A super-large-diameter vertical shaft full-face tunneling machine and its construction method

A technology of full-section roadheader and super-large diameter, which is applied to shaft equipment, well sinking, and earth-moving drilling and mining, etc., can solve the problems of inability to carry out roadheading construction, high cost, poor verticality control of shafts, etc. Power requirements, to achieve the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

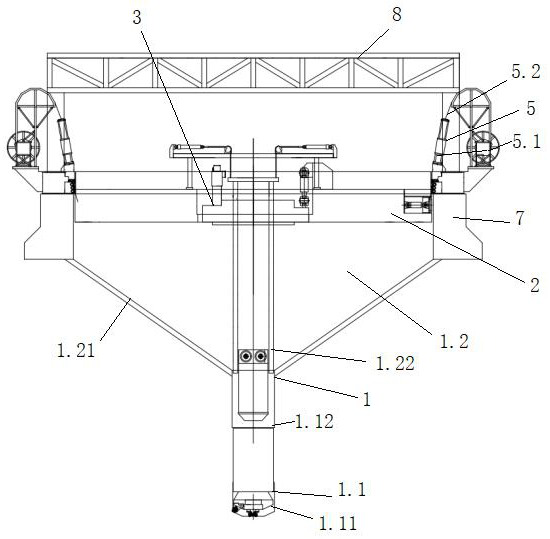

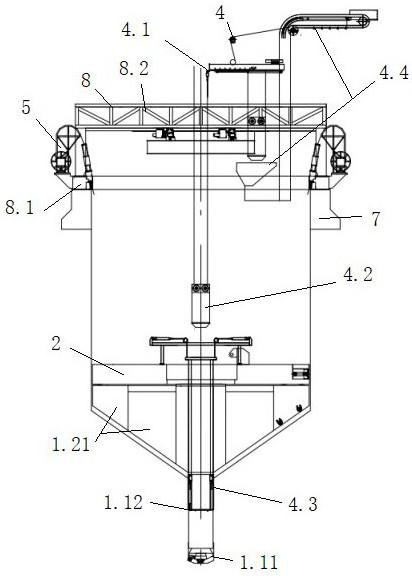

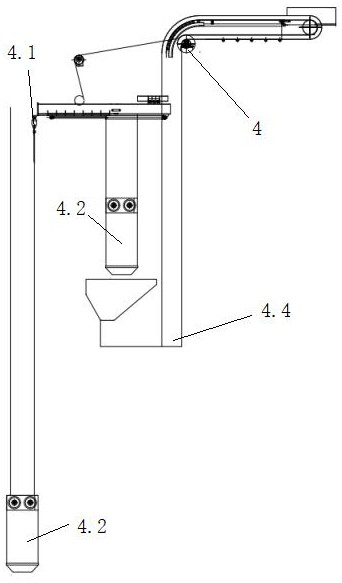

[0043] A super-large-diameter vertical shaft full-face boring machine, see Figure 1-Figure 5 , including excavation system 1, shield body 2, main drive system 3, slag discharge system 4, hoisting system 5, ring segment hoisting system, hydraulic fluid system, electrical control system and pose measurement and guidance system, in which the hydraulic fluid The system, electrical control system, and pose measurement and guidance system are the functional component systems of the super-large-diameter vertical shaft full-face roadheader, and its structure can refer to the existing technology, in which the hydraulic fluid system and the electrical control system are the execution carriers of the roadheader's control functions.

[0044] In this embodiment, the construction site is provided with a shaft lock foundation 7, and a support member 8 is arranged on the shaft lock foundation 7. Here, the support member 8 preferably includes a ring beam 8.1 and a door frame 8.2, and the ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com