Slag pot support for large-diameter vertical steel slag pressurized hot disintegrating pot

A large-diameter, slag tank technology, applied in the field of slag tank supports, can solve problems such as the inability to control the position of the slag tank and the unfavorable withdrawal of the crane plate hook.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

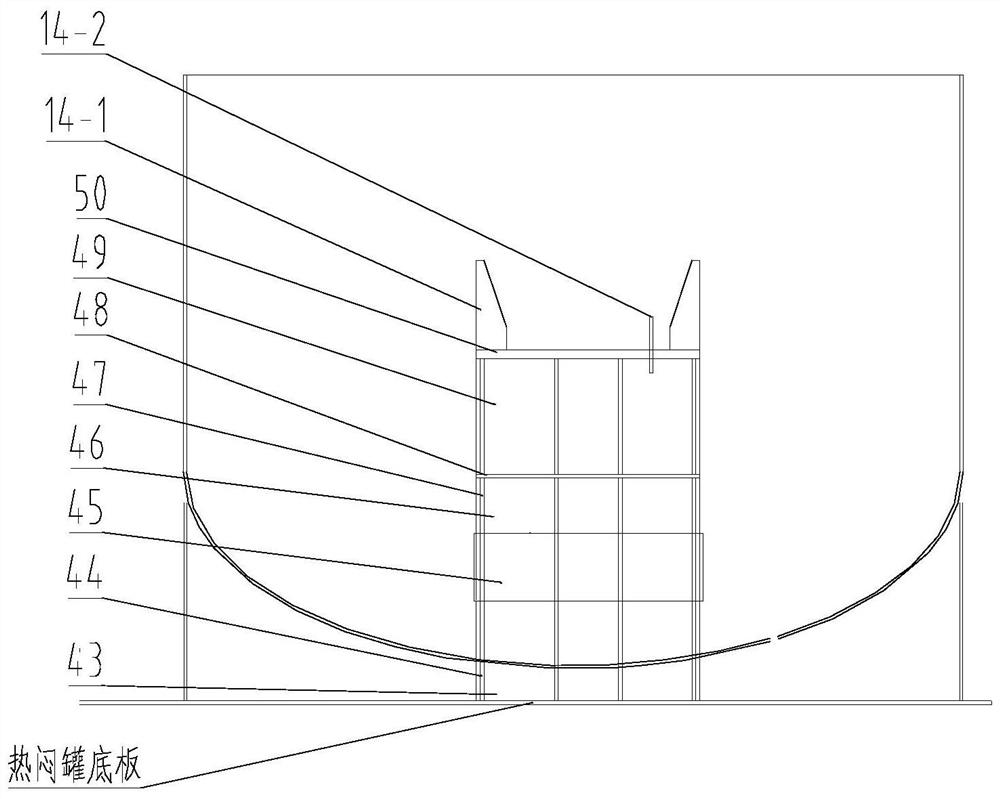

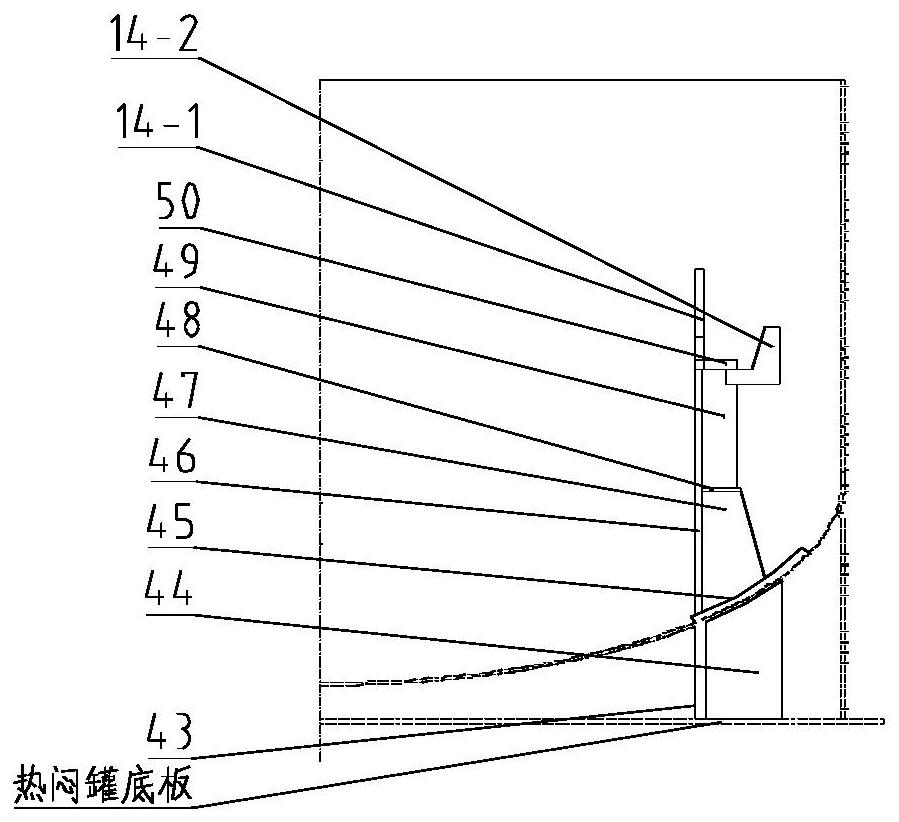

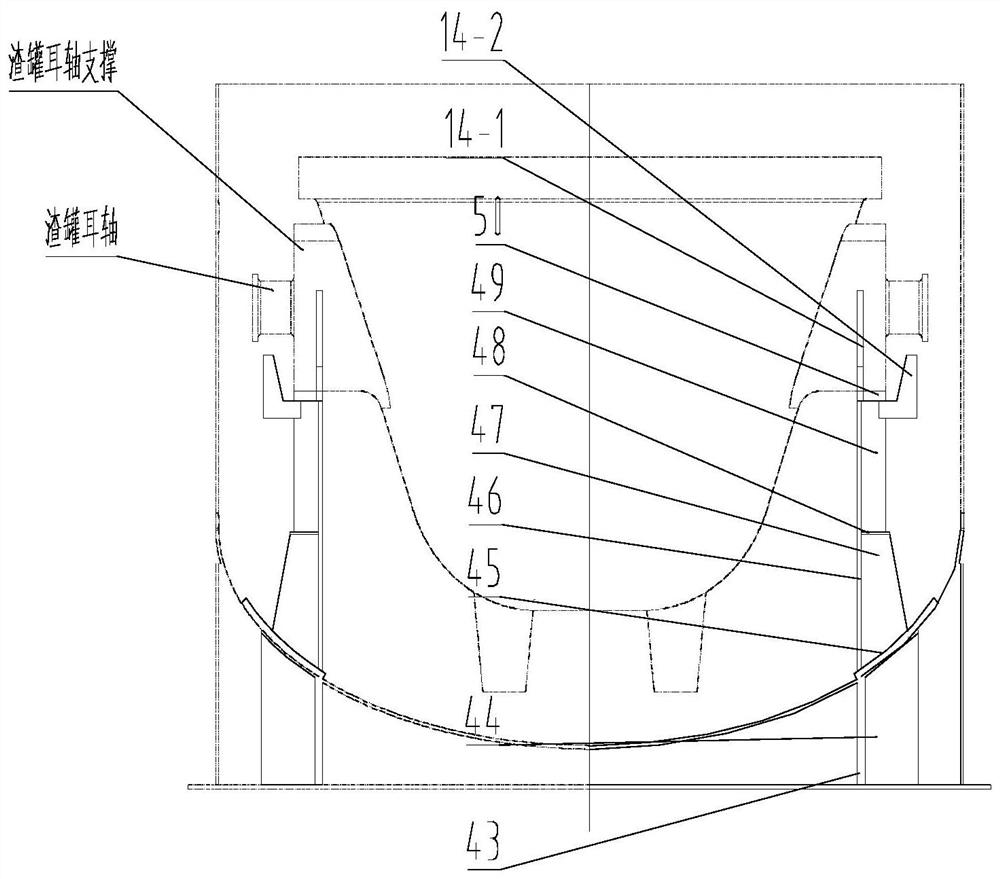

[0027] Such as Figures 1a-5b As shown, a large-diameter vertical steel slag has a slag tank support of autoclaved stuffy tank, and the slag tank support includes: a lower support, a first backing plate 45, a middle support, an upper support and a guide device 14; the lower support Including the lower web 43 and the lower support plate 44; the lower support plate 44 is distributed and welded on the lower web 43, the top end of the lower support plate 44 is welded on the hot stuffy tank body, the upper end surface of the lower web plate 43 is in line with the shape of the lower part of the hot stuffy tank body Fitting, welded on the tank body of the hot stuffy tank, the lower end surface of the lower web 43 is a plane, welded on the bottom plate of the hot stuffy tank; the first backing plate 45 is welded on the hot stuffy tank, used for supporting and welding the middle support, the middle The upper part of the support is connected with an upper support, and the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com