Patents

Literature

30results about How to "Control placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

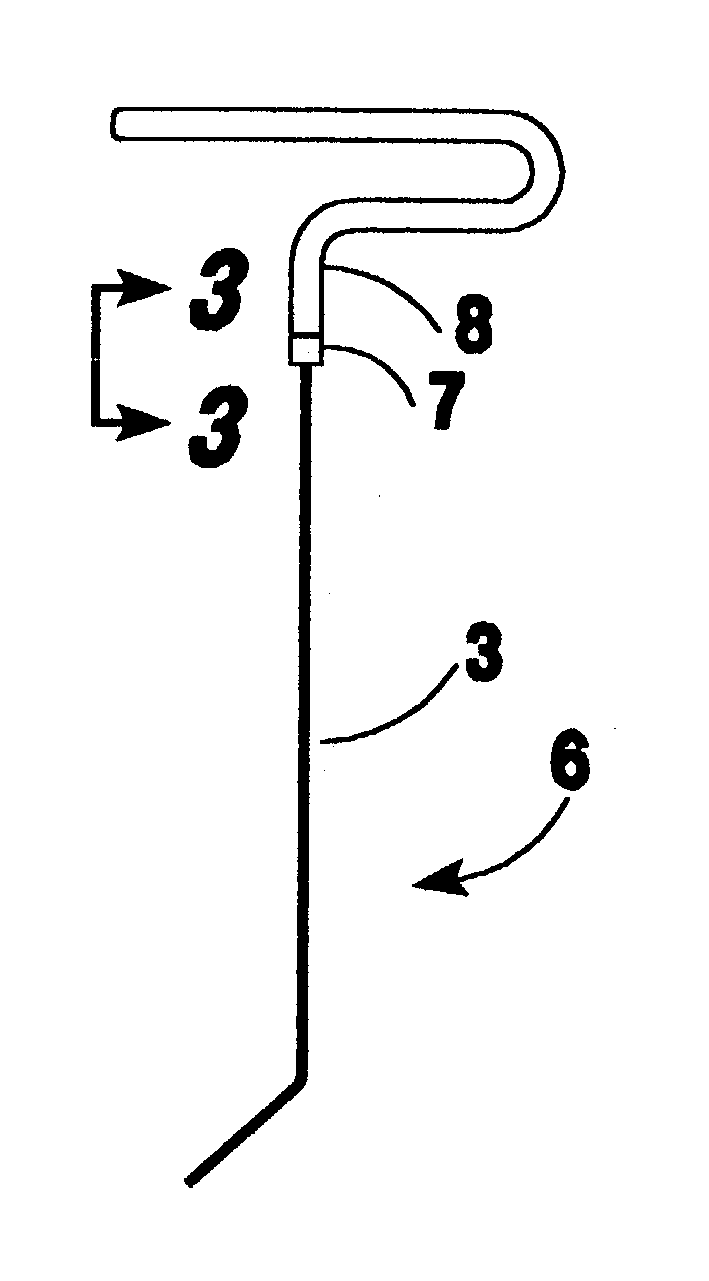

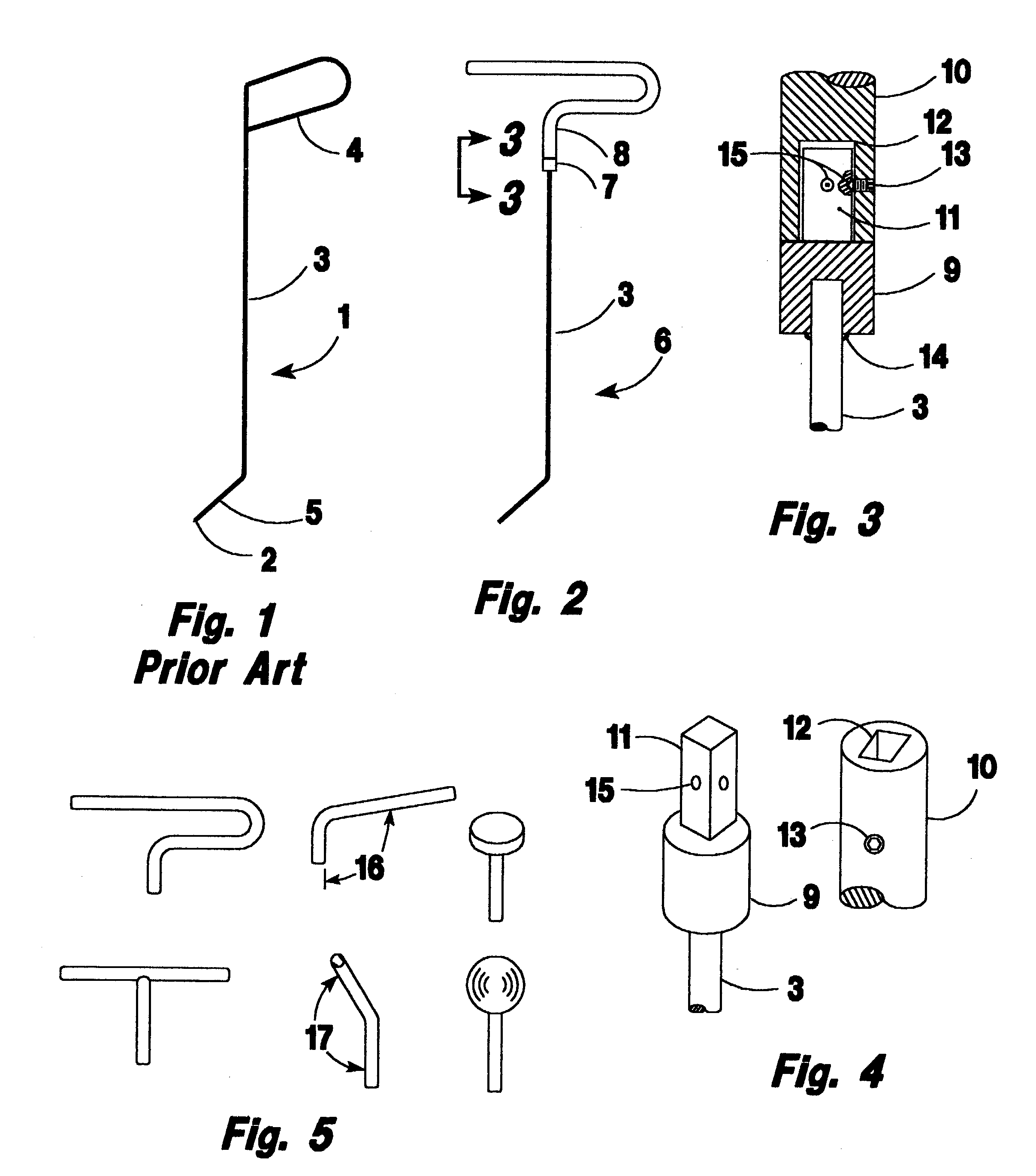

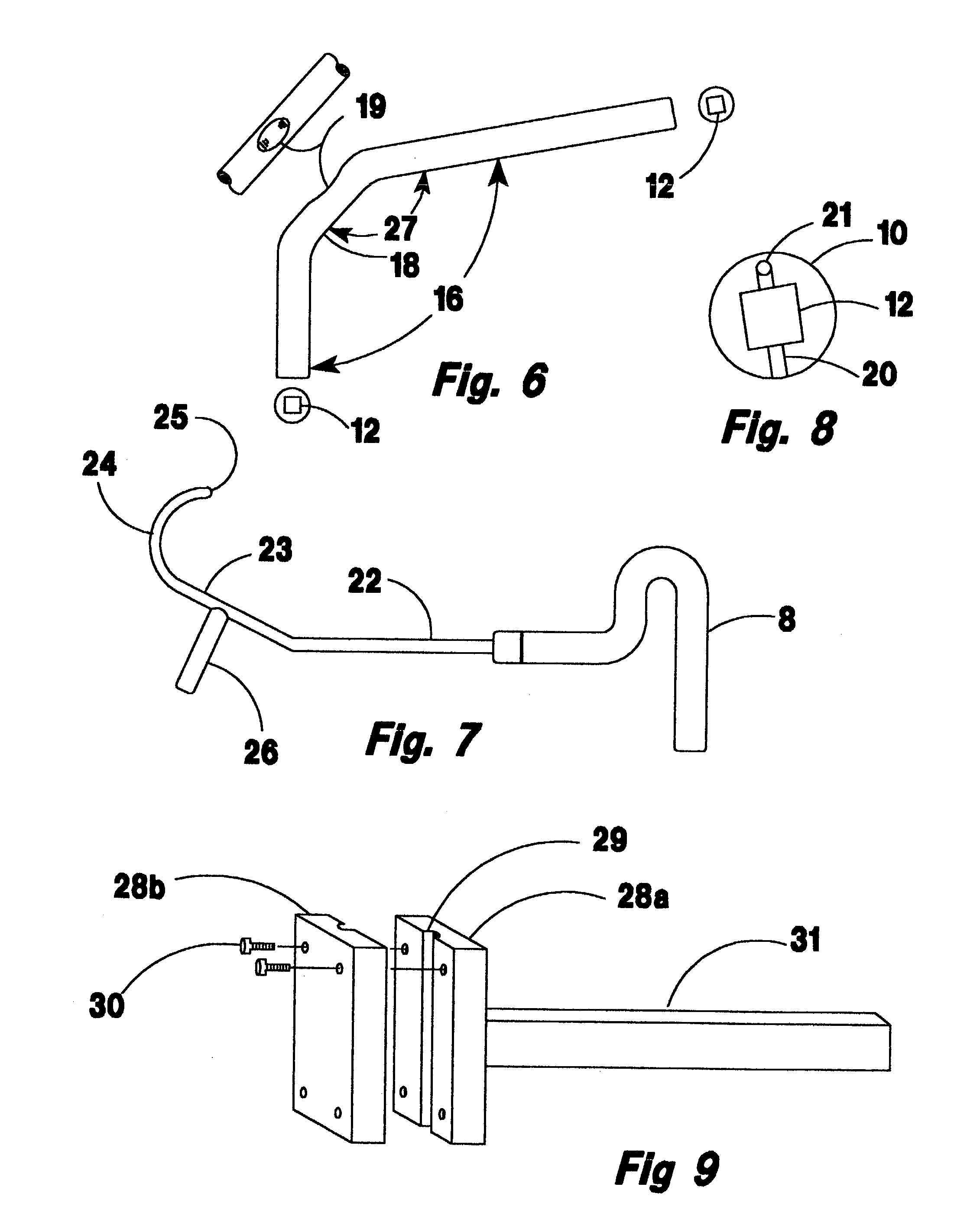

Automobile body dent repair tool

InactiveUS20050252271A1Control placementControl of workingForging/hammering/pressing machinesLacquerMechanical engineering

A set of tools for the process generally known as “paintless dent repair” for removing a class of dents in automobile body panels is modified to have interchangeable handles with a range of positions relative to the working end of the tool. Thus, permitting the modified set of tools to be comprised of many fewer individual tools than is the current practice in the art.

Owner:FREDENBERG GAGIK M +1

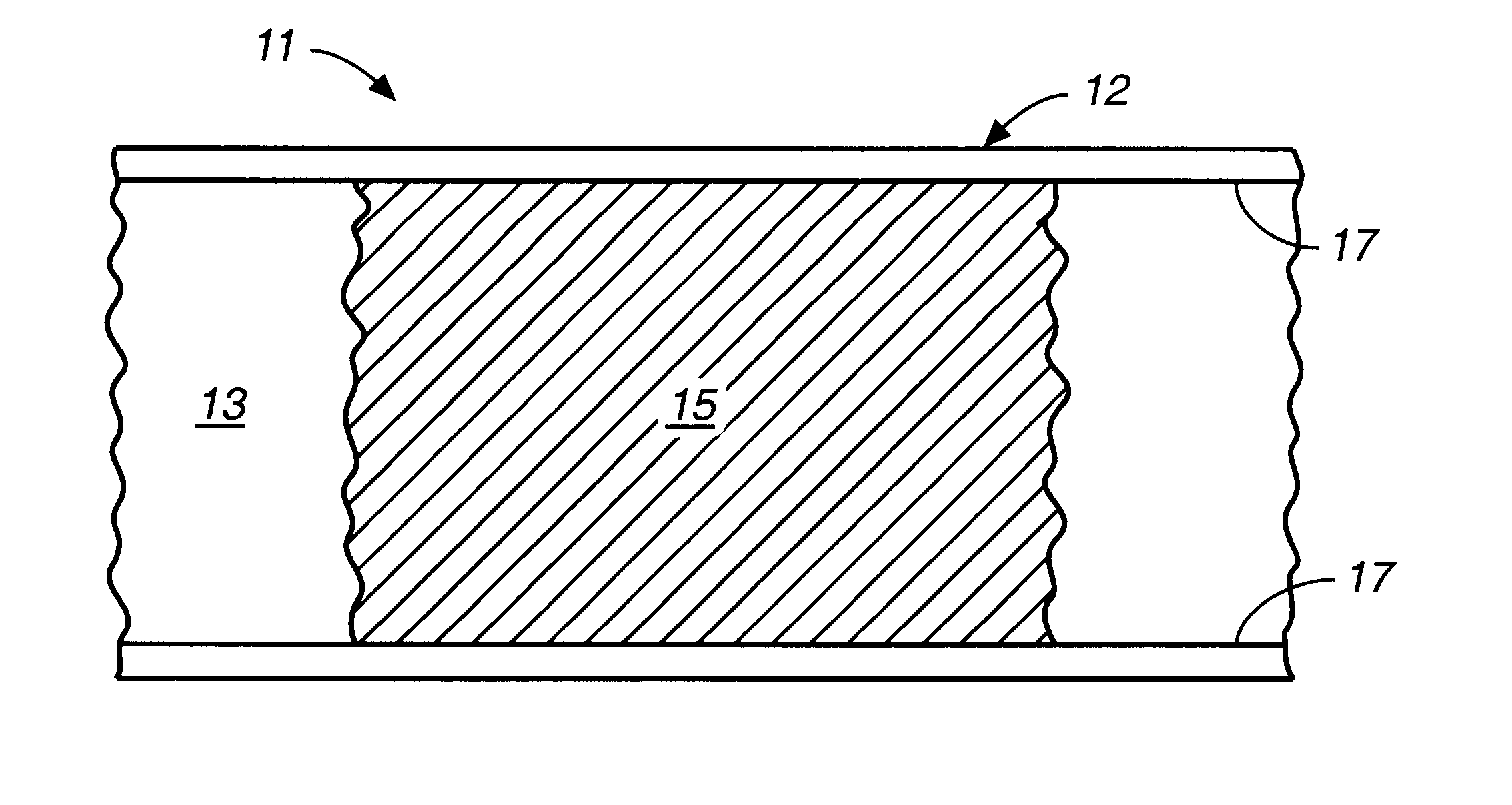

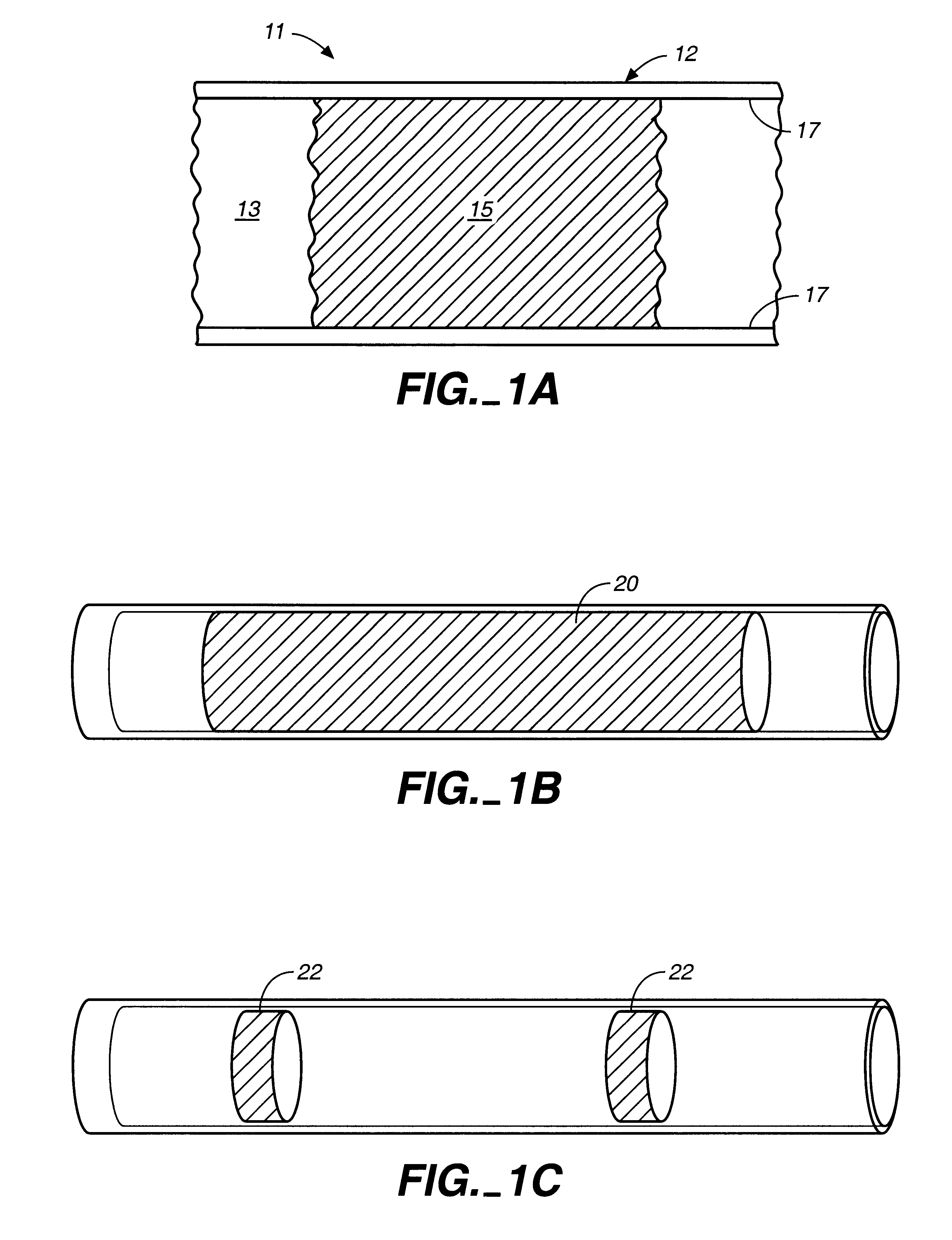

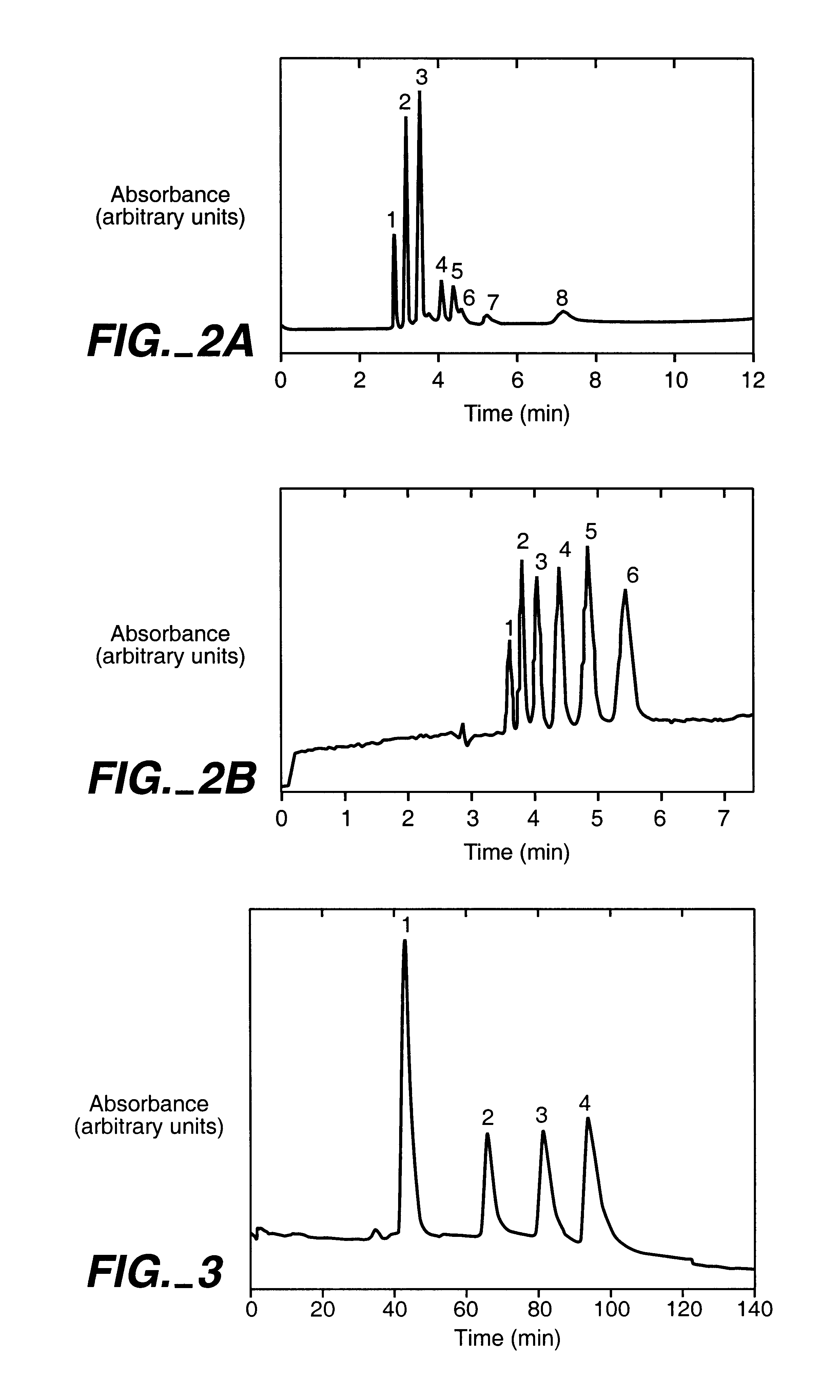

Separation column having a photopolymerized sol-gel component and associated methods

InactiveUS6875348B2Preparation of a separation columnEasy to prepareIon-exchange process apparatusComponent separationAnalyteFrit

A separation column and a method of preparing the separation column are provided. The separation column includes a separation channel and a porous matrix in the channel. The porous matrix includes a metal organic polymer, such as a photopolymer. The porous matrix can be a separation medium adapted to separate a sample of analytes or a frit adapted to retain a separation medium in the channel.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

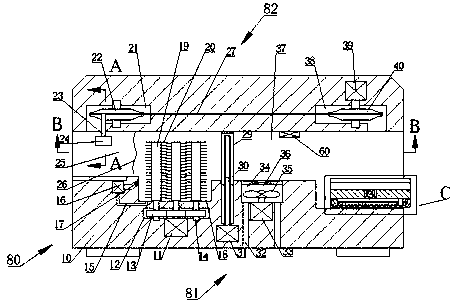

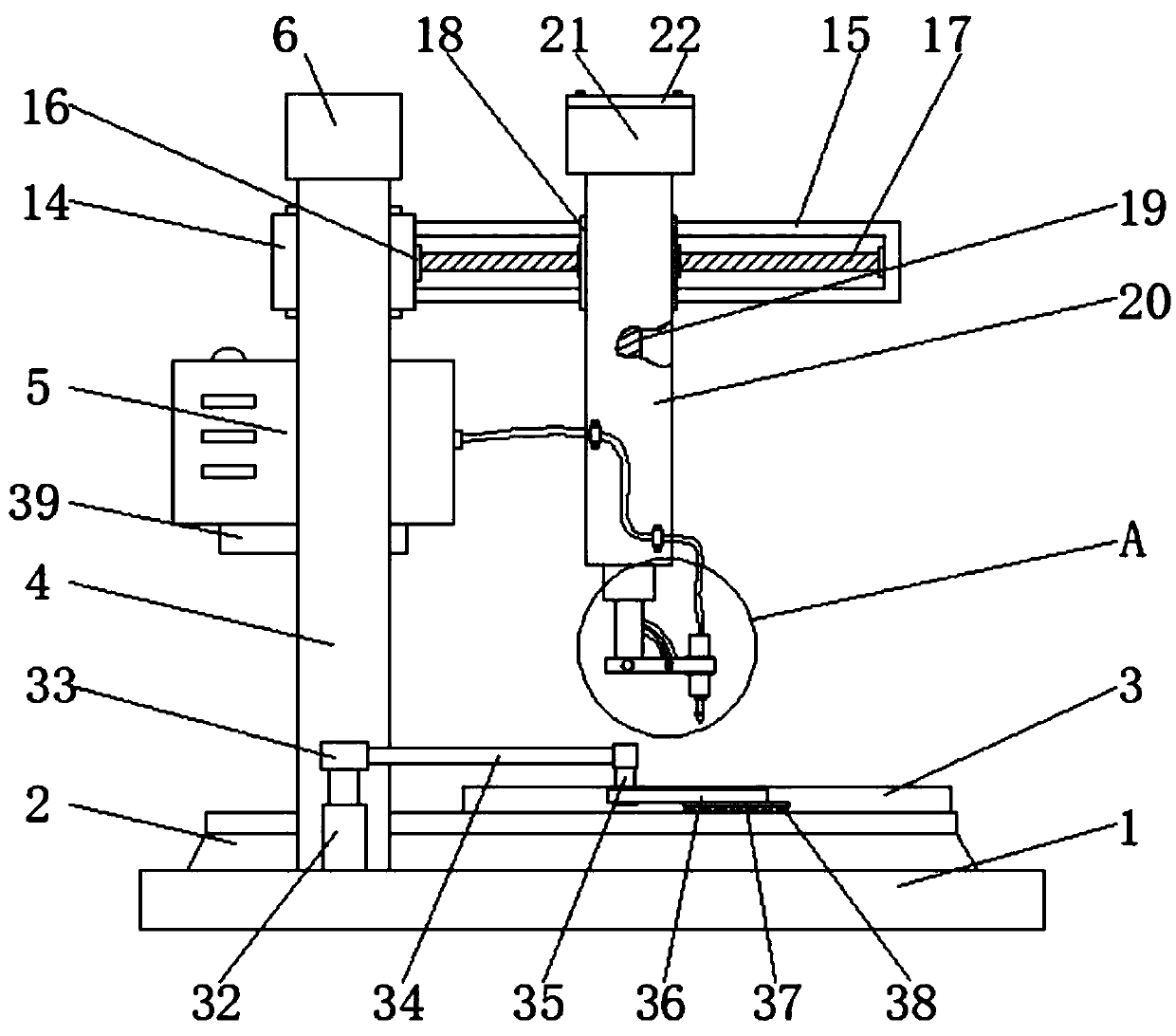

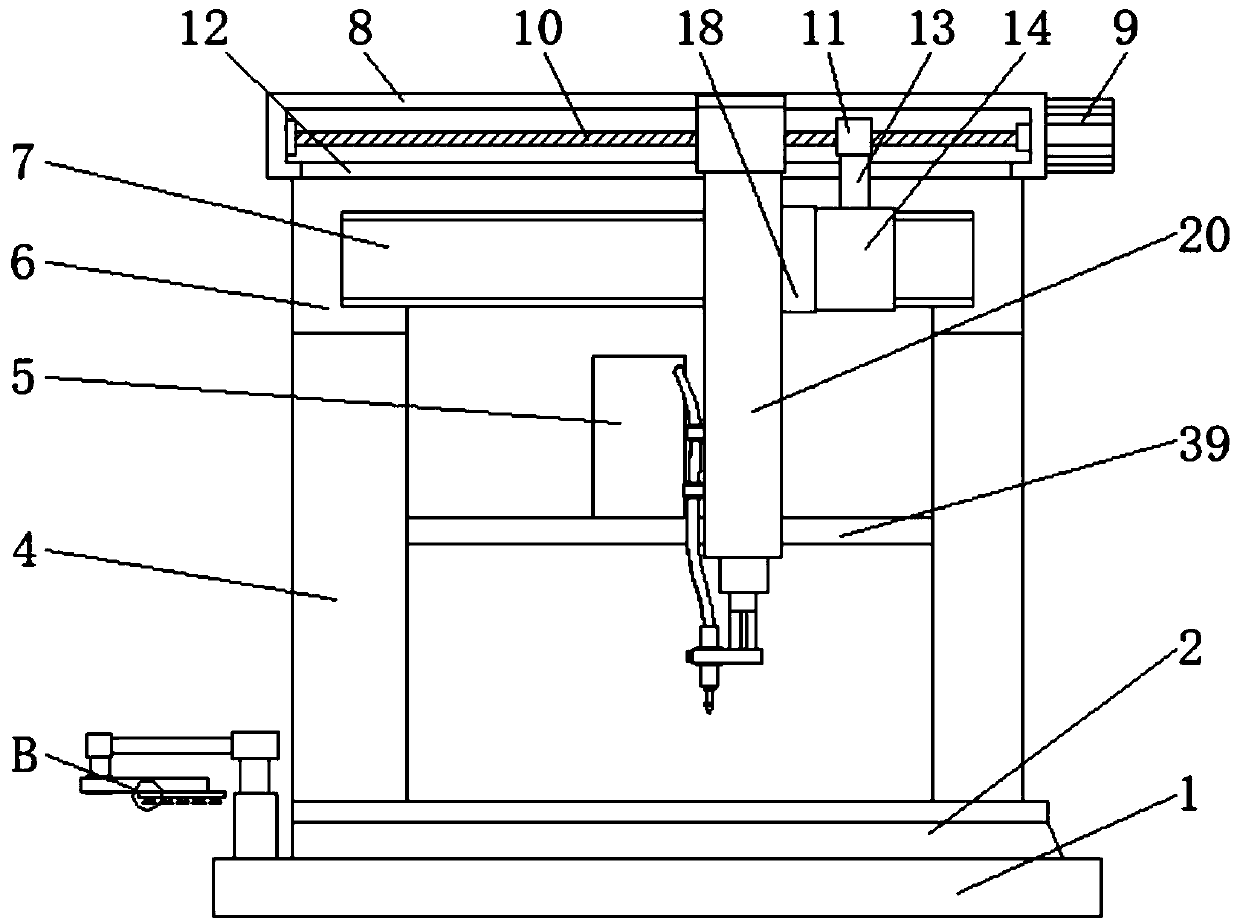

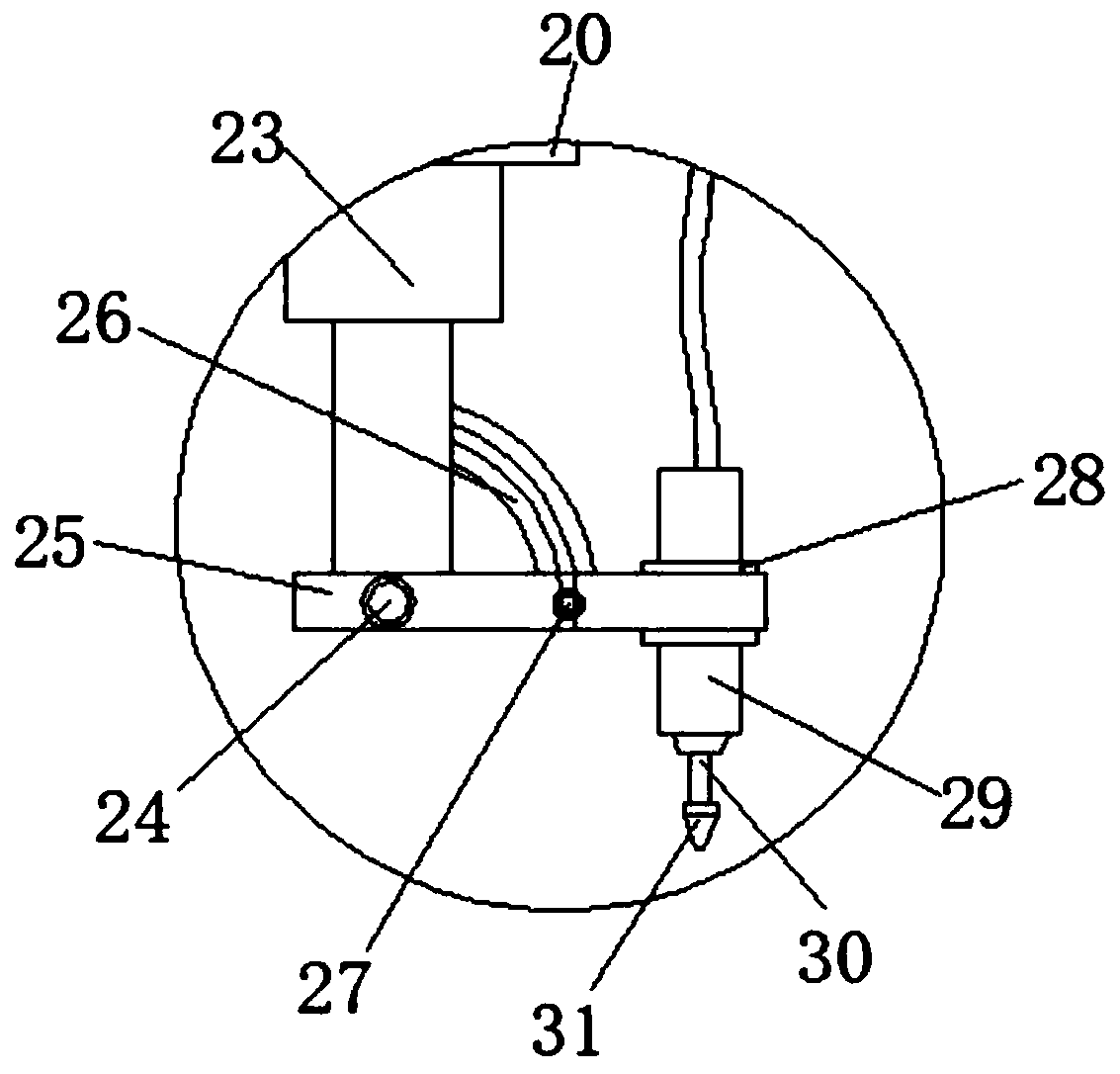

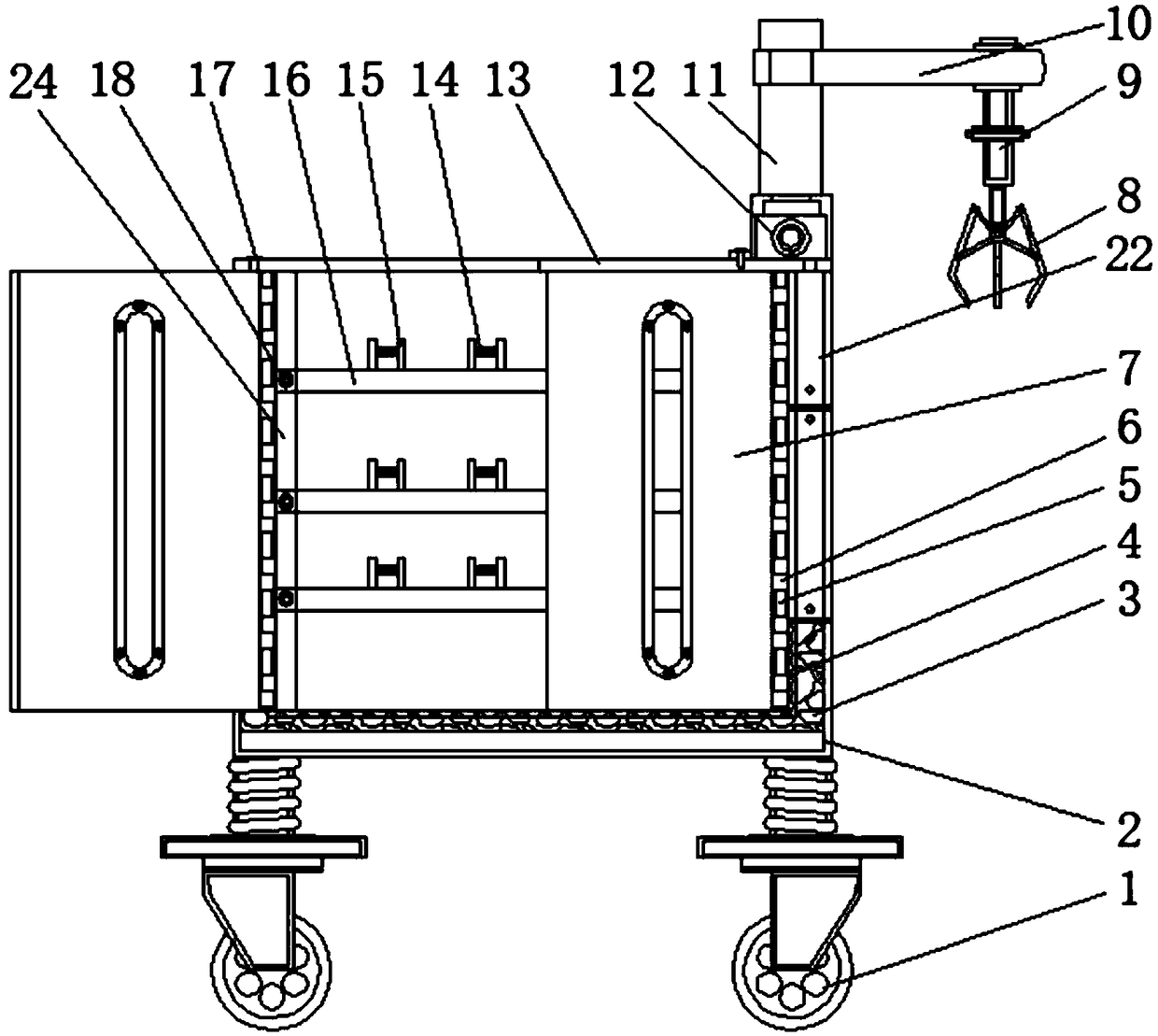

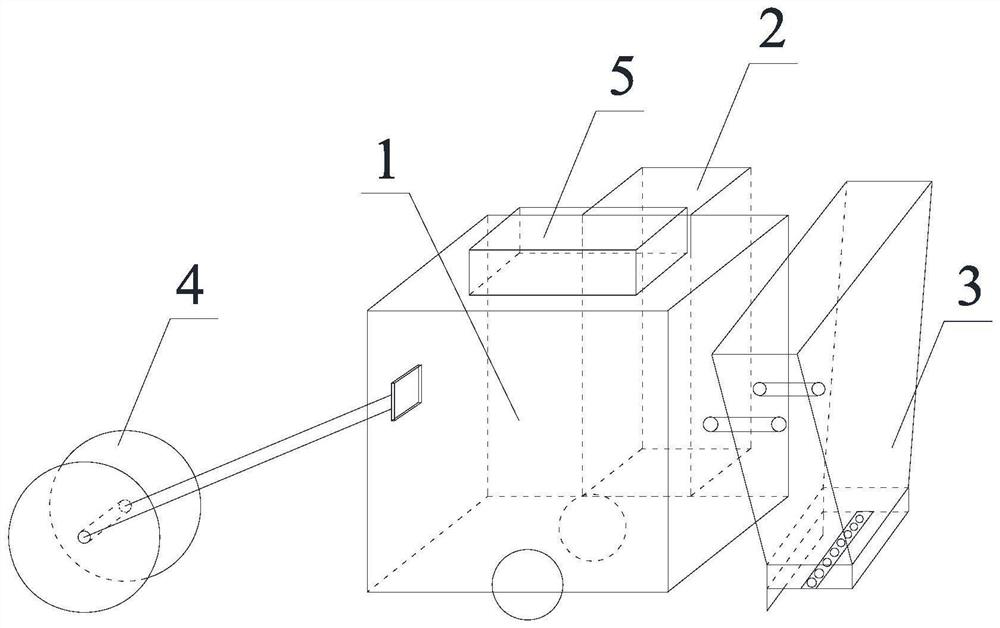

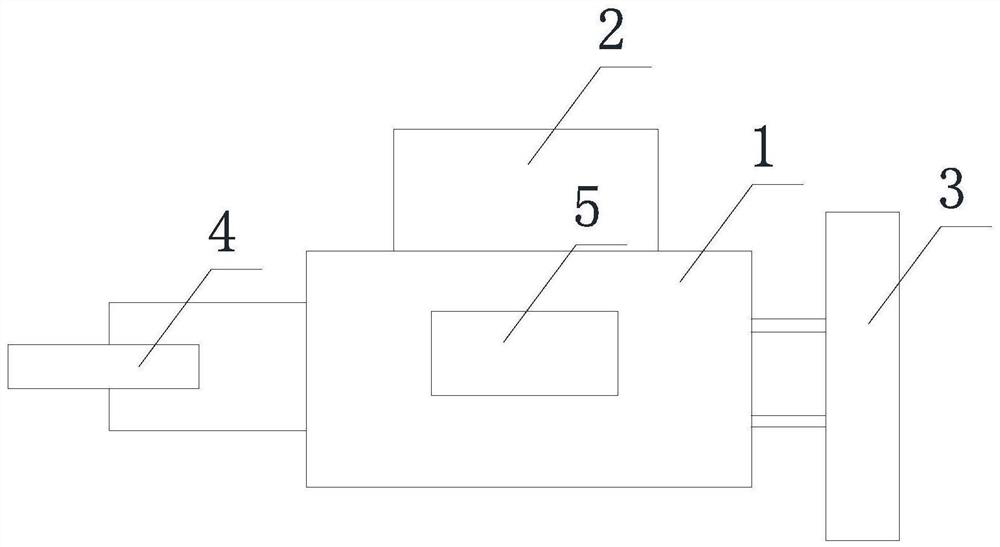

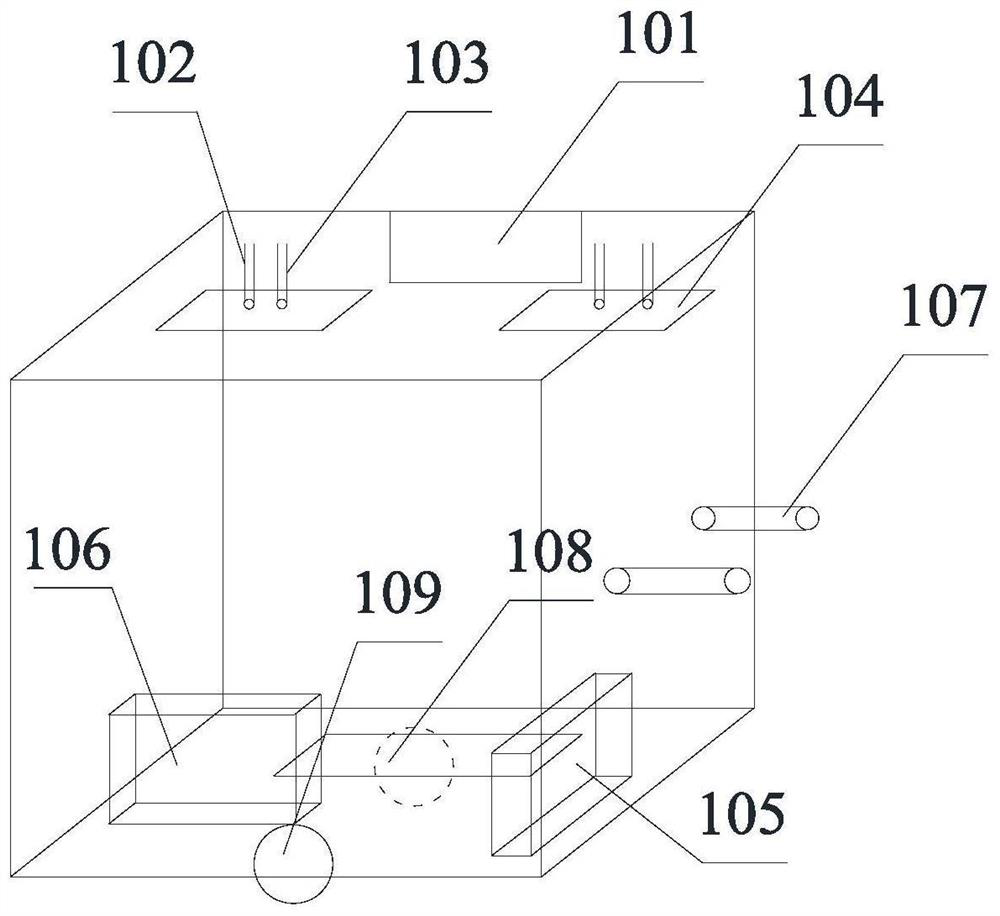

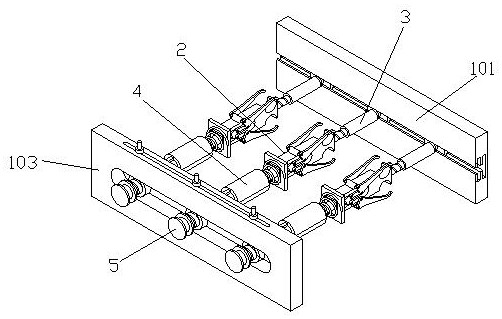

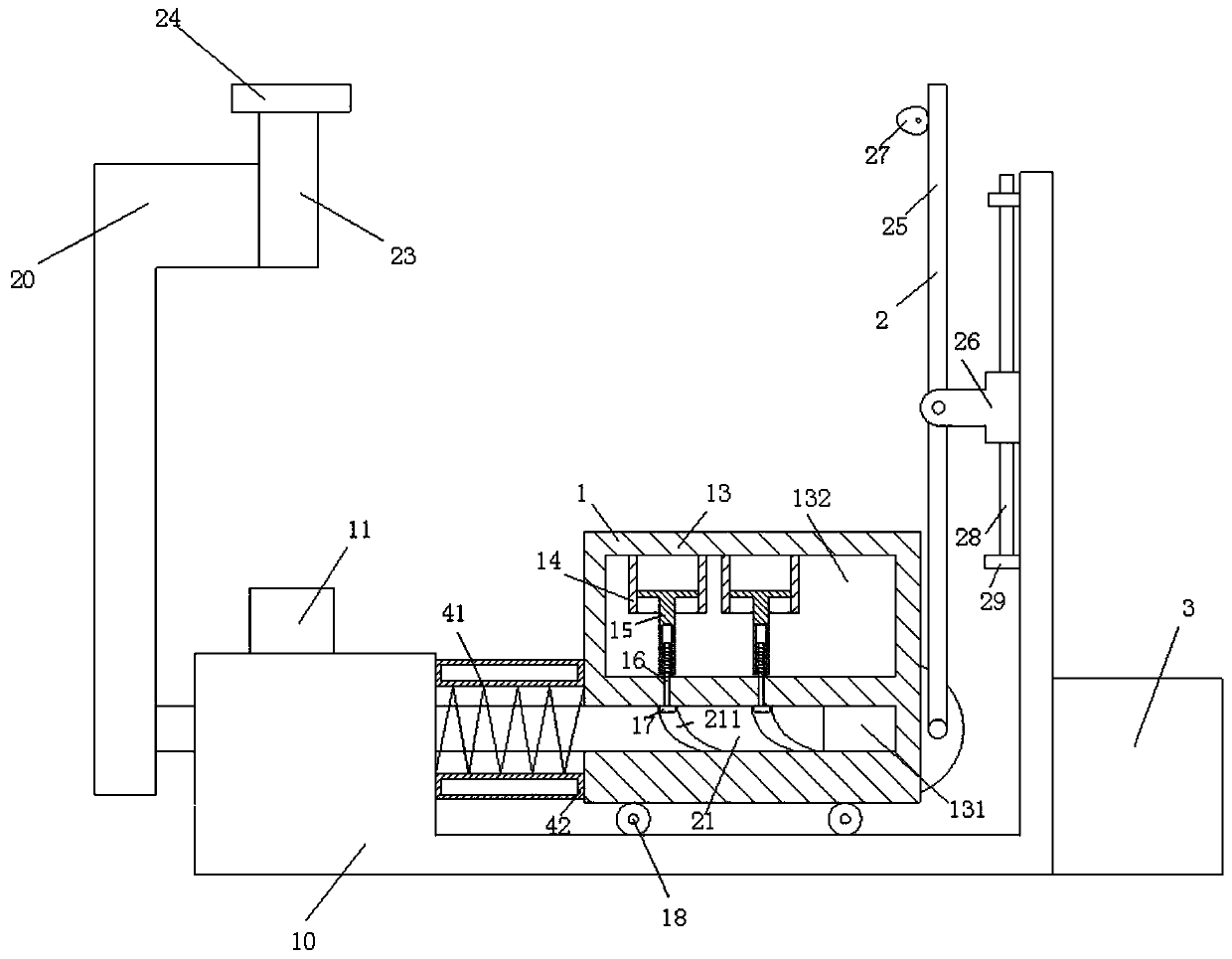

Glass ware cleaning and drying device for medical experiments

InactiveCN110479717APrecise control placementControl placementHollow article cleaningDrying gas arrangementsMotor driveSpray nozzle

The invention discloses a glass ware cleaning and drying device for medical experiments. The glass ware cleaning and drying device comprises a device box body, wherein a cleaning space is formed in the device box body; a scrubbing space communicating with the cleaning space is formed in the bottom wall of the cleaning space; a water pump is fixedly arranged in the inner wall of the left side of the scrubbing space; and a spray nozzle is fixedly arranged on an output pipeline of the water pump. A scrubbing motor is started, and the scrubbing motor drives a gear shaft to rotate; the gear shaft rotates to drive a scrubbing barrel and a cleaning brush to rotate; the cleaning brush can clean a glass ware conveyed to the upper side of the scrubbing space, and the medical glass ware can be cleaned and disinfected independently and continuously, so that the single treatment effect is better, and the sterilization is more thorough; and a clamping head can change according to the size of the clamped glass ware without replacing a mould for clamping the glass ware, so that glass ware cleaning and drying device for medical experiments has higher flexibility to accurately control the glass wareto be placed at a corresponding position.

Owner:ZIBO JUNKANG STATIONERY CO LTD

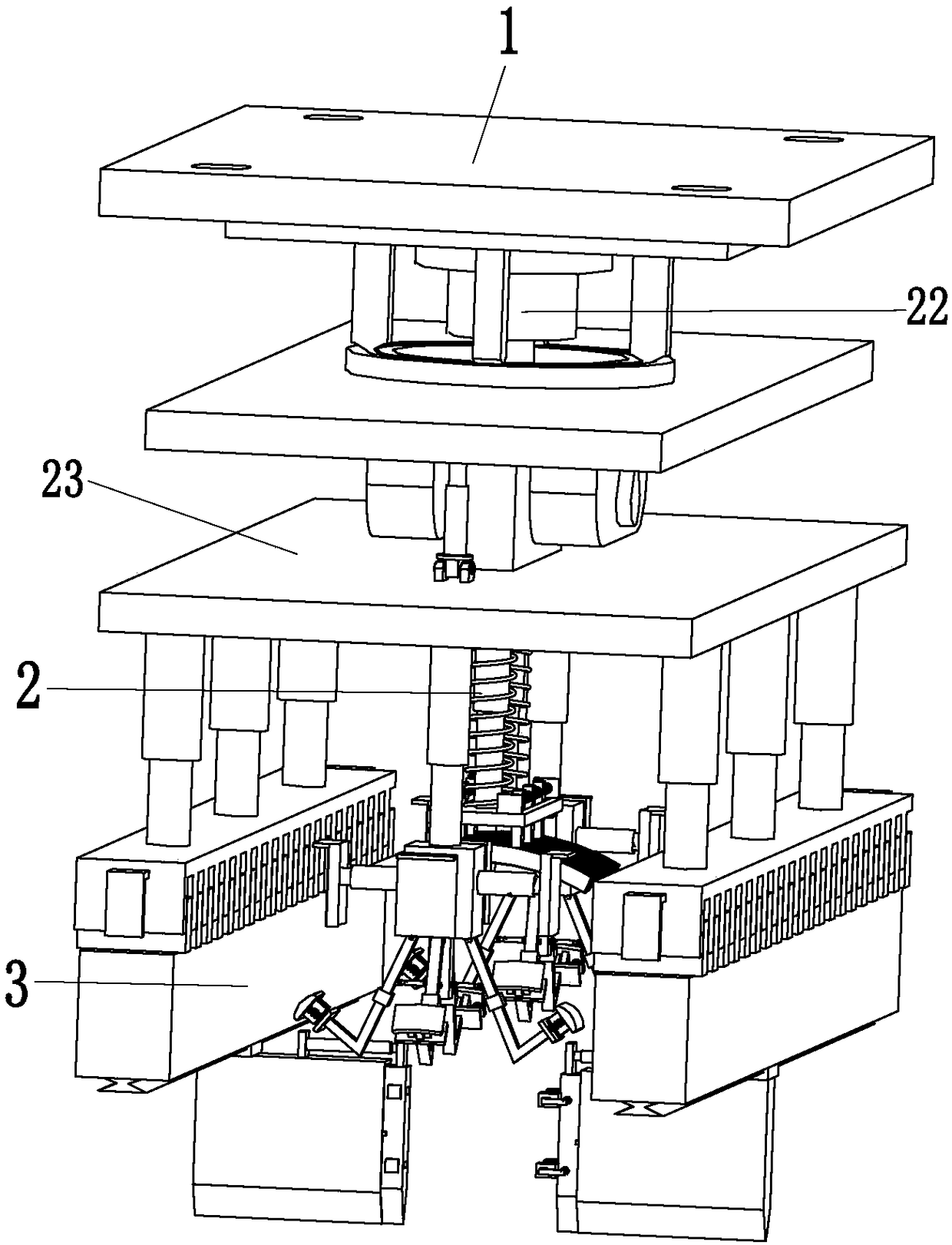

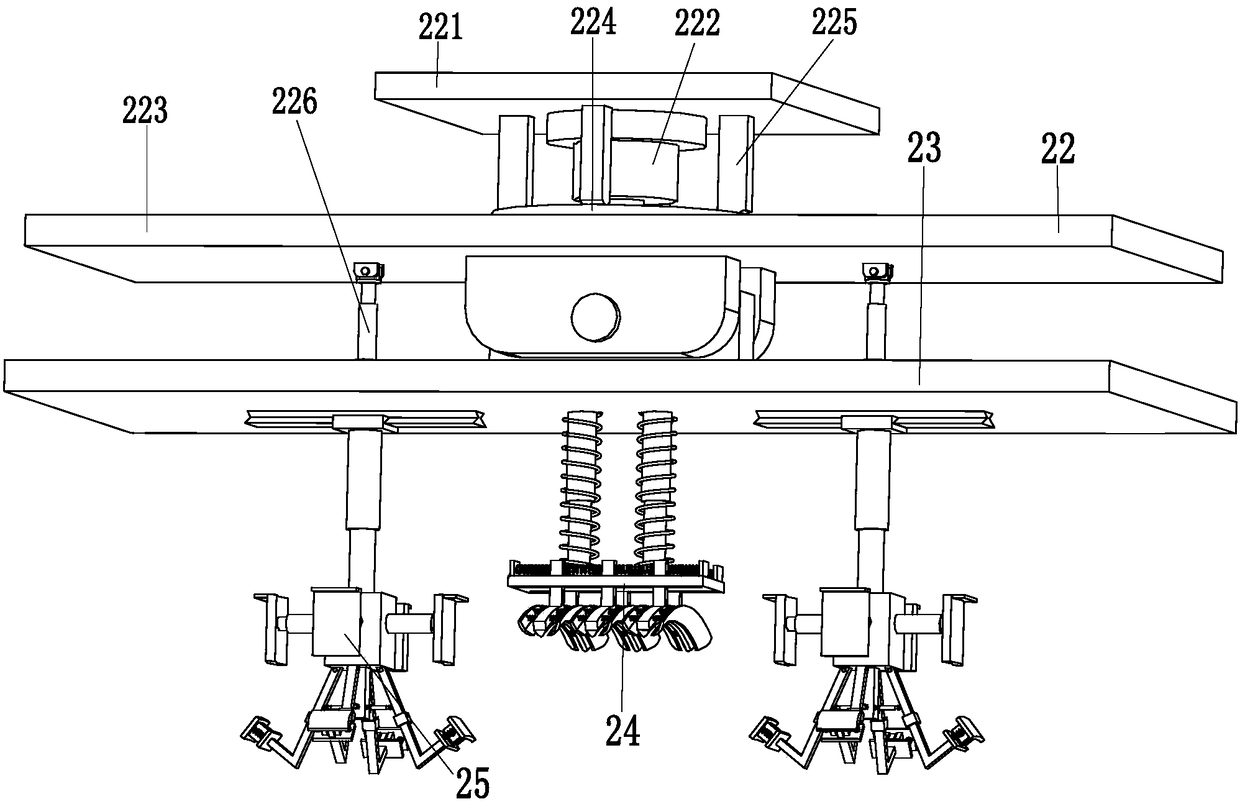

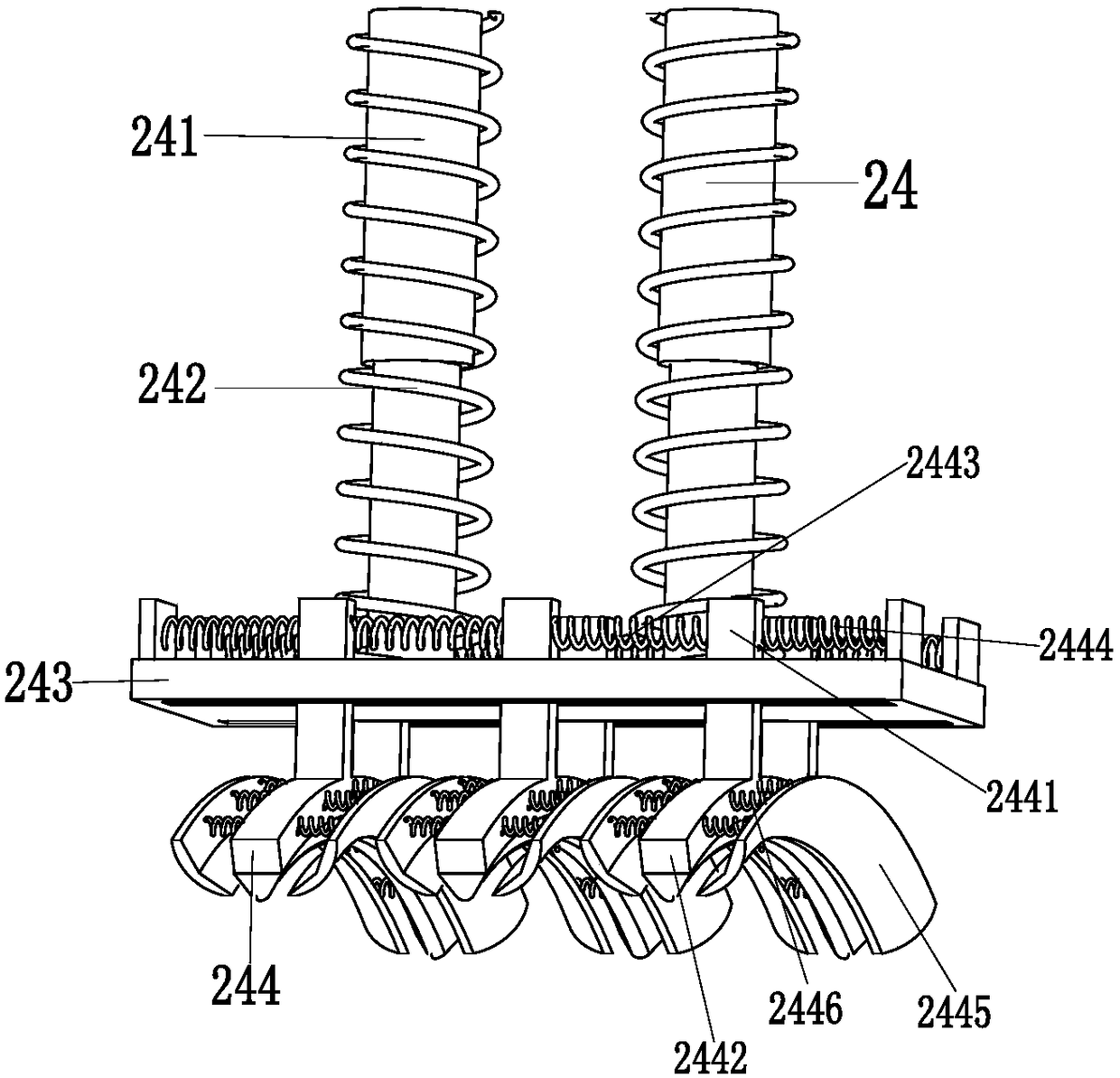

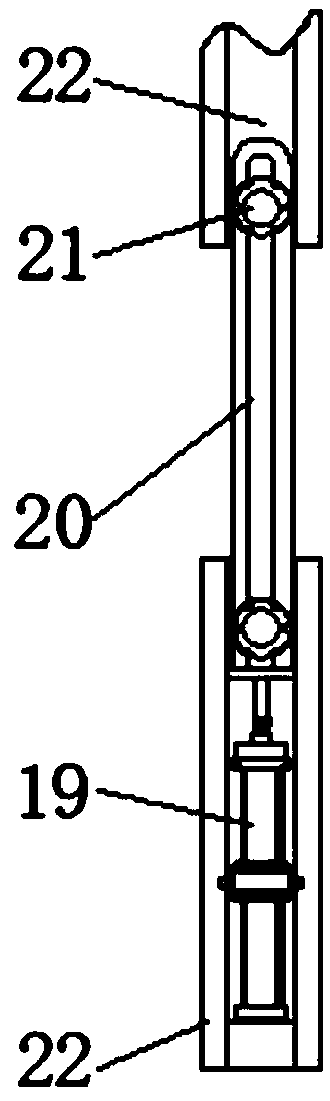

Wastewater treatment equipment hanging bracket

InactiveCN108328473AShaking will not appearImprove work efficiencyLoad-engaging elementsWastewaterSewage treatment

The invention relates to a wastewater treatment equipment hanging bracket. The bracket comprises a mounting top plate, a hoisting gripping device and two leveling devices. The hoisting gripping deviceis mounted at the bottom of the mounting top plate. Mounting holes are symmetrically formed in the mounting top plate. The two leveling devices are symmetrically mounted on the hoisting gripping device. The hoisting gripping device comprises a gripping regulation mechanism, a gripping top plate, a pressing mechanism and supporting mechanisms. By adopting the hanging bracket, the problems that when a digestion tank is mounted, the working efficiency is low, the digestion tank oscillates when being hoisted, hoisting of the digestion tank needs to cooperate with human assistance, a hoisting device special for the digestion tank is absent, and a foundation where the digestion tank is placed needs to be cleaned and leveled manually can be solved; and the functions that corrugated glass reinforced plastic digestion tanks with different patterns are automatically and stably gripped and fixed, and the foundation where the digestion tanks are placed is automatically cleaned and leveled can beachieved.

Owner:龚大娇

Glue dispensing and packing equipment based on mobile phone display screen machining

InactiveCN109530156AControl placementProtection securityLiquid surface applicatorsNon-rotating vibration suppressionEngineeringMachining

The invention discloses glue dispensing and packing equipment based on mobile phone display screen machining. The equipment comprises a fixed plate; the top of the fixed plate is fixedly connected with a damping device; a glue dispensing substrate is arranged at the top of the damping device; support columns are fixedly connected to the top of the fixed plate and positioned on the front and back sides of the damping device; a fixed plate is fixedly connected between the two support columns; the top of the fixed plate is fixedly connected with a glue dropping box; a fixed table is fixedly connected to the tops of the two support columns; and the equipment relates to the technical field of glue dispensing and packing equipment. The glue dispensing and packing equipment based on mobile phonedisplay screen machining solves the problems of incapability of preferably fixing a base disc during fixing of the glue dispensing base disc and need of manual placement and adjustment during fixing in a traditional automatic glue dispensing machine; through a first adjusting electromagnetic extension column and a first rotating arm, the glue dispensing substrate can be preferably controlled to move; and through an absorbing head, the glue dispensing substrate can be absorbed.

Owner:湖北宏旭伟业电子科技有限公司

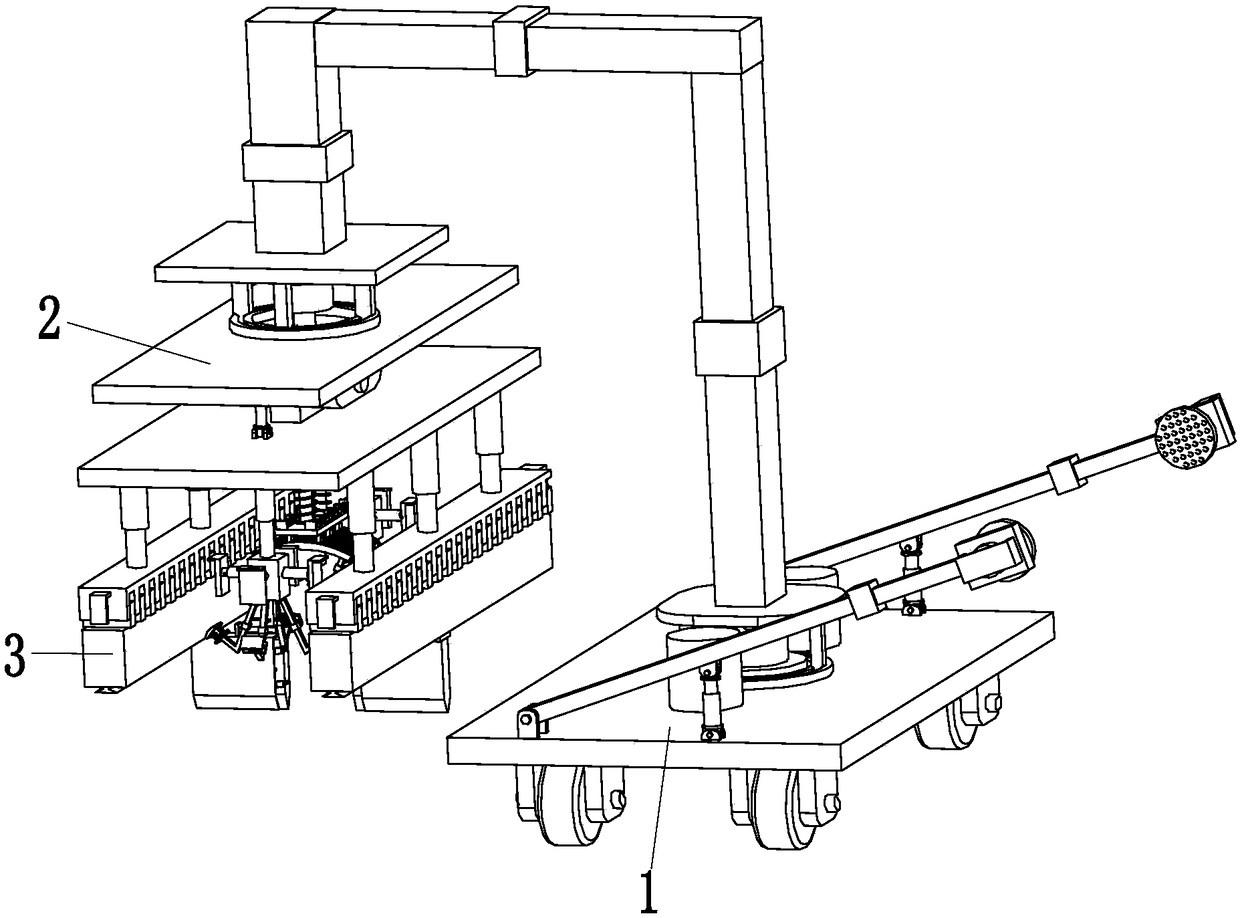

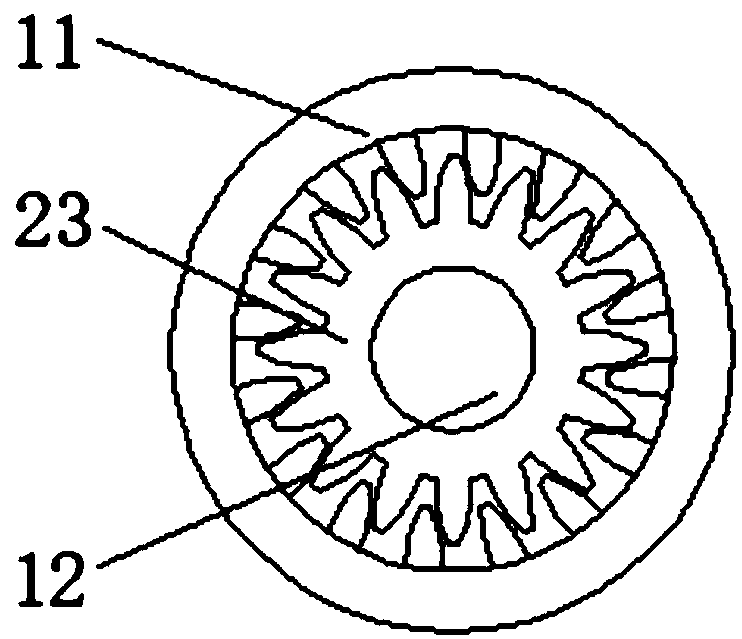

Automatic installation device for domestic sewage

InactiveCN108331151AShaking will not appearReduce labor intensityCesspoolsGeneral water supply conservationGlass fiberSewage

The invention relates to an automatic installation device for domestic sewage. The automatic installation device comprises a supporting device, a lifting and grabbing device and two leveling devices,the lifting and grabbing device is mounted at the top of the supporting device, the two leveling devices are symmetrically mounted on the lifting and grabbing device, and the supporting device comprises a supporting bottom plate, a walking wheel, a balancing weight and a correcting mechanism. The automatic installation device can solve the problems when an existing septic tank is mounted, labor intensity is high, working efficiency is low, a facing direction of the septic tank needs to be manually adjusted, the septic tank can shake in lifting and needs to manual auxiliary cooperation in the lifting process, a special lifting tool for the septic tank is omitted, a foundation for placing the septic tank needs to be manually cleaned and leveled and the like. According to the automatic installation device, the facing directions of corrugated glass fiber reinforced plastic septic tanks with different grains can be automatically adjusted, the septic tanks can be automatically grabbed and lifted, and foundations for placing the septic tanks can be automatically cleaned and leveled.

Owner:丁佐琳

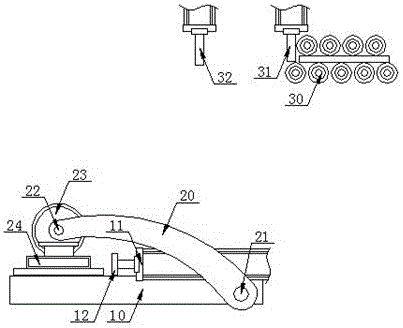

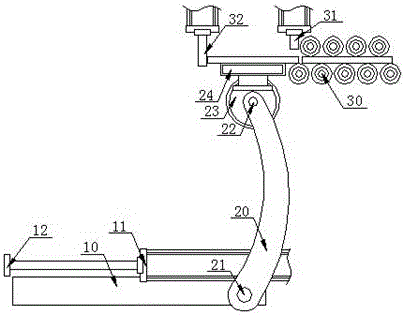

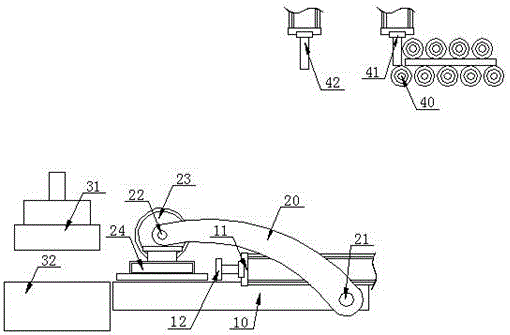

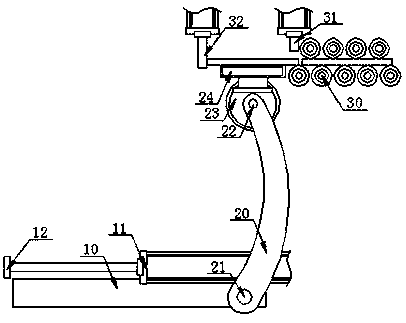

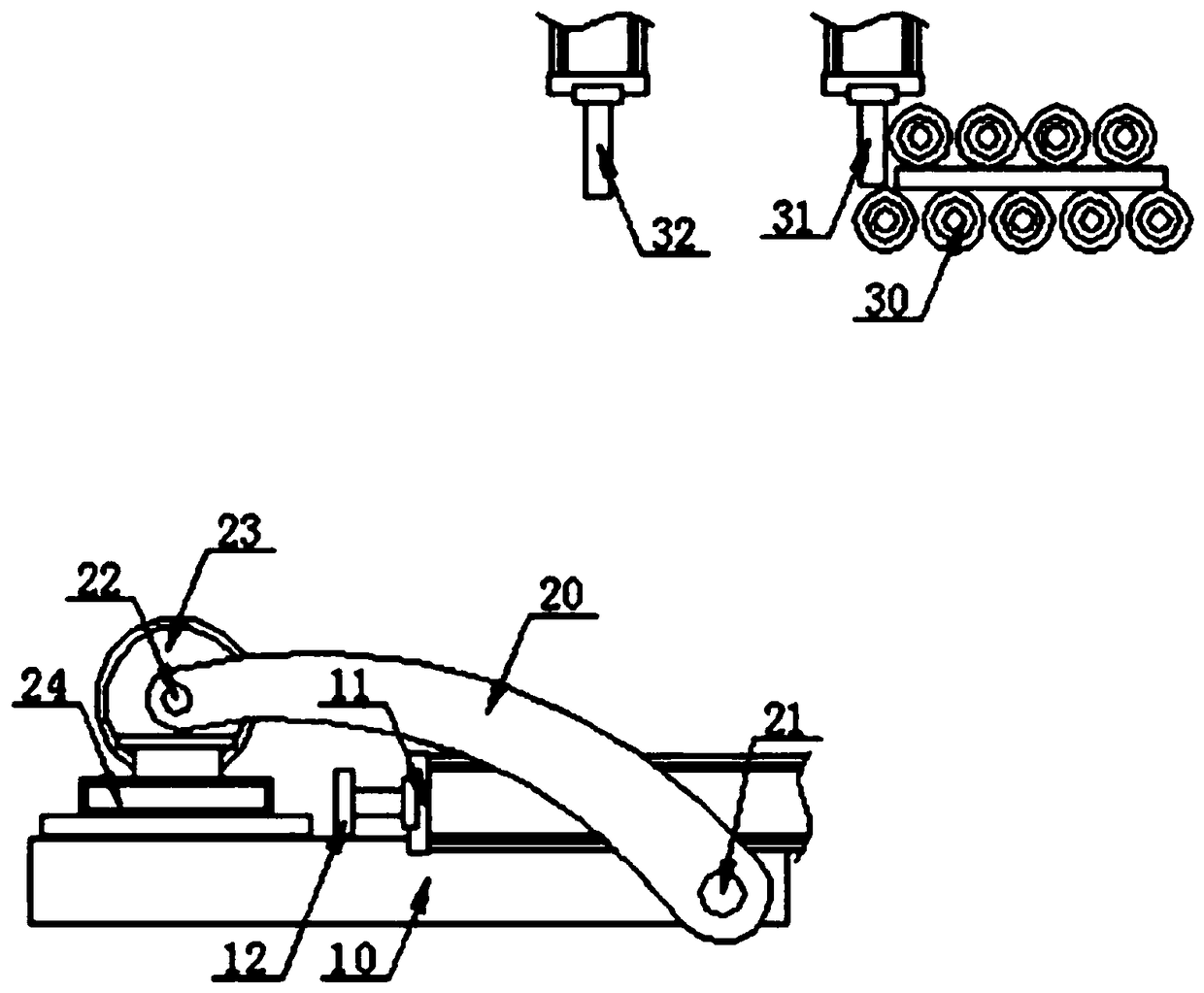

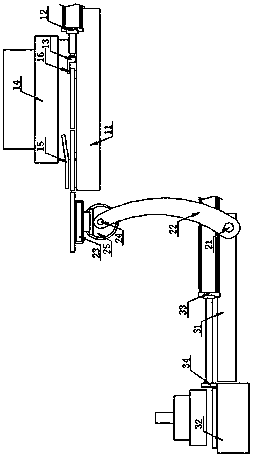

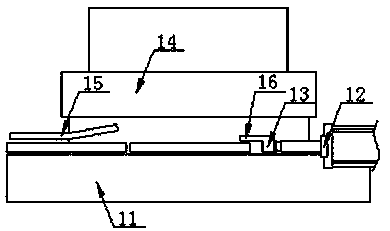

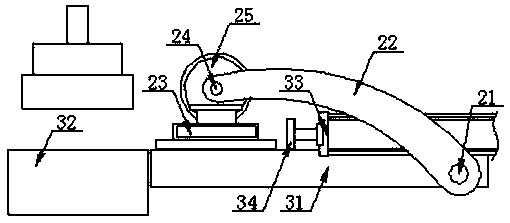

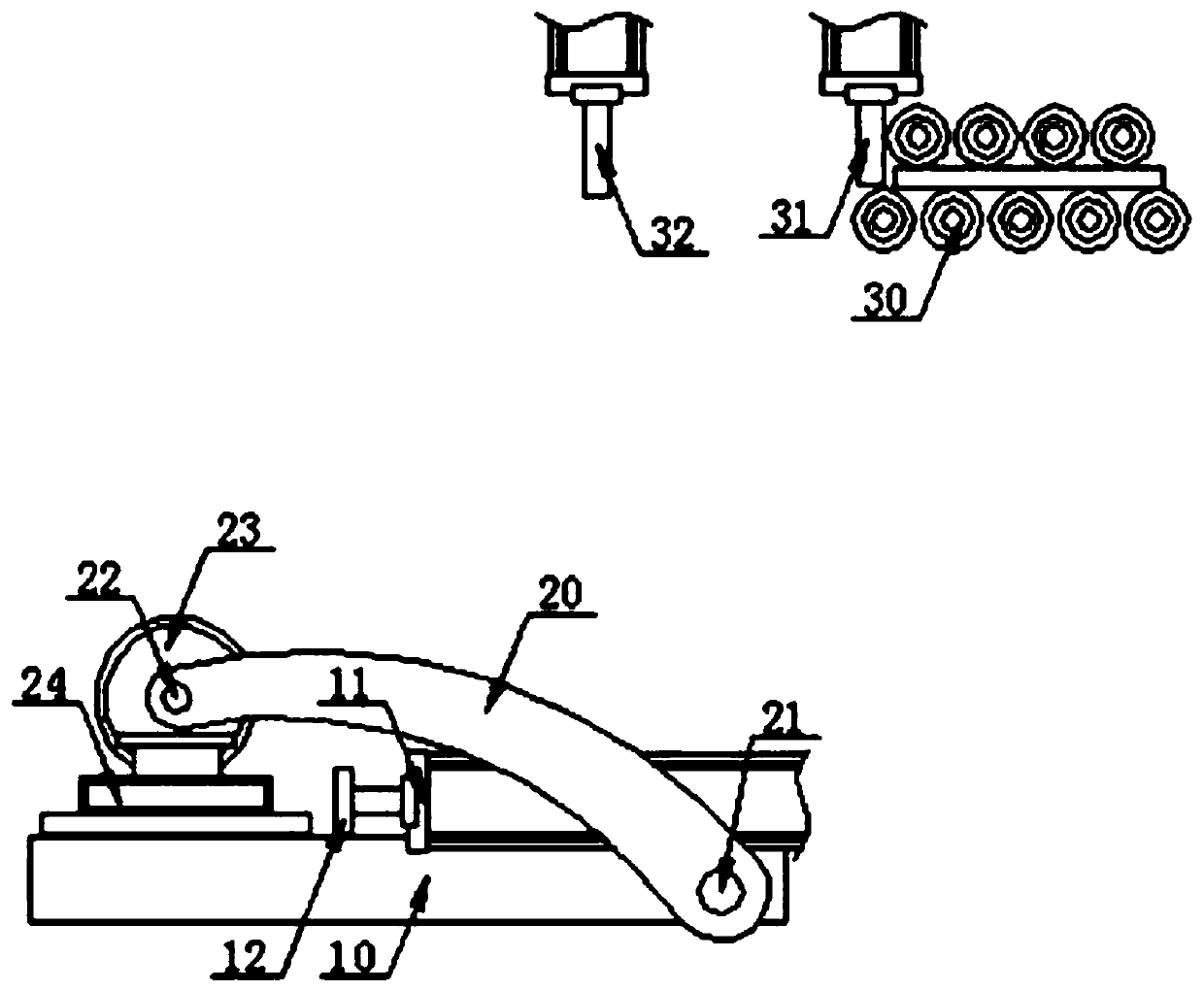

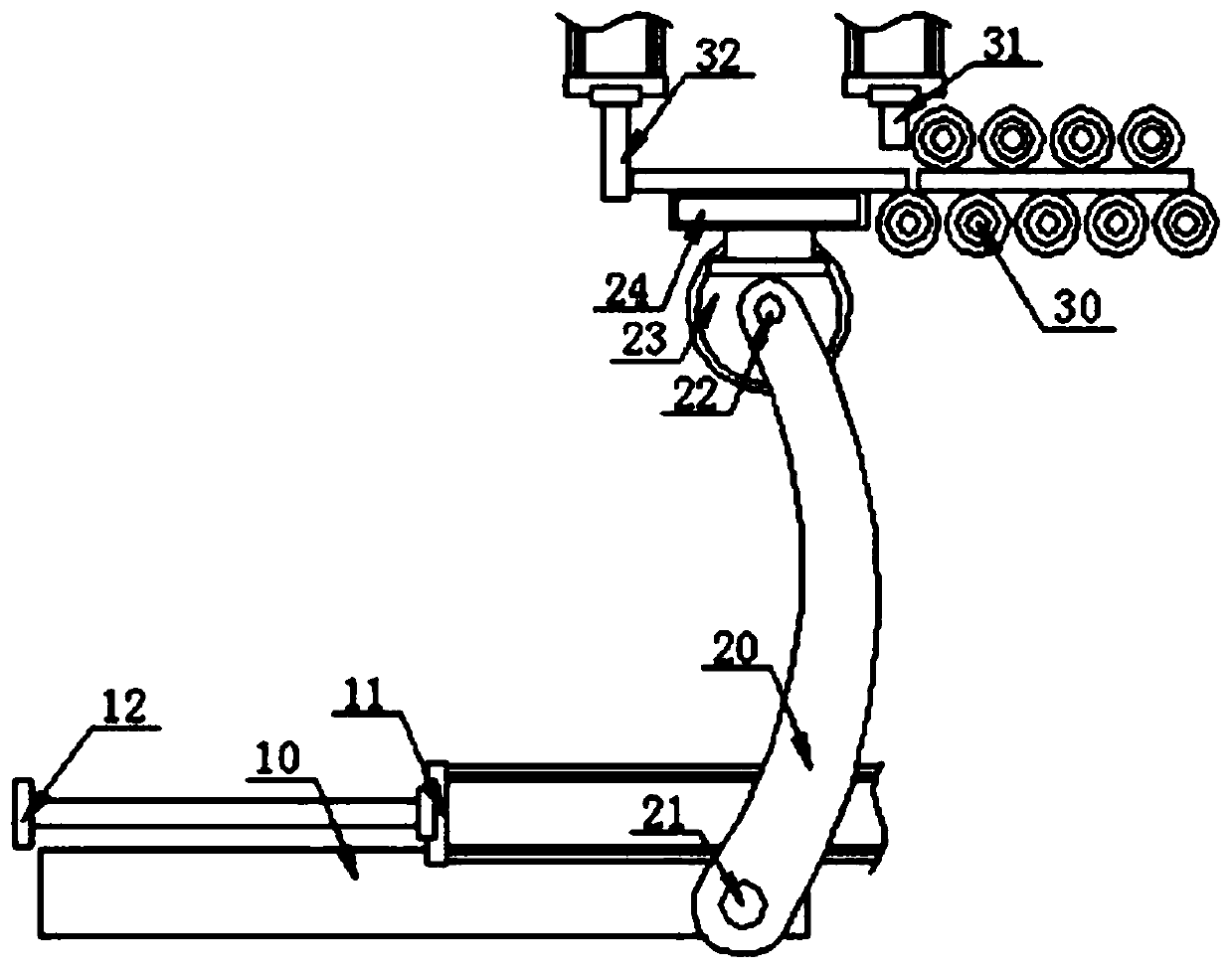

Automatic feeding and punching system for automobile supporting arm assembly

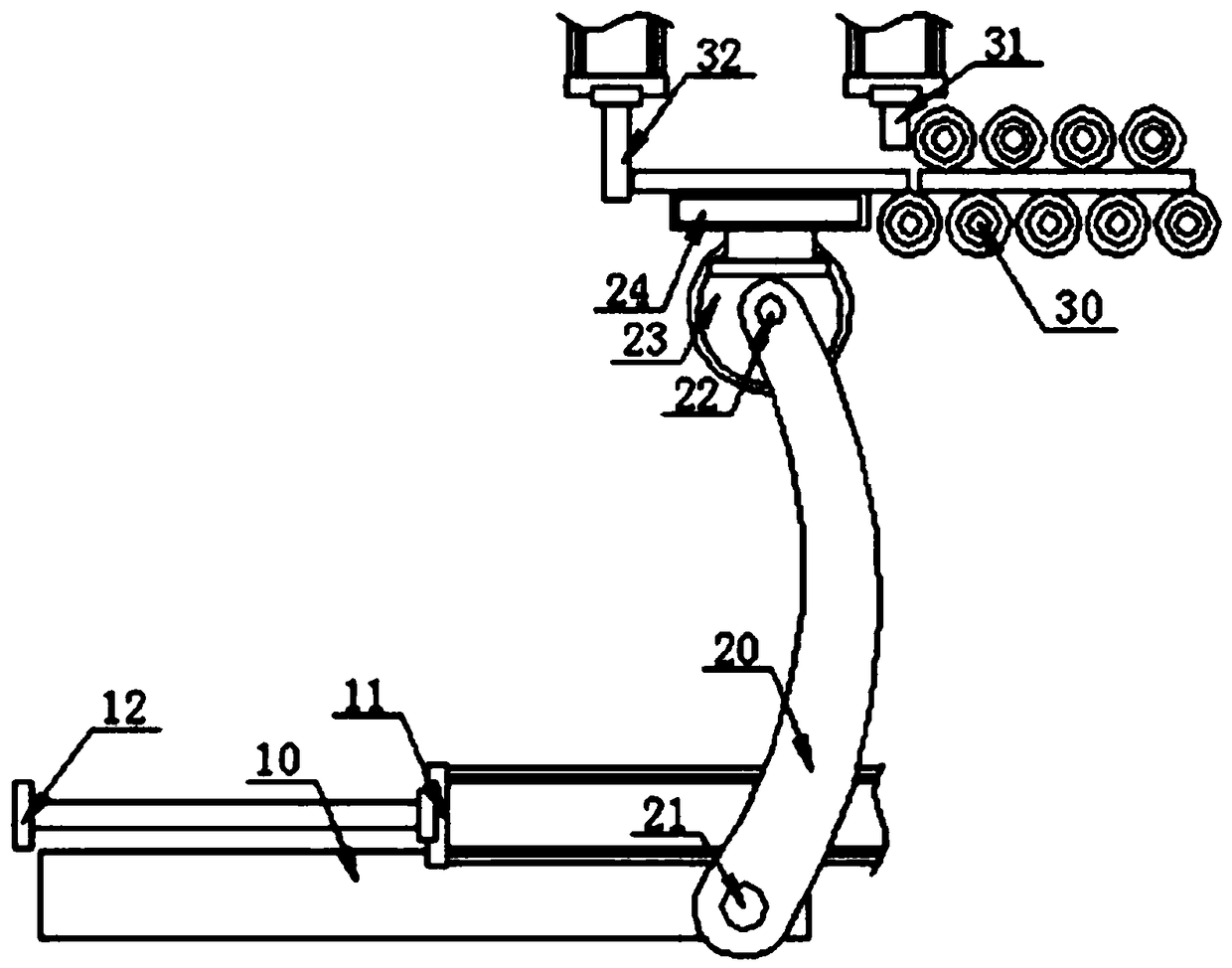

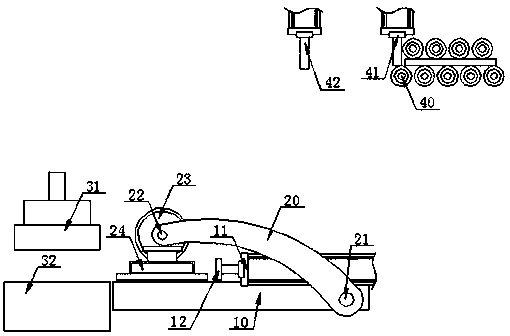

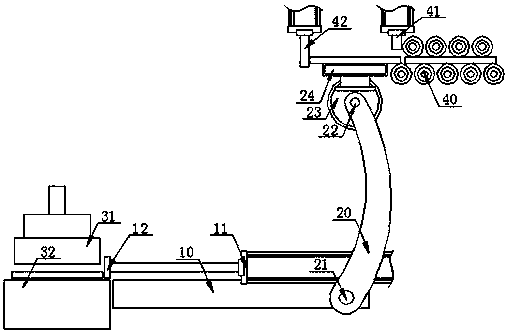

InactiveCN106734690AAutomated crawlingPrecise control over placementMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses an automatic feeding and punching system for an automobile supporting arm assembly. The automatic feeding and punching system for the automobile supporting arm assembly comprises a plate feeding platform, a plate feeding pushing air cylinder and a rotary piece taking swinging arm; one end of the rotary piece taking swinging arm is connected with a rotating driving rotating shaft of which the axis position is fixed; an electromagnetic piece taking sucking disc is arranged at the other end of the rotary piece taking swinging arm; the plate feeding platform is arranged horizontally, and one end of the plate feeding platform faces punching moulding equipment; the rotating driving rotating shaft and the plate feeding pushing air cylinder are arranged at the other end of the plate feeding platform; a piston rod of the plate feeding pushing air cylinder is arranged horizontally, and faces the punching moulding equipment; a plate feeding pushing baffle is arranged at the tail end of the piston rod of the plate feeding pushing air cylinder. According to the automatic feeding and punching system for the automobile supporting arm assembly provided by the invention, the actions of automatically grabbing and feeding of a plate punching operation of the automobile supporting arm assembly can be realized.

Owner:长春市宏宇汽车零部件有限公司

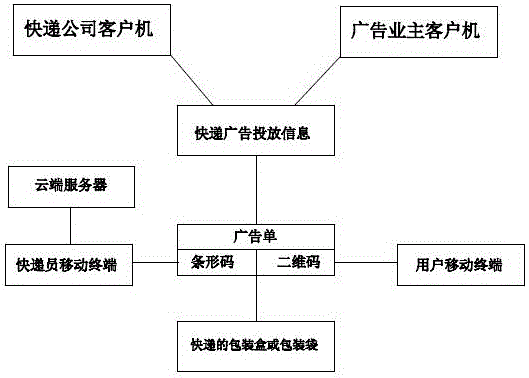

Express-based advertisement delivery system

InactiveCN106651262AControl placementControl scheduleLogisticsMarketingInternet communicationDelivery system

The invention discloses an express-based advertisement delivery system comprising an express company client, an advertisement owner client, advertisement sheets and a user mobile terminal, wherein the express company client is used for releasing express box advertisement delivery information through the Internet; the advertisement owner client is used for receiving the express box advertisement delivery information sent by the express company client through the Internet and calling for bids for the express box advertisement delivery information; the advertisement sheets are adhered on package boxes or package bags of expresses; two-dimensional codes are printed on the advertisement sheets; and the user mobile terminal is used for scanning the two-dimensional codes on the advertisement sheets and communicating with the Internet to obtain two-dimensional code information. The express-based advertisement delivery system disclosed by the invention can effectively control the delivery sites and the delivery times of the advertisement sheets, so that the delivery of the advertisement sheets is more reasonable, the statics and inquiry of the delivery of the advertisement sheets are facilitated, and the implementation of express advertisement is facilitated.

Owner:四川百思创想科技有限公司

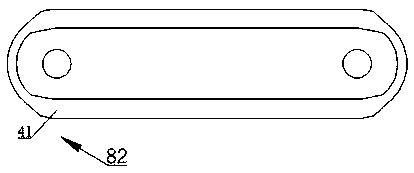

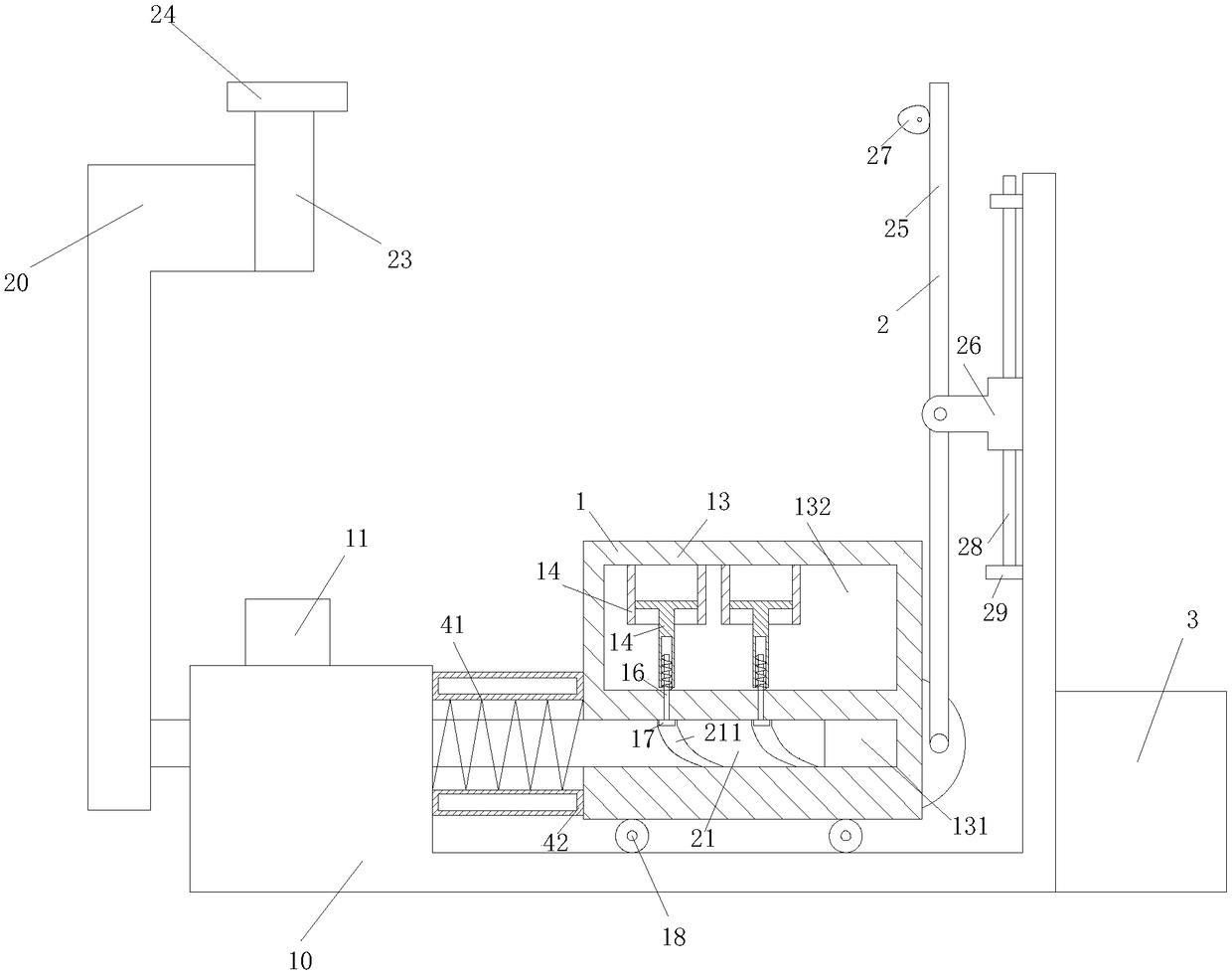

Loading and unloading system for stamping vehicle body connecting bracket

ActiveCN106424411AControl placementReduce labor intensityMetal-working feeding devicesVehicle componentsDrive shaftEngineering

The invention discloses a loading and unloading system for stamping a vehicle body connecting bracket. The loading and unloading system comprises a lower stamping-forming die, a plate loading platform, a plate loading push air cylinder and a rotary taking swing arm, wherein one end of the rotary taking swing arm is connected with a rotation driving shaft, and the position of the axis of the rotation driving shaft is fixed; an electromagnetic taking sucker is arranged at the other end of the rotary taking swing arm; the plate loading platform is horizontally arranged, and one end of the plate loading platform faces the lower stamping-forming die; the top surface of the plate loading platform is as high as that of the lower stamping-forming die; the rotation driving shaft and the plate loading push air cylinder are arranged at the other end of the plate loading platform; and a piston of the plate loading push air cylinder has a two-stage stroke. The loading and unloading system for stamping the vehicle body connecting bracket, provided by the invention, can realize automatic gripping, loading and unloading actions during the stamping operation of the vehicle body connecting bracket.

Owner:佛山云顶汽车部件有限责任公司

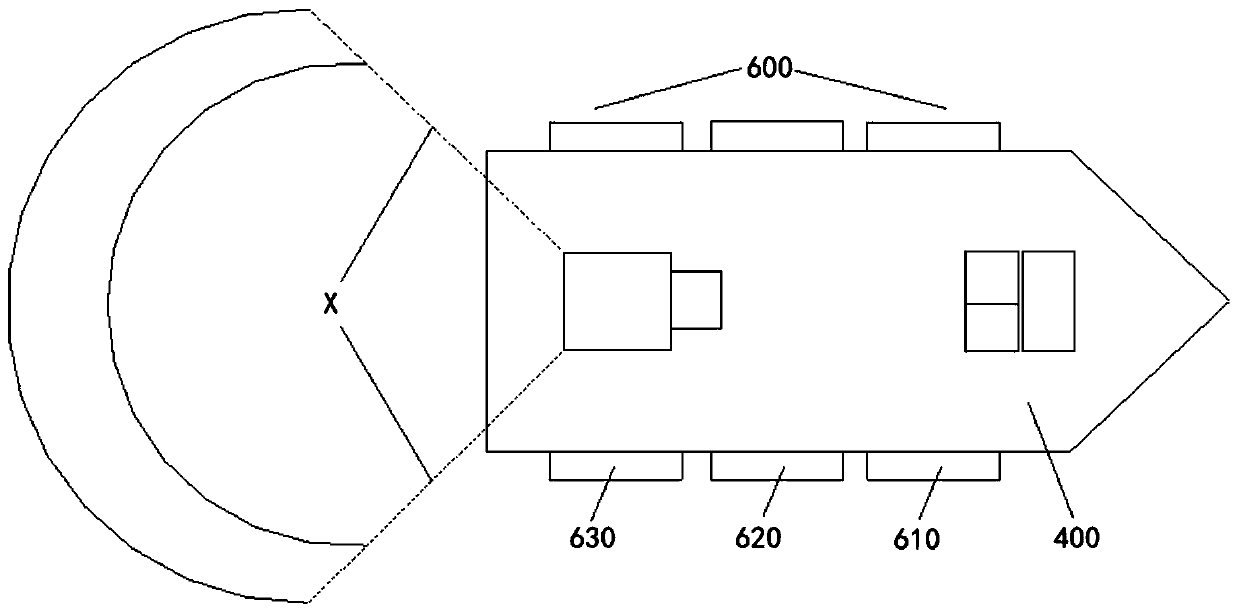

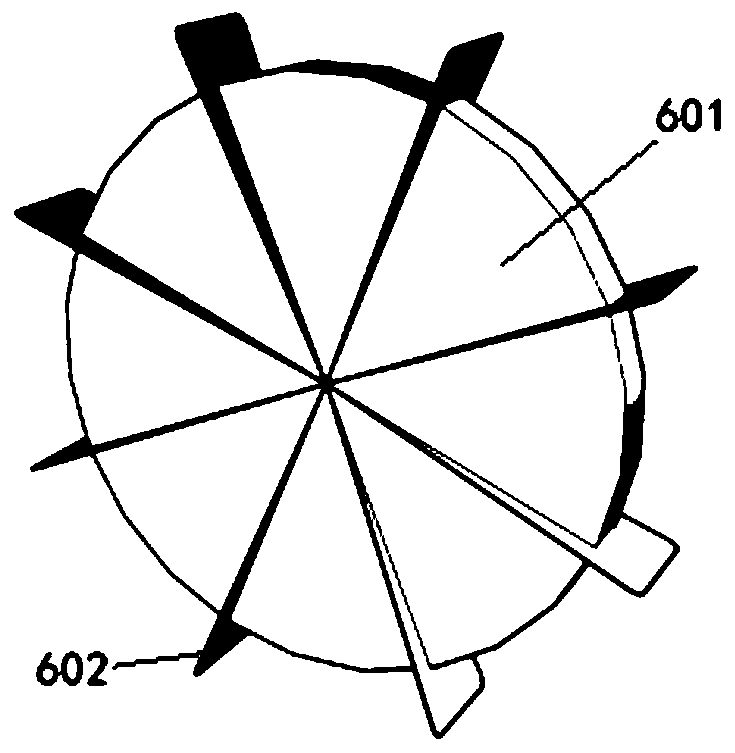

Aquaculture unmanned ship

PendingCN110723257AAvoid interferenceReduce usageGeneral water supply conservationUnmanned surface vesselsWater qualityHull

The invention aims at providing an aquaculture unmanned ship to solve the technical problems that the existing unmanned ship is simple in feeding mode and easy to pollute a water body due to excessiveuse of materials. The structure comprises a water area biological quantity detection device, a water quality monitoring device, a material throwing device and an unmanned ship hull; the aquaculture unmanned ship further comprises a controller, wherein the water area biological quantity detection device is arranged on the unmanned ship hull, and the material throwing device is arranged at the stern of the unmanned ship hull; the water quality monitoring device is arranged at the bow of the unmanned ship hull; the water area biological quantity detection device, the water quality monitoring device and the material throwing device are respectively and electrically connected with the controller; the controller is used for controlling the material throwing device to throw materials with appropriate weight according to water area biological quantity information and / or water quality information. The aquaculture unmanned ship can control the material throwing quantity of the material throwingdevice intelligently and dynamically by combining the water area biological quantity and / or the water quality monitoring data, and the operation cost of the aquaculture is reduced.

Owner:徐玲 +3

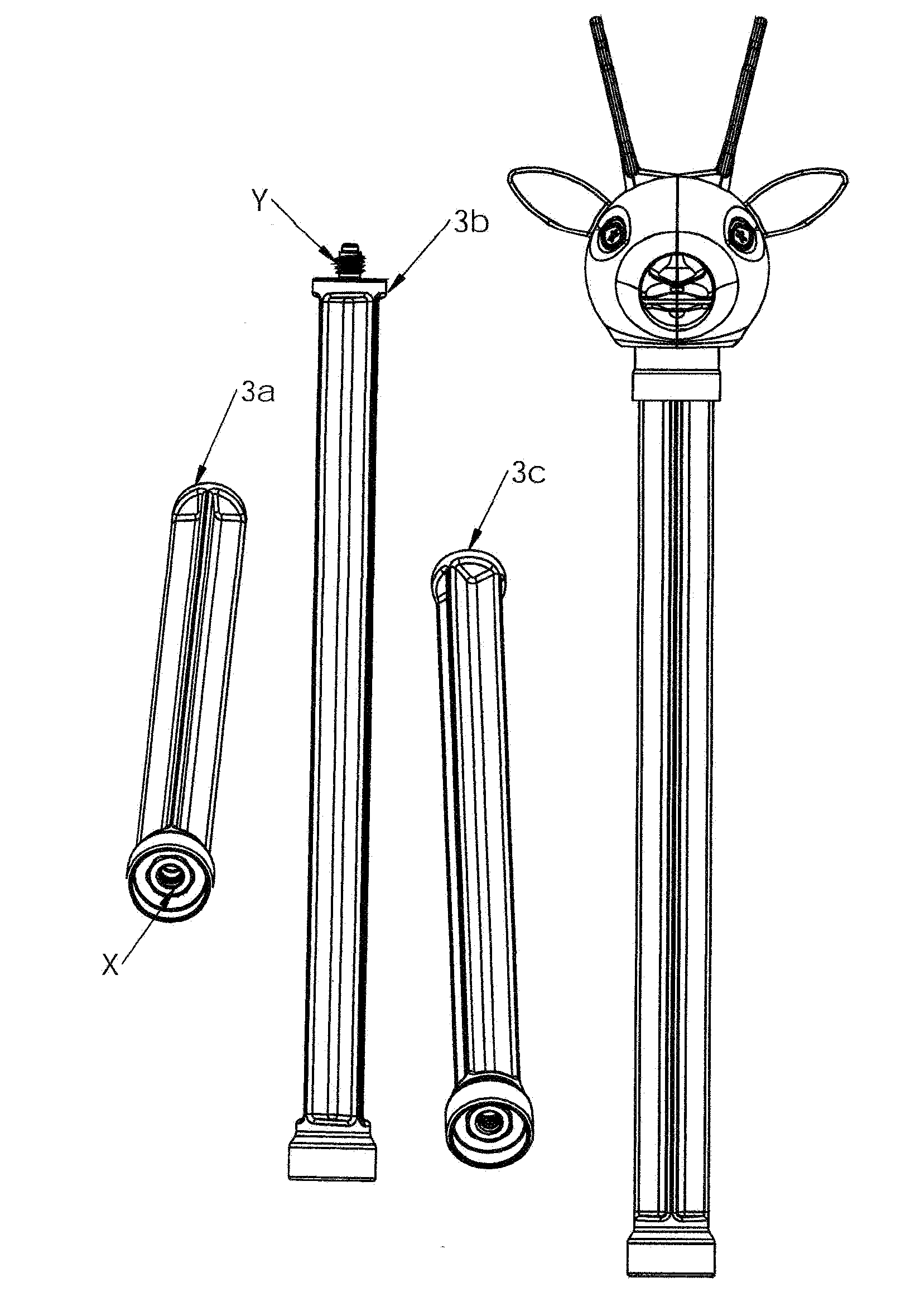

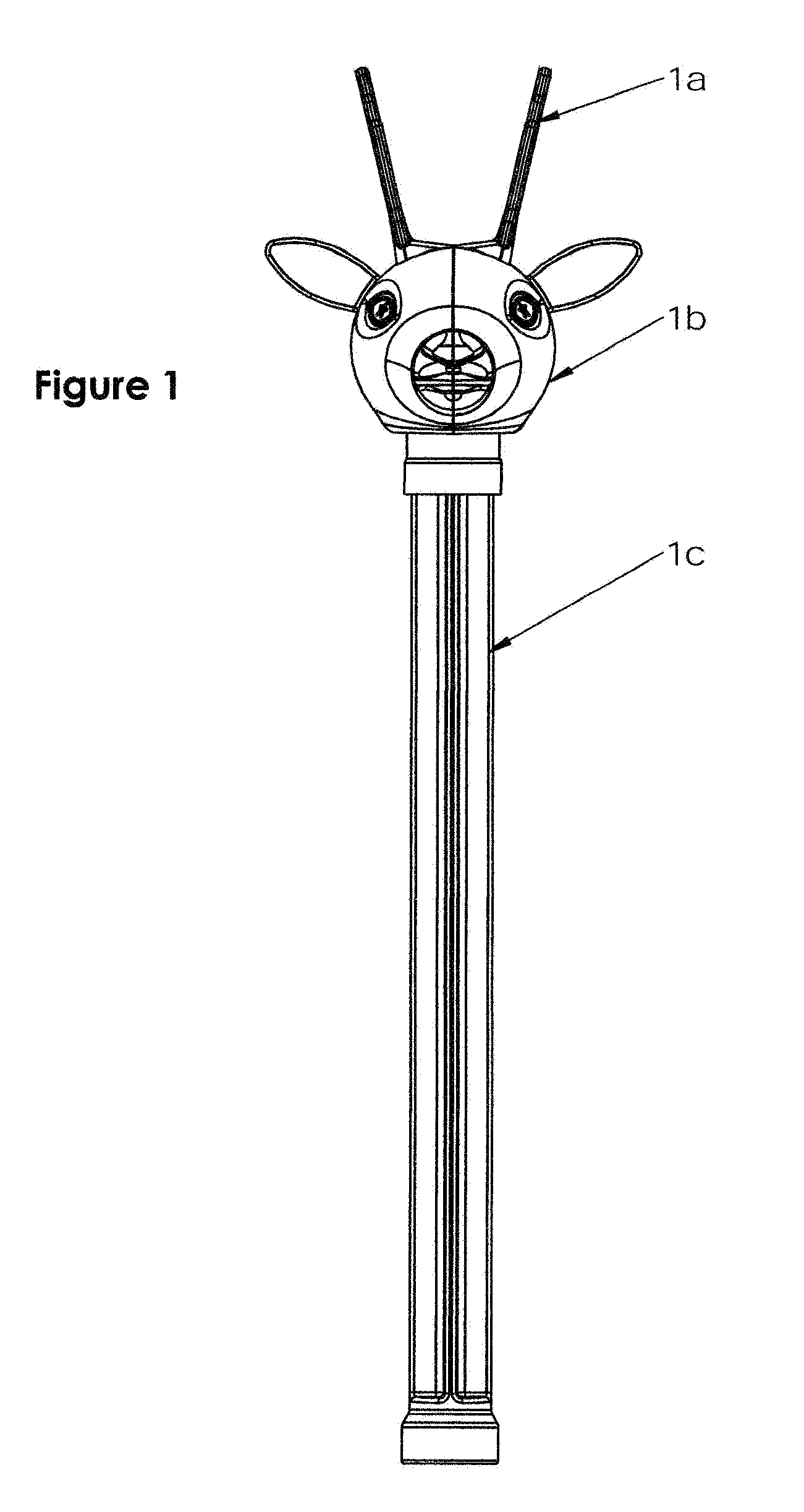

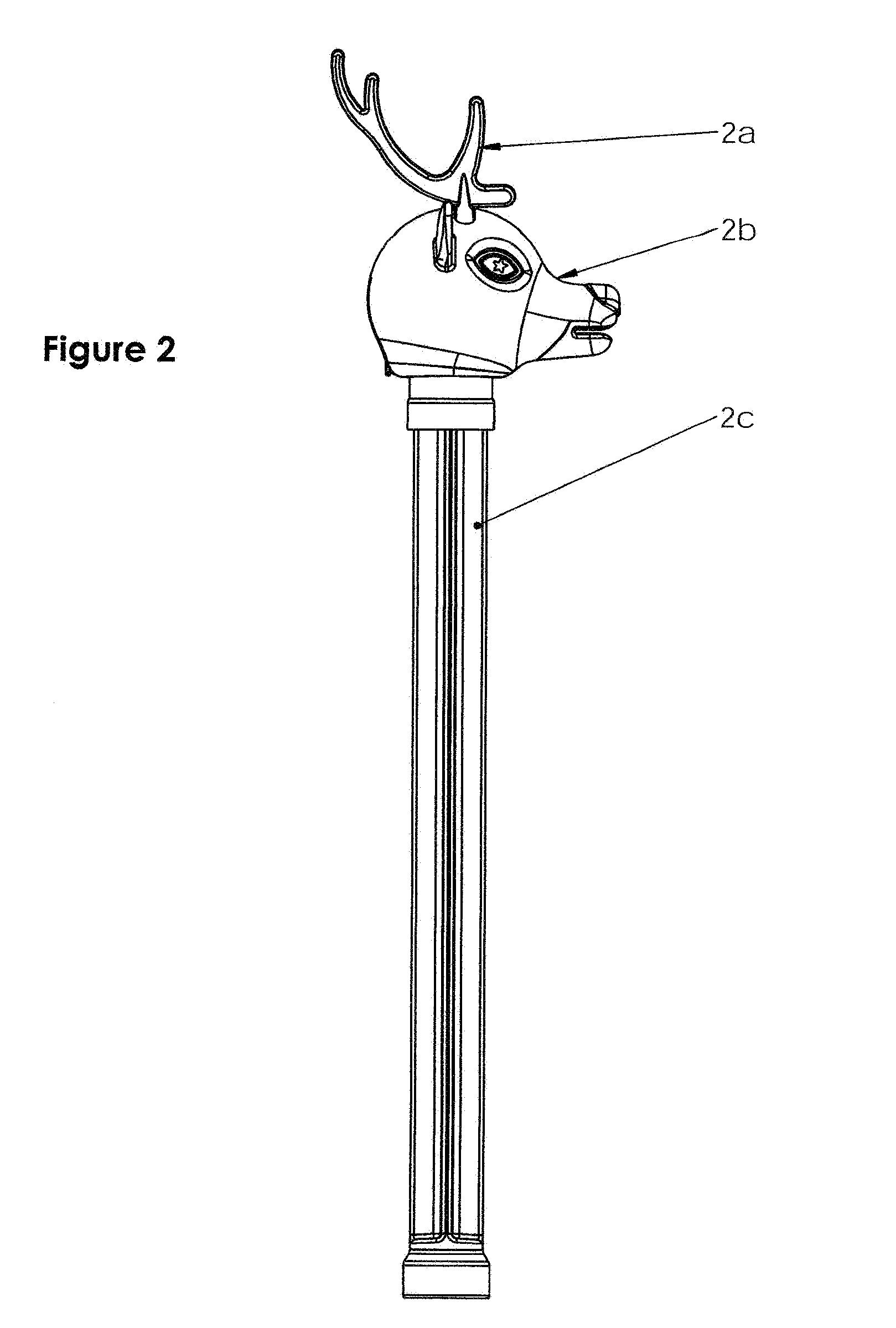

Tree Decorating Assistant

InactiveUS20160082587A1Control placementControl positioningPicture framesSemiconductor/solid-state device manufacturingEngineeringOrnaments

A tree decorating assistant apparatus is disclosed for applying ornaments and lighting to a Christmas (or other seasonal) tree and comprising a decoration support element, provided by a replication of animal antlers (or horns); a decorative animal head section to provide support for the lighting support and is consistent with the animal-related lighting support section configuration; and a handle section to control, lift and permit placement of ornaments and string lighting sections at different points on the tree. Further, to provide for assistance in the case of large and / or tall trees, multiple handle extension elements are attachable to the handle section for reaching greater and greater heights.

Owner:HAIRFIELD RODNEY L

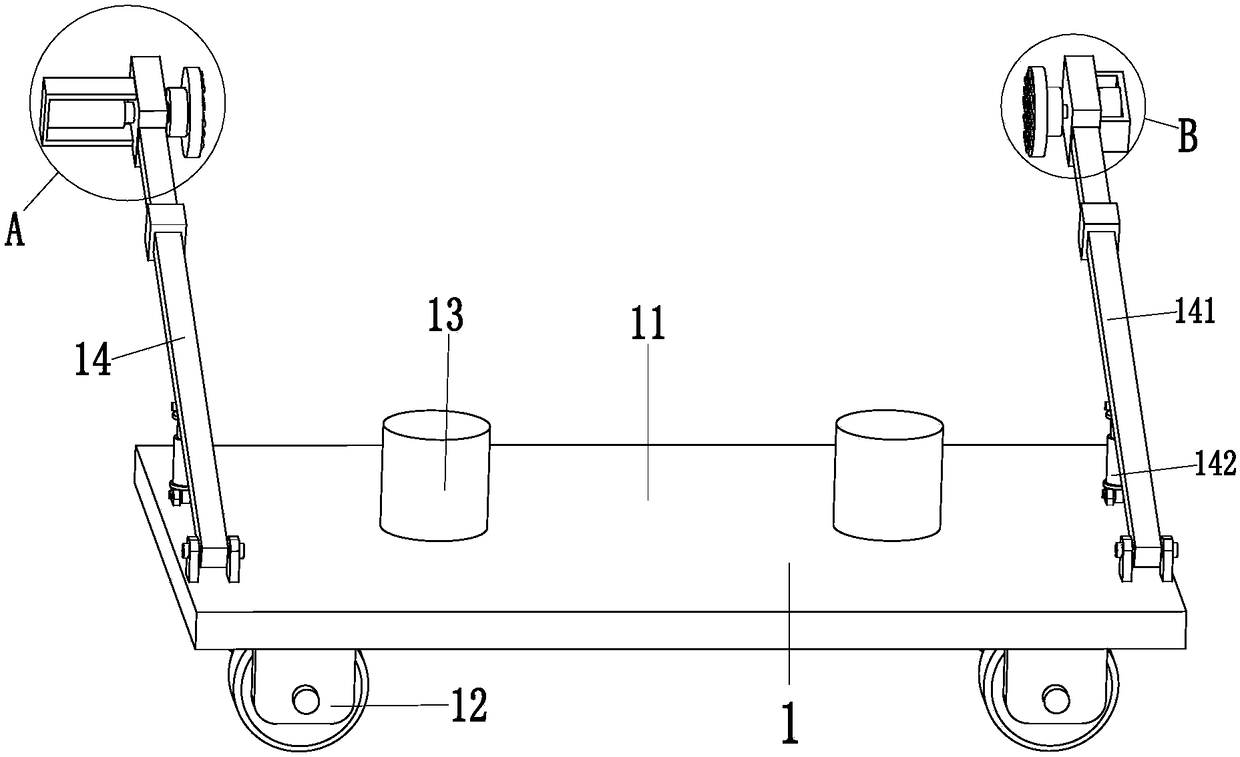

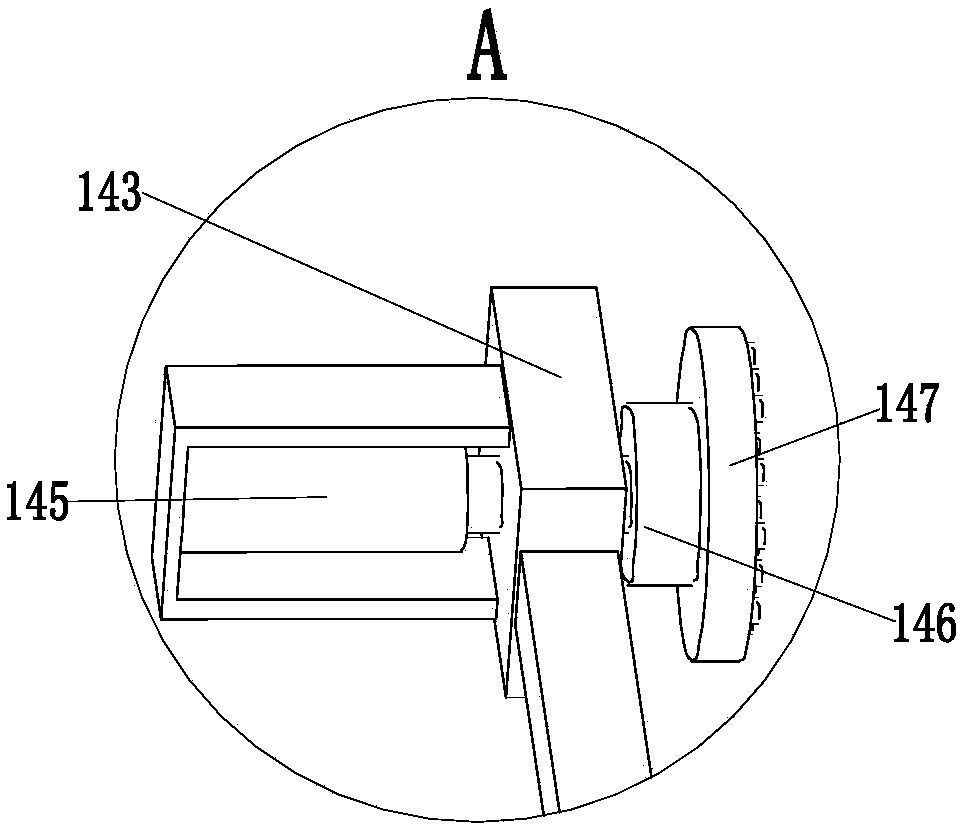

High temperature resistant stamped part transporting device

PendingCN108792493AEasy to placeAvoid damageRigid containersConveyor partsEngineeringHigh-temperature corrosion

The invention discloses a high temperature resistant stamped part transporting device. The device comprises wheels, a motor and a supporting column. A bottom frame is mounted above the wheels, and a high temperature resistant fiber layer is arranged inside the bottom frame. An asbestos layer is arranged inside the high temperature resistant fiber layer. A second hydraulic column is arranged insidethe supporting column, and the supporting column is located on the upper portion of the bottom frame. The second hydraulic column is in threaded connection with the supporting column. A connecting rod is mounted on the upper portion of the second hydraulic column, and lock screws are arranged in the connecting rod. The supporting column is in threaded connection with the connecting rod through the lock screws. According to the high temperature resistant stamped part transporting device, the high temperature resistant fiber layer and the asbestos layer are arranged, the high temperature resistant fiber layer reduces damage of a high temperature to the transporting device, it is guaranteed that the transporting device is used for a long time, the asbestos layer can be used for storing the high temperature produced by the stamped part into the transporting device, and a user is prevented from being scalded by the transporting device by accident when a stamped part is transported.

Owner:江苏同生高品合金科技有限公司

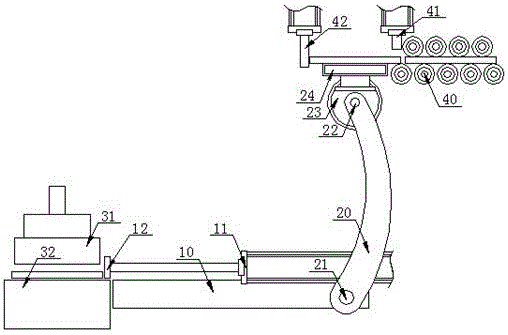

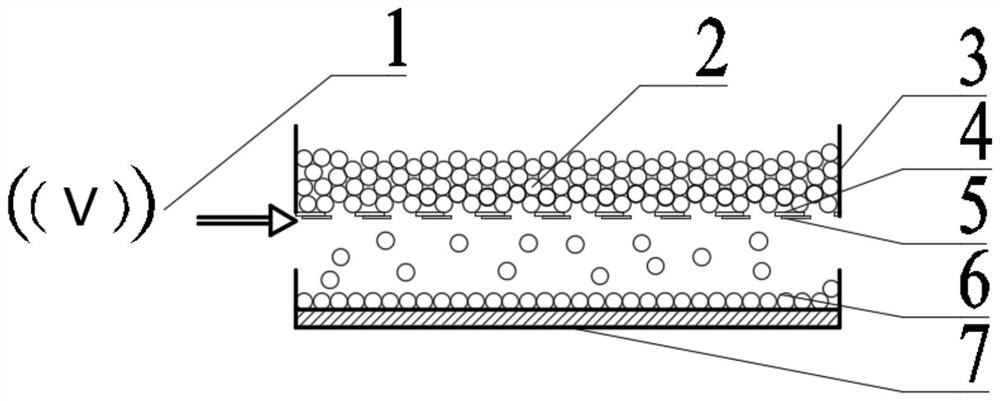

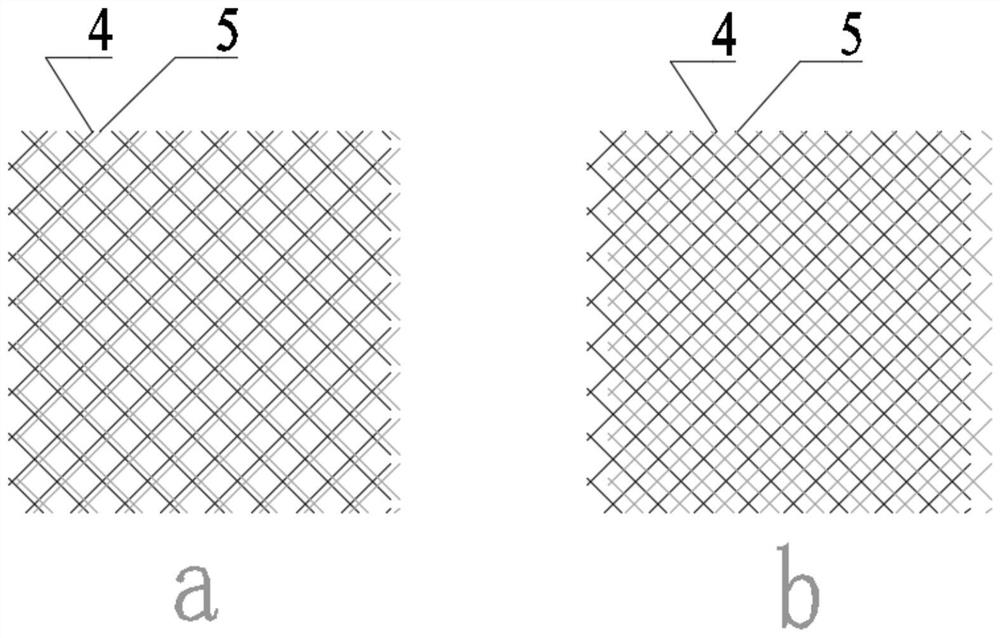

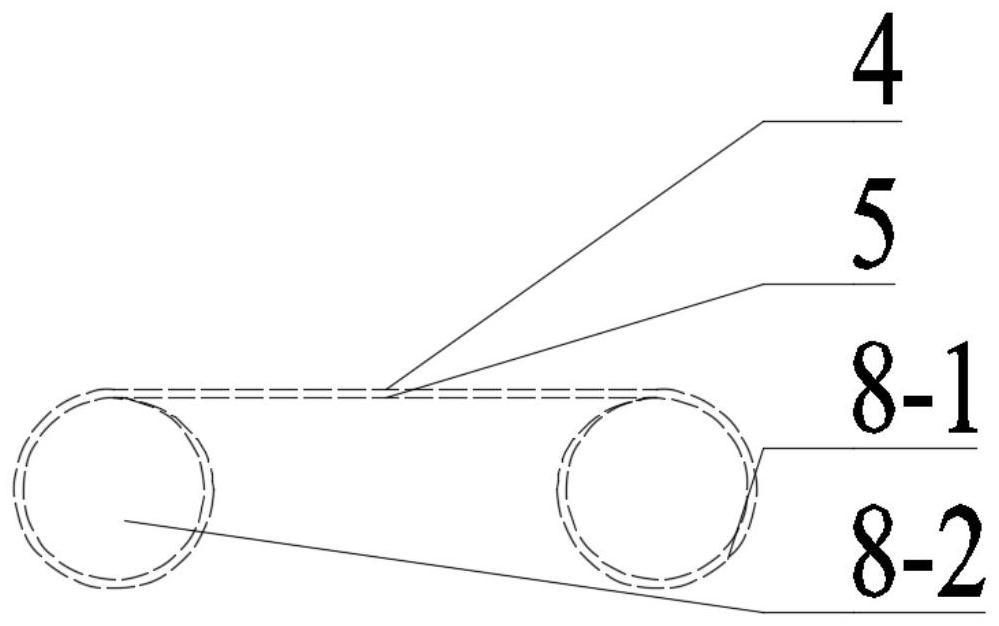

Powder falling control device and method for additive manufacturing

ActiveCN114345702AControl placementConvenient and efficient layingSievingAdditive manufacturing apparatusProcess engineeringControllability

The invention relates to the technical field of powder metallurgy, and provides a powder falling control device and method for additive manufacturing. The device comprises a powder storage bin, a middle bin, a double-layer screen and a screen driving unit; the middle bin is arranged at the lower end of the powder storage bin to keep the stability of powder below the powder storage bin; the double-layer screen is arranged at a powder outlet in the bottom of the middle bin; the double-layer screen cloth is attached to each other, relative displacement parallel to the screen cloth face can be generated between the double-layer screen cloth, interference is generated between the double-layer screen cloth, the sizes of through holes of the double-layer screen cloth are changed, and then the falling amount of powder is controlled. And the screen driving unit controls the relative displacement between the double-layer screens. The powder falling control method comprises the steps of calibration, powder falling start and stop control and powder falling rate control. Compared with existing equipment, the device is simple in structure and high in controllability, the powder feeding speed can be controlled, the device can be particularly used for controlling fine powder, powder laying can be conveniently and efficiently controlled, and the device has wide application prospects.

Owner:UNIV OF SCI & TECH BEIJING

An automatic feeding and stamping system for automobile support arm components

InactiveCN106734690BAutomated crawlingPrecise control over placementMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses an automatic feeding and punching system for an automobile supporting arm assembly. The automatic feeding and punching system for the automobile supporting arm assembly comprises a plate feeding platform, a plate feeding pushing air cylinder and a rotary piece taking swinging arm; one end of the rotary piece taking swinging arm is connected with a rotating driving rotating shaft of which the axis position is fixed; an electromagnetic piece taking sucking disc is arranged at the other end of the rotary piece taking swinging arm; the plate feeding platform is arranged horizontally, and one end of the plate feeding platform faces punching moulding equipment; the rotating driving rotating shaft and the plate feeding pushing air cylinder are arranged at the other end of the plate feeding platform; a piston rod of the plate feeding pushing air cylinder is arranged horizontally, and faces the punching moulding equipment; a plate feeding pushing baffle is arranged at the tail end of the piston rod of the plate feeding pushing air cylinder. According to the automatic feeding and punching system for the automobile supporting arm assembly provided by the invention, the actions of automatically grabbing and feeding of a plate punching operation of the automobile supporting arm assembly can be realized.

Owner:长春市宏宇汽车零部件有限公司

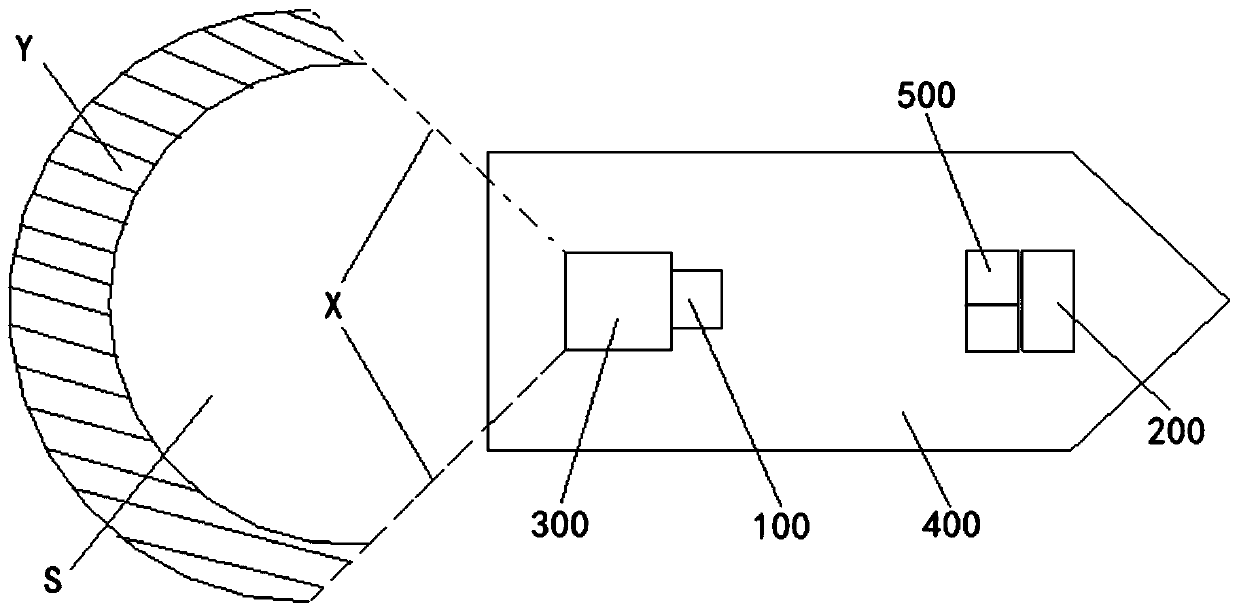

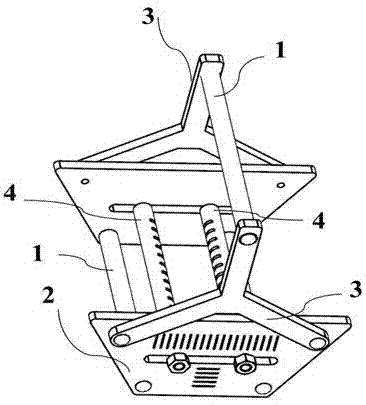

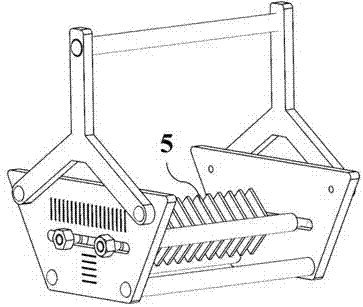

Carrying device for special-shaped wafers

PendingCN107993968APrecise control over placementControl placementSemiconductor/solid-state device manufacturingCorrosionEngineering

The invention discloses a carrying device for special-shaped wafers. The carrying device comprises connecting rods, side plates, lifting bars and supporting rods, wherein the two connecting rods are connected with and fix the two side plates, one connecting rod is connected with and fixes the upper ends of the lifting bars, and the lower ends of the lifting bars are fixed on the side plates respectively; side plate tracks for adjusting space between the two supporting rods and bearing wafers in different sizes are arranged on the side plates, and two ends of each supporting rod are fixed in the side plate tracks; side plate vertical scales for precision control of a wafer corrosion area and side plate horizontal scales for precision adjustment of the supporting rod space are formed in theside plates, and a plurality of grooves for carrying to-be-corroded wafers are formed in the two supporting rods respectively. Flexible adjustment can be realized with adoption of the carrying device,the carrying device adapts to arrangement of non-standard products in different sizes, and by means of the scales, precision control of sample arranging positions and control of a sample corrosion area can be realized. Multi-wafer unified treatment can be realized, working efficiency and operation normalization can be improved, operation risks can be reduced, and sample damage area can be reduced.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Automatic packing unit for injection molding machine

The invention discloses an automatic packing unit for an injection molding machine. The unit comprises a four-axis robot packing device, a detection device, an injection molding machine body, a workpiece storage box and an unqualified workpiece storage box, wherein the four-axis robot packing device is located at the side edge of the injection molding machine body, the defection device is fixed atthe side edge of a conveying sliding rail, and is parallel to the conveying sliding rail, and the storage box is located below a four-axis robot, and is used for receiving a working conveyed by the four-axis robot. Compared with the prior art, the automatic packing unit for the injection molding machine can be fully automatically connected to the injection molding machine and a product full-automatic assembly line through the AGV trolley, can scan the workpiece in a packing process, obtain actual data of the workpiece, compare the actual data with preset data, detect a defect of the workpiece, and determine a quality level of the workpiece, quality inspection and packing processes are organically combined, so that the working efficiency is improved, and by detecting a superior product rate in the workpiece storage box in real time, placement of workpieces with different quality grades is controlled.

Owner:东莞市恒明机器人自动化有限公司

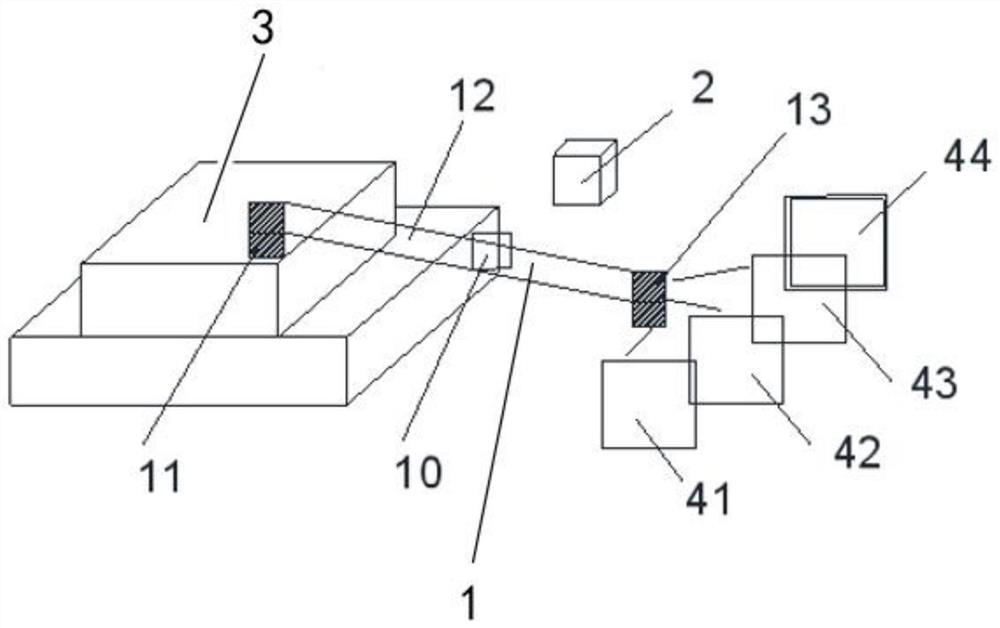

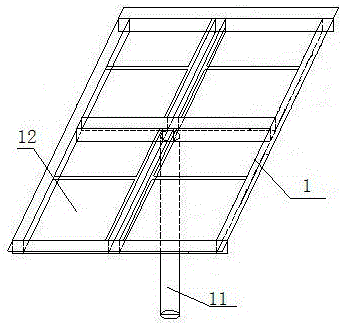

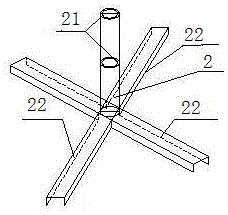

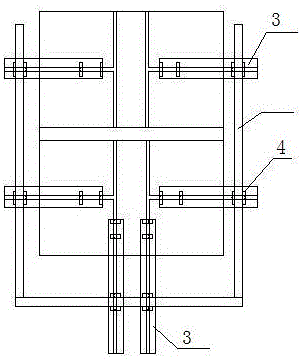

Rotatable welding platform and using method thereof

InactiveCN106736146AEasy to control placementControl placementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to the field of welding operation, in particular to a rotatable welding platform. The rotatable welding platform is characterized by comprising a rotating platform and a base, wherein the rotating platform comprises a supporting column and a horizontal support horizontally arranged at the top of the supporting column; the base comprises a supporting barrel and supporting feet; the supporting column of the rotating platform is inserted into the supporting barrel of the base, so that the horizontal support can horizontally rotate at the top of the base. After adoption of the rotatable welding platform, when the support is welded, the placing position of the support can be easily controlled and the required size of the support is also controlled very easily, so that the construction quality is guaranteed and the construction efficiency is greatly improved.

Owner:CHINA MCC20 GRP CORP

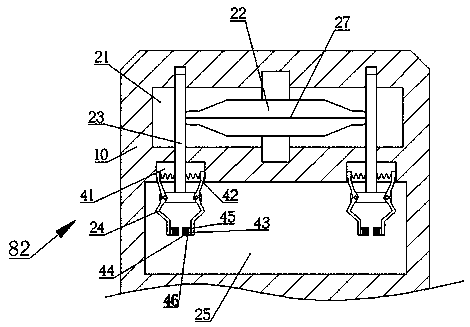

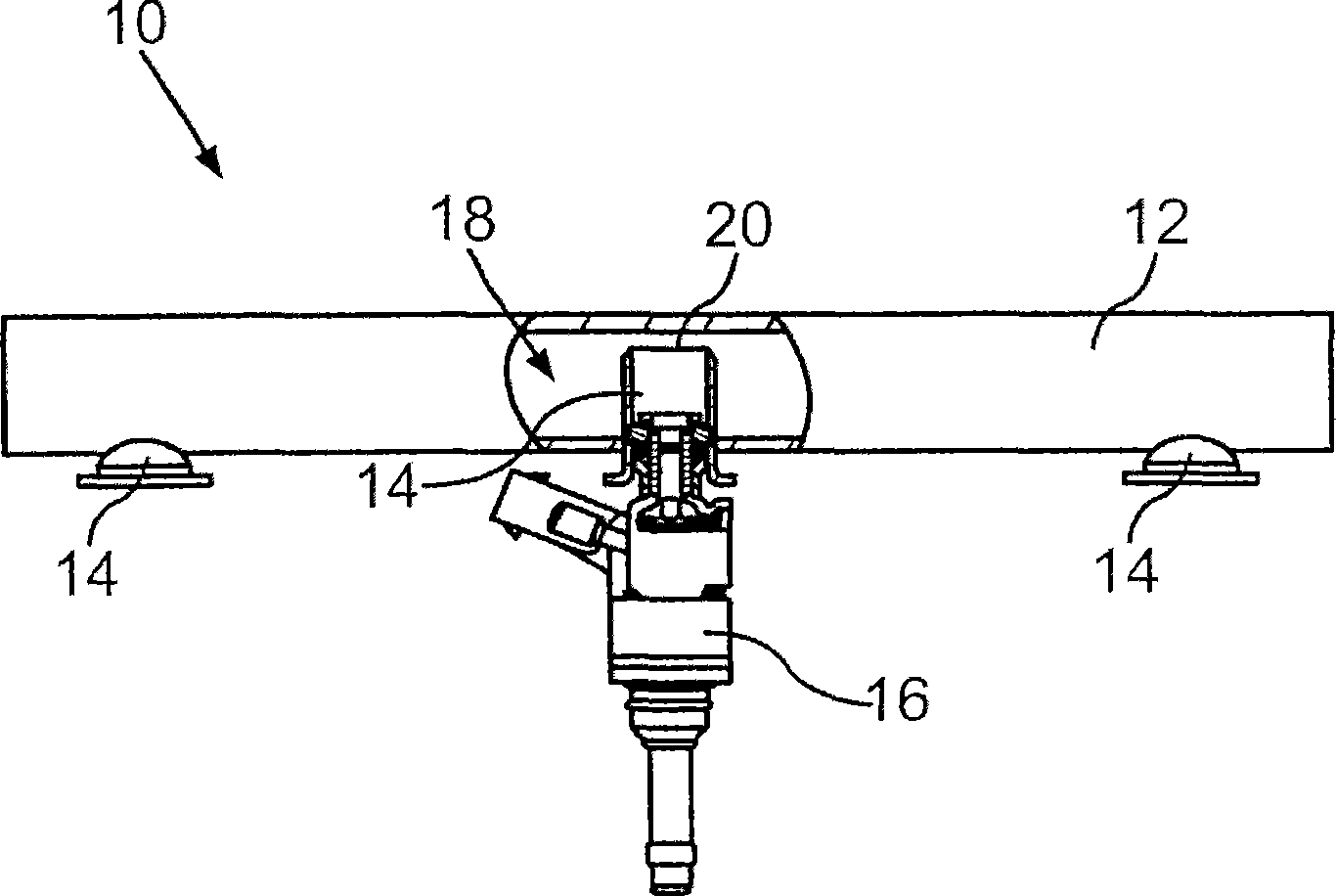

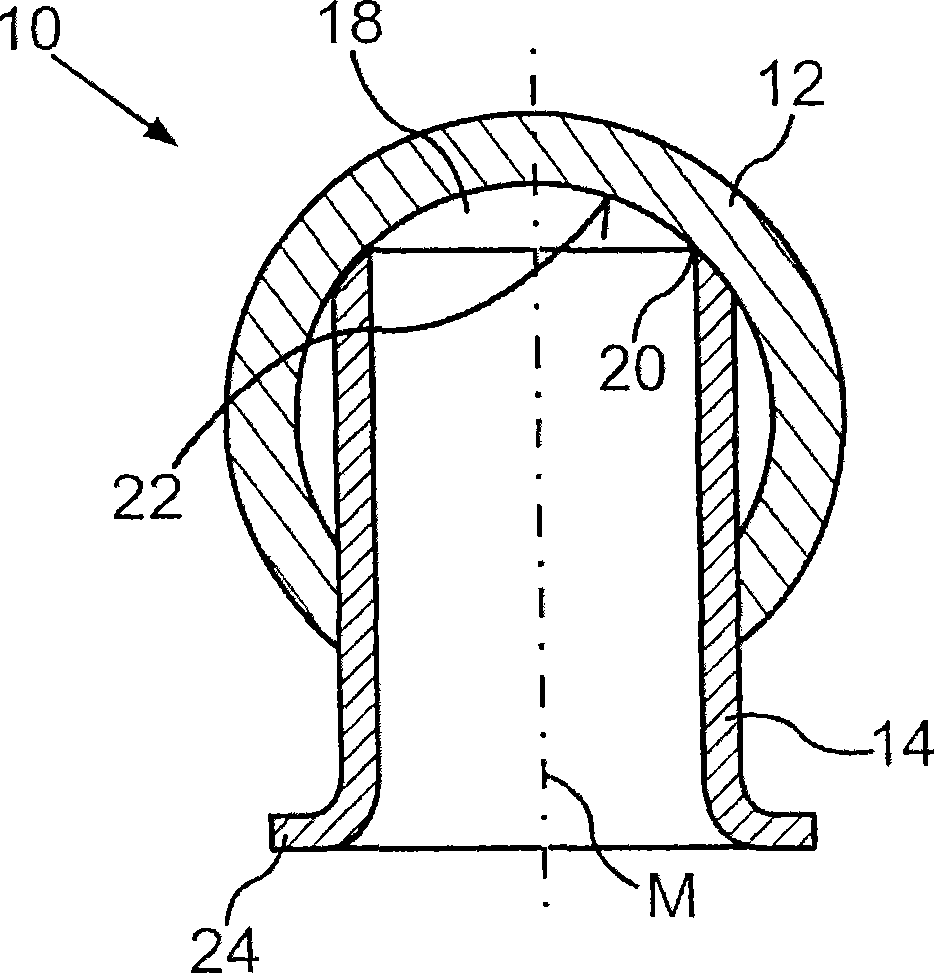

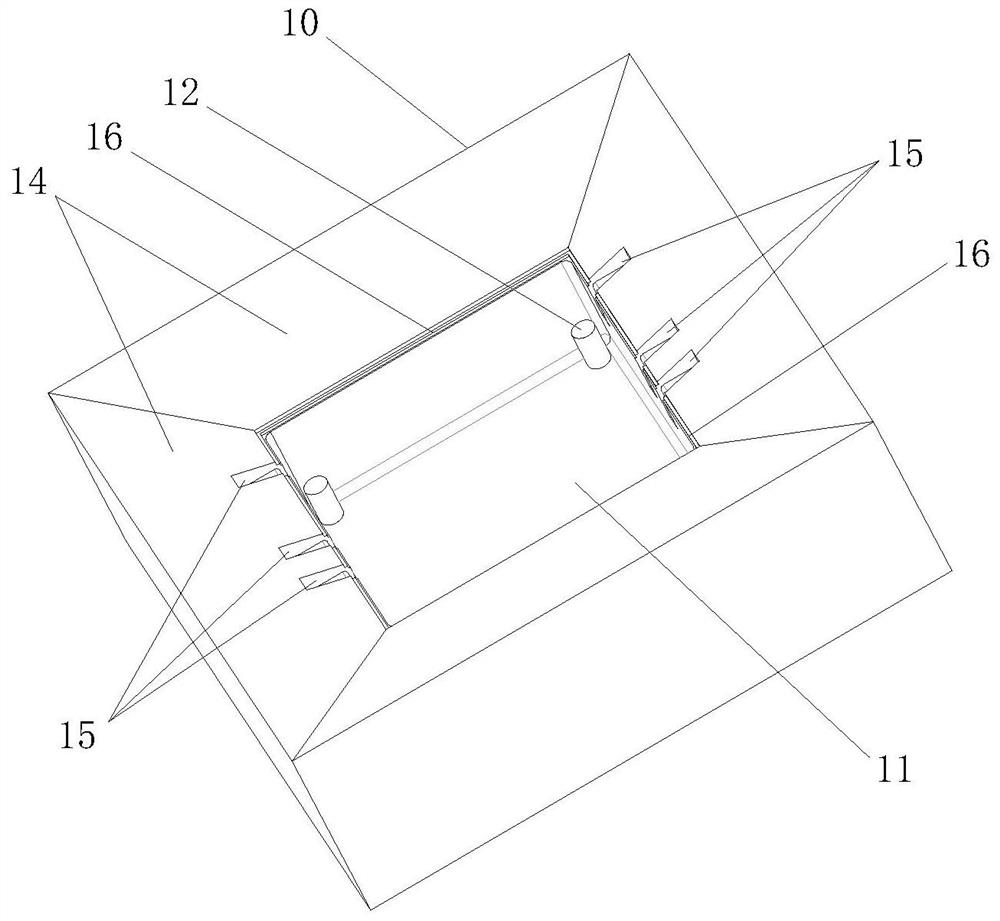

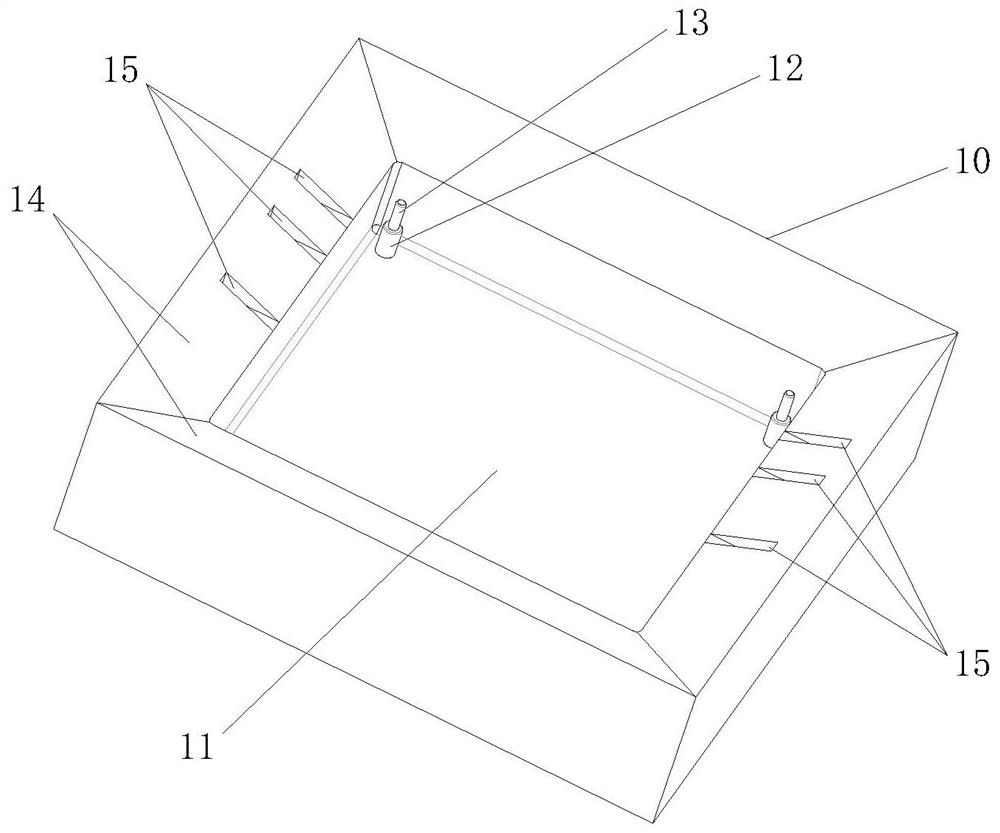

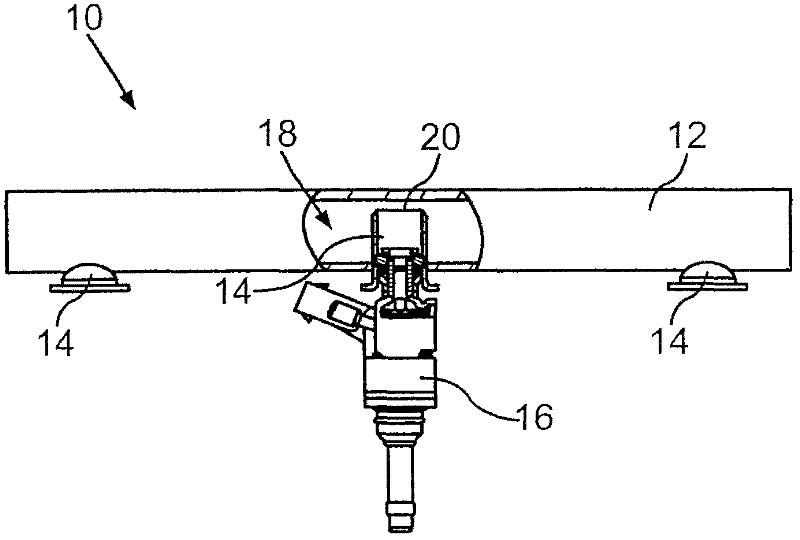

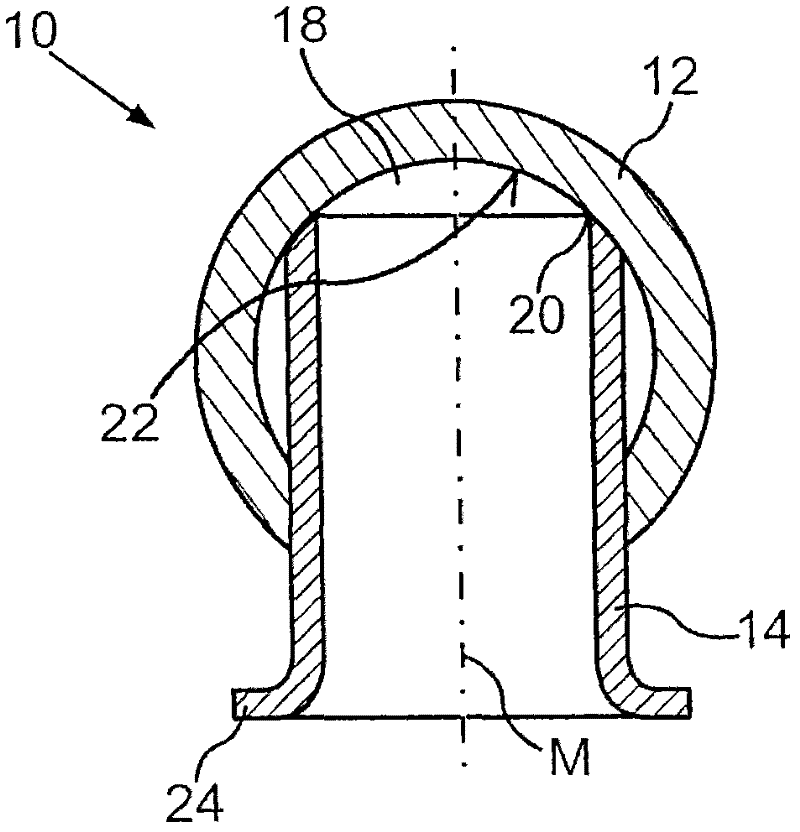

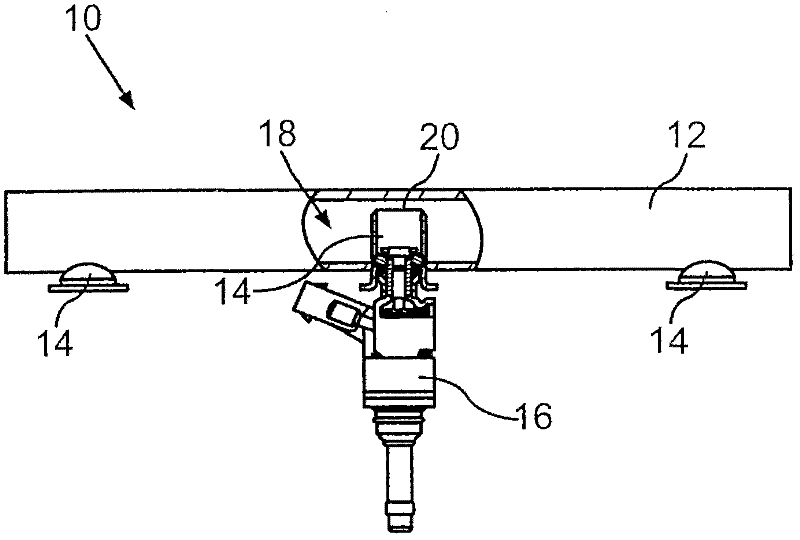

Fuel distribution device for a motor vehicle and method for producing a fuel distribution device

InactiveCN102235282BSave construction spaceMaximum axial extensionLow pressure fuel injectionMachines/enginesInterior spaceFuel distribution

#CMT# # / CMT# Fuel distribution device (10) comprises a fuel pipe (12) and pick-up tube (14), which are arranged with an injector (16). A receiving tube is also provided with interior space (18) of the fuel tube, where the intake pipe is introduced through front opening of the fuel tube. #CMT# : # / CMT# An independent claim is also included for a method for producing fuel distribution device. #CMT#USE : # / CMT# Fuel distribution device used for a motor vehicle. #CMT#ADVANTAGE : # / CMT# The fuel distribution device can be manufactured in a simple and cost-effective manner. #CMT#DESCRIPTION OF DRAWINGS : # / CMT# The drawing shows a partially sectional side view of a fuel distribution device with a fuel pipe. 10 : Fuel distribution device 12 : Fuel pipe 14 : Pick-up tube 16 : Injector 18 : Interior space.

Owner:AUDI AG

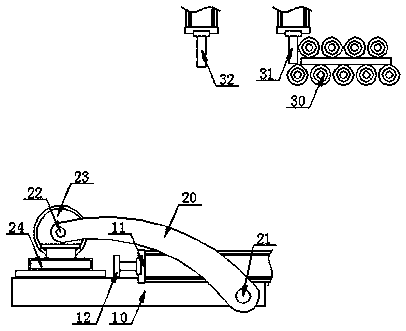

An automatic paving machine for sidewalk brick masonry

ActiveCN112281605BLabor savingLow costRoads maintainenceMovable tracksNumerical controlArchitectural engineering

The invention discloses an automatic paving machine for sidewalk brick masonry, which comprises a main body, a brick bin, a sand distributing part, a compacting part, and a numerical control device; the brick bin is used for storing floor tiles, and the brick bin is fixedly connected to the main body , the joint is provided with holes for floor tiles to pass through; the main body is used for laying floor tiles, and the bottom is provided with holes for floor tiles to pass through; the sand spreading part is used for laying sand and gravel, and the compacting part is used for compacting floor tiles The real parts are respectively arranged at the front and rear ends of the main body; the numerical control device is fixedly connected with the main body, and is electrically connected with the main body, the brick bin, and the sand distributing part, and is used to control the work of the main body, the brick bin, and the sand distributing part. During the laying process, the present invention can automatically level sand, place bricks, pave and compact automatically. Compared with manual brick laying, the efficiency is greatly improved, the paving is neat and accurate, saving costs and labor. Realized the automatic paving of sidewalk floor tiles.

Owner:NANCHANG CAMPUS OF JIANGXI UNIV OF SCI & TECH

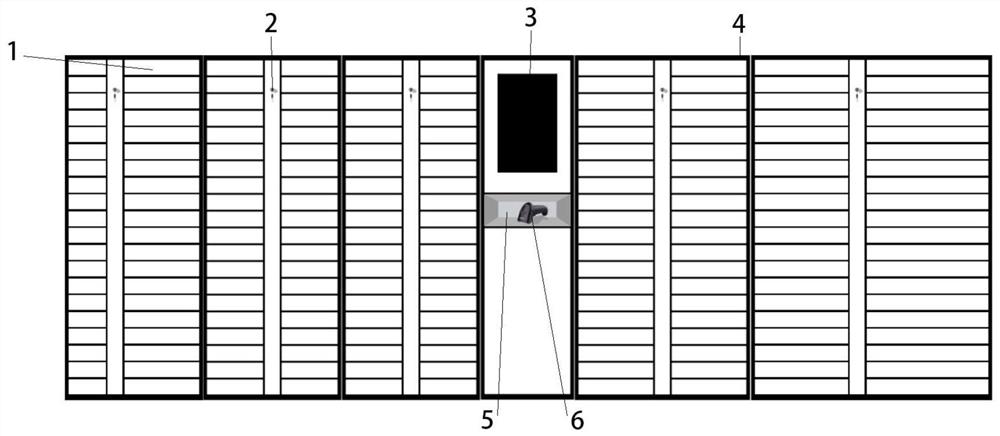

Batch board intelligent mantissa storage cabinet and management method

InactiveCN113693383AControl placementControl accessCabinetsSensing by electromagnetic radiationComputer hardwareControl system

A batch board intelligent mantissa storage cabinet is provided by the present invention and comprises a cabinet body and a control system, wherein the cabinet body is provided with a plurality of independent storage units, the storage units are distributed in an array mode, the cabinet body is provided with a detection device, the detection device is a code scanning gun and is used for scanning a batch board temporary mantissa management and control two-dimensional code label, a display device is arranged in the middle of the cabinet body, the display device is a display screen and is used for outputting and displaying batch board information list data, the storage units are integrally connected with the cabinet body, the display device is fixedly connected with the cabinet body, and the display device is connected with the output end of the control system. The code scanning gun is wirelessly connected with the input end of the control system through signal transmission. According to the intelligent batch board mantissa storage cabinet, batch board placement can be controlled, the manual board finding time is shortened, a control system controls in and out of batch boards, and temporary batch board list data are inquired in real time.

Owner:HUIZHOU TECHUANG ELECTRONIC TECH CO LTD +1

Electronic device packaging mold

InactiveCN113690037APrevent glue from spillingEasy to demouldEncapsulation/impregnationMagnetic coreStructural engineering

The invention discloses an electronic device packaging mold which is used for integrally packaging a winding and a magnetic core assembly and forming a packaging layer on the surface, and a plurality of positioning holes are formed in the winding. The electronic device packaging mold comprises an open mold body, the mold body is provided with a glue injection groove which is sunken downwards, a vertically-arranged supporting column corresponding to the positioning hole is arranged on the bottom face in the glue injection groove, and the size of the cross section of the supporting column is greater than that of the cross section of the positioning hole; and the supporting columns are supported on the surface of the winding where the positioning holes are located. According to the electronic device packaging mold, the supporting columns are connected with the winding positioning holes in an aligned mode, the winding can be controlled to be placed at the proper position, and therefore the packaging size is accurately controlled.

Owner:无锡燊旺和电子科技有限公司

Fuel distribution device for a motor vehicle and method for producing a fuel distribution device

InactiveCN102235282ASave construction spaceMaximum axial extensionLow pressure fuel injectionMachines/enginesInterior spaceFuel distribution

The invention relates to a fuel distribution device for a motor vehicle, the fuel distribution device comprises: a fuel pipe (12) and at least a receiving tube (14) disposed on the fuel pipe (12) and used for an injector (16). The receiving tube (14) partially inserts into the internal space (18) of the fuel pipe (12), and is provided with an opening at one end side, and via the end side opening fuel can enter into the receiving tube (14). Herein, the main part of the receiving tube (14) is disposed to be in the internal space (18) of the fuel pipe (12), and only a small part inserts out of the fuel pipe (12). Additionally, the invention relates to a method producing the fuel distribution device (10).

Owner:AUDI AG

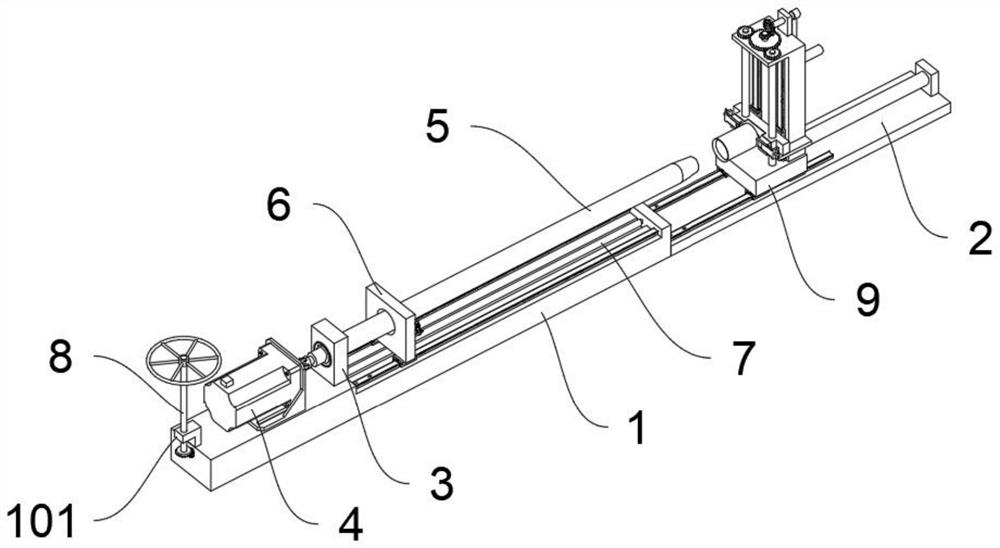

Automatic feeding and stamping system for automobile corbel assemblies and control circuit thereof

ActiveCN109304406AEasy to adjustEnergy savingMetal-working feeding devicesMetal working apparatusPower unitEngineering

The invention relates to the technical field of machining equipment, in particular to an automatic feeding and stamping system for automobile corbel assemblies and a control circuit thereof. The automatic feeding and stamping system for the automobile corbel assemblies comprises a feeding platform, a plate feeding and pushing air cylinder, a rotary part taking swing arm, a moving unit, a power unit and an air collecting tank; one end of the rotary part taking swing arm is fixedly connected with a rotary driving rotation shaft, and the other end of the rotary part taking swing arm is provided with an electromagnetic part taking suction cup; the feeding platform is horizontally arranged, one end faces stamping molding equipment, and the other end of the feeding platform is provided with therotary driving rotation shaft and the feeding and pushing air cylinder; one end of the rotary driving rotation shaft is provided with a spiral sliding groove, and a piston rod of the feeding and pushing air cylinder is horizontally arranged and faces the stamping molding equipment; the moving unit is connected with the feeding platform through a spring and rotatably connected with the spiral sliding groove end of the rotary driving rotation shaft; and the power unit is slidably connected with the feeding platform and movably connected with the moving unit. Therefore, the problems that energy sources are wasted, operation is difficult, and the requirement on the personnel skill level is high are solved.

Owner:ZHAOQING UNIV +1

Stamping loading and unloading system for body connection bracket

ActiveCN106424411BControl placementReduce labor intensityMetal-working feeding devicesVehicle componentsDrive shaftEngineering

The invention discloses a loading and unloading system for stamping a vehicle body connecting bracket. The loading and unloading system comprises a lower stamping-forming die, a plate loading platform, a plate loading push air cylinder and a rotary taking swing arm, wherein one end of the rotary taking swing arm is connected with a rotation driving shaft, and the position of the axis of the rotation driving shaft is fixed; an electromagnetic taking sucker is arranged at the other end of the rotary taking swing arm; the plate loading platform is horizontally arranged, and one end of the plate loading platform faces the lower stamping-forming die; the top surface of the plate loading platform is as high as that of the lower stamping-forming die; the rotation driving shaft and the plate loading push air cylinder are arranged at the other end of the plate loading platform; and a piston of the plate loading push air cylinder has a two-stage stroke. The loading and unloading system for stamping the vehicle body connecting bracket, provided by the invention, can realize automatic gripping, loading and unloading actions during the stamping operation of the vehicle body connecting bracket.

Owner:佛山云顶汽车部件有限责任公司

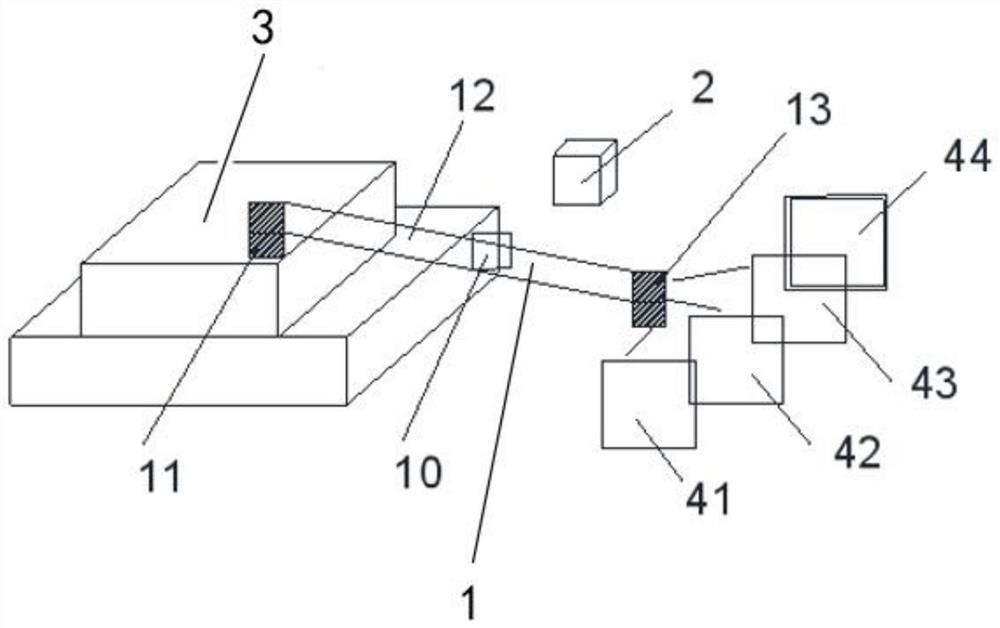

An automatic transition system for sheet metal processing blanking to forming

ActiveCN106583542BImprove work efficiencyAutomate operationsMetal-working feeding devicesPositioning devicesPunchingManipulator

The invention discloses an automatic transition system for converting blanking to forming in sheet-metal working. The automatic transition system comprises a punching blanking mechanism, a transfer mechanical arm and a punching forming mechanism which are sequentially arranged from the upstream end to the downstream end. The punching blanking mechanism comprises a punching blanking lower die base and a blanking pushing cylinder. The transfer mechanical arm comprises a rotary driving spindle, a rotary piece-collecting swing arm and an electromagnetic piece-collecting suction cup. The punching forming mechanism comprises a forming feeding platform, a punching forming lower die and a forming feeding cylinder. The downstream end of the punching blanking lower die base is located above the upstream end of the forming feeding platform. The rotary driving spindle is arranged at the upstream end of the forming feeding platform. The downstream end of the forming feeding platform is connected with the punching forming lower die, and the top surface of the forming feeding platform and the top surface of the punching forming lower die are horizontally coplanar. By the adoption of the automatic transition system, automatic operations of grabbing discharge, station transfer feeding and forming or punching feeding of blanked sheets can be realized.

Owner:WUHU YUANSHAN MACHINERY MFG CO LTD

An automatic packing unit of an injection molding machine

The invention discloses an automatic packing unit for an injection molding machine. The unit comprises a four-axis robot packing device, a detection device, an injection molding machine body, a workpiece storage box and an unqualified workpiece storage box, wherein the four-axis robot packing device is located at the side edge of the injection molding machine body, the defection device is fixed atthe side edge of a conveying sliding rail, and is parallel to the conveying sliding rail, and the storage box is located below a four-axis robot, and is used for receiving a working conveyed by the four-axis robot. Compared with the prior art, the automatic packing unit for the injection molding machine can be fully automatically connected to the injection molding machine and a product full-automatic assembly line through the AGV trolley, can scan the workpiece in a packing process, obtain actual data of the workpiece, compare the actual data with preset data, detect a defect of the workpiece, and determine a quality level of the workpiece, quality inspection and packing processes are organically combined, so that the working efficiency is improved, and by detecting a superior product rate in the workpiece storage box in real time, placement of workpieces with different quality grades is controlled.

Owner:东莞市恒明机器人自动化有限公司

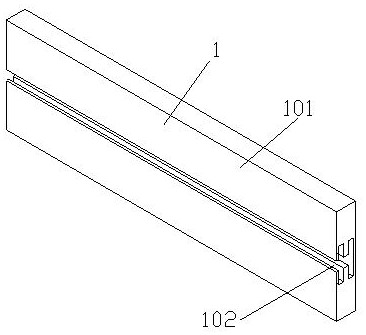

Step type bridge for laying cables with different diameters

Owner:江苏瑞仕达电气设备有限公司

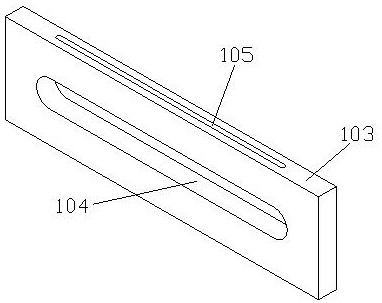

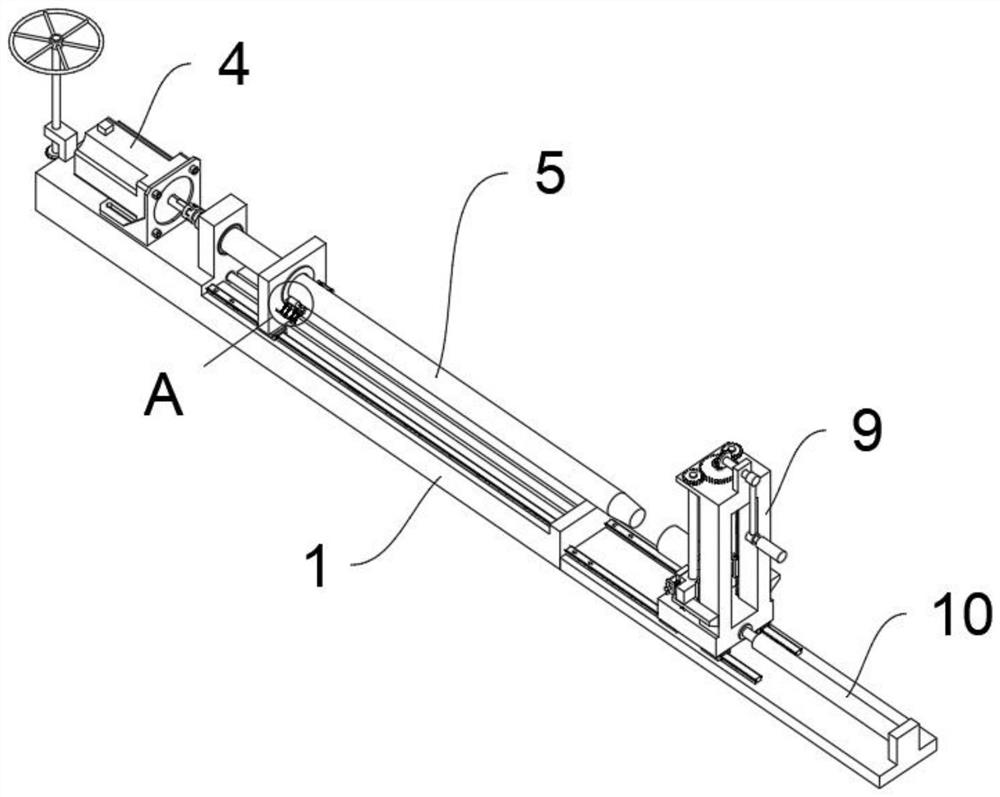

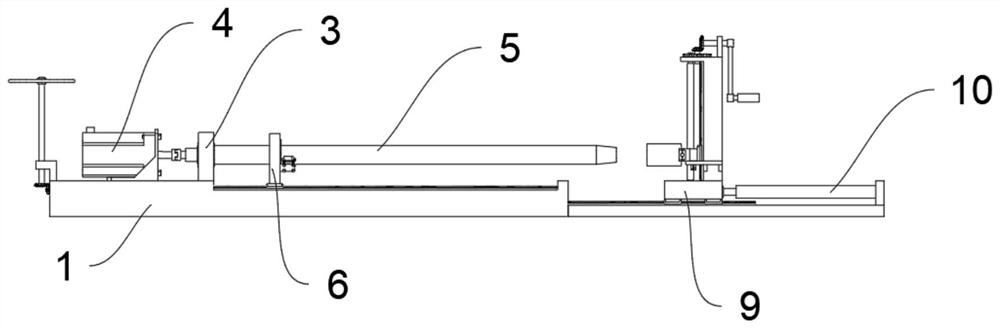

Automobile product necking die

InactiveCN112091089AFast alignment reductionEasy to assembleShaping toolsMetal-working feeding devicesAutomotive productStructural engineering

The invention discloses an automobile product necking die, and relates to the technical field of dies. The problems that a die structure used at present cannot rapidly reduce parts needing to be necked, adjustment is not conveniently and rapidly carried out according to the length of machined tubular parts, and the accessories are replaced by a relatively big margin are solved. The automobile product necking die comprises a base, the base further comprises an L-shaped frame, the L-shaped frame is located at the front end of the top of the base, the top of the L-shaped frame is bent forwards, ahand wheel shaft is rotationally arranged in the middle of the bent position, a hand wheel is fixedly arranged on the outer side of the top of the hand wheel shaft, and a splicing base is fixedly arranged at the bottom of the rear side of the base. By arranging the necking die, alignment reduction can be rapidly carried out on ports of tubular workpieces, the necking die is fixed to the front side of an alignment pile through a self-locking piece and a locking screw, assembly and replacement are convenient, the necking die and a conical trapezoidal die at the rear end of a rolling pile can bedetached and replaced, and necking dies at different angles can be installed for necking machining.

Owner:新昌县凌智机械有限公司

An automatic feeding and stamping system for automobile support arm components and its control circuit

ActiveCN109304406BChange the stroke of the horizontal movementLow skill level requiredMetal-working feeding devicesMetal working apparatusControl engineeringControl theory

Owner:ZHAOQING UNIV +1

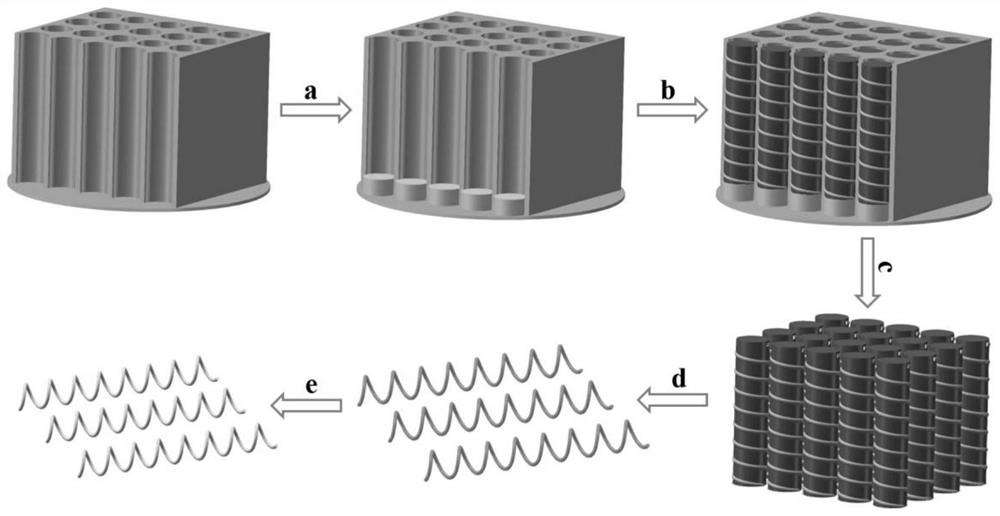

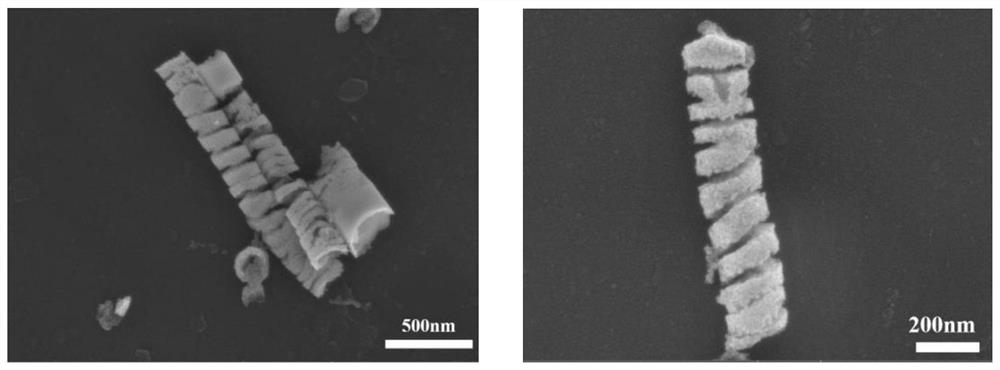

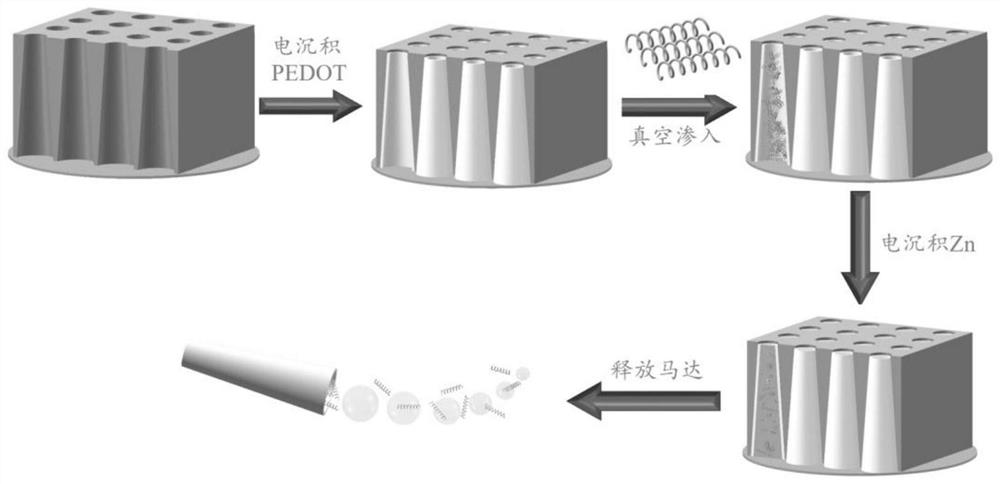

A kind of preparation method of multistage micro-nano motor

ActiveCN108609578BComplete tasks efficientlyControl placementDecorative surface effectsIndividual molecule manipulationNanomotorEngineering

The invention provides a preparation method of a multi-stage micro-nano motor. By the preparation method, a novel chemically-driven micromotor loaded with a magnetic field-driven nanomotor is prepared. The multi-stage micro-nano motor can move in a chemical field firstly and gradually release the magnetically-driven nanomotor and the released nanomotor can move under the driving of a magnetic field so as to perform own target tasks. By the preparation method, the placement position of the nanomotor can be further accurately controlled, so that the small motor operates in a finer working area;meanwhile, small motors with different driving ways can be loaded, so that the application value of the multi-stage micro-nano motor in more aspects is achieved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com