Automobile body dent repair tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

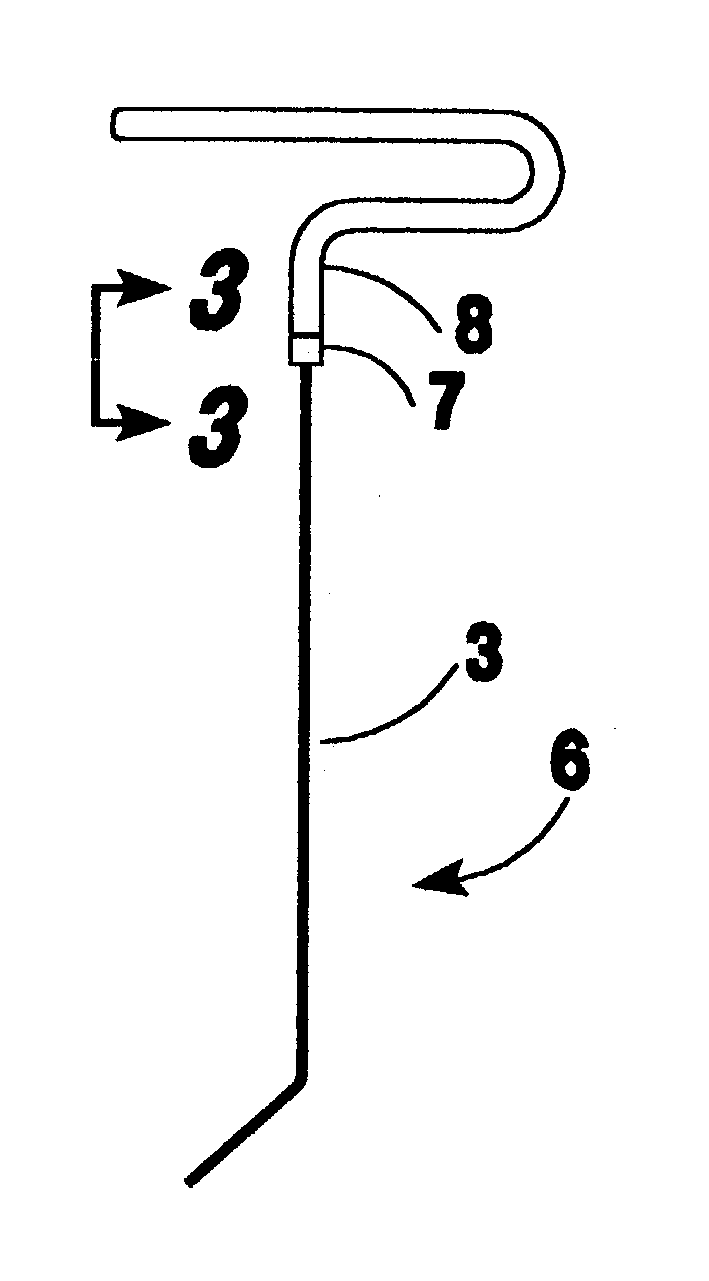

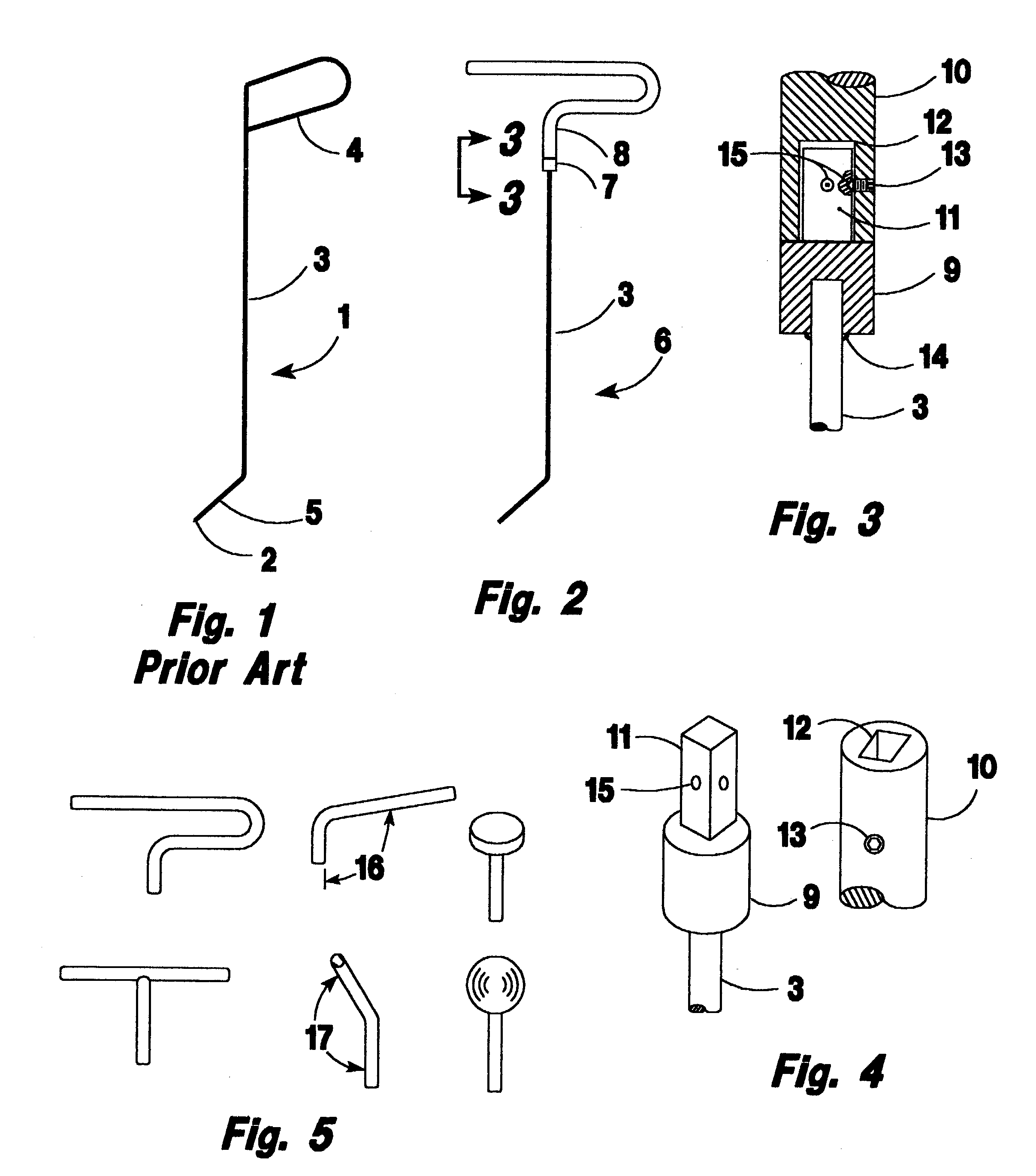

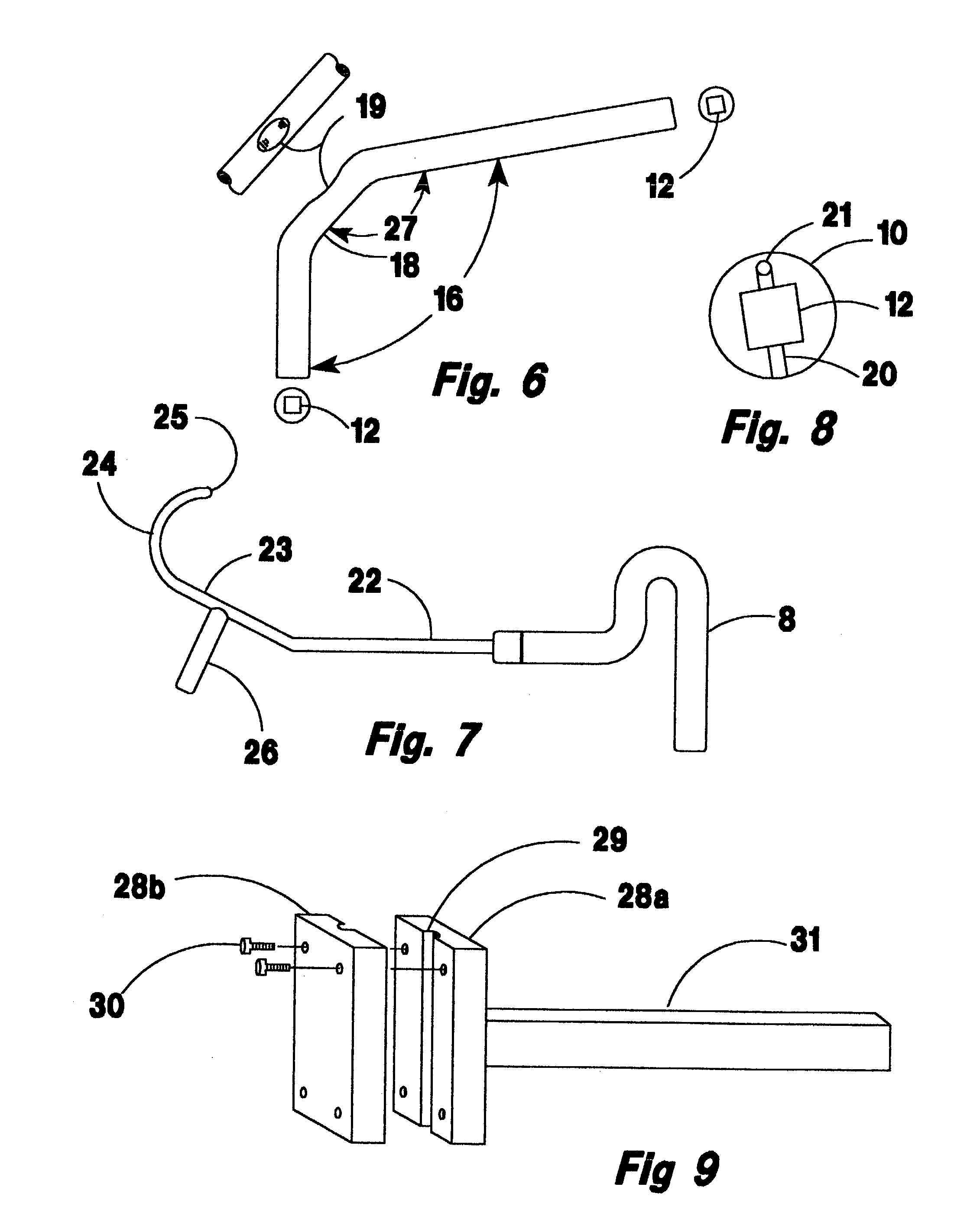

[0069]FIG. 1 is representative of a typical paintless dent repair tool (1) in the prior art It is comprised of three essential parts, a working tip 2 at the distal end, a long thin shank 3, and a handle 4 at the proximal end. Typically, the handle is a length of the shank stock formed into a loop or L then covered with a vinyl or similar protective coating for providing both gripping friction and avoiding metal contact with the auto body under repair. As can be seen, the whole assembly is fixed. The handle is a light structure and is in a fixed orientation with the working tip. A set of tools usually contains several tools with the distal end bent into either a radially projecting segment 5 or a hook. A hook if used, is often an arc of approximately 180 degrees for working the far side of a dent.

[0070] A full set of paintless dent repair tools may be as many as 300 individual tools. If each has a handle made from 20 inches of high quality steel, approximately 40% of the steel used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com