Stamping loading and unloading system for body connection bracket

A technology for connecting brackets and car bodies, which is applied in the field of stamping loading and unloading systems for car body connecting brackets, which can solve problems such as high labor intensity, low operating efficiency, and stamping and forming processing errors, and achieve less work-related accidents, high operating efficiency, and labor-intensive small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

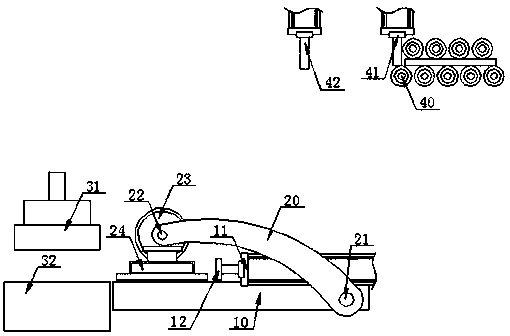

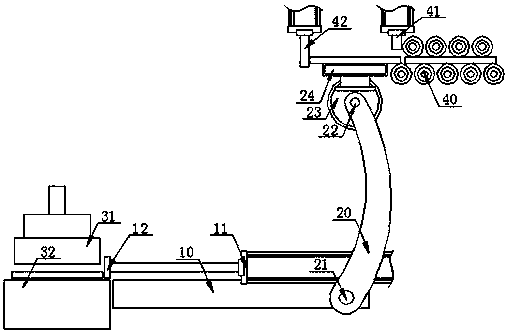

[0016] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as Figure 1 to Figure 2 As shown, a stamping loading and unloading system for the connecting bracket of the vehicle body includes stamping equipment, a plate loading platform 10, a plate loading and pushing cylinder 11, and a rotary pick-up swing arm 20; the stamping equipment includes a stamping upper die 31 and stamping forming lower die 32; one end of the rotary pick-up swing arm 20 is connected to the rotary drive shaft 21 with a fixed axis position, and the other end of the rotary pick-up swing arm 20 is provided with an electromagnetic pick-up sucker 24; the plate The loading platform 10 is arranged horizontally and one end faces the stamping forming lower die 32, and the top surface height of the sheet material loading platform 10 is the same as the top surface height of the stamping forming lower die 32, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com