Multifunctional adit heading machine simulation test platform and use method thereof

A technology of simulation test and roadheader, which is applied in the field of tunneling, can solve the problems of large scale difference and achieve the effect of highlighting the mechanical characteristics, high applicability, and simplifying the form of the main tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

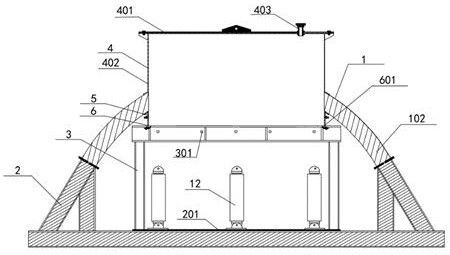

[0077] Example 2, such as Figure 14~Figure 18 As shown, the difference between it and Embodiment 1 is that the boring equipment is a boring machine 13, the inner cover plate 404 of the imitation pressure housing 4 is omitted, the working end of the boring machine 13 is inserted into the starting sleeve 5, and the sealing assembly 6 passes through the The wire brush 601 closely adheres to the working end of the roadheader 13 to play a sealing role to prevent the pressure body 9 from flowing out; inject the pressure body 9 into the imitation pressure shell 4 to check the performance of the excavation equipment under different buried depths, and obtain the specific excavation parameters of the equipment. Optimize equipment deficiencies. And by changing the form of the bench, it can meet the simulation tests of branch tunnel boring machines in different directions, which can be recycled and reprocessed, reducing the test cost, and realizing multi-directional simulated branch tunn...

Embodiment 3

[0078] Example 3, such as Figure 19 As shown, the difference between it and Embodiment 1 is that the outer cylinder 402 of the imitation pressure shell 4 and the starting sleeve 5 are merged into a straight sleeve 15 and penetrated on the cutting opening 102 of the composite segment 1, and the cutting opening The inner wall of the circular port at the bottom of 102 is provided with multiple water-tight sealing parts 14, which reduces the difficulty of manufacturing, prevents the problem that the special-shaped interface cannot be welded and sealed, the device is simpler, and the test is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com