Tower pole base mounting device in cold climate

An installation device and climate technology, applied in the direction of towers, building types, buildings, etc., can solve the problems of unsolved problems of tower base installation in cold climates, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

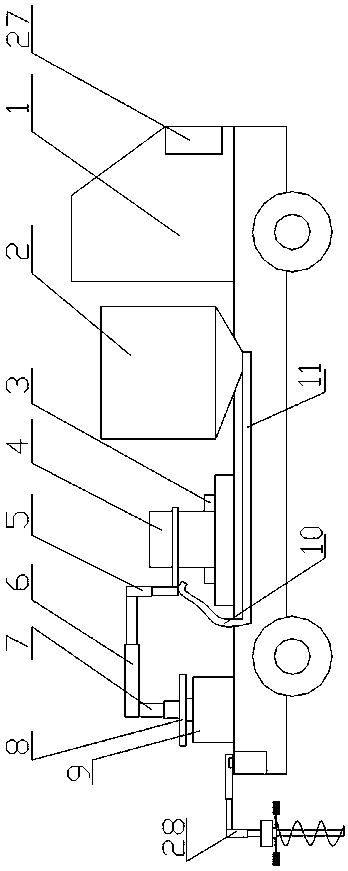

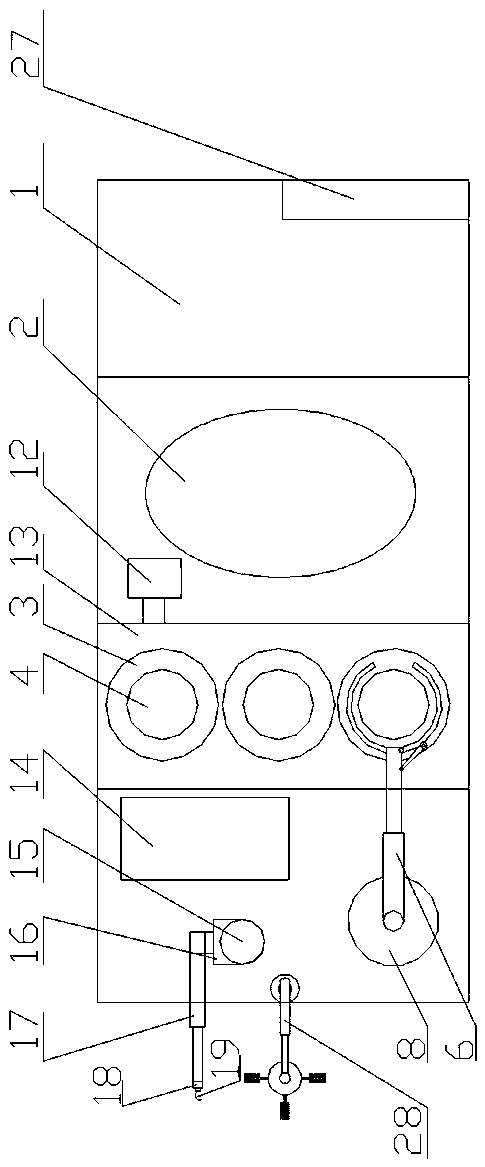

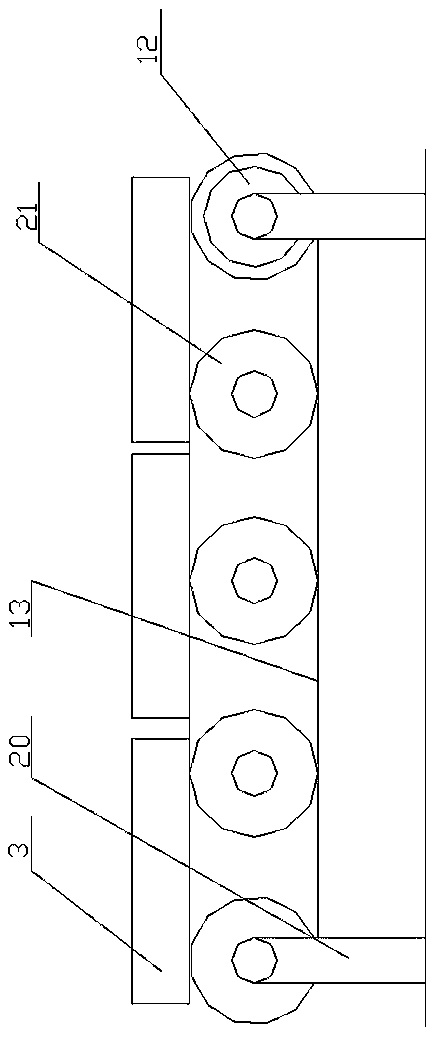

[0027] A tower rod base installation device in cold climates, comprising a foundation pit excavation mechanism 28 arranged on the mobile trolley 1, a bearing mechanism arranged on the mobile trolley 1, arranged on the mobile trolley 1 and connected with the mobile trolley 1 The installation mechanism that matches the bearing mechanism, the pouring mechanism that is arranged on the mobile trolley and cooperates with the installation mechanism, the laying mechanism that is arranged on the said mobile trolley, and the foundation pit that is arranged on the mobile trolley The control mechanism of the excavation mechanism 28, the bearing mechanism, the installation mechanism, the pouring mechanism and the laying mechanism;

[0028] The foundation pit excavation mechanism 28 includes an excavation steering motor 281 arranged on the mobile trolley 1, a foundation pit telescopic arm 282 arranged on the output shaft of the excavation steering motor 281, and a foundation pit telescopic a...

Embodiment 2

[0037] The difference from Embodiment 1 is that the control mechanism 27 is a PLC installed on the moving trolley.

[0038] The installation base column, installation telescopic column, installation telescopic arm, opening and closing telescopic rod, laying telescopic rod, laying column, and laying arm used in this implementation are all hydraulic telescopic rods, and an oil pool is set on the mobile trolley, because it is a conventional The technical means will not be described in detail in this embodiment.

Embodiment 3

[0040] The difference from the second embodiment is that the diameter of the earth drill is 600 mm and the depth is 1000 mm.

[0041] The method of ground drilling can quickly excavate the ground to meet the specified foundation pit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com