Outdoor fiber laying method

A laying method and optical fiber technology, applied in optical fiber/cable installation, optics, light guide, etc., can solve the problems of lack of construction process guidance documents, low degree of automation of construction equipment, unsatisfactory communication efficiency, etc., to achieve strong maintainability, The effect of high construction efficiency and improved selection of core wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] 本发明提供了一种室外光纤铺设方法,包括铺设前清扫、预放滑轮和皮套、牵引机预放距离、铺设中注意事项、铺设后光缆保护以及集中熔接等。

[0023] details as follows:

[0024] 1、铺设前应清扫桥架,检查桥架有无毛刺等可能划伤光缆的缺陷,并进行处理;清理预埋管内的泥沙等堵塞物。

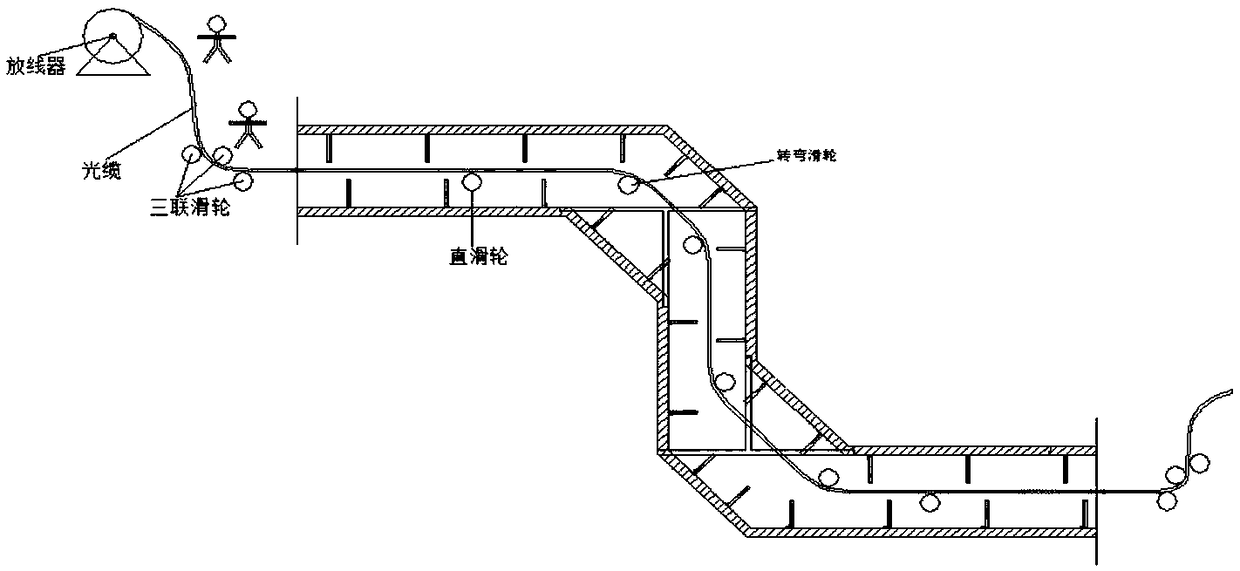

[0025] 2、在光缆沟内,每隔一定距离预放直线滑轮,可在井口对应的位置处放置,每个井口处均放置直线滑轮;在拐弯处放置转弯滑轮。

[0026] 在光缆沟进线处、出线处设置三联滑轮;

[0027] 其中,可以在转弯滑轮处的底层桥架上设置挡板,其中,挡板的宽度大于两个桥架水平方向之间的间距,以防止牵引机牵引光缆过程中转弯滑轮受力偏移。

[0028] 3、在管道的进线口处设置皮套,从而可以在布设过程中有效保护光缆,减轻光缆牵引阻力;所述皮套可采用与管道摩擦力大、但与光缆外皮摩擦力小的胶皮,防止光缆外皮与管口直接接触,摩擦刮伤外皮。

[0029] 4、光缆放线位置不少于两个人操作,以便应急突发情况;光缆从光缆盘上方放出并保持松弛弧形,光缆布放过程中严禁扭转、打小圈、浪涌等现象。

[0030] 根据《综合布线系统工程设计规范》GB50311-2007相关要求,当光缆采用桥架布放时,桥架内侧的弯曲半径不应小于300mm。管线布设2芯或4芯光缆时,弯曲半径不应小于25mm;管线布设室外光缆时,弯曲半径不小于光缆外径的10倍。

[0031] 5、设置多个牵引机,牵引机与放线处之间的距离以及相邻两个牵引机之间的距离不大于350m,且中间不大于两个拐角。

[0032] 6、光缆沟布设施工时按照“先难后易,先长后短”的原则,光缆布放时优先进行室外长距离主干线路上光缆铺设,其次进行次干线上长距离光缆铺设,然后进行室外短距离光缆铺设,最后进行室内光缆铺设。

[0033] 7、光缆布放在光缆沟不同层桥架上时应遵循先下后上的原则。首先布设最底层桥架光缆,待该层桥架光缆...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com