Powder falling control device and method for additive manufacturing

A technology of additive manufacturing and powder, which is applied in the direction of additive manufacturing, additive processing, chemical instruments and methods, etc. It can solve the problems of large space occupation, high precision requirements, and inability to implement powder addition, and achieves simple structure and controllability Strong, achieve the effect of directional deposition of powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

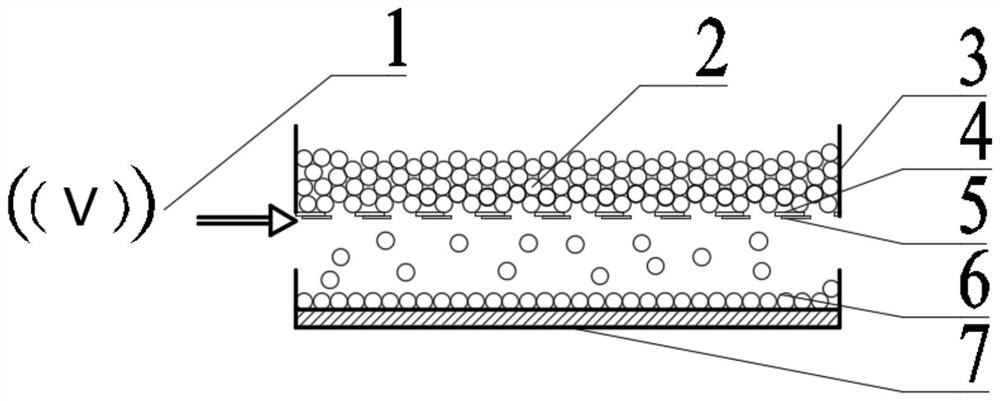

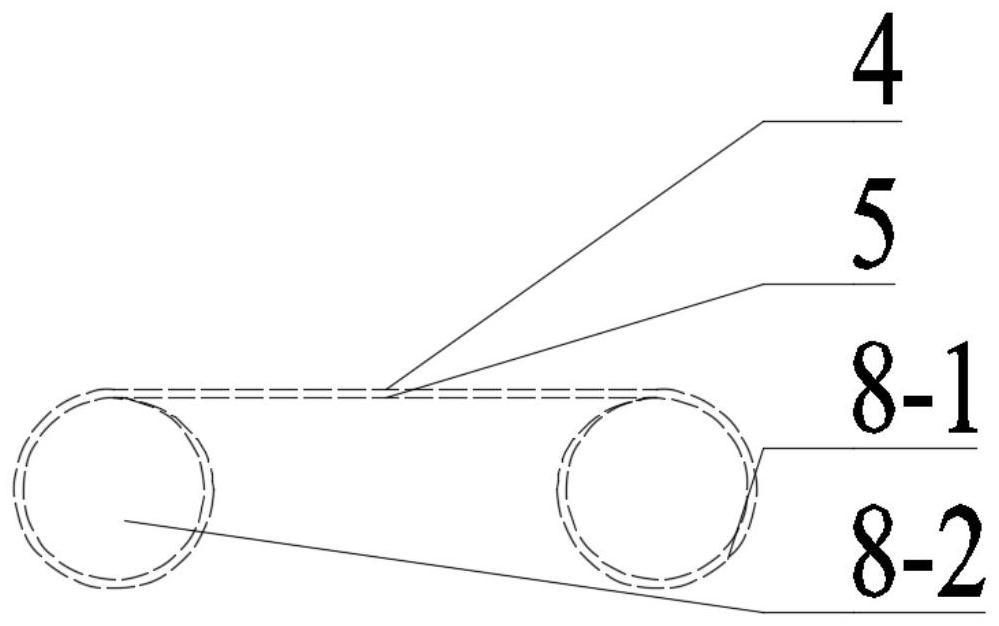

[0049] Such as figure 1 As shown, a device for controlling powder falling includes a powder outlet covered with a double-layer mesh screen (the first screen cloth 4 and the second screen cloth 5 ) and a screen cloth driving unit 8 .

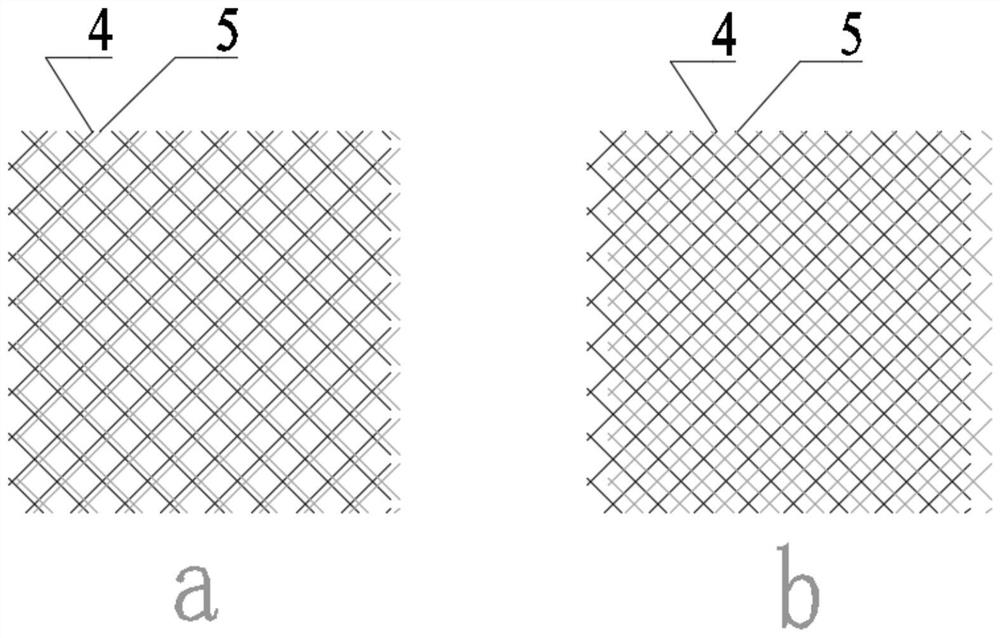

[0050] The device includes a powder outlet covered with double-layer screens 4 and 5, the double-layer screens 4 and 5 are attached and relatively movable, and the screens 4 and 5 have mesh holes. Such as figure 2 , image 3 As shown, the drive unit 8 can control the relative movement of the screens 4 and 5, thereby controlling the aperture size of the passing holes formed after the interference of the double-layer screens 4 and 5, thereby controlling the powder flow rate. In addition, in the feeding state, when the drive unit 8 moves the screens 4 and 5, the screen holes of the first screen 4 and the second screen 5 will overlap to form a channel (passing hole) with a larger aperture, and the powder Falls through the channel and deposits on ...

Embodiment 2

[0061] On the basis of Example 1, such as Figure 4 As shown, a controlled powder drop device for additive manufacturing includes a moving mechanism, a vibration unit 1, and a powder storage bin 9, an intermediate bin 10, and double-layer screens 4, 5 arranged in sequence from top to bottom.

[0062] The device is arranged on a moving mechanism and can move along a set path.

[0063] The powder storage bin 9 is arranged at the top for storing the powder to be placed. The intermediate bin 10 is connected to the lower part of the powder storage bin 9 for maintaining the stability of the powder below. The double-layer screens 4, 5 are placed at the opening below the intermediate bin 10 through the fixing unit 11, and the screen driving device 8 is connected to the double-layer screens 4, 5 to control the flow of powder.

[0064] Preferably, the whole powder storage bin 9 can be in the shape of a funnel or other shapes with an open top and an open bottom.

[0065] Preferably, t...

Embodiment 3

[0072] A device capable of directional deposition, on the basis of embodiment 2, comprising a template;

[0073] A template is introduced outside the second screen 5 to control the pattern of powder laying. The template can be a board with square holes or other patterns.

[0074] The movement of the template can also be controlled to control the orientation of the powder laying, so that the directional deposition of the powder can be further realized. Through the combination of multiple above-mentioned devices, each device controls the deposition of different powders at different positions, thereby realizing multi-material powder laying.

[0075] Compared with the existing equipment, the device of the present invention has simple structure, strong controllability, can control the powder feeding speed, is especially used for the control of fine powder, and can control the powder laying conveniently and efficiently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com