An automatic feeding and stamping system for automobile support arm components and its control circuit

A technology of automatic feeding and arm support, applied in electrical program control, program control in sequence/logic controllers, and manufacturing tools, etc., can solve the problems of difficulty in operation, waste of energy, and high level of personnel skills, and achieve low labor intensity. , The effect of high work efficiency and not easy to work accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

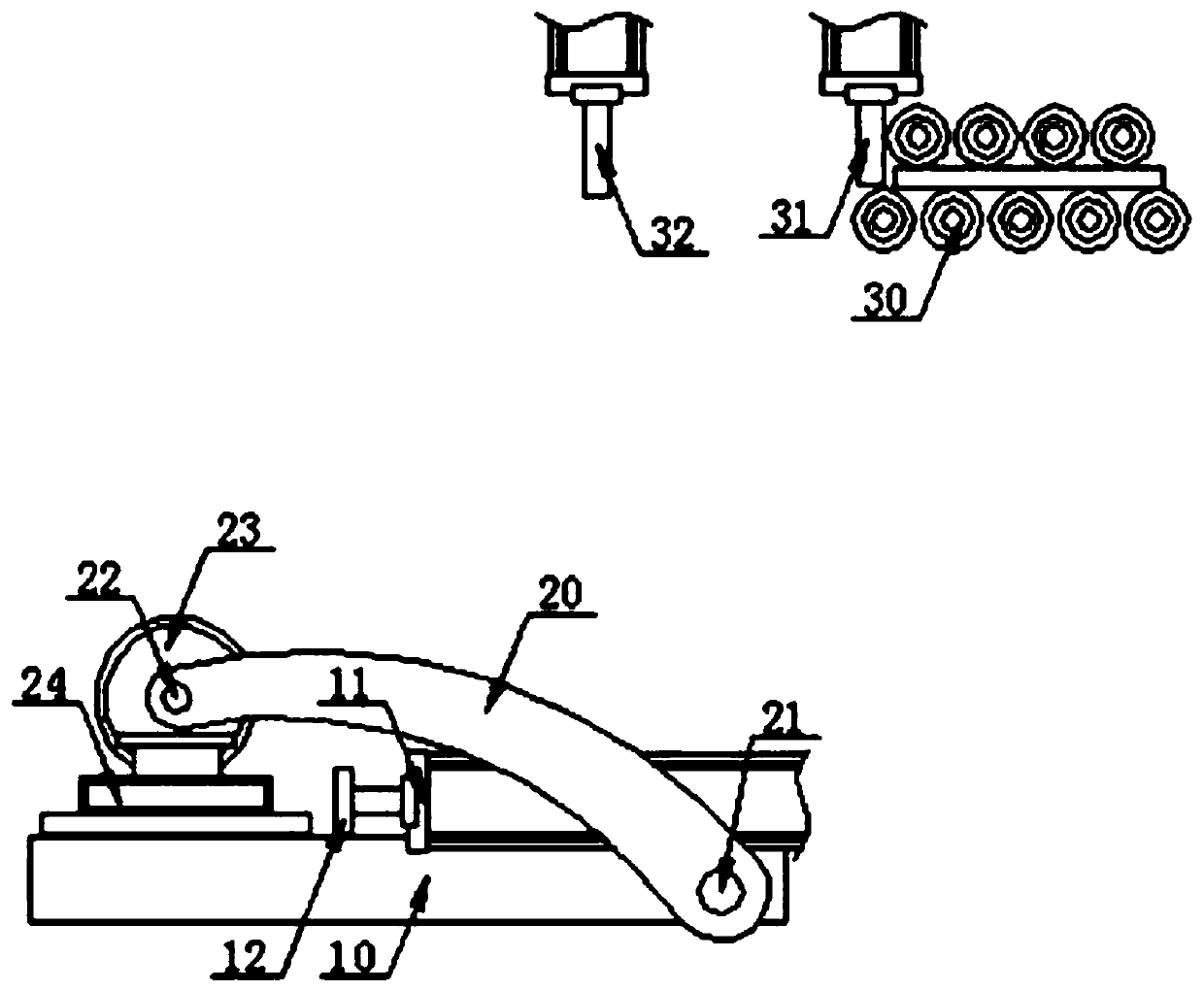

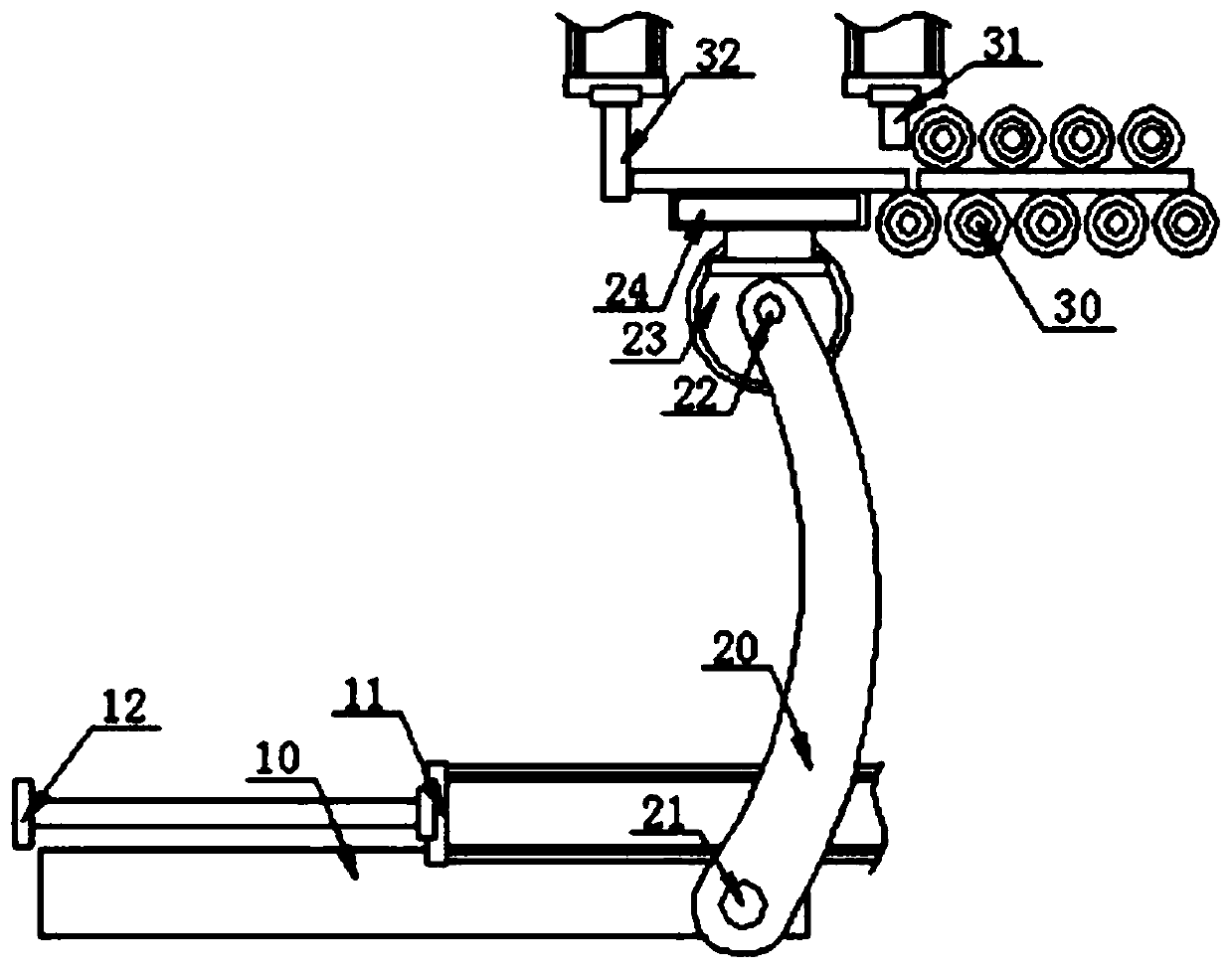

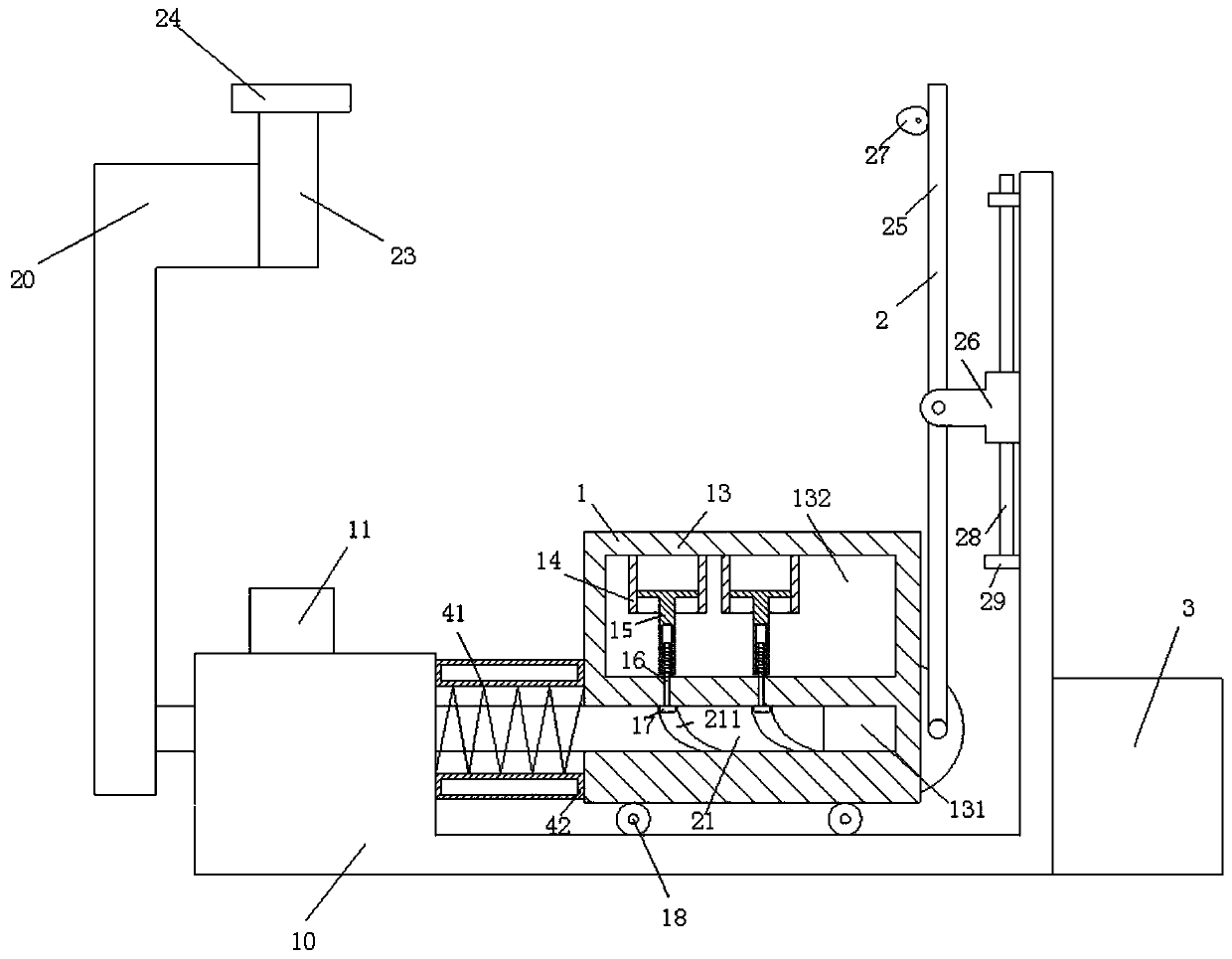

[0032] As an embodiment of the present invention, the other end of the rotary pick-up swing arm 20 is also provided with an angle adjustment shaft 22 and an angle adjustment dial 23 arranged on the angle adjustment shaft 22 for driving the angle adjustment. Turntable 23 is an angle adjustment motor that rotates around the angle adjustment shaft 22 , the electromagnetic pick-up chuck 24 is arranged on the roller surface of the angle adjustment turntable 23 , and the electromagnetic pick-up chuck 24 is parallel to the angle adjustment shaft 22 axis.

[0033] As an embodiment of the present invention, the rotary fetching swing arm 20 is arc-shaped, and the rotary fetching swing arm 20 is bent toward one side of the stamping and forming equipment.

[0034] As an embodiment of the present invention, it also includes a sheet material feeding roller set 30, a first feeding gear cylinder 31 and a second feeding gear cylinder 32 arranged above the rotary drive shaft 21. The feeding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com