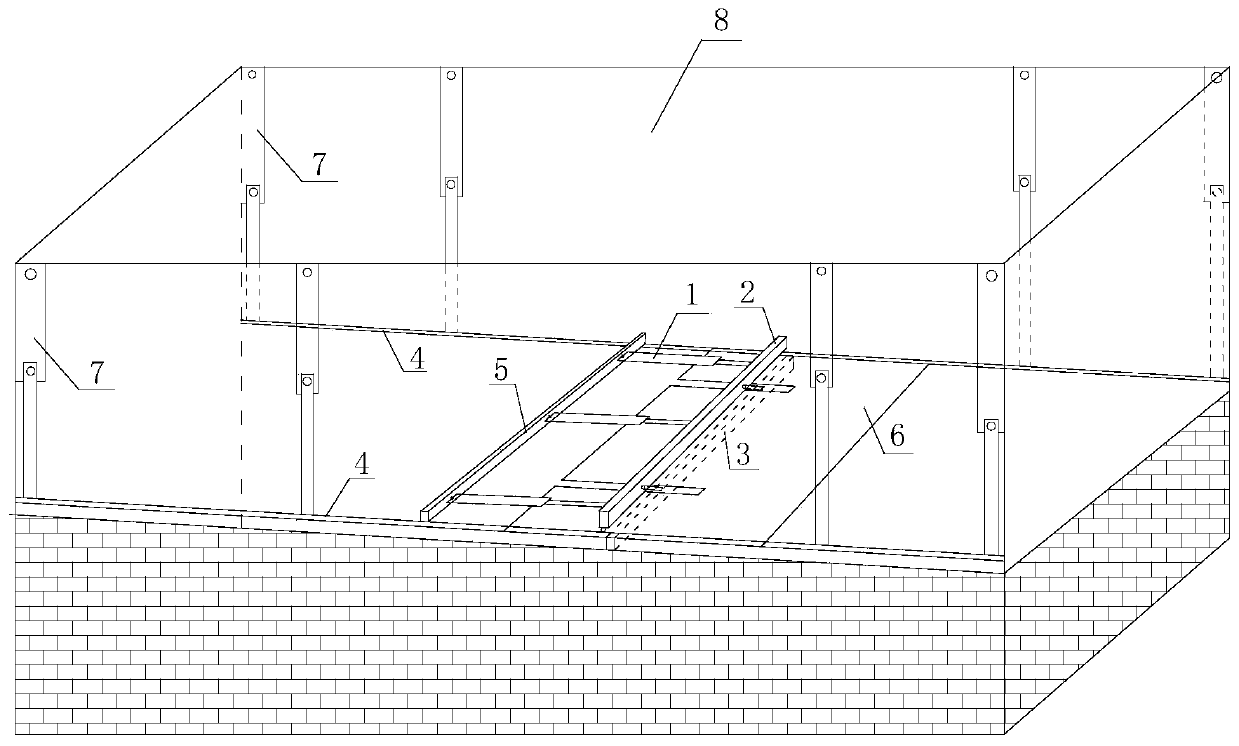

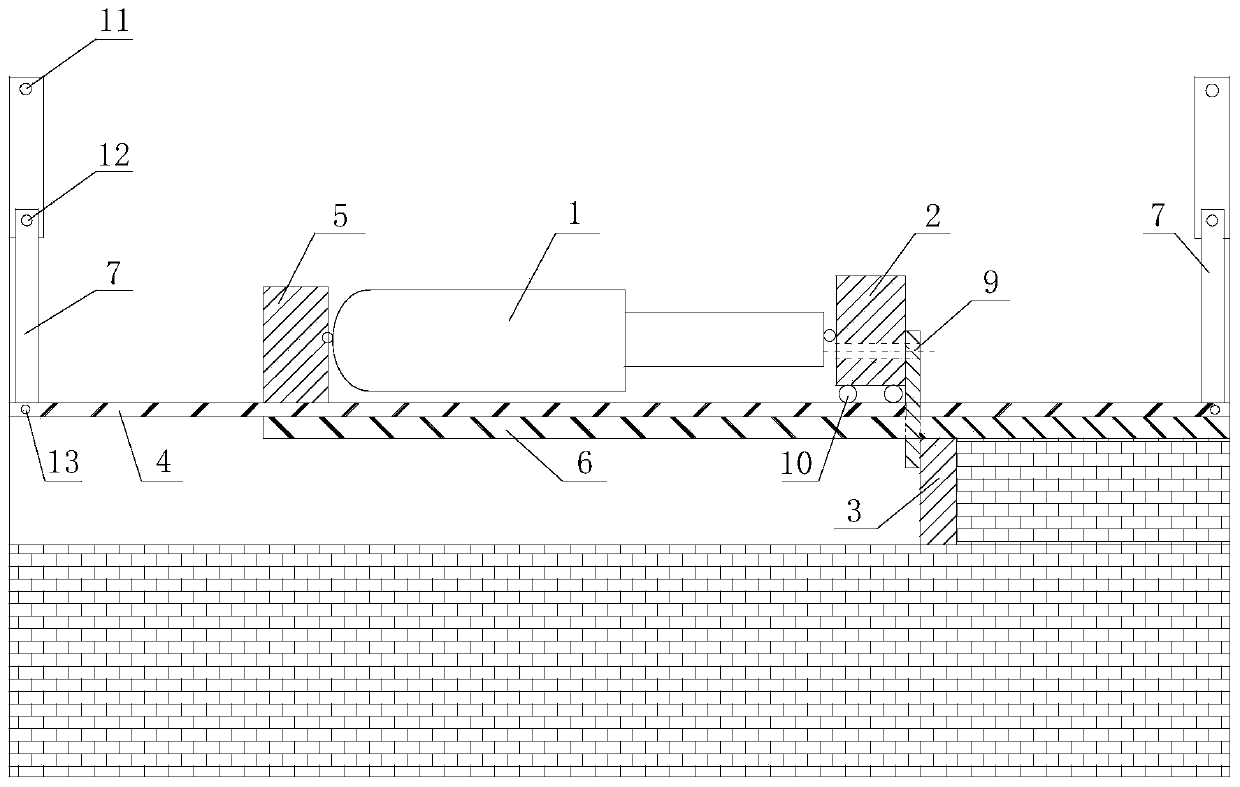

Paving device for analogue simulation experiment material and use method of paving device

ActiveCN108120817ALaying to achievePreparing sample for investigationEarth material testingEngineeringUltimate tensile strength

The invention discloses a paving device for an analogue simulation experiment material and a use method of the paving device. The paving device comprises an analogue simulation experiment bench as well as a hydraulic pushing jack, a guiding crossbeam, an extrusion crossbeam, two parallel guiding rails, a fixed beam and a cover plate which are arranged in the analogue simulation experiment bench, wherein the hydraulic pushing jack is located above the guiding rails, the cover plate is located below the guiding rails, and the guiding rails are used for the cover plate and the guiding crossbeam to move; and the guiding crossbeam and the extrusion crossbeam are fixedly connected, the fixed beam and the guiding crossbeam are correspondingly arranged in parallel and are respectively connected totwo ends of the hydraulic pushing jack, connecting holes are respectively formed in two ends of the connecting beams, and two ends of the fixed beam are respectively fixedly connected with the two guiding rails through the connecting holes. According to the paving device, the problems that the strength and thickness of a rock layer paved at the lower part are influenced by traditional vertical knocking and vibration are solved; and by arranging the new paving device, a paved local rock body and a paved lower rock layer are not influenced in the paving process.

Owner:CHINA SHENHUA ENERGY CO LTD +2

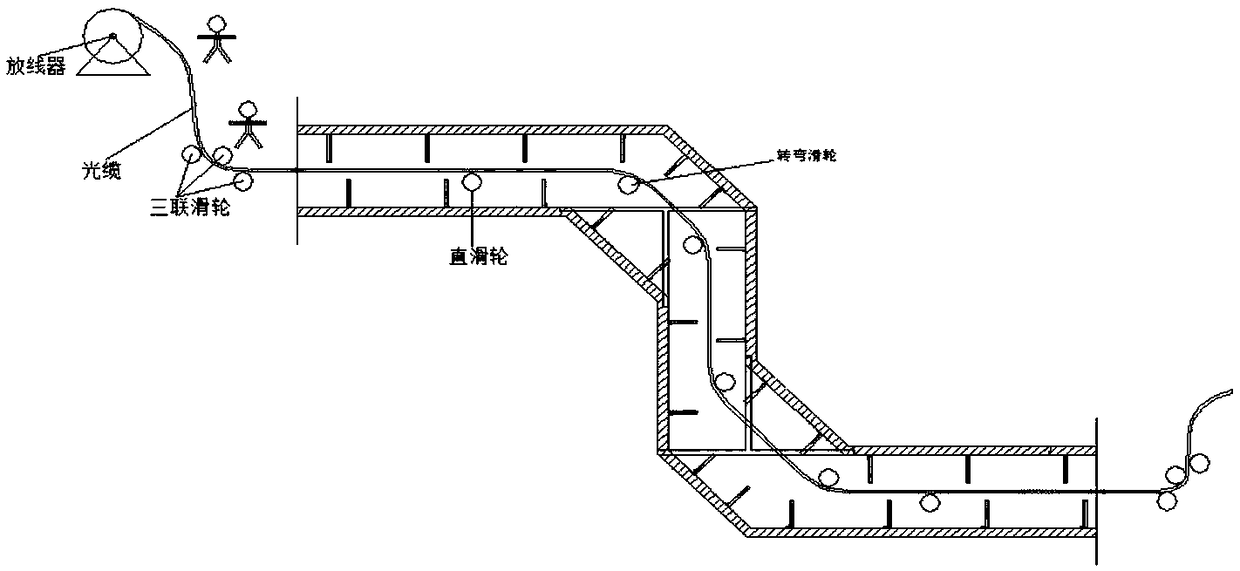

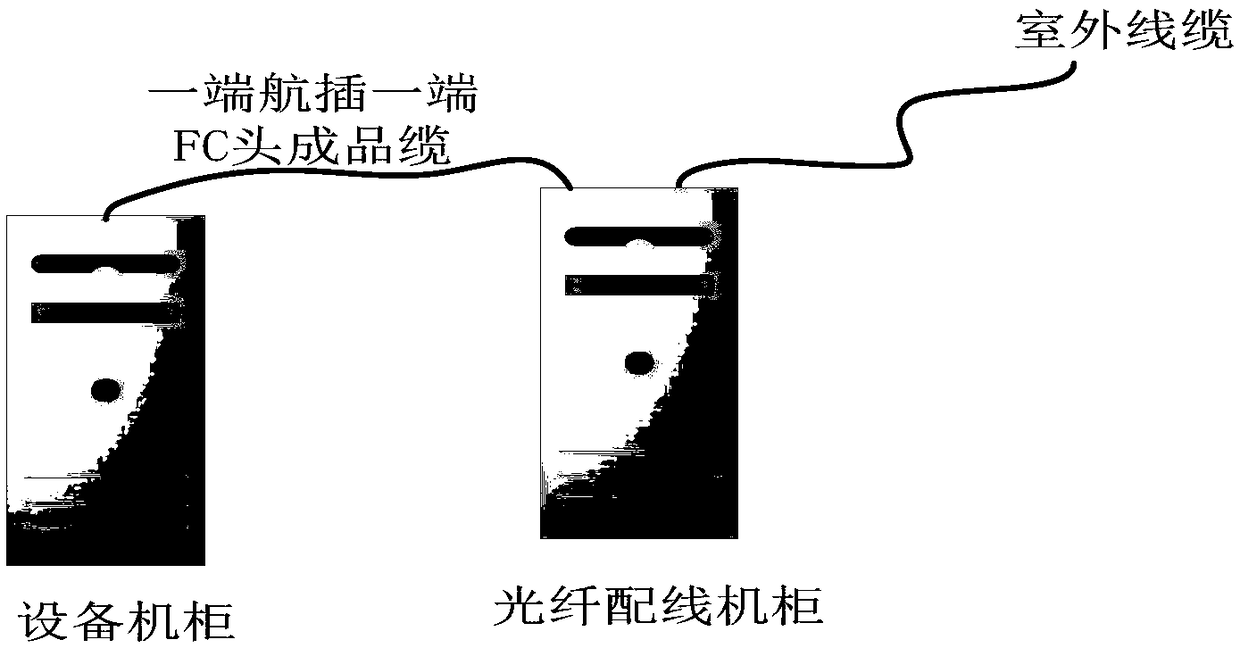

Outdoor fiber laying method

InactiveCN109407251ALaying to achieveReduce lossOptical fibre/cable installationCoupling light guidesDistribution frameMaintainability

The invention discloses an outdoor fiber laying method capable of laying a fiber and improving automation degree, easy to operate, having a low fiber damage rate and a halved workload, and achieving concentrated laying. The method, by pre-installing a linear pulley, a turning pulley, a triple pulley, and a traction machine and by means of constraint of the positions and the distances of the previous modules and the laying sequence of an optical cable, lays the optical cable, achieves high automation degree and high construction efficiency, and reduces fiber loss. In addition, an original fiberterminal box is removed, and all individual optical cables are fusion spliced to a fiber distribution frame to achieve unified incoming, unified fusion splicing, and unified outgoing, and ensure thetidiness, the appearance and the coordination of an equipment cabinet inside an equipment room. The method improves the maintainability of each unit finished cable and the selection diversity of corewires to a certain extent, and achieves good maintainability.

Owner:HEBEI HANGUANG HEAVY IND

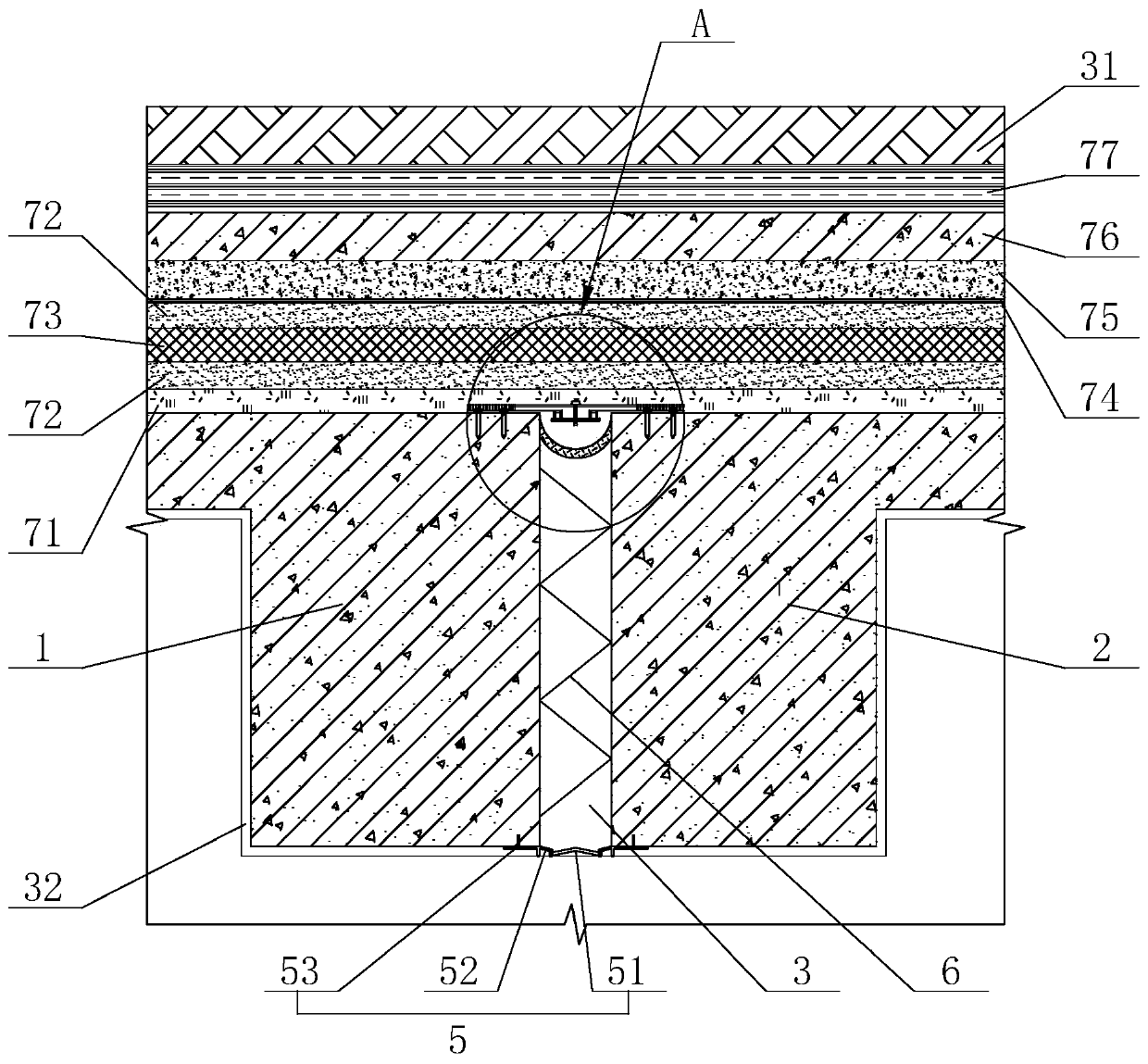

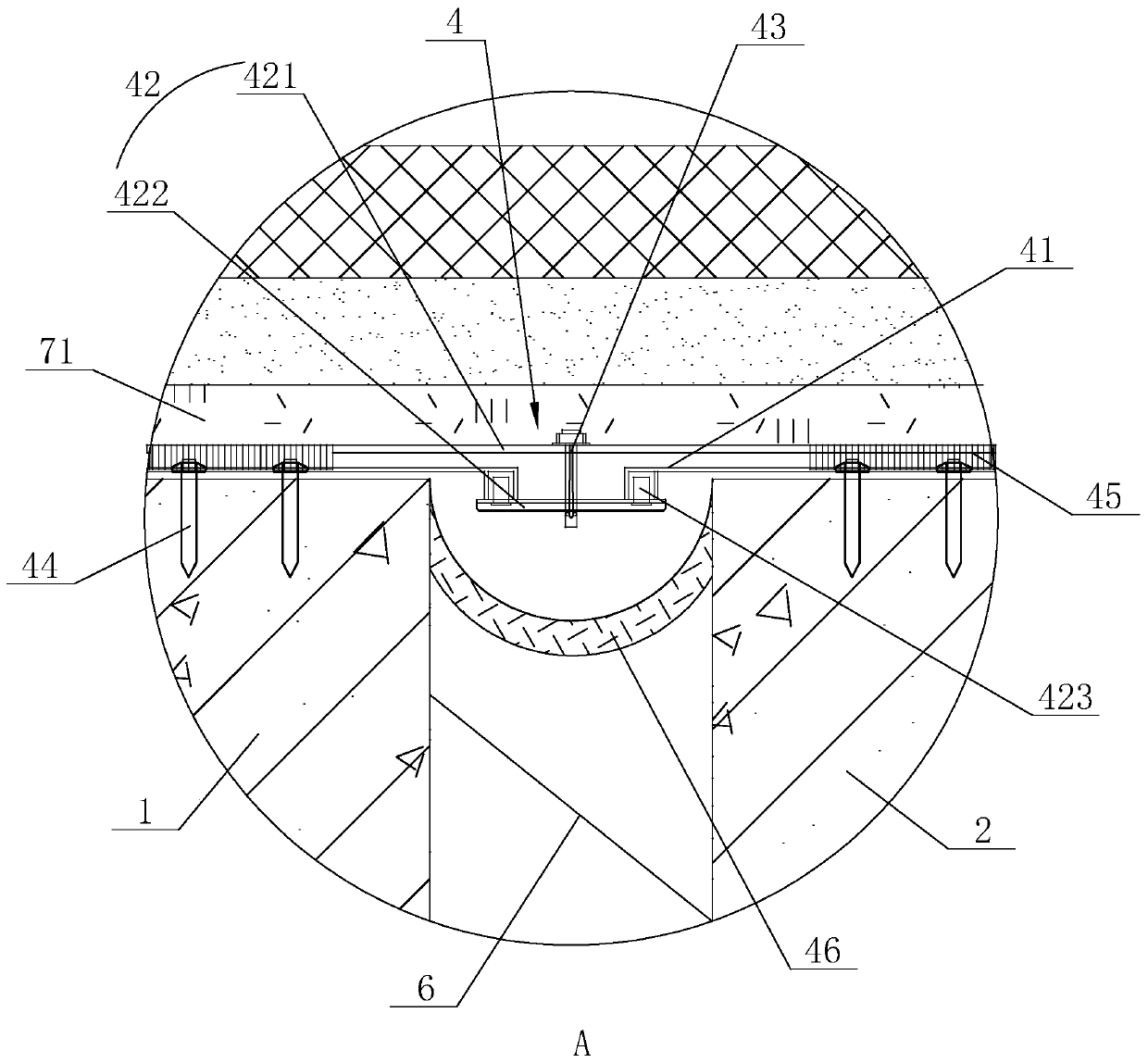

Flush joint waterproof structure for roof deformation joint

InactiveCN111255101AGuaranteed continuityEasy accessBuild-up roofsRoof covering insulationsWater stopArchitectural engineering

The invention relates to a flush joint waterproof structure for a roof deformation joint. The flush joint waterproof structure comprises a first wall body and a second wall body arranged on one side of the first wall body, wherein the first wall body and the second wall body are separated to form the vertical deformation joint with a certain distance; a waterproof assembly and a reinforcement assembly are arranged in the deformation joint, and the waterproof assembly comprises an upper waterproof part and a lower waterproof part arranged at the upper end and the lower end of the deformation joint; a water stop belt is arranged below a middle shaft control rod, the two ends of the water stop belt are in lap joint with the first wall body and the second wall body, and the position, where thejoint is located, of the middle part of the water stop belt is bent downwards to form an elastic bending part with a drainage function; and a plastic surface layer is arranged on the outermost side above the first wall body and the second wall body, a reinforced concrete plate is arranged below the first wall body and the second wall body, the reinforcement assembly comprises a plurality of reinforcement plates sequentially connected in the deformation joint, and the two ends of the reinforcement plates are fixedly connected with the first wall body and the second wall body. The flush joint waterproof structure for the roof deformation joint not only ensures the continuity of the roof surface layer, but also meets the waterproof requirement.

Owner:上海豪昆建筑设计有限公司

Direct buried cable laying method and special cable protection sleeve for the method

ActiveCN108565785BEnhance storage and drainage capacityExtended service lifeCable installations in underground tubesApparatus for laying cablesDirect-buried cableEngineering

Owner:中铁十五局集团电气化工程有限公司

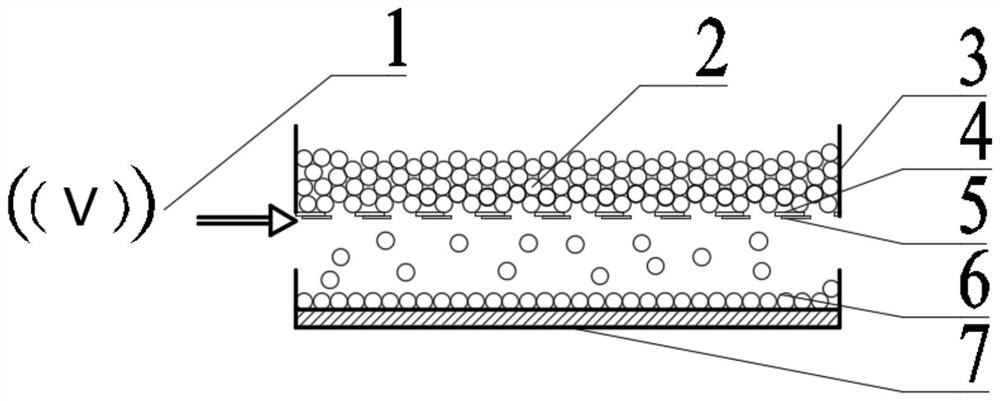

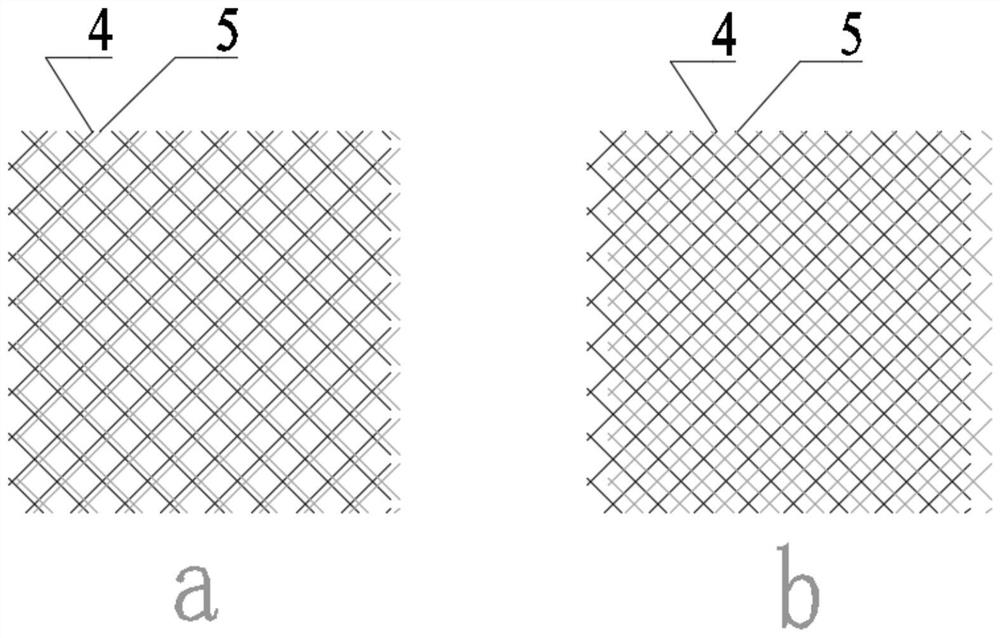

Powder falling control device and method for additive manufacturing

ActiveCN114345702AControl placementConvenient and efficient layingSievingAdditive manufacturing apparatusProcess engineeringControllability

The invention relates to the technical field of powder metallurgy, and provides a powder falling control device and method for additive manufacturing. The device comprises a powder storage bin, a middle bin, a double-layer screen and a screen driving unit; the middle bin is arranged at the lower end of the powder storage bin to keep the stability of powder below the powder storage bin; the double-layer screen is arranged at a powder outlet in the bottom of the middle bin; the double-layer screen cloth is attached to each other, relative displacement parallel to the screen cloth face can be generated between the double-layer screen cloth, interference is generated between the double-layer screen cloth, the sizes of through holes of the double-layer screen cloth are changed, and then the falling amount of powder is controlled. And the screen driving unit controls the relative displacement between the double-layer screens. The powder falling control method comprises the steps of calibration, powder falling start and stop control and powder falling rate control. Compared with existing equipment, the device is simple in structure and high in controllability, the powder feeding speed can be controlled, the device can be particularly used for controlling fine powder, powder laying can be conveniently and efficiently controlled, and the device has wide application prospects.

Owner:UNIV OF SCI & TECH BEIJING

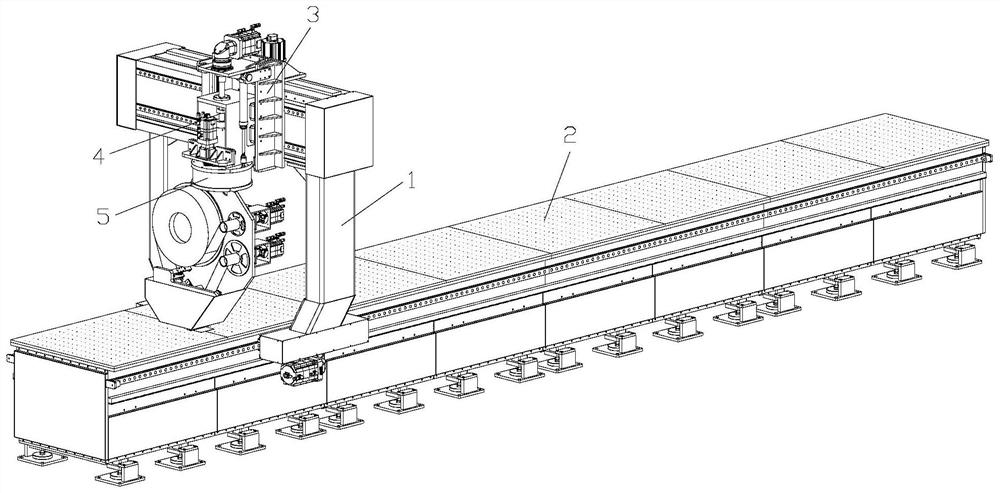

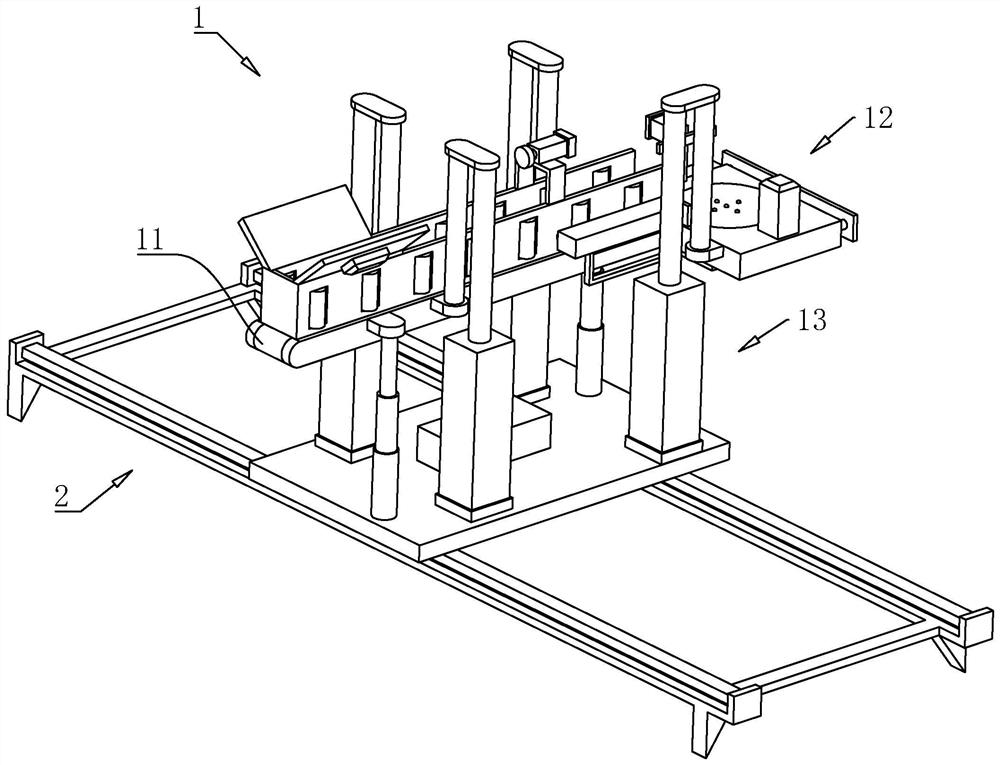

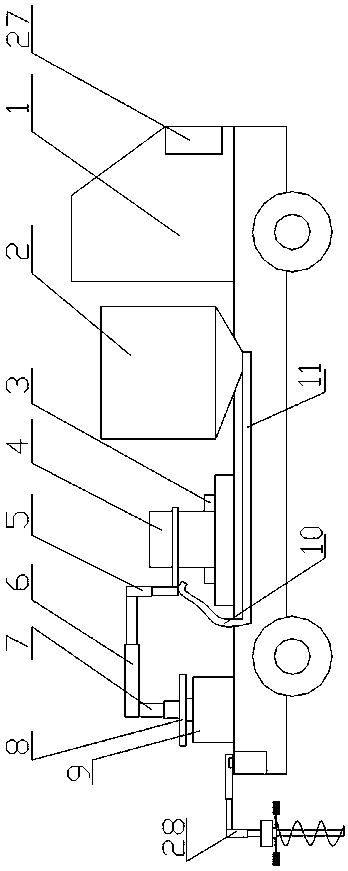

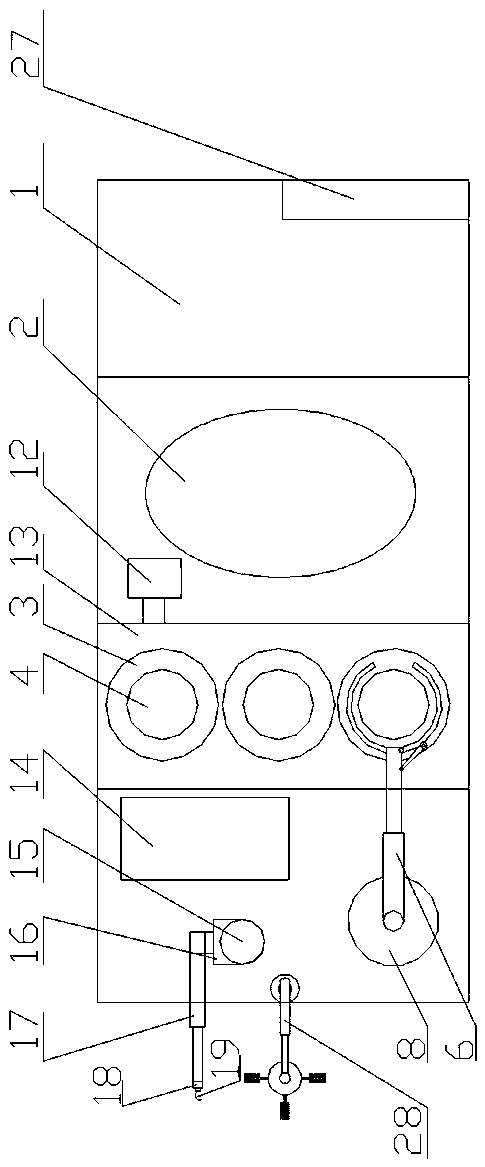

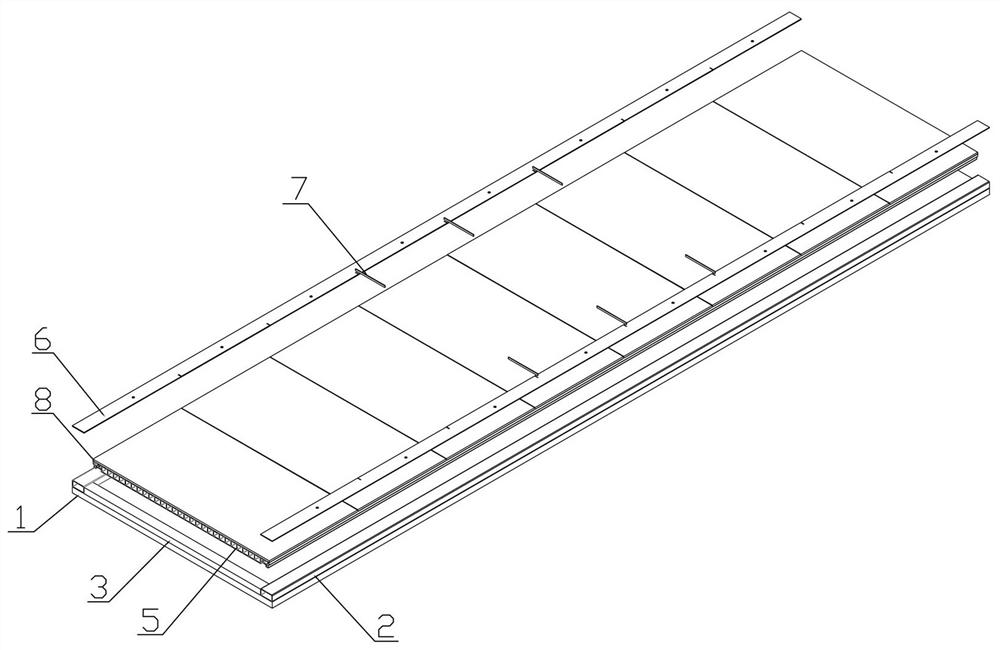

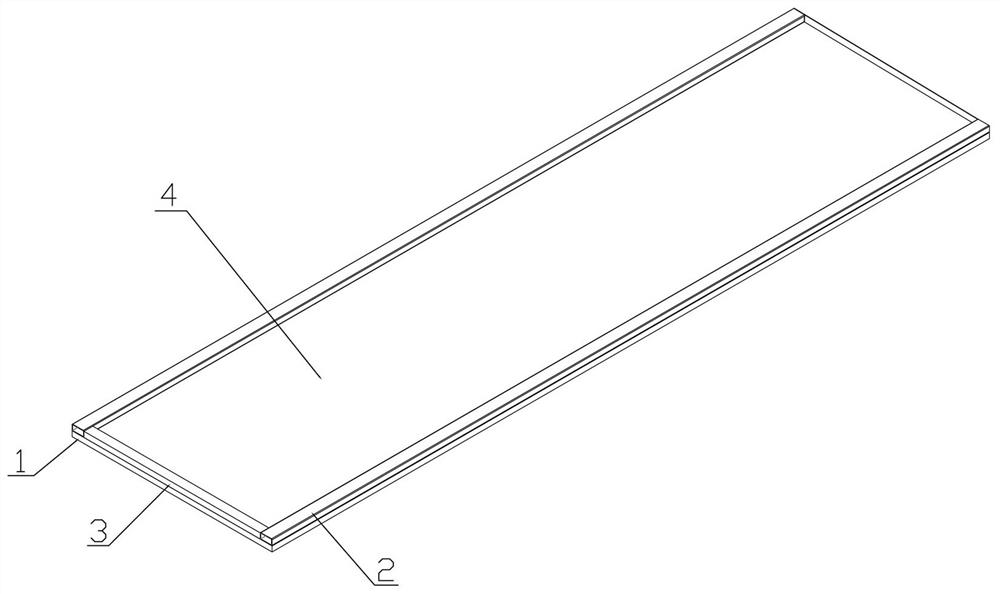

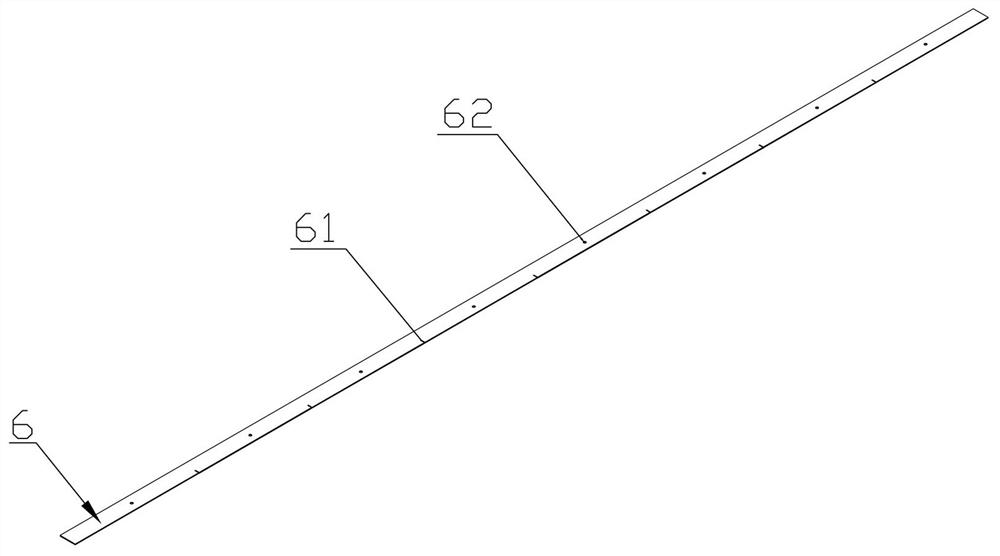

Flat plate automatic belt laying equipment and control method thereof

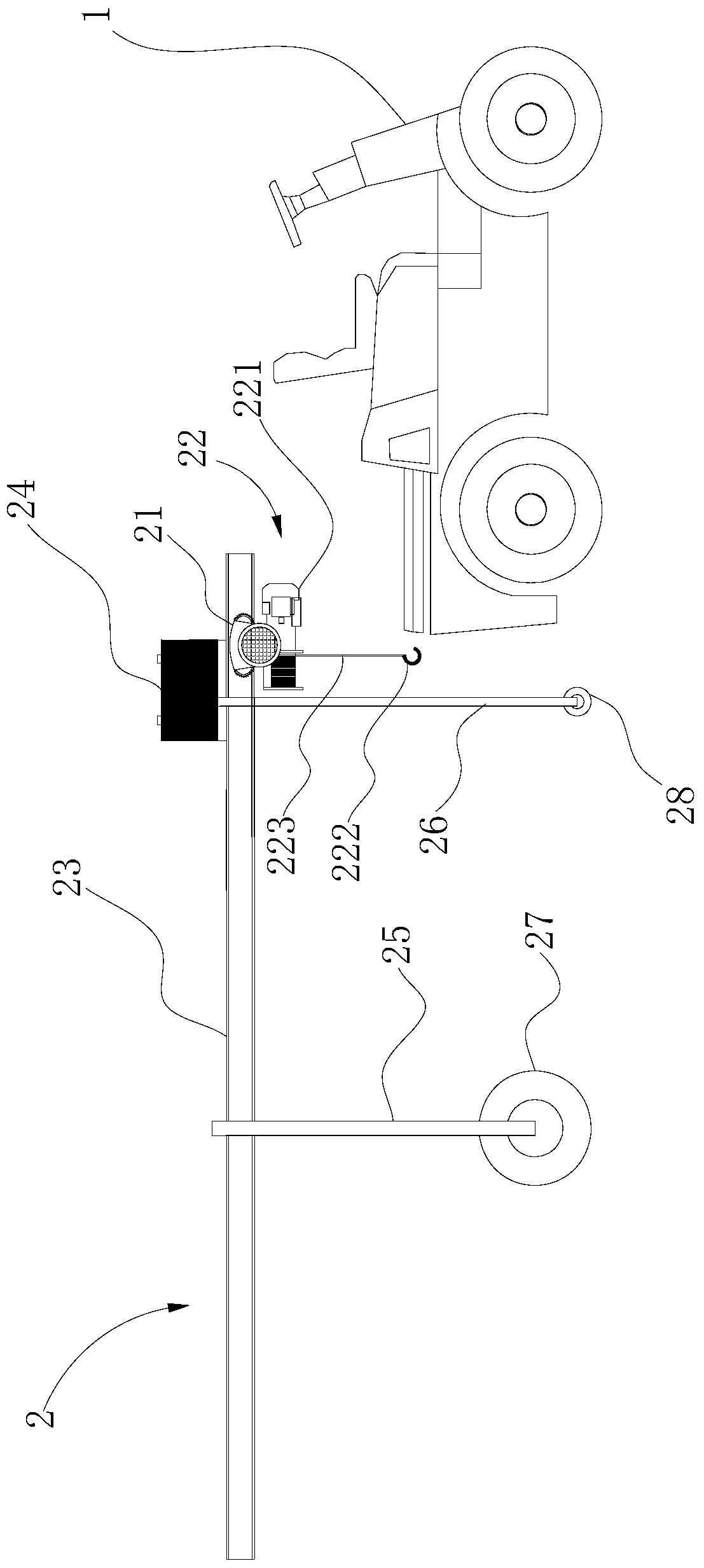

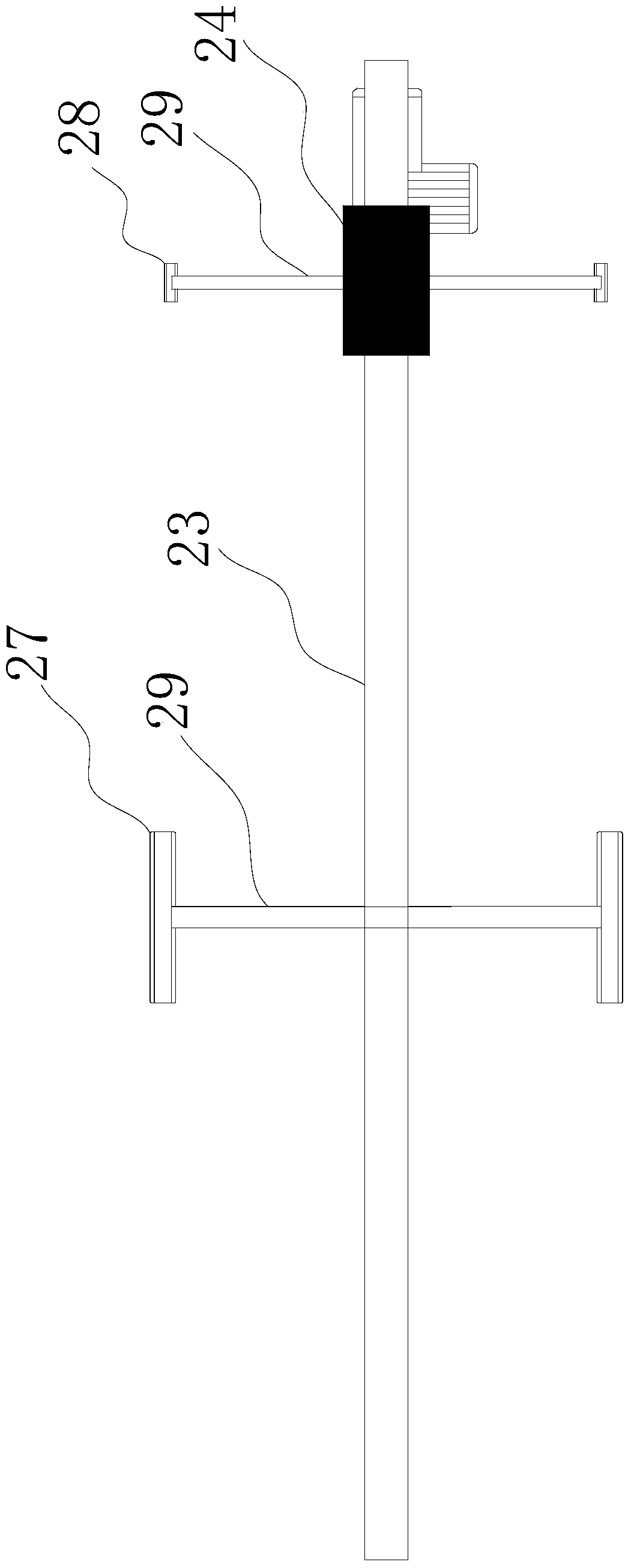

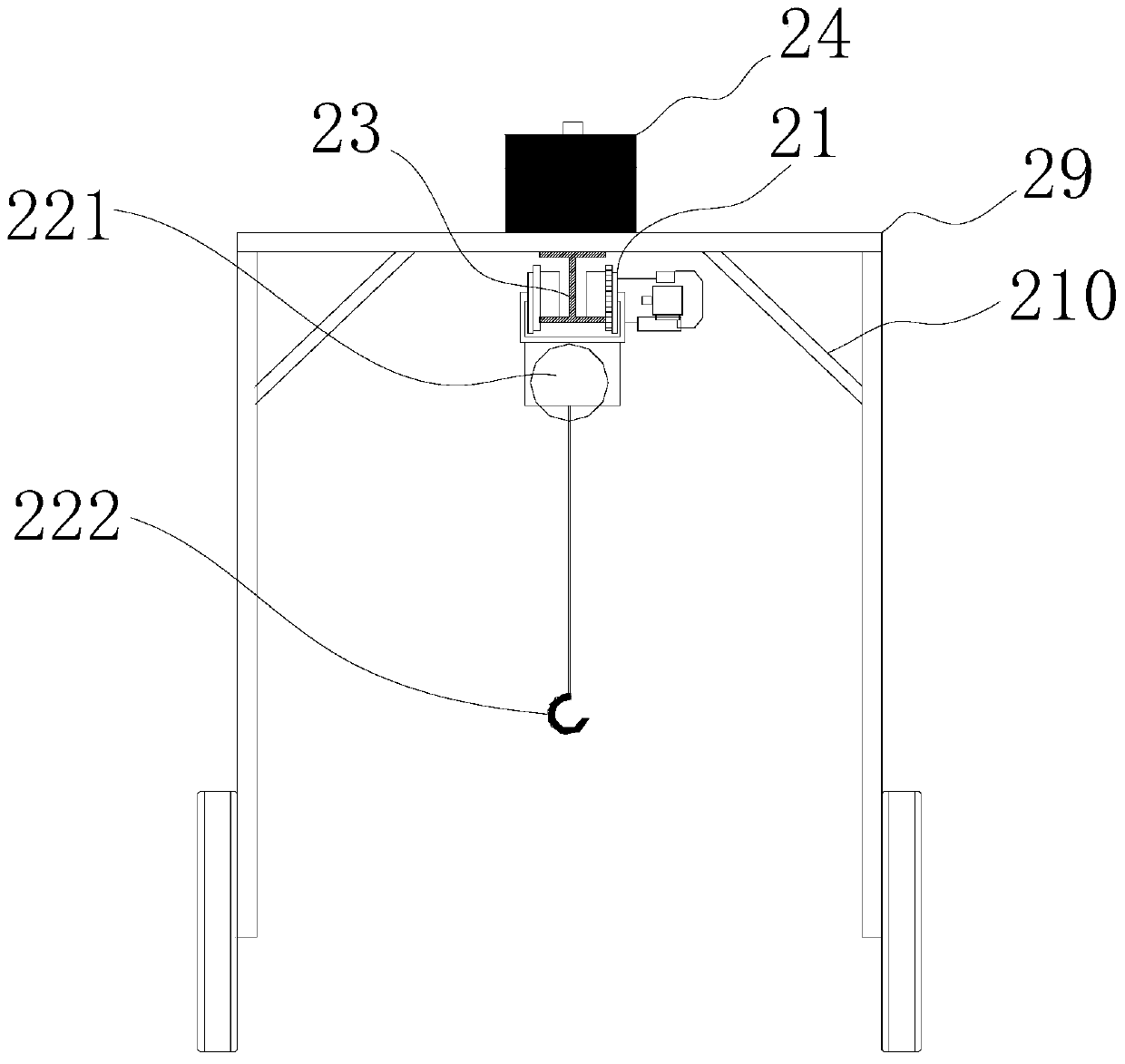

ActiveCN113085223ALaying to achievePlay a pulling roleArticle deliveryWebs handlingElectric machineryPortal frame

The invention relates to the technical field of carbon fiber composite material preforming equipment, in particular to an automatic belt laying device. A driving unit is arranged on a portal frame and can drive a laying unit to move, the laying unit is fixed on the portal frame through a sliding table seat, and a lifting assembly is arranged on the sliding table seat and can drive the laying unit to move in the vertical direction; and a rotating assembly is further arranged on the sliding table seat and can drive the laying unit to rotate by 360 degrees, so that the laying unit can achieve multi-angle material belt laying. A first air expansion shaft is arranged in the laying unit and used for fixing and supporting a material disc, a second air expansion shaft and a third air expansion shaft are used for winding an isolating membrane and release paper respectively, the three air expansion shafts are all driven by power provided by a motor to rotate, and in the unwinding process of the material disc, unwinding is driven through the first air expansion shaft, and the second air expansion shaft plays a certain traction role on the unwinding of the material disc in the process of winding the isolating membrane.

Owner:常州新创航空科技有限公司

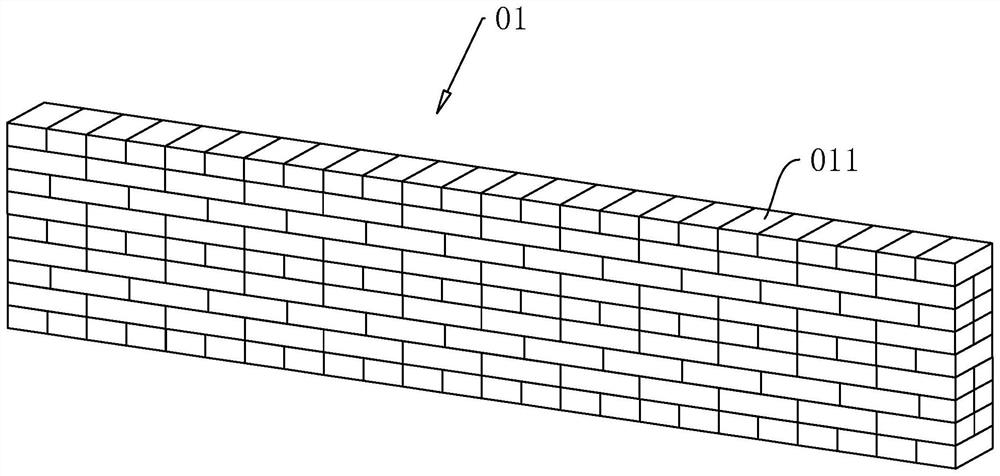

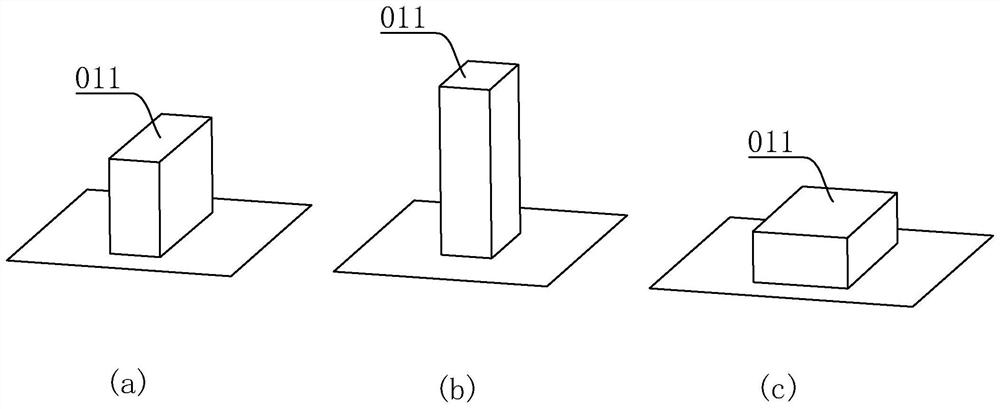

Membrane construction device and construction method

PendingCN114775617AReduce workloadLaying to achieveFoundation engineeringMechanical engineeringArchitectural engineering

The invention relates to a tire mold construction device and method, and relates to the field of building construction, the tire mold construction device comprises a laying mechanism, and the laying mechanism comprises a conveying assembly and a discharging assembly; the conveying assembly is used for conveying bricks, limiting plates are arranged on the two sides of the conveying assembly in the conveying direction, and the distance between the limiting plates on the two sides is larger than the thickness of the bricks and smaller than the length and width of the bricks. The discharging assembly is arranged at the conveying tail end of the conveying assembly and comprises a placement plate, a pushing cylinder and a feeding cylinder, the conveying assembly conveys bricks to the placement plate, the pushing cylinder and the feeding cylinder are located on the different sides of the conveying direction of the conveying assembly, the pushing cylinder is used for pushing over the bricks towards one side of the feeding cylinder, and the feeding cylinder is located on the side, close to the conveying assembly, of the placement plate; the feeding cylinder is used for pushing the bricks pushed by the pushing cylinder to the side, away from the conveying assembly, of the containing plate. And the movement mechanism is used for driving the laying mechanism to move. The method has the effect of reducing the workload of constructors.

Owner:XIAN COAL CONSTR ENG

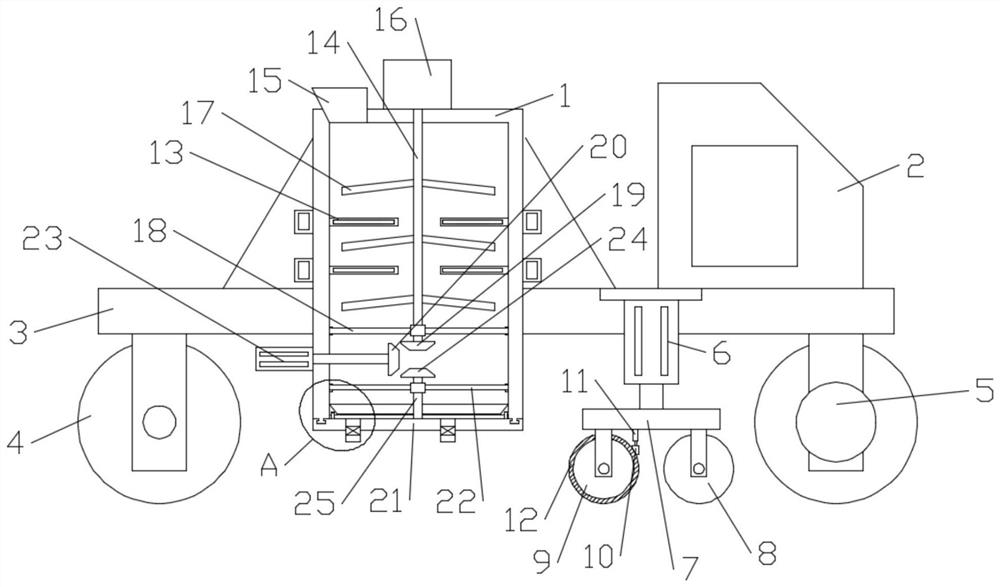

A small asphalt laying trolley device for uniform feeding

InactiveCN110130192BLay evenlyUniform feeding effectRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to the technical field of asphalt paving, and specifically discloses a small-sized asphalt paving trolley device for uniform feeding, including an asphalt tank fixed on one side of the support platform and having a feeding part at the bottom, and a fixed installation on the other side of the support platform. The rolling part at the bottom of one side, the inside of the asphalt tank rotates along its central axis and is provided with a stirring mechanism for mixing the asphalt materials in the asphalt tank; the linkage between the stirring mechanism and the feeding part; the bottom of the asphalt tank The end is an open structure, and the feeding part includes a screed plate that is rotated and sealed at the open structure at the bottom end of the asphalt tank, and the screed plate is provided with a plurality of discharge ports with different moving radii. The present invention solves the problem in the prior art that the asphalt material cannot be evenly dropped on the ground during the asphalt paving process through the linkage design of the blanking part and the stirring mechanism, and ensures the quality of the asphalt paving.

Owner:滁州天禾建筑工程有限公司

Laying device and using method of similar simulation experiment material

ActiveCN108120817BLaying to achievePreparing sample for investigationEarth material testingStructural engineeringMechanical engineering

The invention discloses a paving device for an analogue simulation experiment material and a use method of the paving device. The paving device comprises an analogue simulation experiment bench as well as a hydraulic pushing jack, a guiding crossbeam, an extrusion crossbeam, two parallel guiding rails, a fixed beam and a cover plate which are arranged in the analogue simulation experiment bench, wherein the hydraulic pushing jack is located above the guiding rails, the cover plate is located below the guiding rails, and the guiding rails are used for the cover plate and the guiding crossbeam to move; and the guiding crossbeam and the extrusion crossbeam are fixedly connected, the fixed beam and the guiding crossbeam are correspondingly arranged in parallel and are respectively connected totwo ends of the hydraulic pushing jack, connecting holes are respectively formed in two ends of the connecting beams, and two ends of the fixed beam are respectively fixedly connected with the two guiding rails through the connecting holes. According to the paving device, the problems that the strength and thickness of a rock layer paved at the lower part are influenced by traditional vertical knocking and vibration are solved; and by arranging the new paving device, a paved local rock body and a paved lower rock layer are not influenced in the paving process.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Device and method for laying fibers

InactiveCN102156339BEasy to carryLaying to achieveOptical fibre/cable installationThermometers using physical/chemical changesFiberEngineering

The invention relates to a device for laying fibers, which comprises a shell, an idler wheel, a gluing module, a limiting module and a compacting module, wherein the idler wheel, the gluing module, the limiting module and the compacting module are all arranged on the shell; the gluing module can rotate around a core shaft and is used for assembling an adhesive tape roll and placing fibers stuck and covered by the adhesive tape; the core shaft is vertical to the moving direction of the device for laying fibers in construction process; the limiting module has a limiting structure which is used for restraining the fibers and positioning the fibers at the position capable of being stuck and covered by the adhesive tape; the compacting module is used for applying force to the adhesive tape sticking and covering the fibers; and the idler wheel is arranged on the bottom of the device for laying fibers and is used for moving the device for laying fibers in a rolling manner. The invention also provides a method for laying fibers. The device and method provided by the invention have the advantages that the construction efficiency is high, the laid fibers are beautiful, the maneuverability is high, the device is portable, and the like.

Owner:FOCUSED PHOTONICS

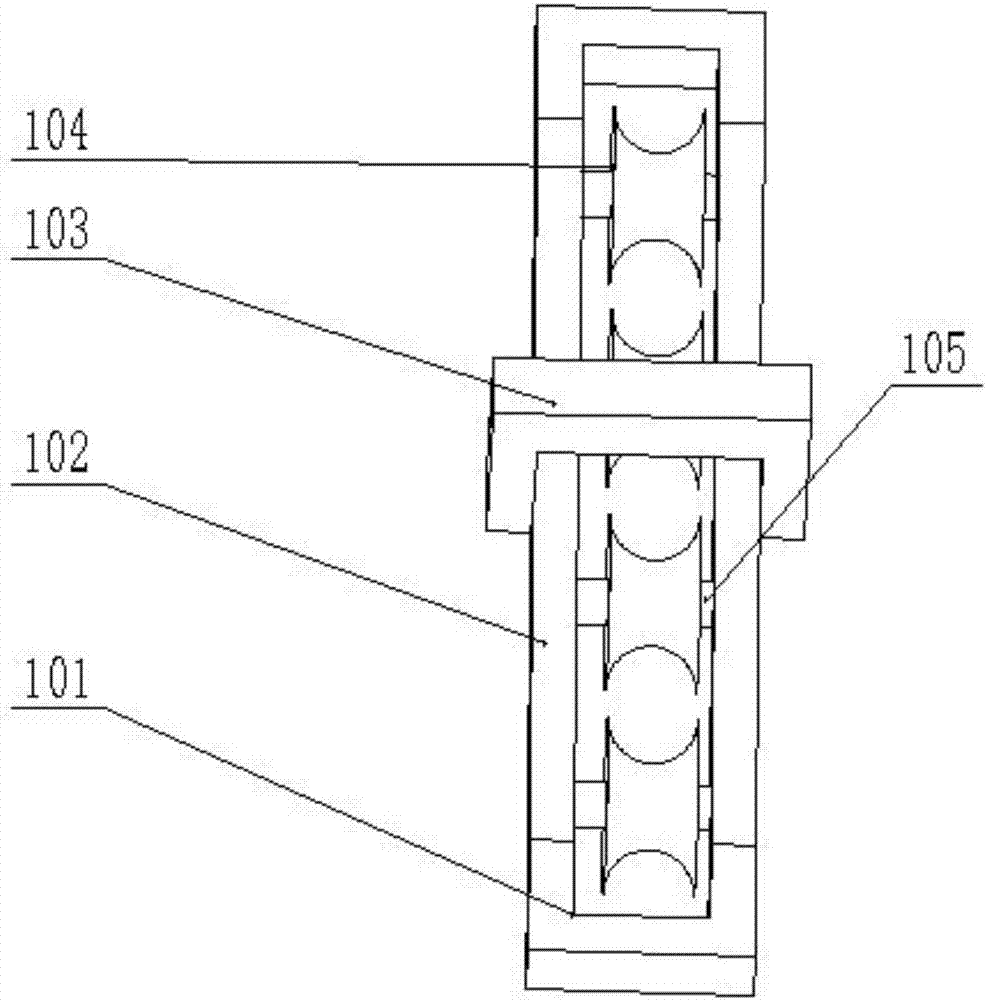

A device and method for transporting and laying permanent partitions in power tunnels

ActiveCN106065779BAchieve short-distance horizontal transportationLaying speed is fastUnderground chambersTunnel liningElectric power systemKeel

Owner:GUANGZHOU RAIL TRANSIT CONSTR SUPERVISION CO LTD

Cable laying construction method

ActiveCN113241682AReduce negative impactReduce the number of wells dugCable installations in cable chambersOptical fibre/cable installationArchitectural engineeringStructural engineering

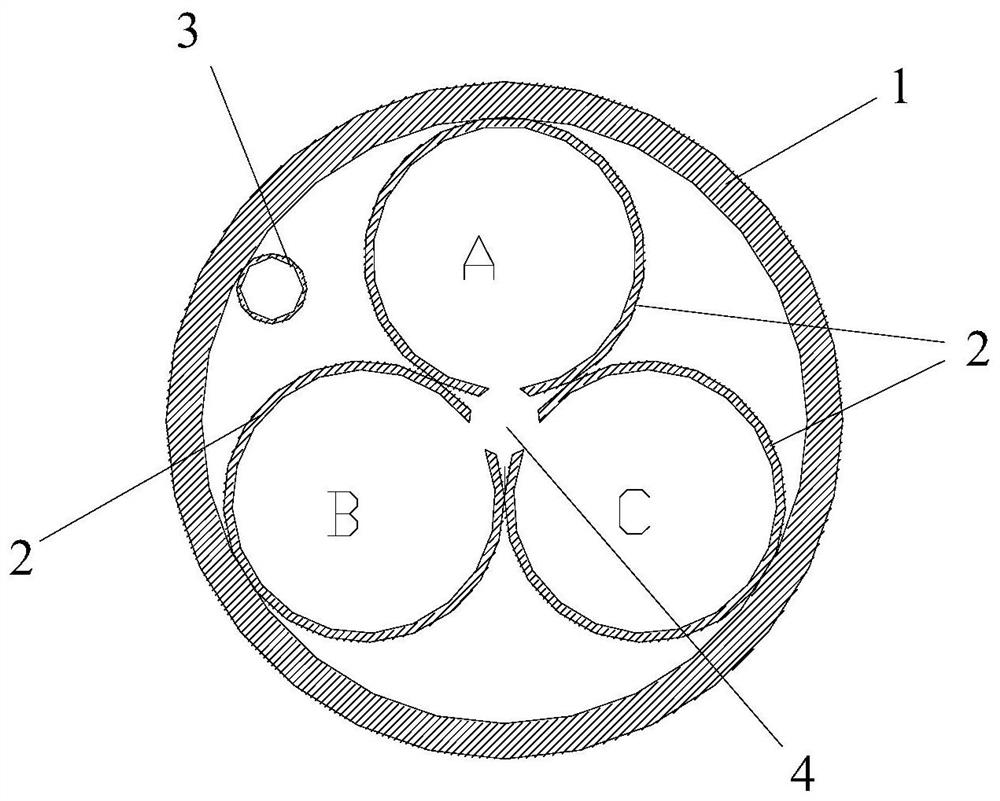

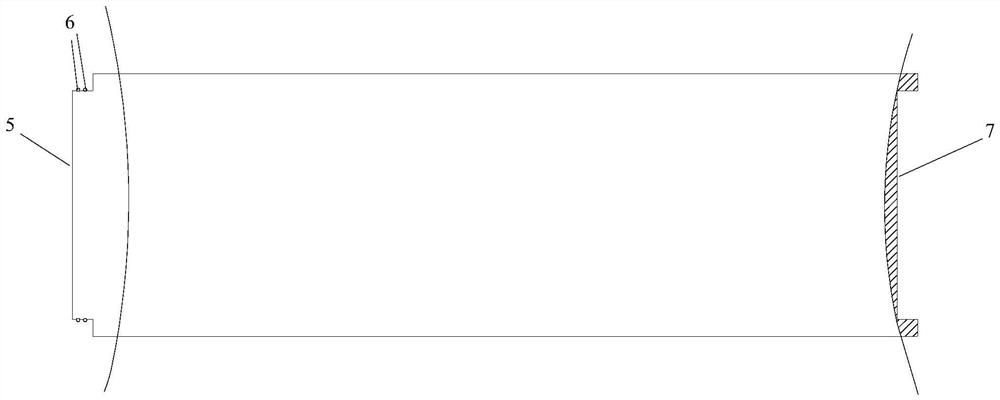

The invention provides a cable laying construction method. The method comprises the steps of 1, setting a pipeline for laying a cable; 2, arranging a cable jacking well and a cable receiving well, and carrying out pipeline jacking operation from the cable jacking well to the cable receiving well by adopting a pipeline jacking device underground so as to lay a pipeline; and 3, laying three cables A, B and C in the same loop into the same pipeline so as to realize the laying of the cables, wherein the pipeline is formed by inserting or welding a plurality of pipe sections. According to the cable laying construction method, the pipeline of the cable can be laid in a non-excavation ground mode, so that cable laying is achieved, and the excavation amount is greatly reduced. In addition, according to the method, the construction period can be greatly shortened, and the quality and the service life of the laid cable are guaranteed.

Owner:GUANGDONG WEIHENG POWER TRANSMISSION & DISTRIBUTION ENG +1

Cable pipe laying method and device and chain belt

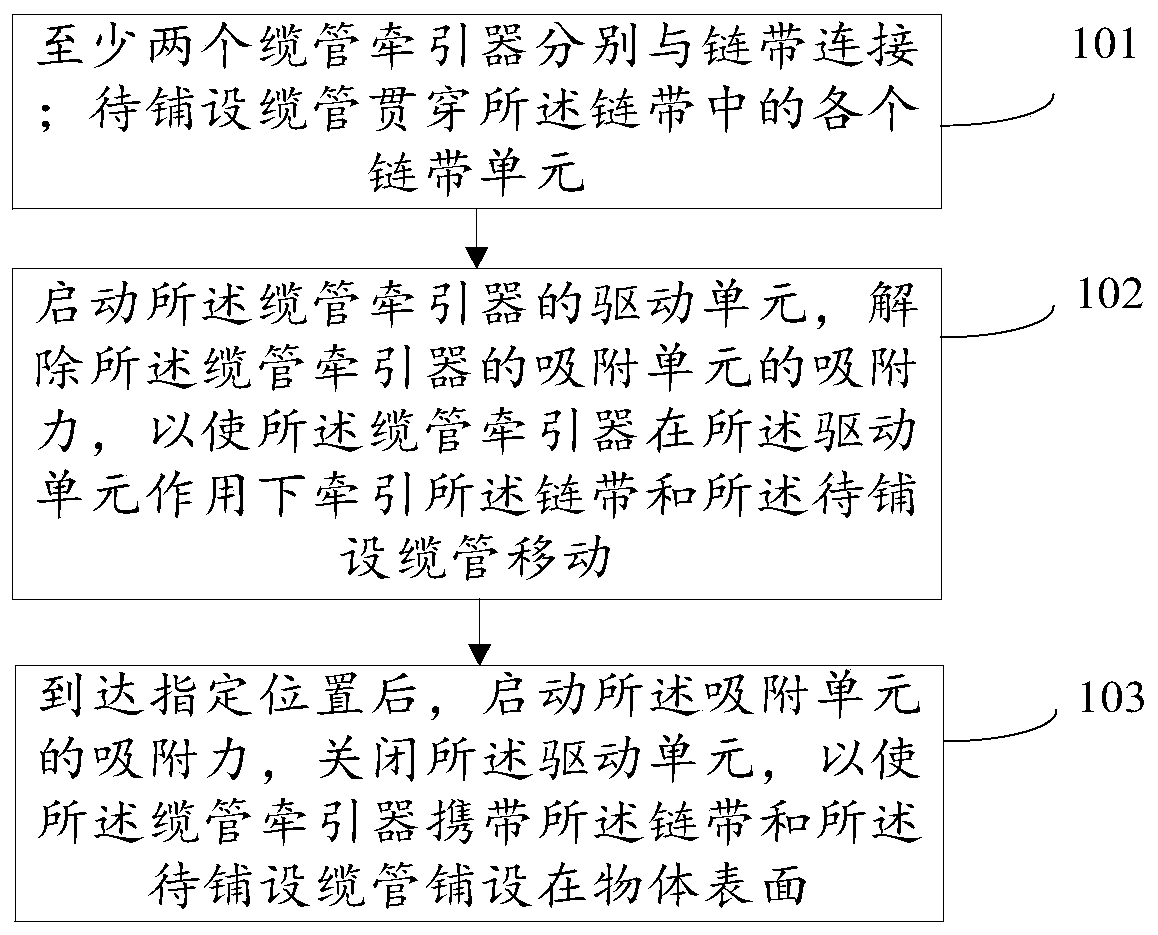

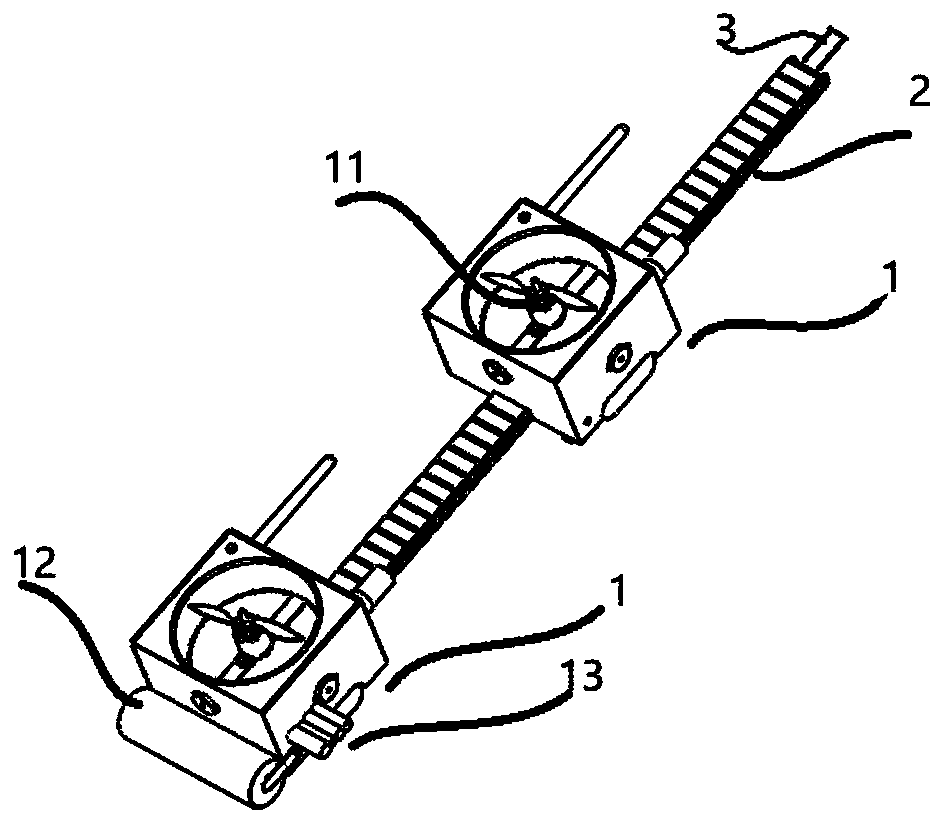

PendingCN111207243ALaying to achieveThreats to personal safetyPipe laying and repairHauling chainsStructural engineeringControl theory

The invention discloses a cable pipe laying method and device and a chain belt. The method comprises the steps that at least one cable pipe tractor is connected with the chain belt; a to-be-laid cablepipe penetrates through each chain belt unit in the chain belt; rotor wing units of the cable pipe tractors are started, and adsorption force of adsorption units of the cable pipe tractors is relieved, so that the cable pipe tractors drag the chain belt and the to-be-laid cable pipe to move under the action of the rotor wing units; and after the chain belt and the to-be-laid cable pipe arrive ata designated position, the adsorption force of the adsorption units is started, and the rotor wing units are stopped, so that the cable pipe tractors carry the chain belt and the to-be-laid cable pipeto be laid on the surface of an object. By means of the technical scheme, the cable pipe tractors achieve high-altitude cable pipe laying under the action of the rotor wing units and the adsorption units, personnel participation is not needed, and threats to personal safety of high-altitude operation personnel are avoided; and meanwhile, the high-altitude operation efficiency can be effectively improved.

Owner:林钢

Insulation board laying device for floor heating

PendingCN114086746AAffect the laying effectReduce labor intensityBuilding constructionsMechanical engineeringGround level

The invention relates to an insulation board laying device for floor heating, and relates to the technical field of insulation board laying. The insulation board laying device for floor heating comprises a movable frame, the movable frame is provided with a ground leveling device, a floor mat laying device and a glue solution coating device, the ground leveling device comprises an impurity removal mechanism and a dust suction mechanism, the impurity removal mechanism is used for removing protruding impurities on the ground, the dust suction mechanism is used for sucking and removing sundries, the floor mat laying device comprises a mat conveying mechanism and a flattening mechanism, the mat conveying mechanism conveys a floor mat to the ground, the flattening mechanism compacts the floor mat on the ground, the glue solution coating device is used for coating the floor mat with glue, and a containing box used for stacking insulation boards is arranged at the top of the movable frame. The process of removing sundries on the ground, laying the ground mat and coating the glue solution is continuously carried out, the working efficiency is effectively improved, after the glue solution coating is completed, the insulation board in the containing box can be laid on the ground mat coated with the glue solution, the operation is simple and rapid, and the efficiency is high.

Owner:杭州日新人工环境工程有限公司

Cable laying robot

ActiveCN104779558BLaying to achieveSimple layingApparatus for laying cablesElectrical and Electronics engineeringChassis

The invention discloses a cable laying robot. The cable laying robot comprises a first top wall mechanism, a first fork shearing push mechanism, a passive type pseudo parallel steering mechanism, a second fork shearing push mechanism and a second top wall mechanism which are connected in sequence, wherein the first top wall mechanism and the second top wall mechanism comprise chuck bodies, top wall supports which are installed on the chuck bodies and can move in an extension mode relative to the radial directions of the chuck bodies and first driving mechanisms, a second driving mechanism used for driving the first fork shearing push mechanism to move in an extension mode relative to the first top wall mechanism is arranged on the first fork shearing push mechanism, the passive type pseudo parallel steering mechanism comprises two subdivision chassis which are arranged oppositely and a steering mechanism, the subdivision chassis are arranged outside a cable in a sleeved mode, and a third driving mechanism used for driving the second fork shearing push mechanism to move in an extension mode relative to the second top wall mechanism is arranged on the second fork shearing push mechanism. The cable laying robot can creep in various pipelines such as a horizontal pipeline, or a vertical pipeline or an inclined pipeline, laying of the cable is achieved, and the cable laying robot cannot be limited by the thickness and the length of the cable.

Owner:WUHAN UNIV OF TECH

A flat automatic tape laying equipment and its control method

ActiveCN113085223BLaying to achievePlay a pulling roleArticle deliveryWebs handlingFiberElectric machinery

The invention relates to the technical field of carbon fiber composite material preforming equipment, in particular to an automatic tape laying device. The driving unit is arranged on the gantry frame and can drive the laying unit to move. The platform is equipped with a lifting component that can drive the laying unit to move in the vertical direction, and a rotating component is also installed on the sliding platform to drive the laying unit to rotate 360 degrees, so that the laying unit can realize tape laying at multiple angles; The first inflatable shaft is set in the laying unit to fix the support tray, the second inflatable shaft and the third inflatable shaft are used to roll the release film and the release paper respectively, and the three inflatable shafts are all The motor provides power to drive the rotation. During the unwinding process, the material tray not only drives the unwinding through the first air-expanding shaft, but also plays a certain role in the unwinding of the material tray during the process of rewinding the isolation film by the second air-expanding shaft. pulling effect.

Owner:常州新创航空科技有限公司

Tower pole base mounting device in cold climate

PendingCN108798196AExcavation realizedAvoid the phenomenon of a large amount of soil accumulationTowersControl engineeringTower

The invention provides a tower pole base mounting device in cold climate. The tower pole base mounting device comprises a foundation pit excavation mechanism, a bearing mechanism, a mounting mechanism, a pouring mechanism, a laying mechanism and a control mechanism, wherein the foundation pit excavation mechanism is arranged on a moving trolley; the bearing mechanism is arranged on the moving trolley; the mounting mechanism is arranged on the moving trolley and matched with the bearing mechanism; the pouring mechanism is arranged on the moving trolley and matched with the mounting mechanism; the laying mechanism is arranged on the moving trolley; and the control mechanism is arranged on the moving trolley and used for controlling the foundation pit excavation mechanism, the bearing mechanism, the mounting mechanism, the pouring mechanism and the laying mechanism. The phenomenon that multiple constructors conduct on-site construction simultaneously in the cold climate is reduced, foundation pit excavation can be conducted, precast pieces are pre-buried, gaps are poured, and a heat-insulation grass mat is laid after pouring.

Owner:国网河南省电力公司唐河县供电公司

Composite device for bathroom tiles and mounting method of composite device

PendingCN112443119AImprove affordabilityPrecisely control the paving gapFlooringMetal stripsEngineering

The invention discloses a composite device for bathroom tiles and a mounting method of the composite device, and relates to the technical field of decorative tiles. The composite device comprises a wood-plastic plate located at the bottom, metal plates fixed to the two sides of the long edge of the wood-plastic plate, baffles fixed to the two sides of the short edge of the wood-plastic plate, a base plate arranged in a containing cavity defined by a steel plate and the baffles, a pressing strip fixed to the upper end of the metal plates and provided with a groove in one side of the pressing strip, a metal strip inserted into the groove of the pressing strip, and tiles laid on the base plate, wherein one sides of every two adjacent tiles abut against the two sides of the metal strip correspondingly. According to the composite device, one sides of the two adjacent tiles abut against the two sides of the metal strip correspondingly, so that the gap of the laid tiles is equal to the thickness of the metal strip, and the paving gap during tile composite is accurately controlled.

Owner:ZHEJIANG YASHA DECORATION

Multi-stage flow channel blood vessel chip based on additive manufacturing

The invention discloses a multi-stage flow channel blood vessel chip based on additive manufacturing in the field of bionic chips, the multi-stage flow channel blood vessel chip comprises a substrate and a double-layer blood vessel channel located on the surface of the substrate, the double-layer blood vessel channel comprises an inlet and an outlet which are used for circularly introducing intravenous endothelial cells, and a closure contraction part is arranged between the inlet and the outlet; the closure contraction part comprises elastic salient points which define a rectangular matrix, and the radius of the elastic salient points is larger than the distance between the elastic salient points. According to the technical scheme, a blood vessel chip structure is designed according to the characteristics of skull capillaries, so that in-vitro culture of the stent and the HUVECs is implemented, a blood vessel forming mechanism is analyzed, the cost of in-vitro culture of organs is reduced, an innovative design concept of the blood vessel embedded stent with the balustrade vein characteristics is provided, and the stent has a good application prospect. And in combination with in-vitro culture of dynamic perfusion, the vascularization process is disclosed better, and a new way is provided for regeneration of bone tissues.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com