Carrying device for special-shaped wafers

A carrier device and chip technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inappropriate devices, irregular actions, and high risks, so as to improve efficiency, save resources, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

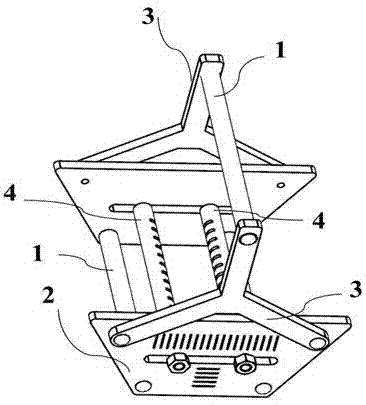

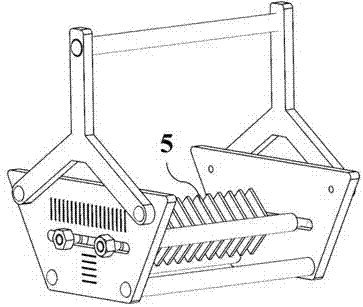

[0018] Example: refer to Figure 1 to Figure 8 , using this device to determine the polar surface of a square cadmium sulfide (CdS) wafer with polarity, the specific steps are as follows:

[0019] (1) Place the CdS crystal ingot on the cutting machine to cut the wafer or large-area sample, and the cutting thickness is controlled at 600-700μm;

[0020] (2) Cut the wafer / large-area sample into square pieces of 15㎜х15㎜, with a cutting error of ±0.5mm;

[0021] (3) Adjust the distance between the support rods 4 of the carrying device through the side plate track 2-1, and control it between 10mm-12mm;

[0022] (4) Place the cut square piece 5 vertically in the groove 4-1 on the pole 4 of the carrying device, and the sharp corner of the square piece is lower than the bottom edge of the pole 4;

[0023] (5) Prepare hydrochloric acid in the container: corrosion solution with deionized water volume ratio of 1:5; concentration of hydrochloric acid is 36%-38%; corrosion at room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com