A construction method for connecting walls under ground for underground facilities

A technology for underground facilities and construction methods, applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve the problem that the groove forming machine cannot meet the requirements of lateral trench excavation, the cable trench underpinning method is not suitable for the local area, the strength and stiffness Failing to meet the construction requirements and other problems, to achieve the effect of convenient vertical operation method, convenient equipment installation and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

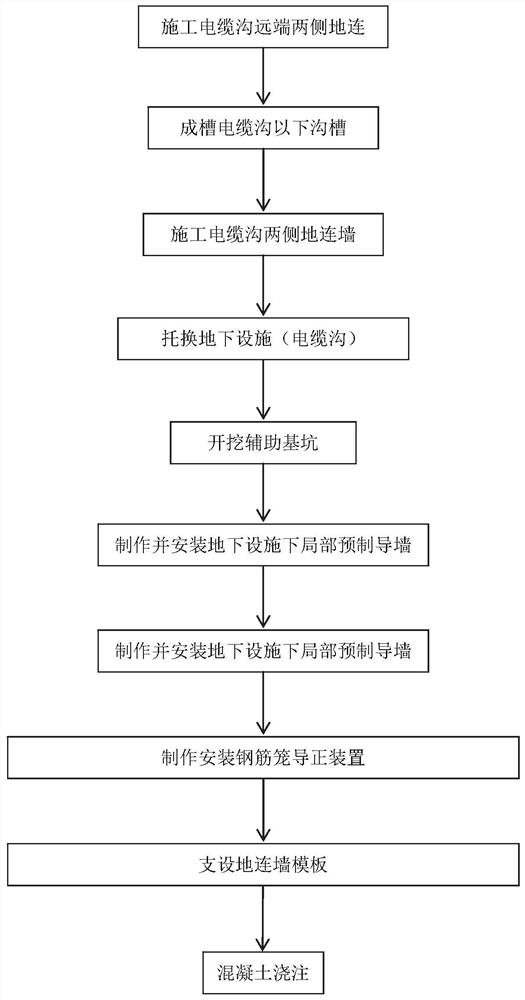

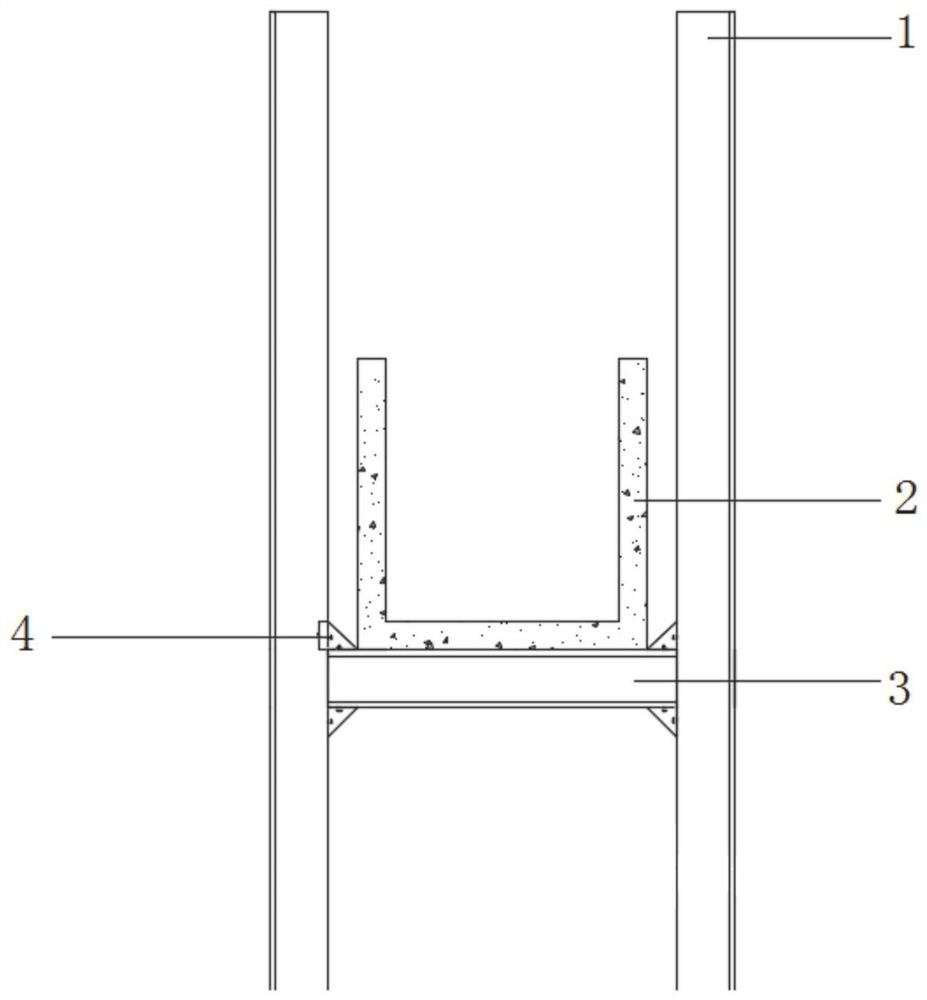

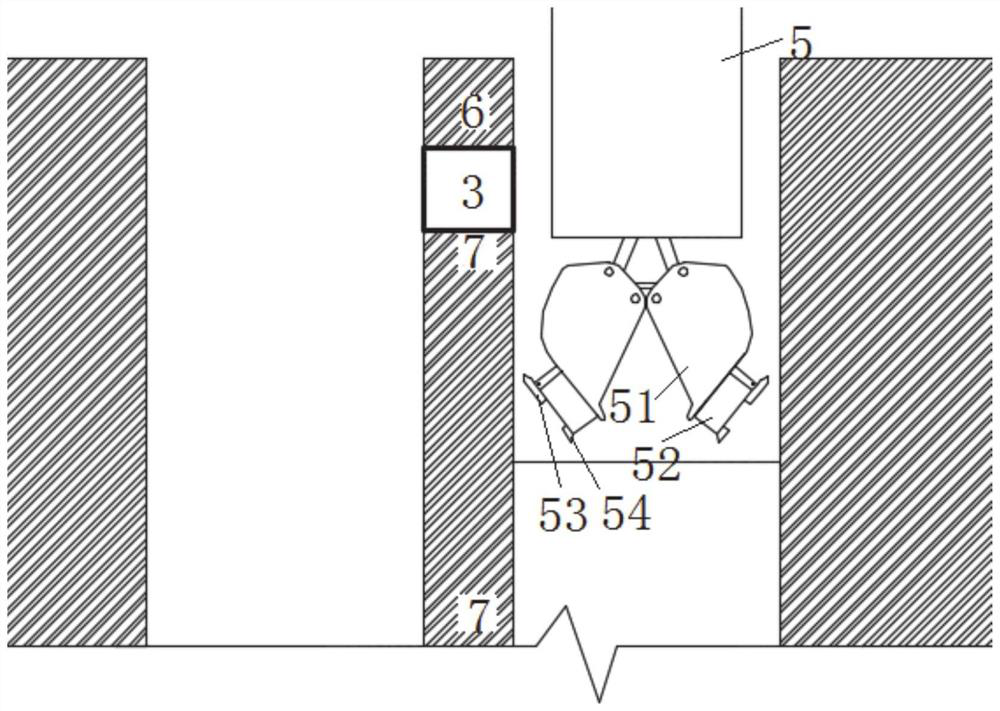

[0047] This embodiment provides a construction method for connecting walls under underground facilities, such as figure 1 As shown, the construction of the connecting walls on both sides of the underground facilities is completed, and there is a cable trench 2 in the middle space of the connecting walls. The cable trench 2 is supported by the underpinning device, so that the ground connection wall has enough support to provide excavation space, so as to construct auxiliary foundation pits, underpin underground facilities, assist foundation pit excavation, and guide wall excavation under the cable trench. Prefabricate the local guide wall, install the segmental reinforcement cage positioning device at the bottom of the pit, make the guiding device for installing the reinforcement cage, and connect the reinforcement cage in segments; then lower the reinforcement cage, and support the ground connection wall formwork on the auxiliary foundation pit base.

[0048] The specific cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com