Batch board intelligent mantissa storage cabinet and management method

A technology of storage cabinets and management methods, applied in cabinets, instruments, induction recording carriers, etc., can solve the problems of difficulty in obtaining batch boards, affecting the appearance of the workshop, wasting time, etc., and achieve the effect of reducing the time for manual board finding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

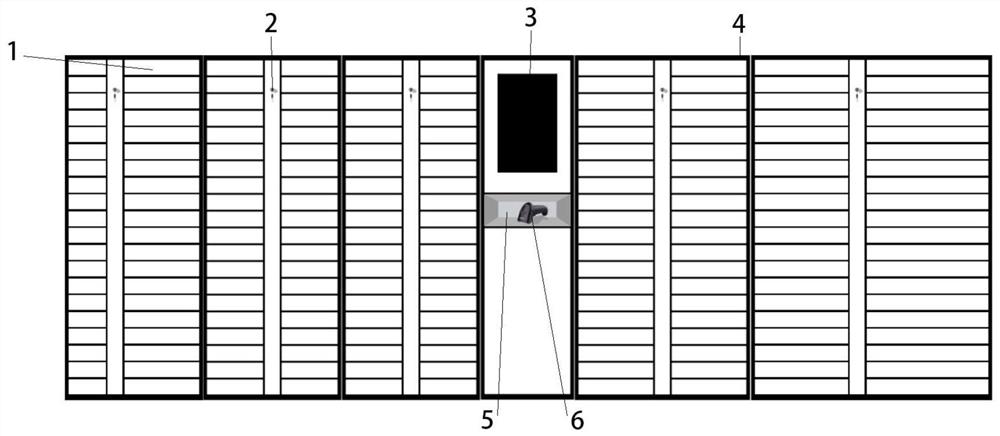

[0033]The employee first uses the card reading sensor module to identify the employee card. After the identification is passed, the display prompts and the touch screen selects the deposit step; when depositing, the barcode scanner scans the temporary mantissa control QR code label and sends a signal to the control system, which then Identify the mantissa of the batch plate number, and query the free storage unit 1 through the touch screen of the display screen. After confirming the free storage unit, the employee selects the appropriate storage unit 1 according to the size of the board, and selects the storage unit 1 on the display. The corresponding cabinet door automatically Pop open, and when the batch boards are stored, the infrared sensor module of the cabinet door 4 senses whether there is something blocking the cabinet door from closing. If so, the system receives the blocking signal, and the system sends a signal to the announcer. The announcer reminds employees to clea...

Embodiment 2

[0035] The employee first uses the card reader sensor module to identify the employee card. After the identification is passed, the display prompts and the touch screen selects the removal step; when taking it out, the employee first inquires the mantissa of the batch board required by the control system through the display screen, and the control system receives the signal to check the storage cabinet. Whether there is a necessary batch board, when there is a relevant batch board stored in storage unit 1, the operator can touch the screen to select a single or batch check to open the storage unit 1 corresponding to the batch board mantissa to pick up the goods. After confirming the selection, the relevant storage unit cabinet Open the door and wait for the employee to take out the batch board. After the batch board is taken out, when the cabinet door is closed, the item sensing module senses whether there are circuit boards in the storage unit 1. If so, the system receives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com