Flush joint waterproof structure for roof deformation joint

A waterproof structure and deformation joint technology, applied in the direction of roof, roof covering, building components, etc., can solve the problems of weakened waterproof performance of building structure, reduce the fluency of roof drainage, and can not meet the requirements, so as to improve impact resistance and waterproof insulation. Heat resistance, prevent cracking, increase service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

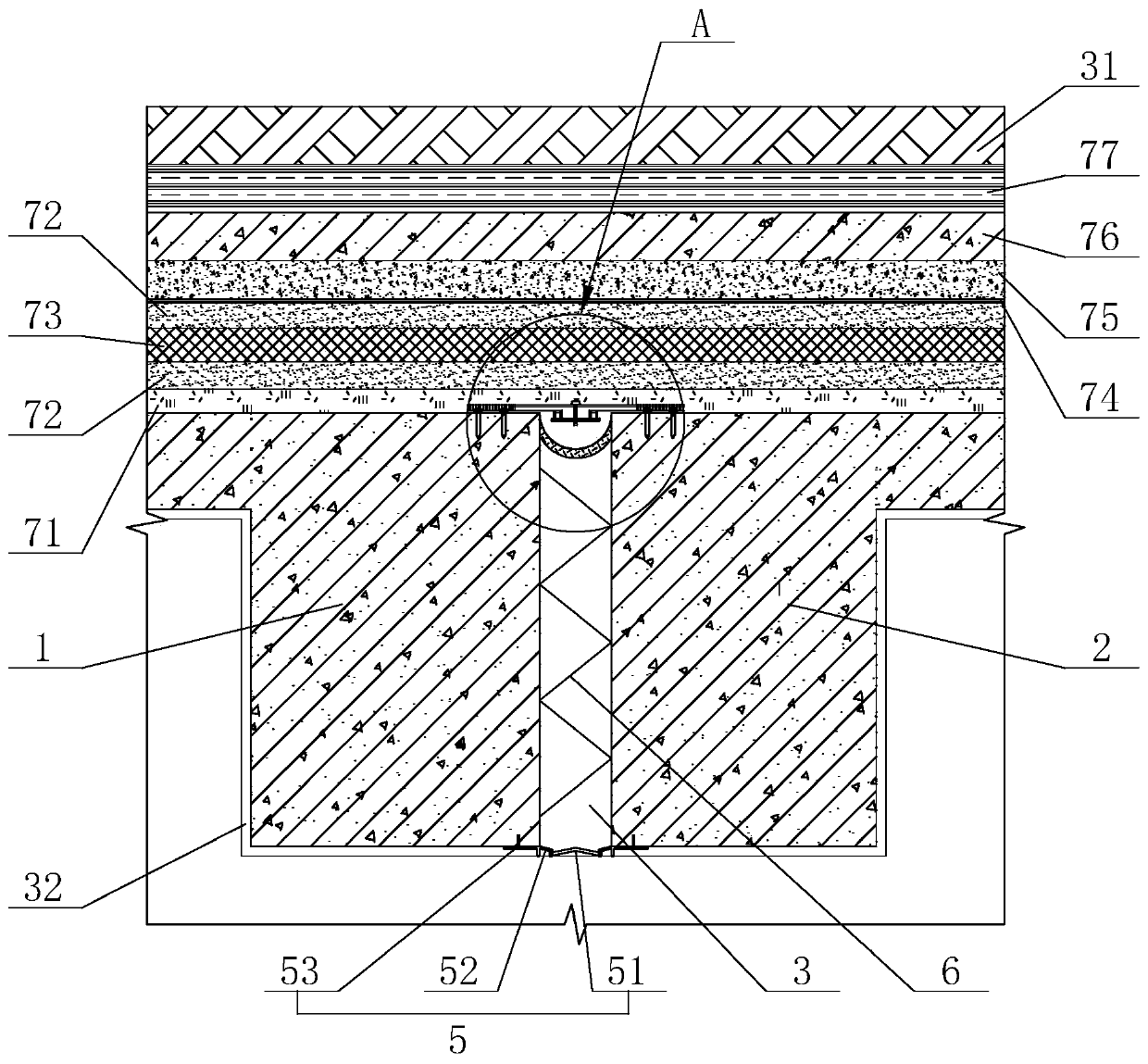

[0035] refer to figure 1 , is a flat seam waterproof structure for roof deformation joints disclosed by the present invention, comprising a first wall 1 and a second wall 2 arranged on one side of the first wall 1, the first wall 1 and the second wall 2 is made of reinforced concrete. The first wall 1 and the second wall 2 are disconnected to form vertical deformation joints 3 with a certain distance. The deformation joints 3 are provided with waterproof components and reinforcement components. The waterproof part 4 and the lower waterproof part 5.

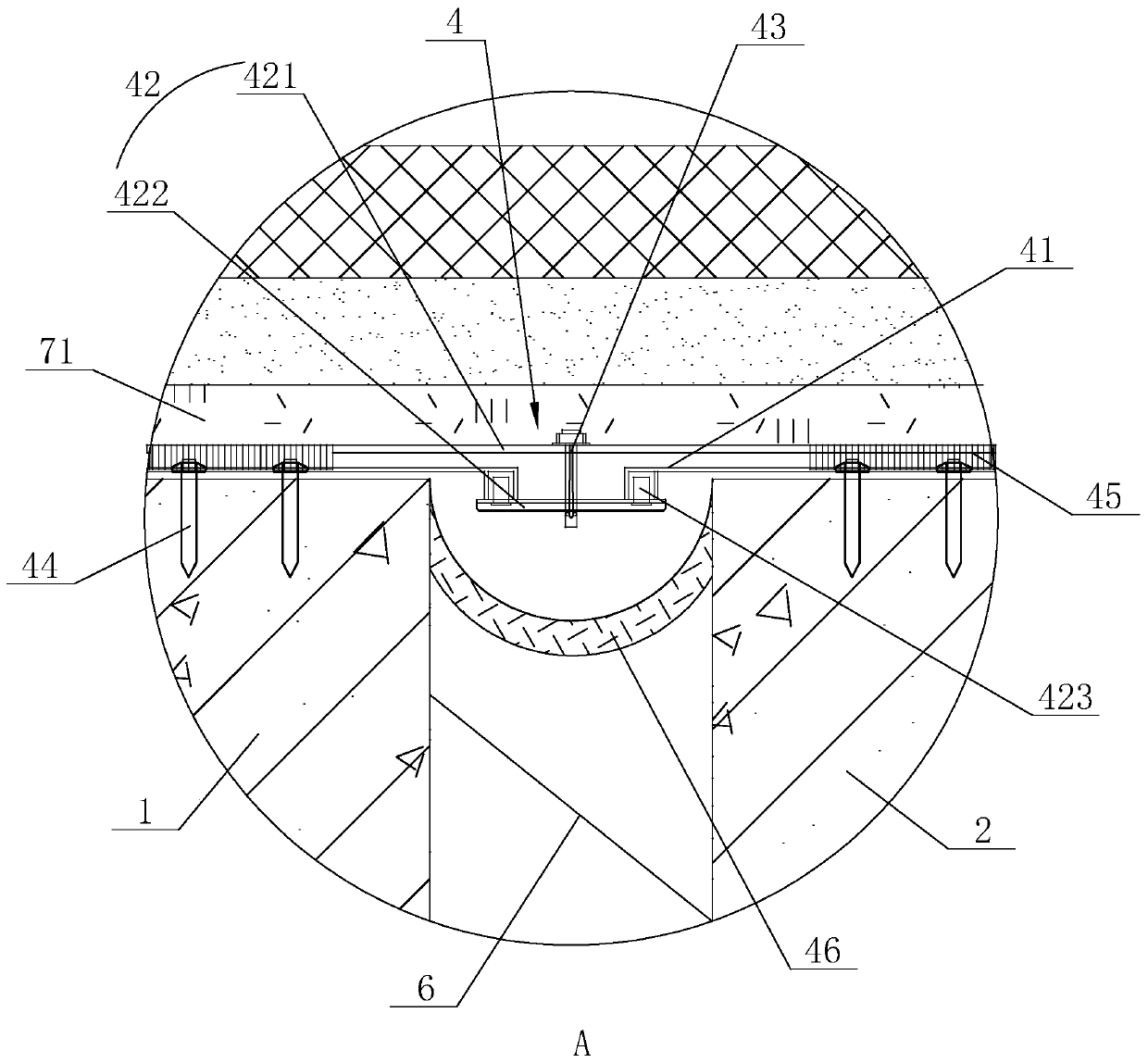

[0036] Further, refer to figure 2 , The upper waterproof part 4 includes an upper metal frame 41, a central plate 42, a central axis control rod 43 and a plurality of expansion bolts 44, in this embodiment. The upper metal frame 41 and the central plate 42 are preferably made of aluminum alloy, and the expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com