Patents

Literature

44results about How to "Automated crawling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

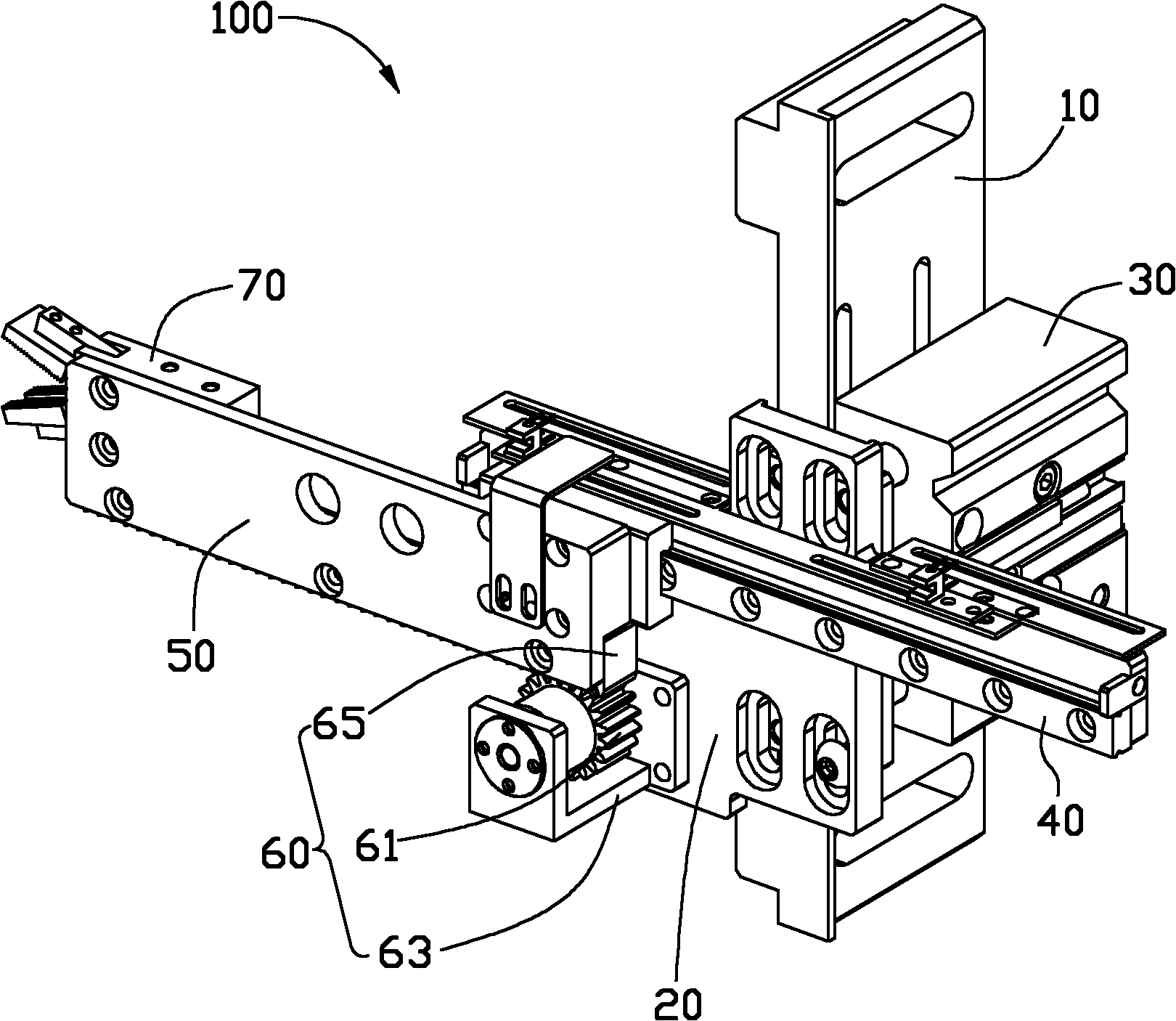

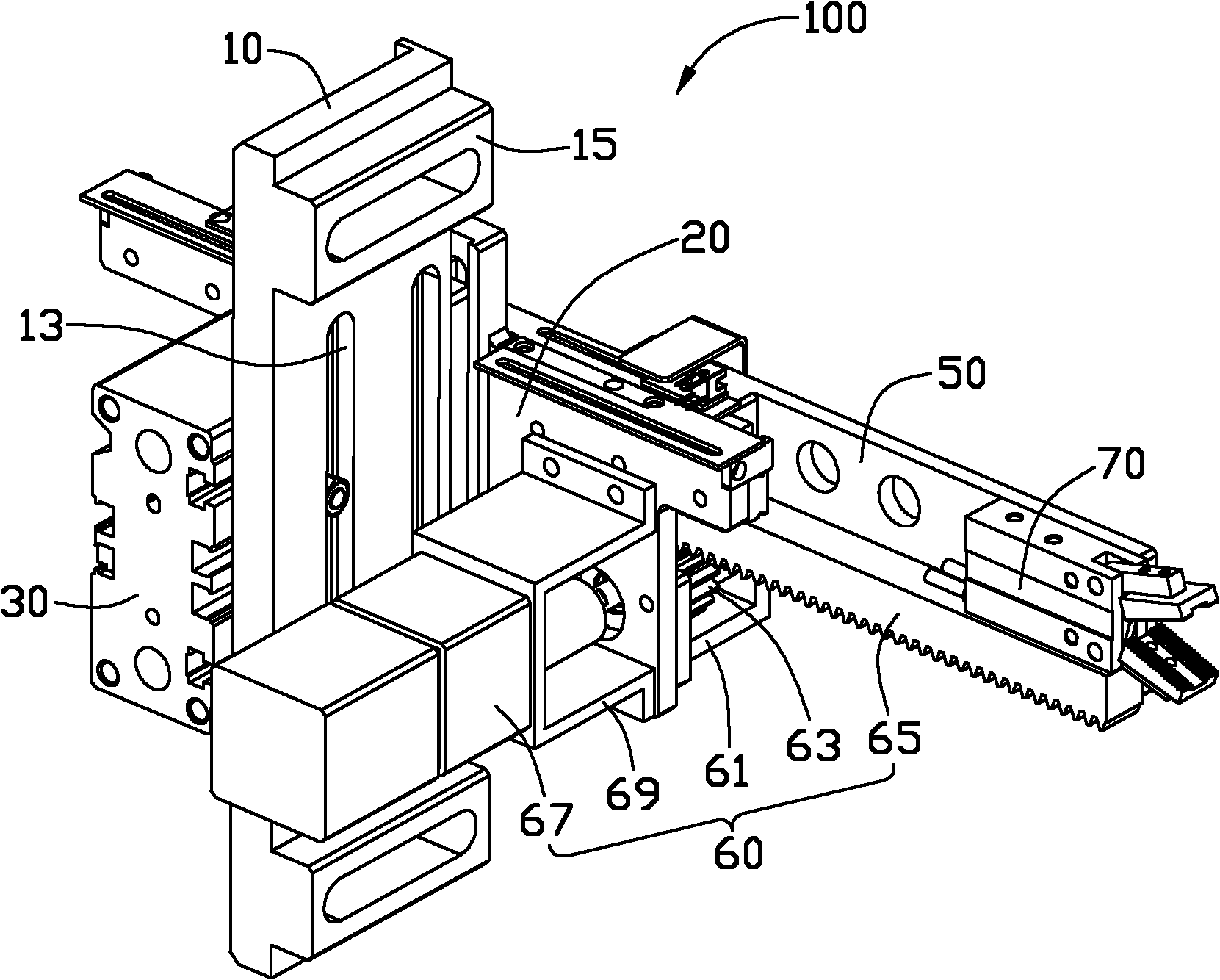

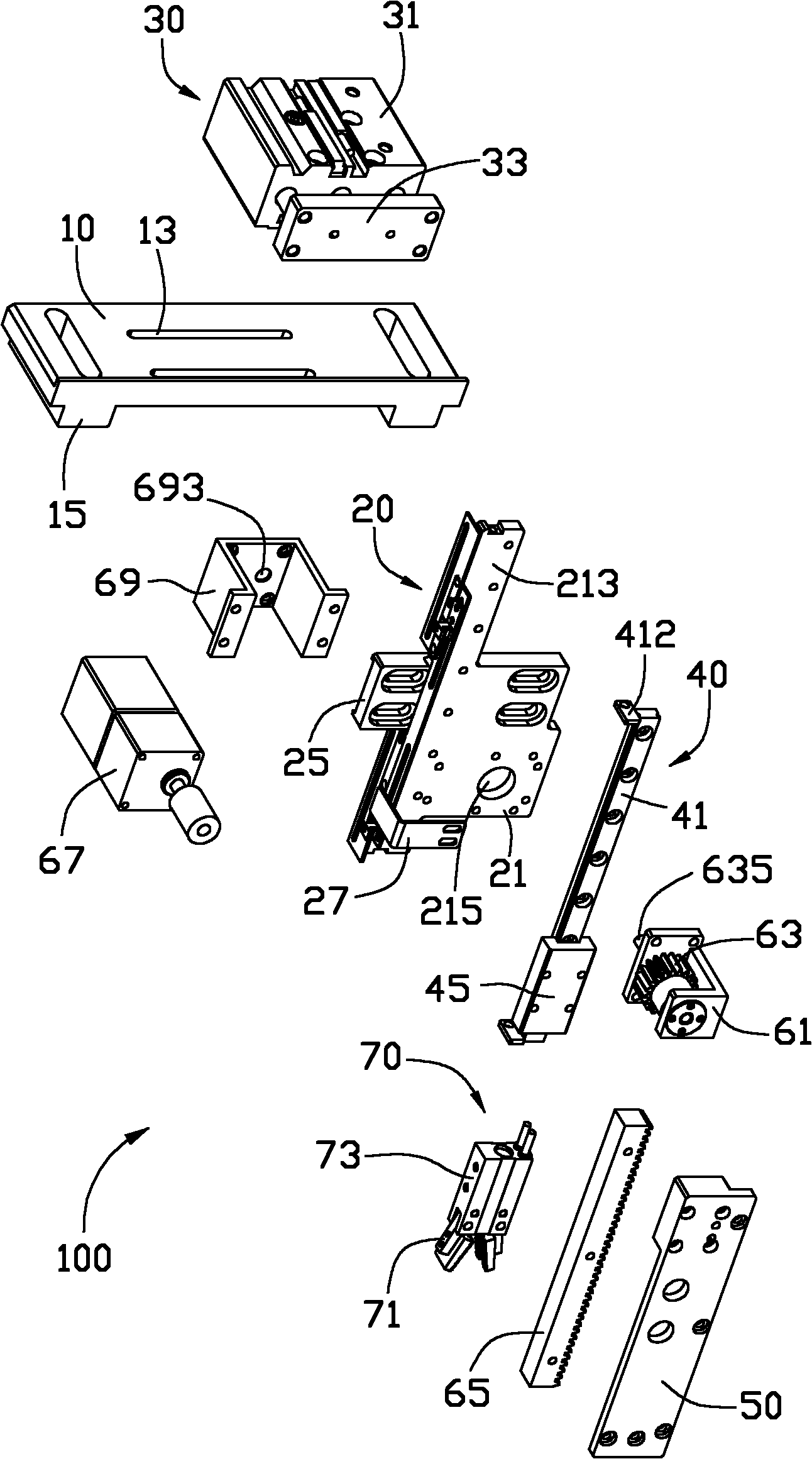

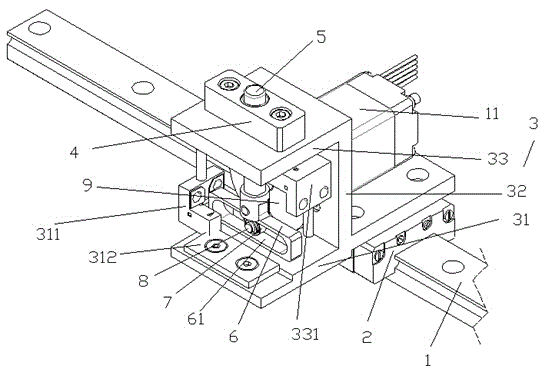

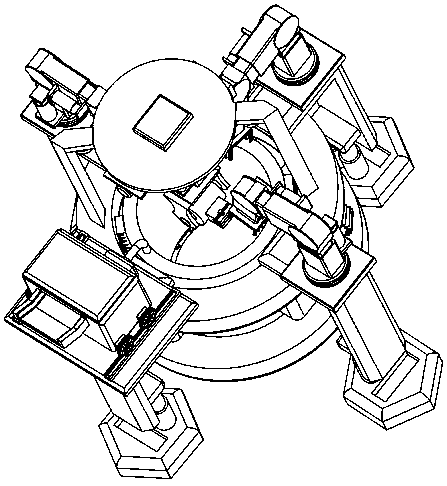

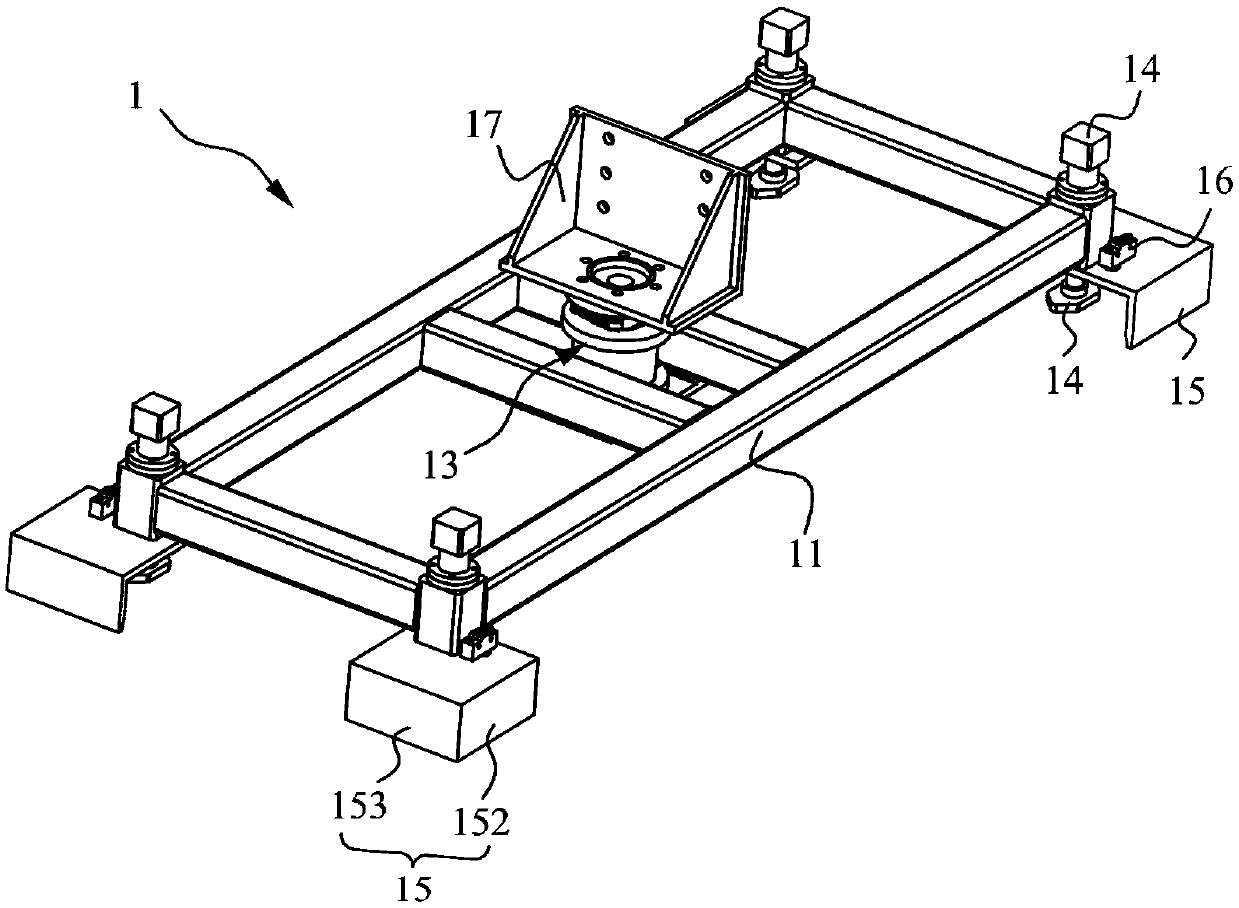

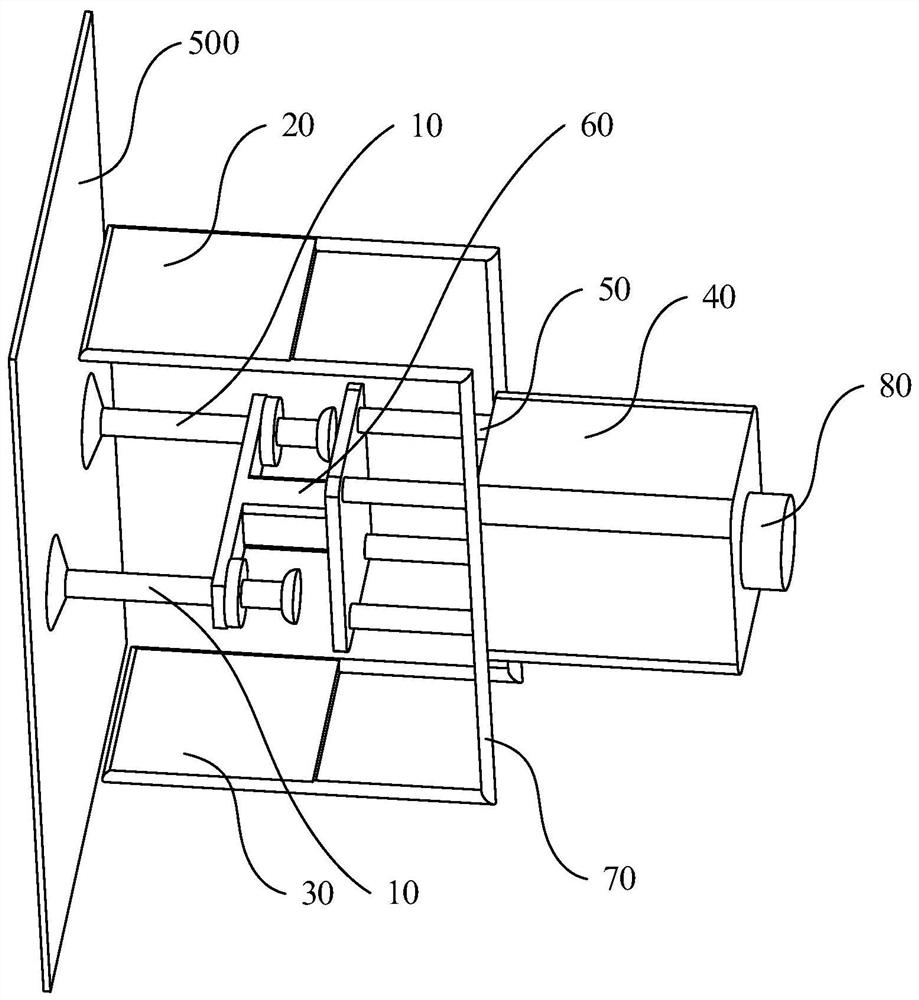

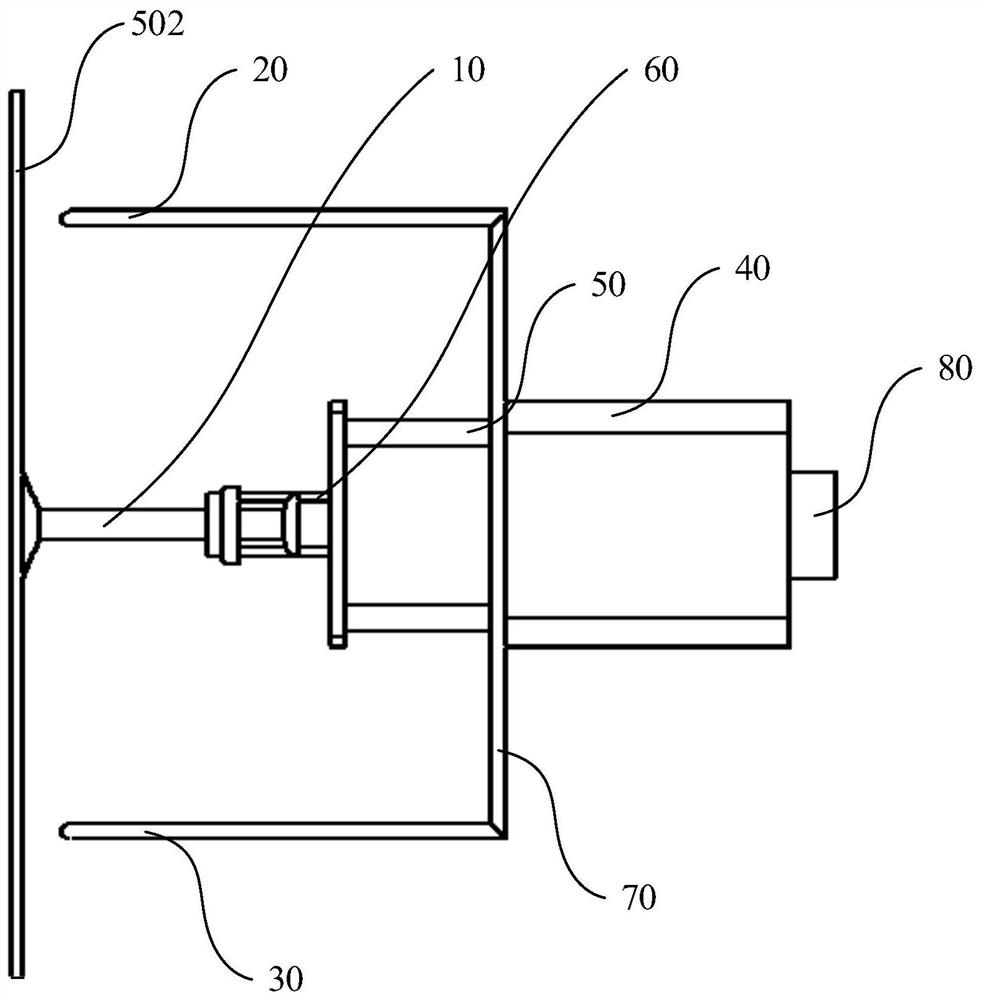

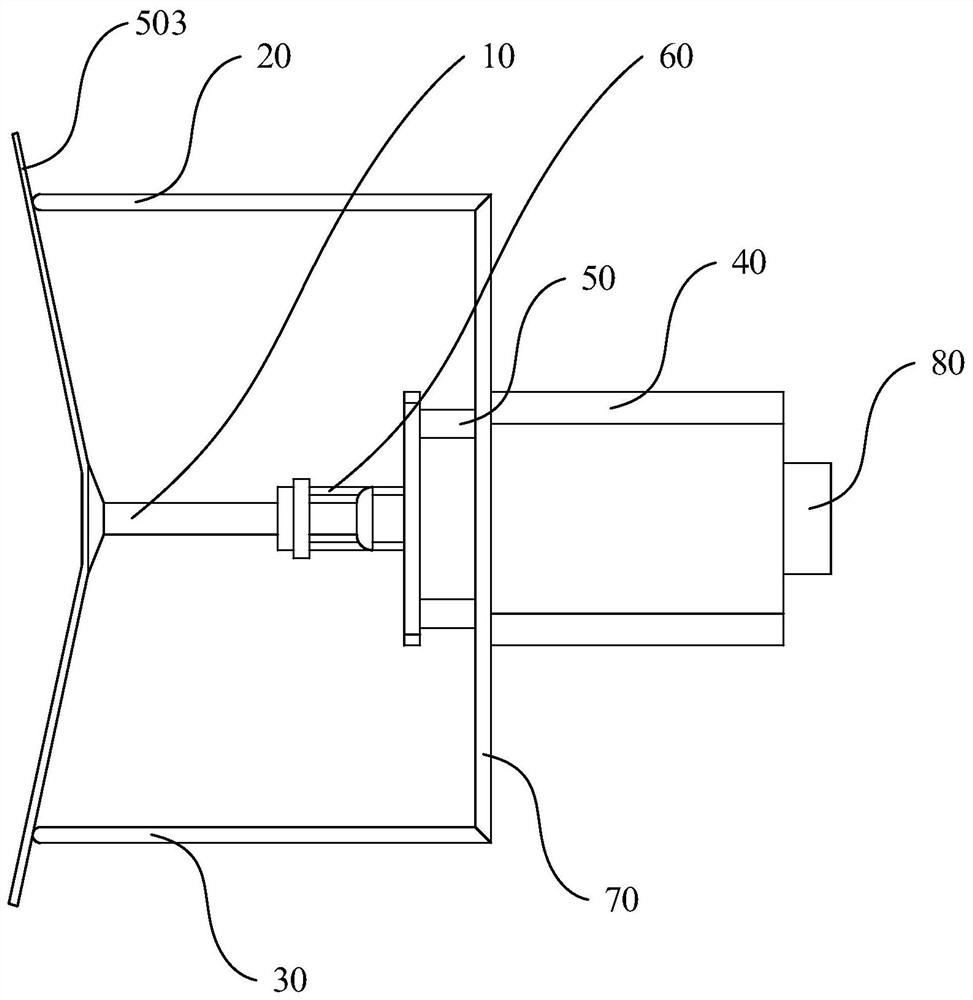

Clamping device for manipulator

InactiveCN102371499ASimple structureReduce volumeProgramme-controlled manipulatorMechanical apparatusElectric machineryEngineering

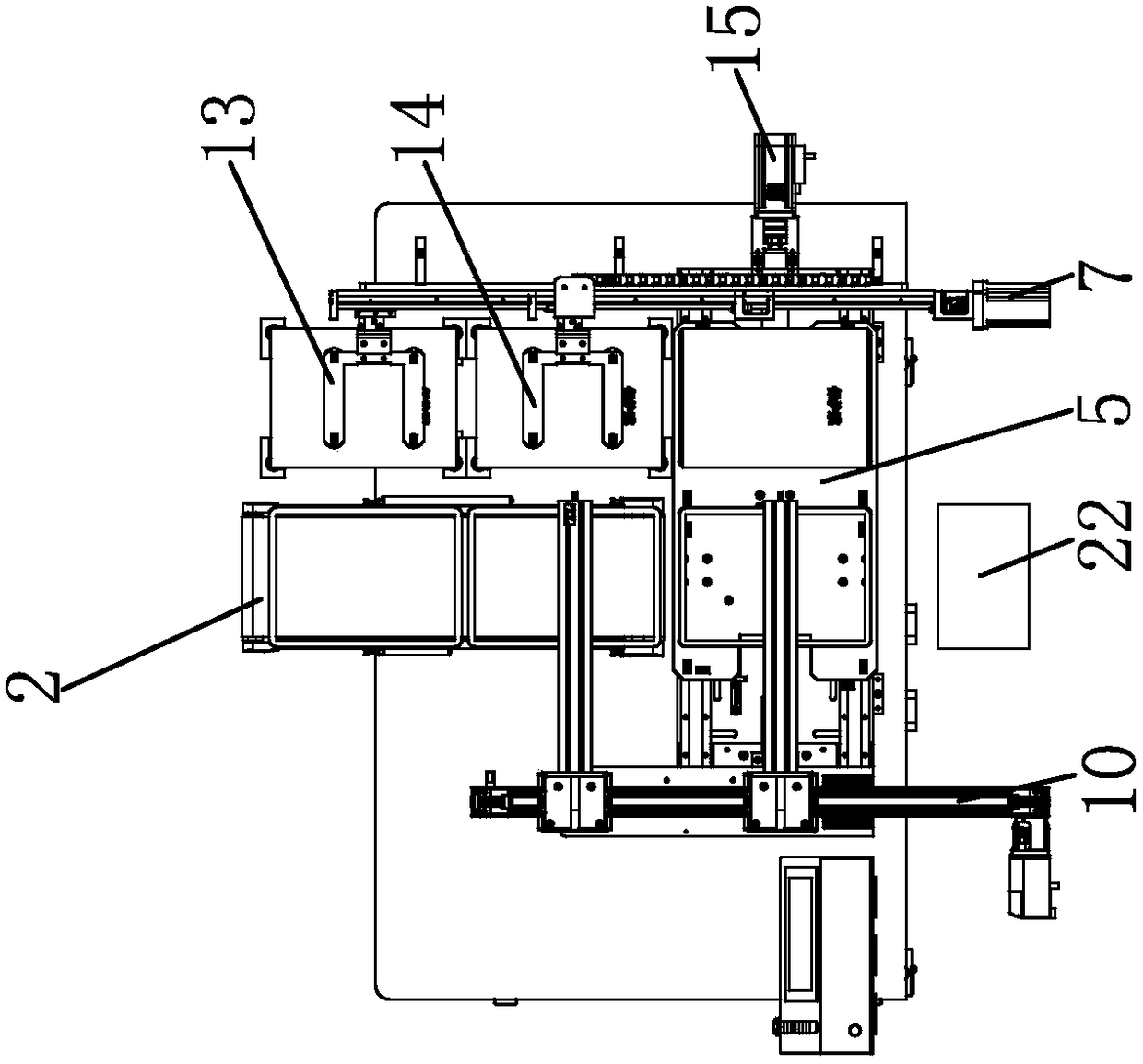

The invention discloses a clamping device for a manipulator, and the clamping device comprises a supporting base, a mounting frame, a horizontal driving device and a clamping jaw device, wherein the mounting frame is arranged on the supporting base and can move relative to the supporting base along a vertical direction; the horizontal driving device comprises a base, a gear, a rack and a driving motor; the base is fixedly arranged on the mounting frame; the gear comprises a gear shaft; the gear is rotatably arranged on the base; the gear shaft extends out of the base and is connected to the driving motor; the rack is engaged with the gear; the gear is driven by the driving motor to cause the rack to horizontally slide relative to the gear; and the clamping jaw device is fixedly mounted on the rack and can slide relative to the mounting frame along with the rack in the horizontal direction.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

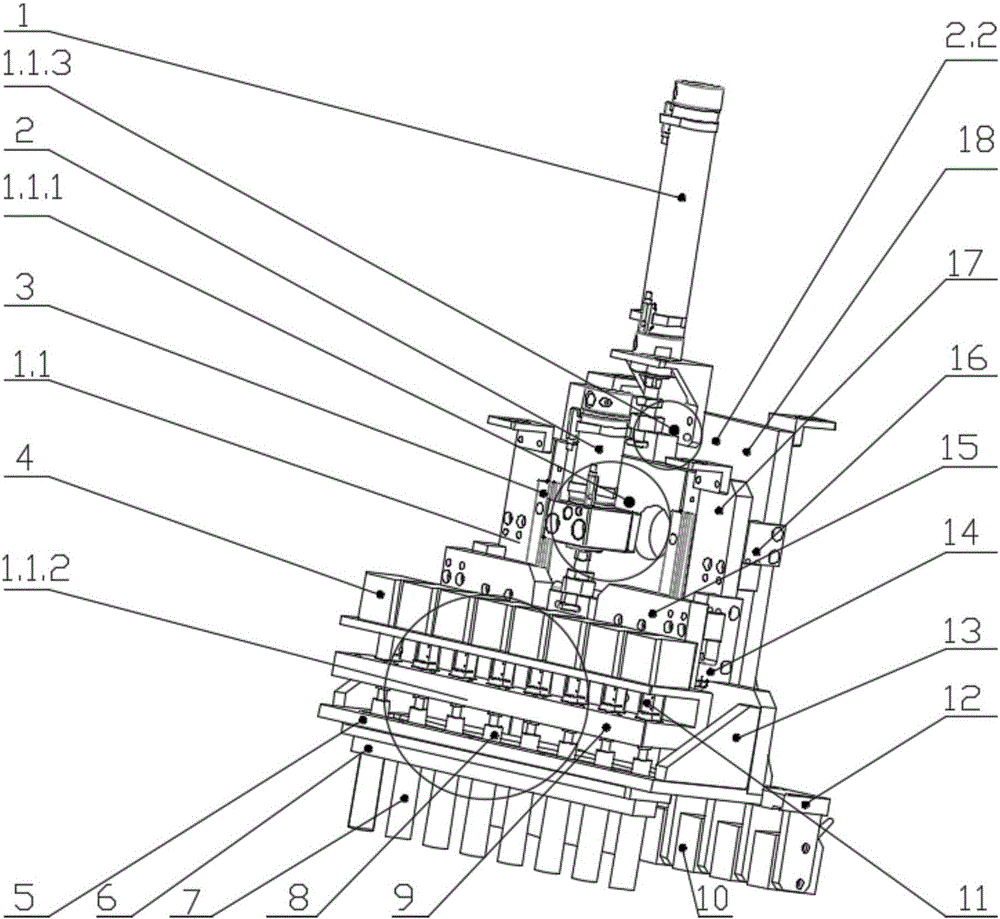

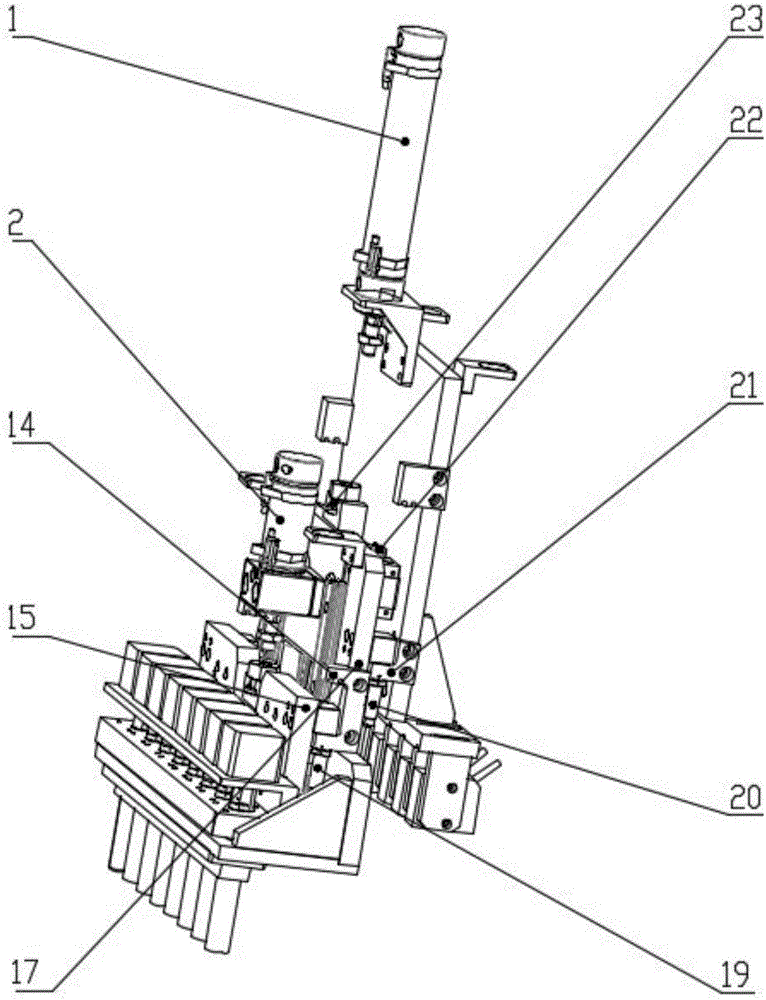

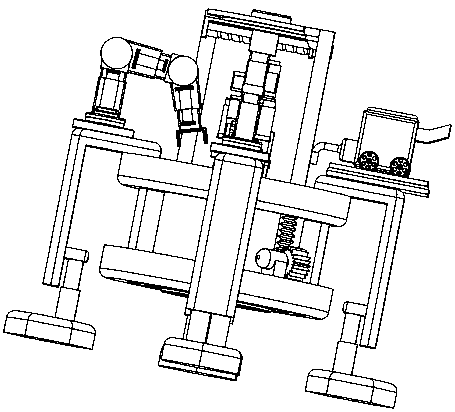

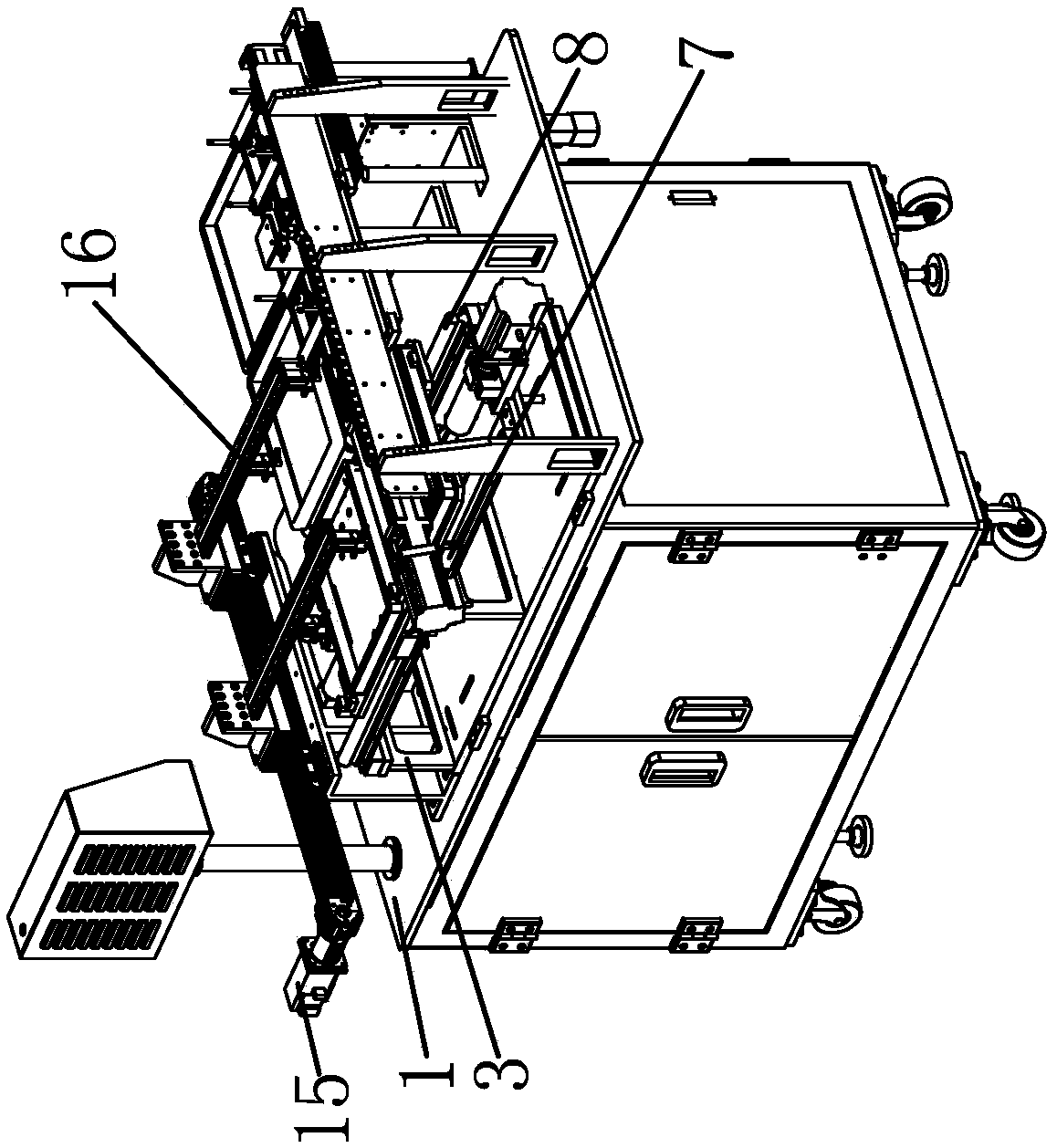

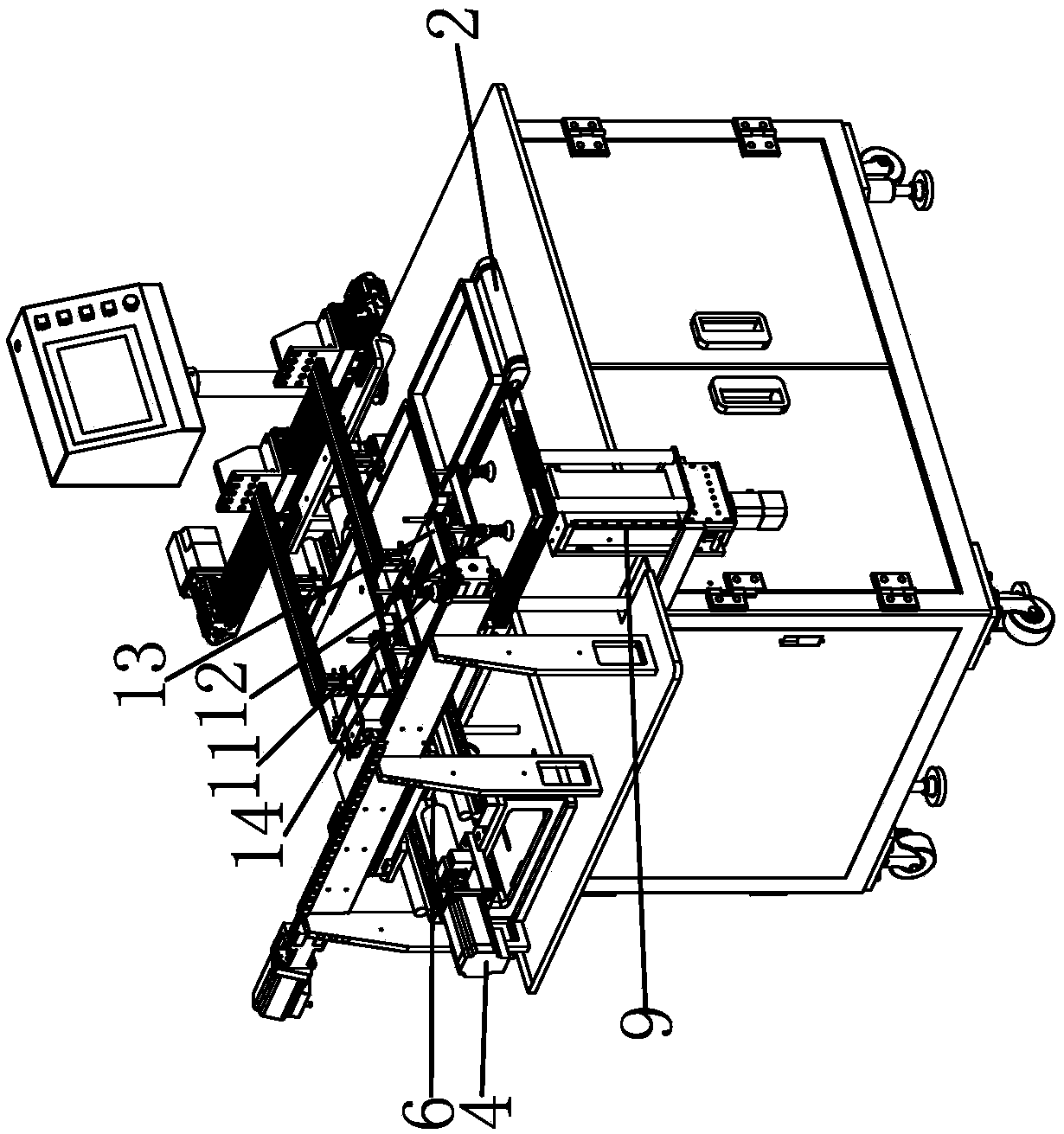

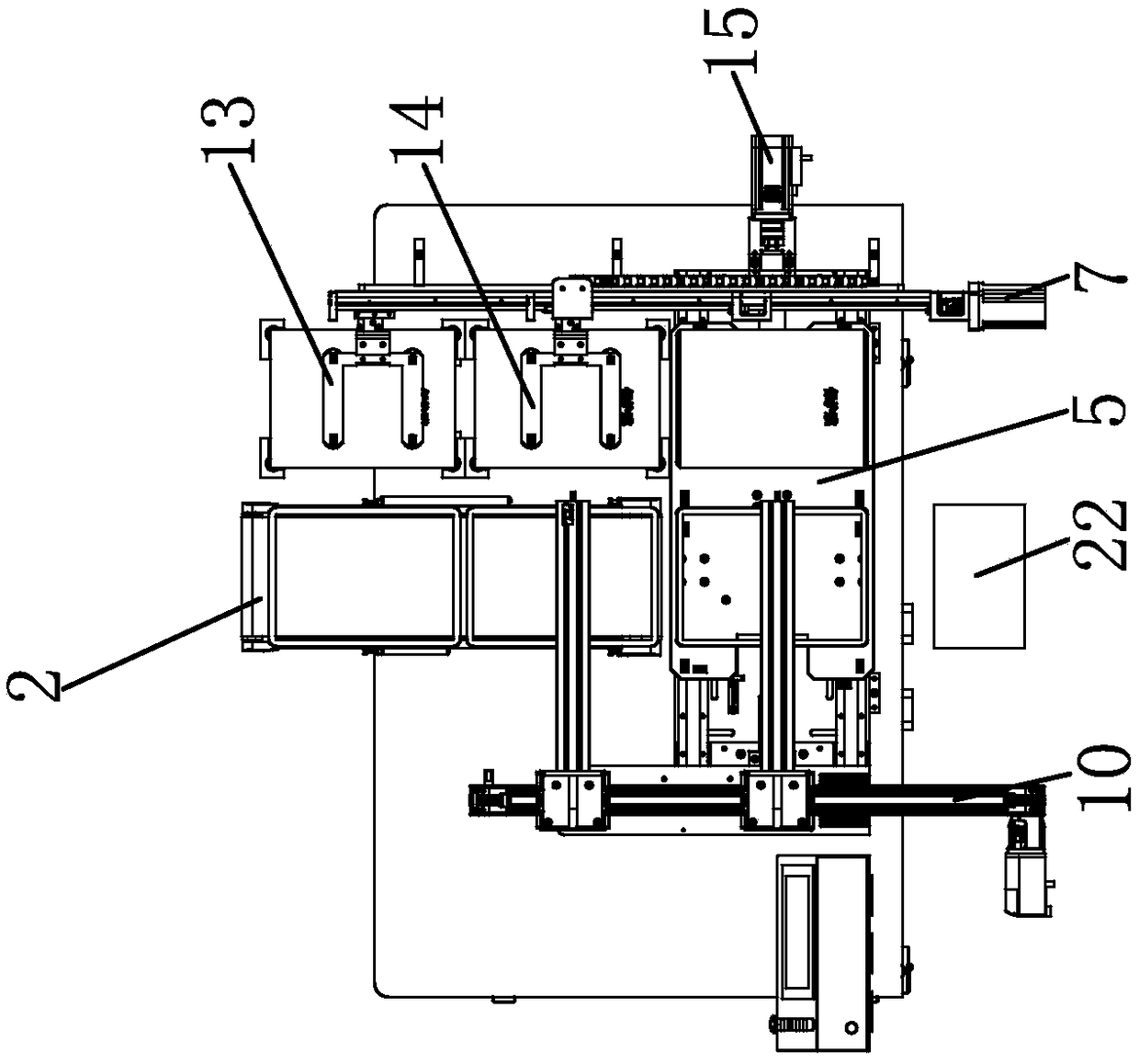

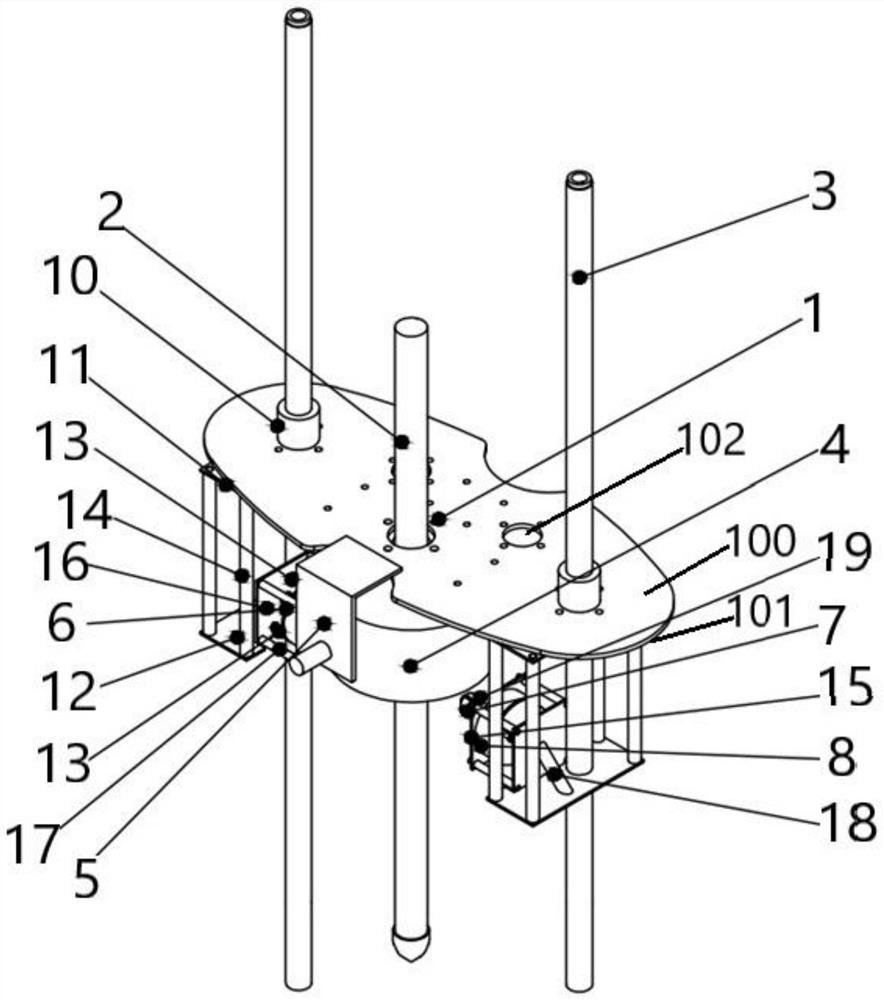

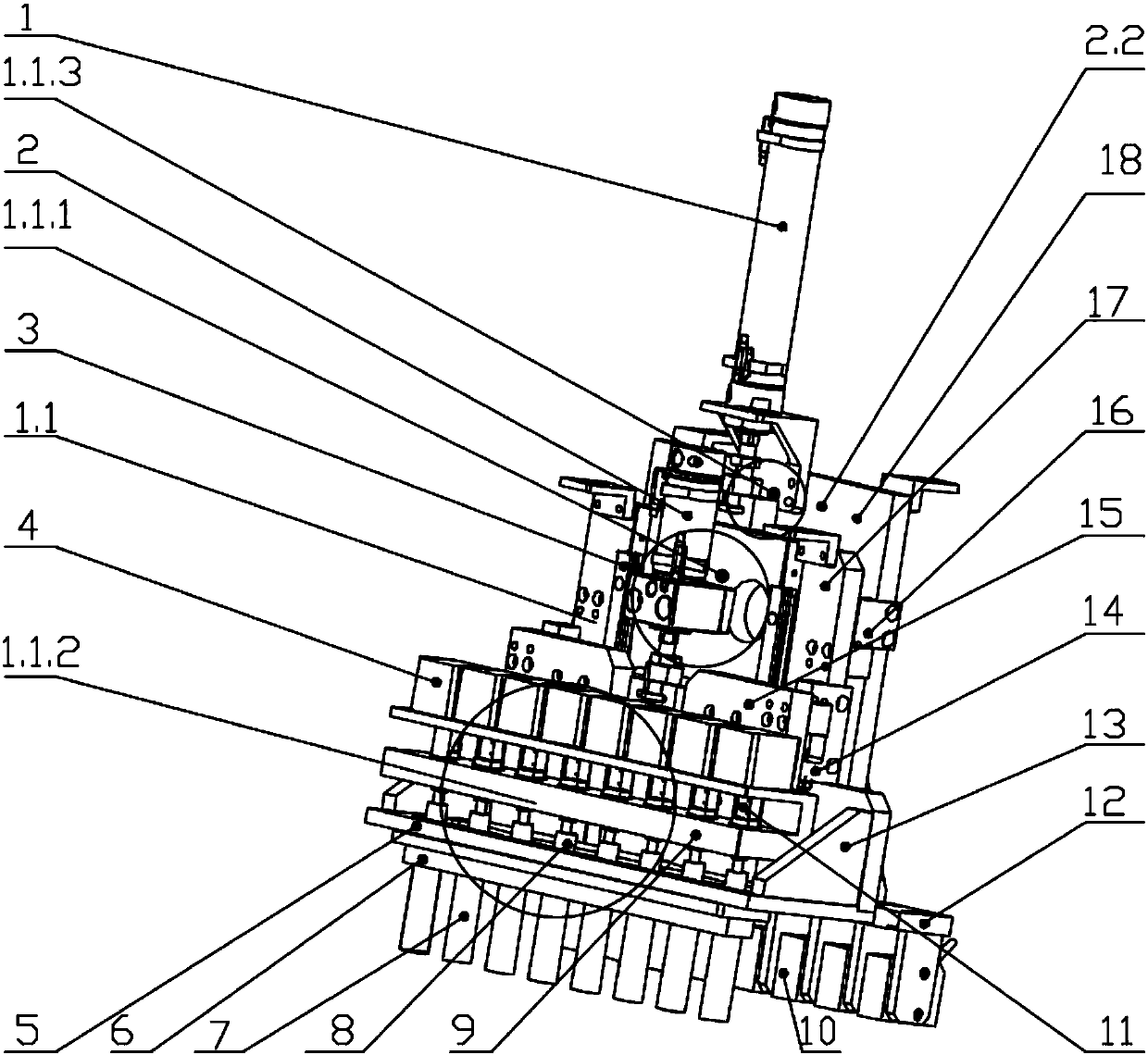

Lithium battery sorting manipulator device

InactiveCN105935663ARealize the function of comparison and error correctionAutomated crawlingSortingEngineeringLithium-ion battery

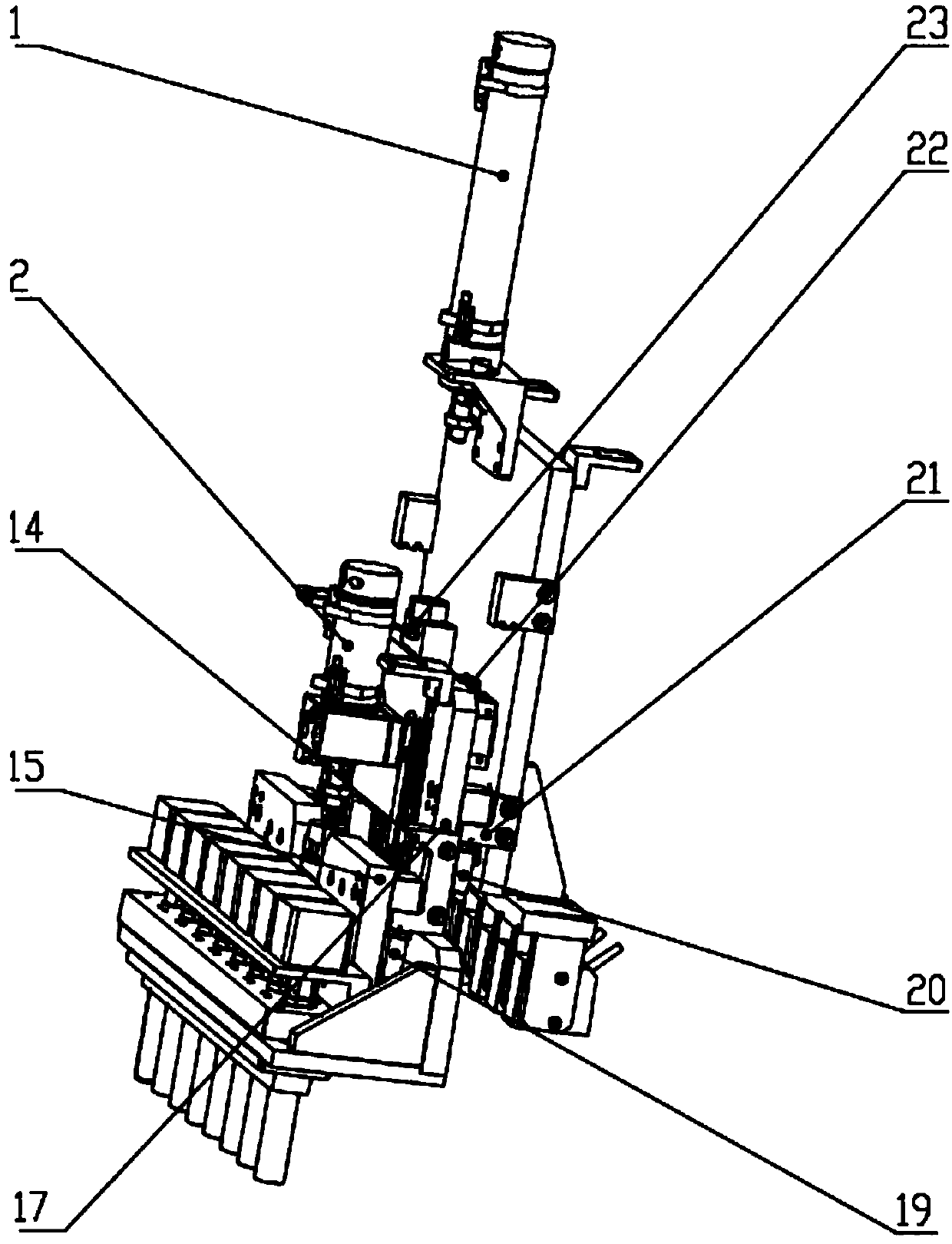

The invention discloses a lithium battery sorting manipulator device. The lithium battery sorting manipulator device comprises a lithium battery grabbing and unloading unit composed of a local up-down translation structure (1.1.1), an integrated displacement structure (1.1.3) and a lithium battery adsorption location structure (1.1.2), wherein the integrated displacement structure (1.1.3) carries out integrated up-down large-range translation at one side of a lithium battery code scanning unit (2.2) by linking with the lithium battery grabbing and unloading unit (1.1); and the local up-down translation structure (1.1.1) locally translates in the lithium battery grabbing and unloading unit (1.1) by linking with the lithium battery adsorption location structure (1.1.2), and carries out automatic grabbing, code scanning and unloading on lithium batteries (7) through the lithium battery adsorption location structure (1.1.2). The lithium battery sorting manipulator device disclosed by the invention is capable of realizing grabbing, code scanning and unloading for the lithium batteries at any positions in a tray, and realizing a comparison and error correction function through comparison between code scanning data and data scanned on the tray.

Owner:CHINA UNIV OF MINING & TECH

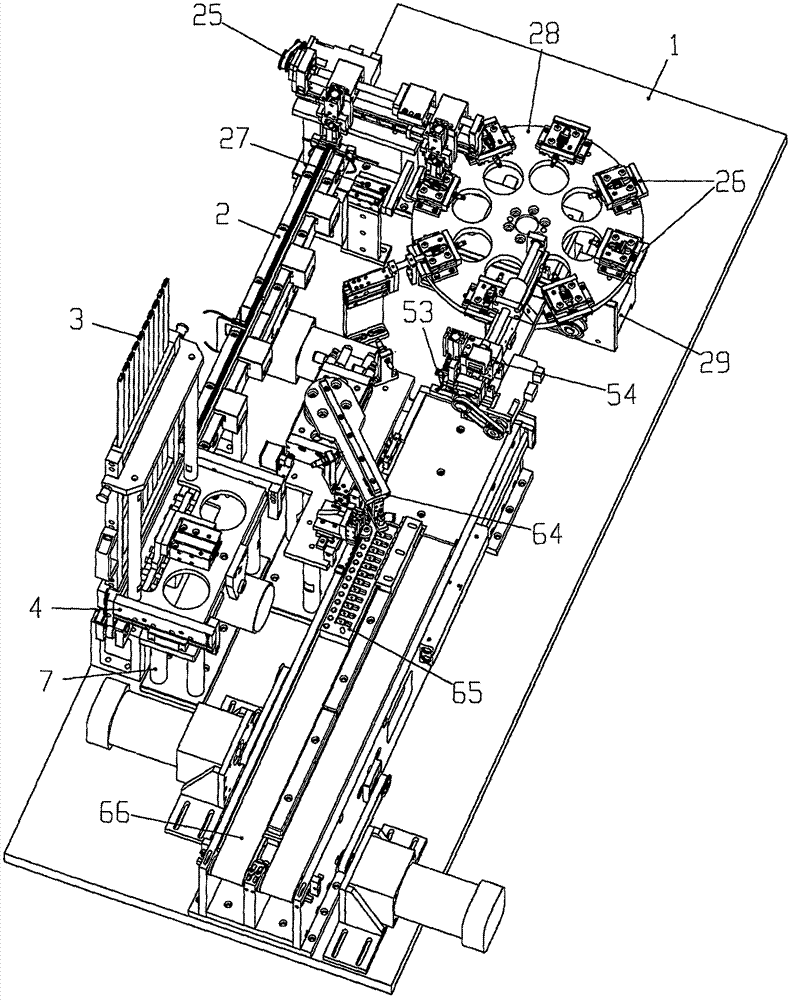

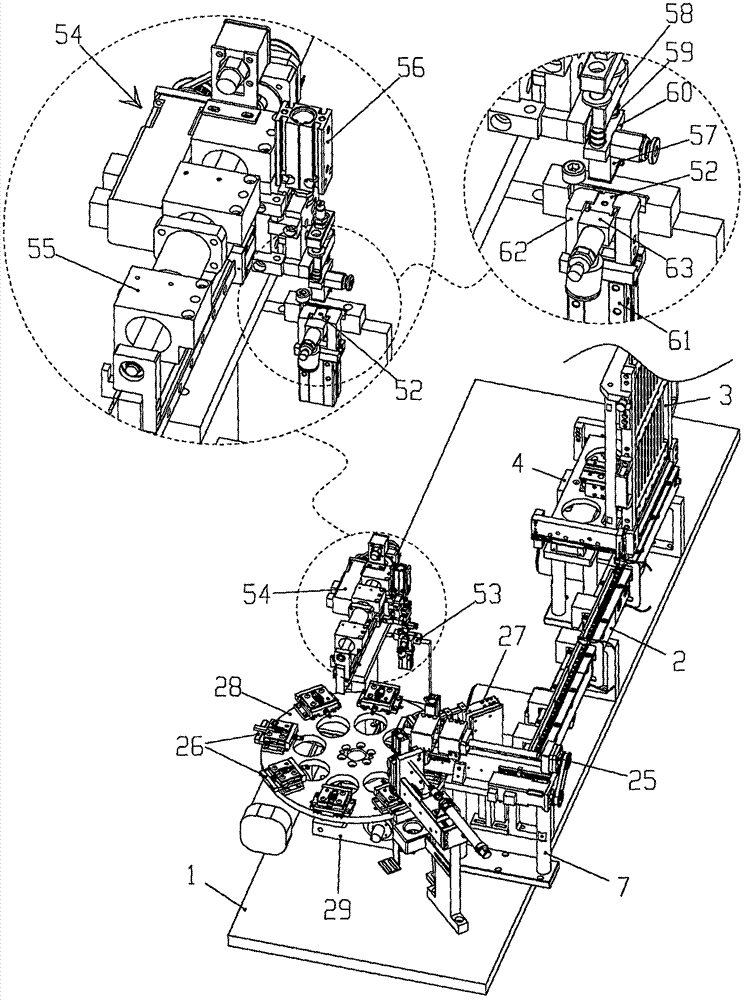

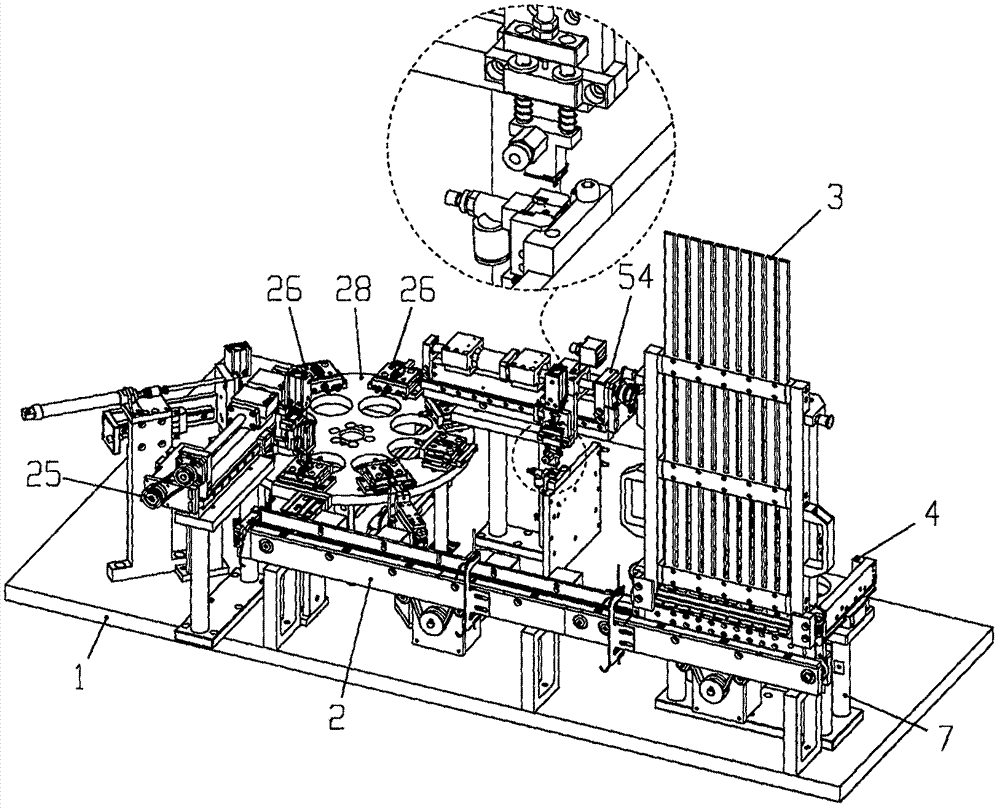

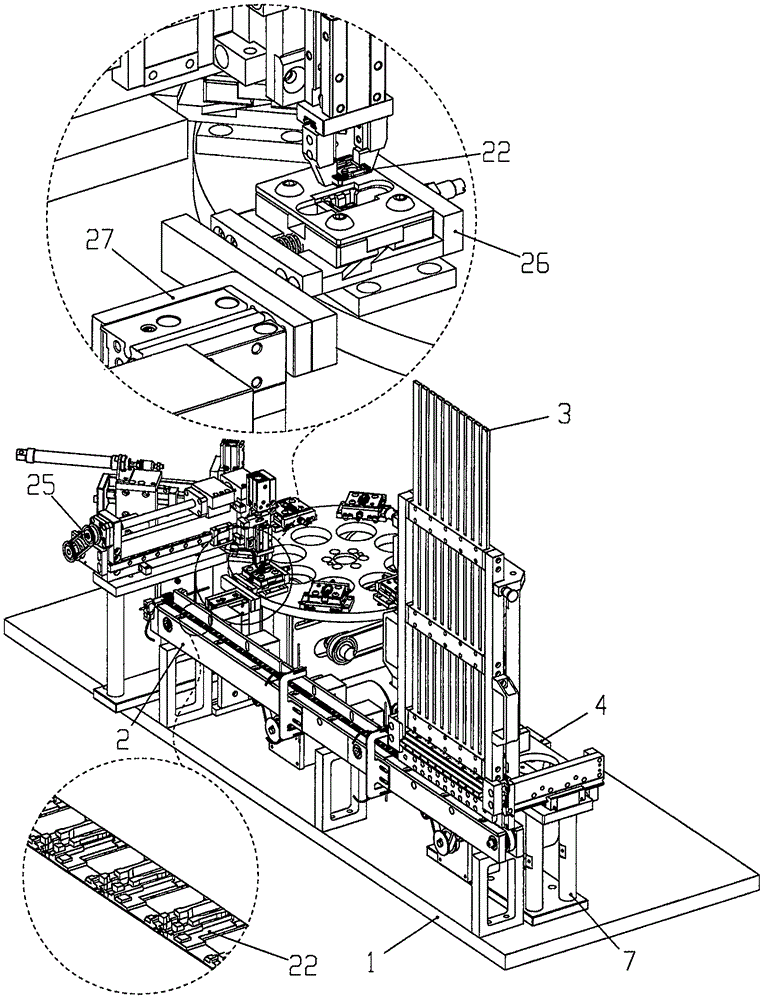

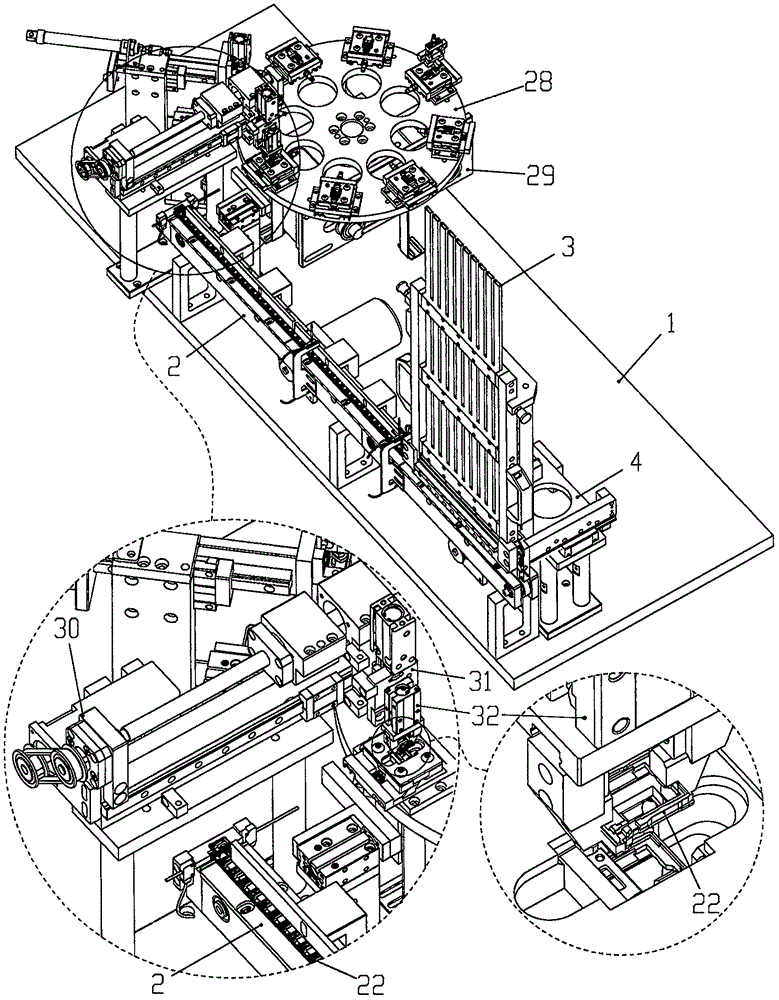

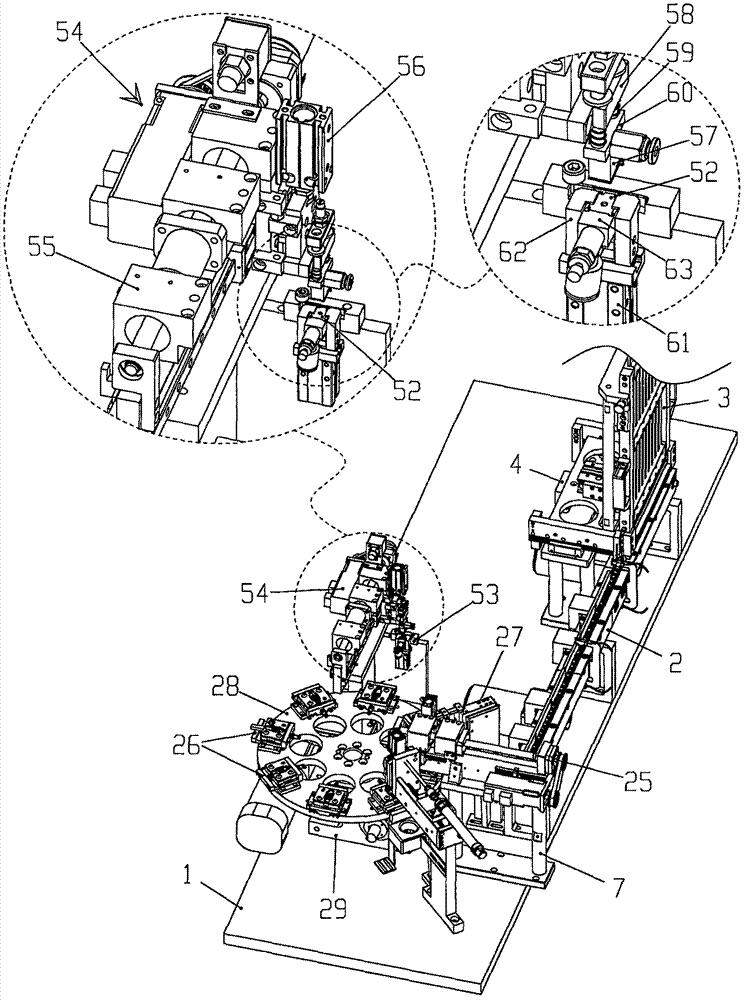

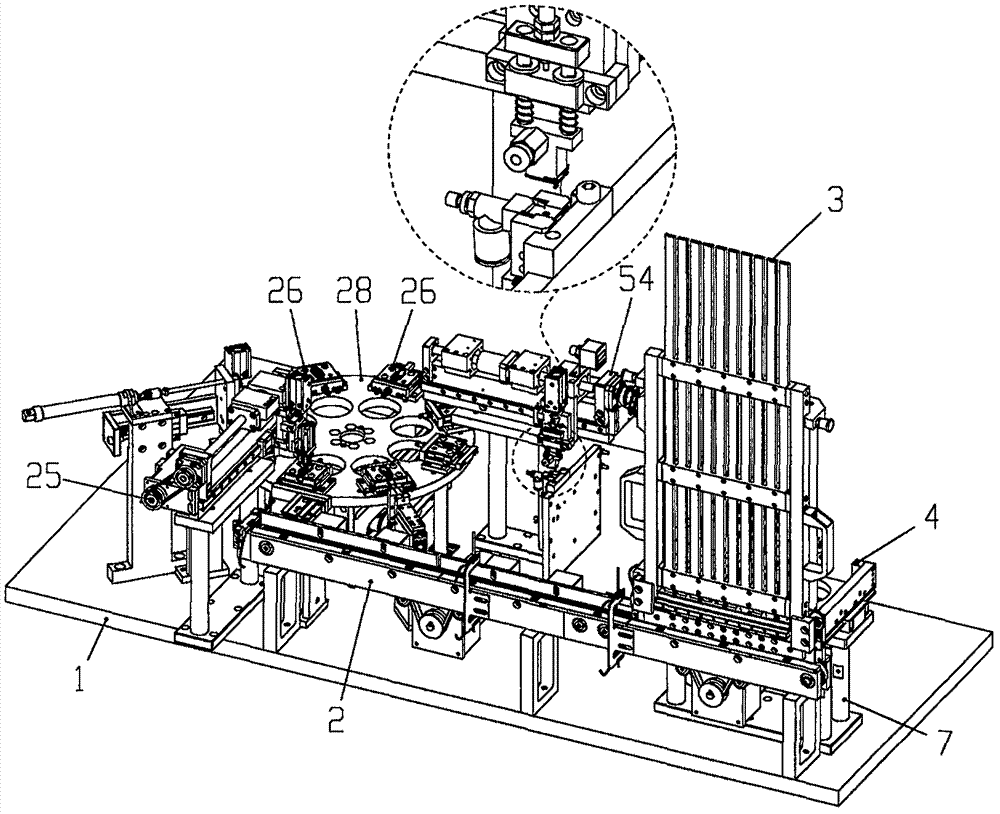

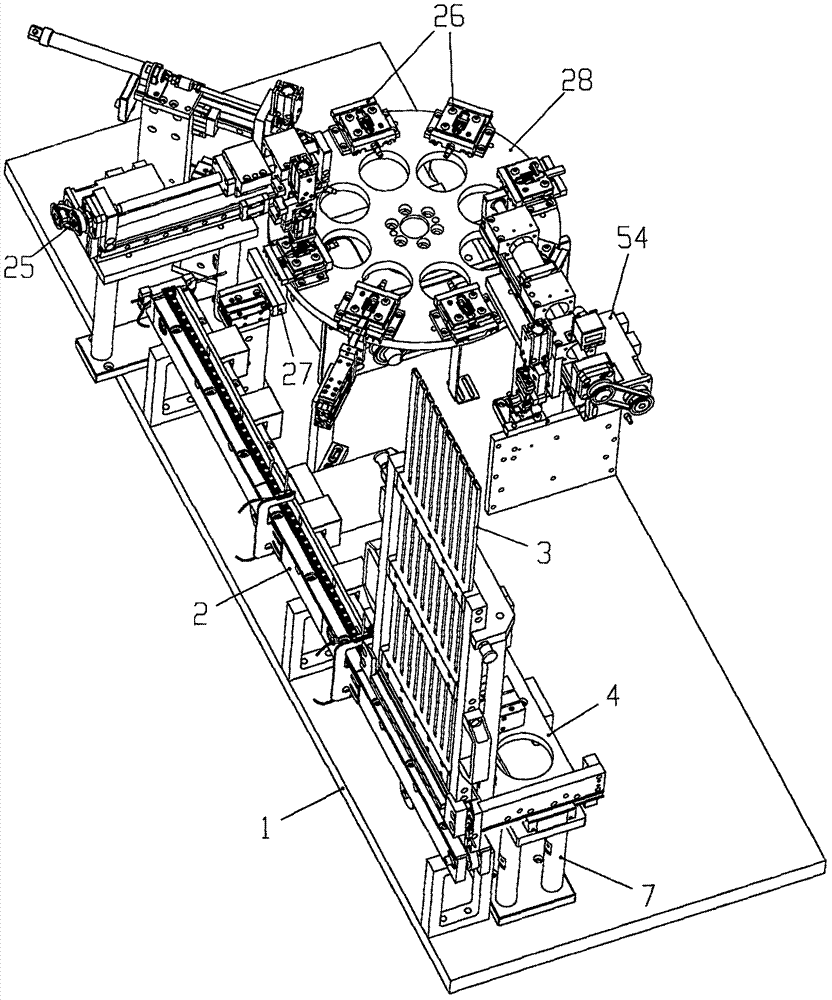

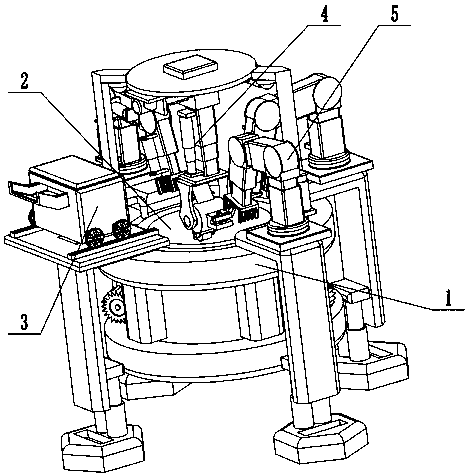

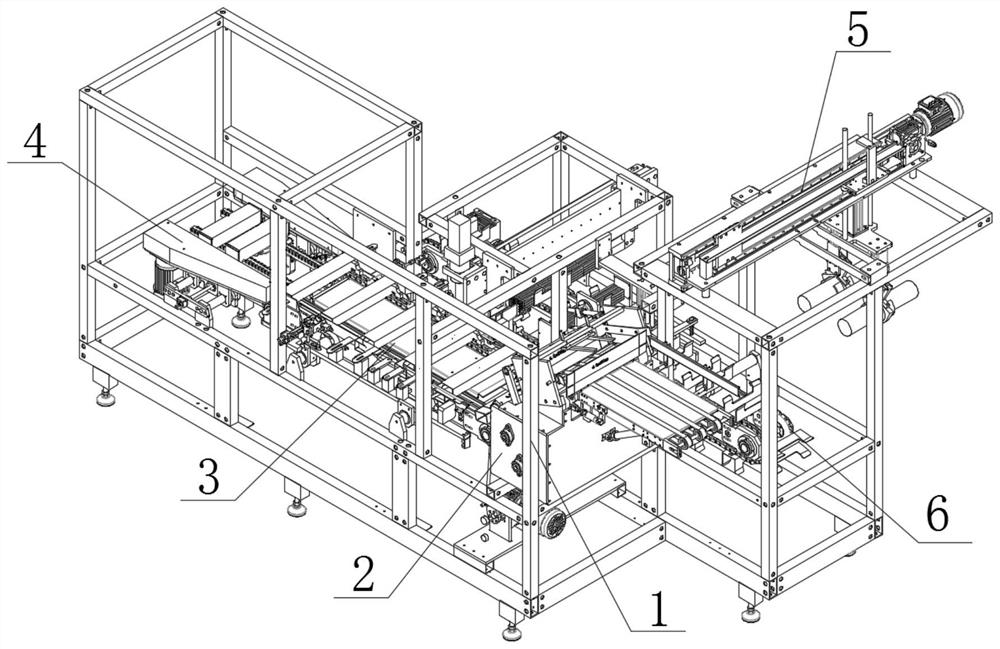

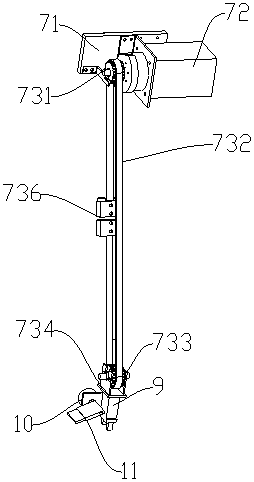

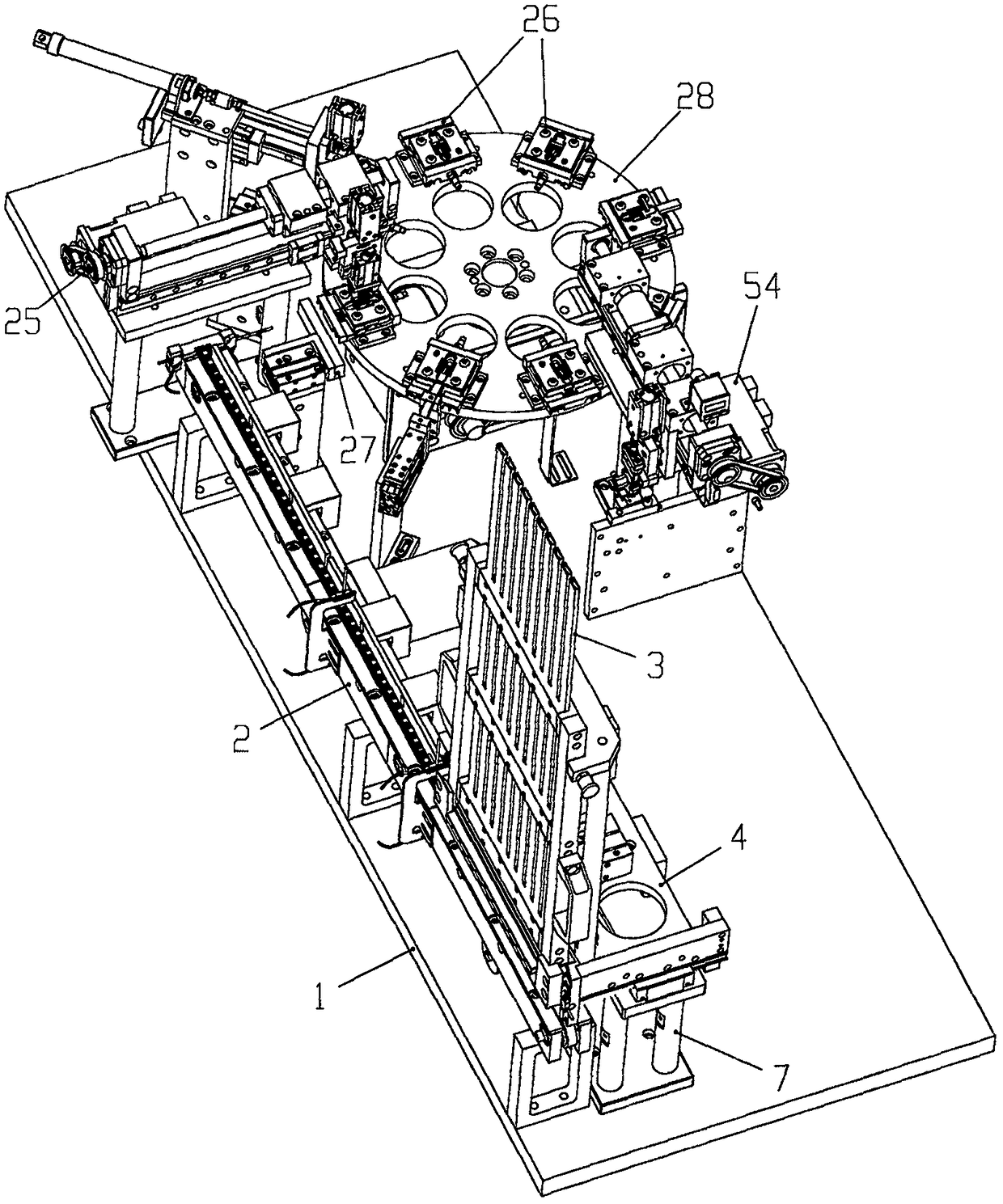

Flexible manufacturing assembly line for assembly of auxiliary insertion piece of robot

ActiveCN107196176ANo collisionNo impactContact member manufacturingContact member assembly/disassemblyAssembly lineElectronic component

The invention relates to automatic assembly equipment of an electronic component, in particular to automatic assembly line equipment for outputting an insertion piece. A flexible manufacturing assembly line for assembly of an auxiliary insertion piece of a robot comprises an automatic clamping mechanism, a large rotation disc, a carrying tool, a carrying tool conveying belt, a positioning mechanism, a swinging arm manipulator, a contact sheet correction mechanism and a contact sheet robot, wherein the automatic clamping mechanism is used for fixing the insertion piece, the large rotation disc is used for driving the automatic clamping mechanism to do circumferential rotation, the carrying tool is used for carrying a contact sheet, the carrying tool conveying belt is used for transmitting the carrying tool, the positioning mechanism is used for precisely positioning the carrying tool, the swinging arm manipulator is used for grabbing the contact sheet from the carrying tool, the contact sheet correction mechanism is used for achieving position correction of the contact sheet, and the contact sheet robot is used for picking up the contact sheet from the contact sheet correction mechanism and assembling the contact sheet onto the automatic clamping mechanism. In the flexible manufacturing assembly line for assembly of the auxiliary insertion piece of the robot, stepped feeding and accurate positioning of the contact sheet are achieved by the carrying tool conveying tool, and automatic correction and assembly of the contact sheet are achieved by the contact sheet robot.

Owner:广州博义知识产权运营有限公司

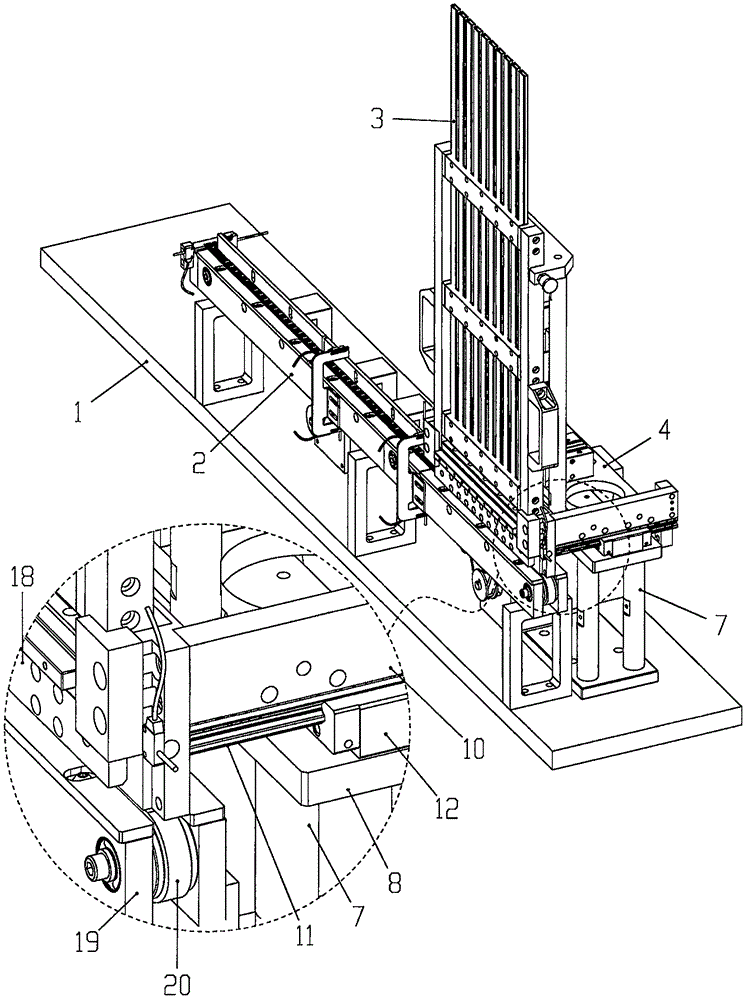

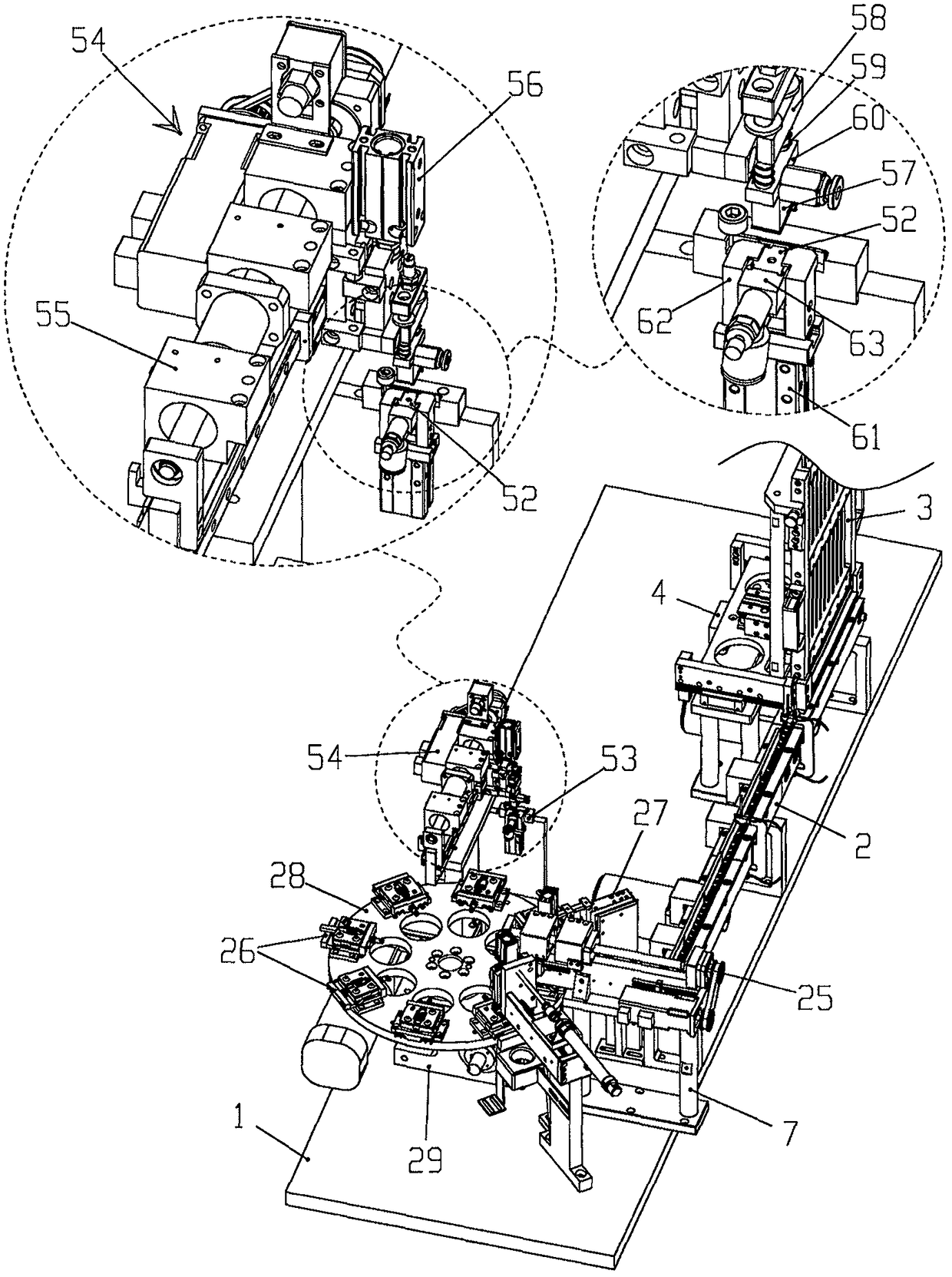

Intelligent conveying and assembling complete equipment for connectors

ActiveCN107175486AImprove surface qualityAutomated crawlingMetal working apparatusProduction lineEngineering

The invention relates to automatic assembling equipment of electronic components, in particular to automatic assembling production line equipment used for outputting connectors. Intelligent conveying and assembling complete equipment for the connectors comprises a workbench, a storage mechanism which is used for storing the connectors, a conveyor belt mechanism which is used for conveying the connectors, a feeding mechanism which is used for putting the connectors to the conveyor belt mechanism from the storage mechanism, a feeding robot which is used for grabbing the connectors from the conveyor belt mechanism to an automatic clamping mechanism and a discharging mechanism which is used for discharging the connectors from the automatic clamping mechanism. By means of the intelligent conveying and assembling complete equipment for the connectors, ordered output of the connectors is achieved, after the connectors are adjusted to preset angles, the connectors are put on a conveyor belt, smooth and controllability of the connector moving process are guaranteed through the storage mechanism and the feeding mechanism, picking of the connectors is completed through the feeding robot, and centering, positioning and fixing of the connectors are achieved through the automatic clamping mechanism.

Owner:陕西力奥远诚信息工程有限公司

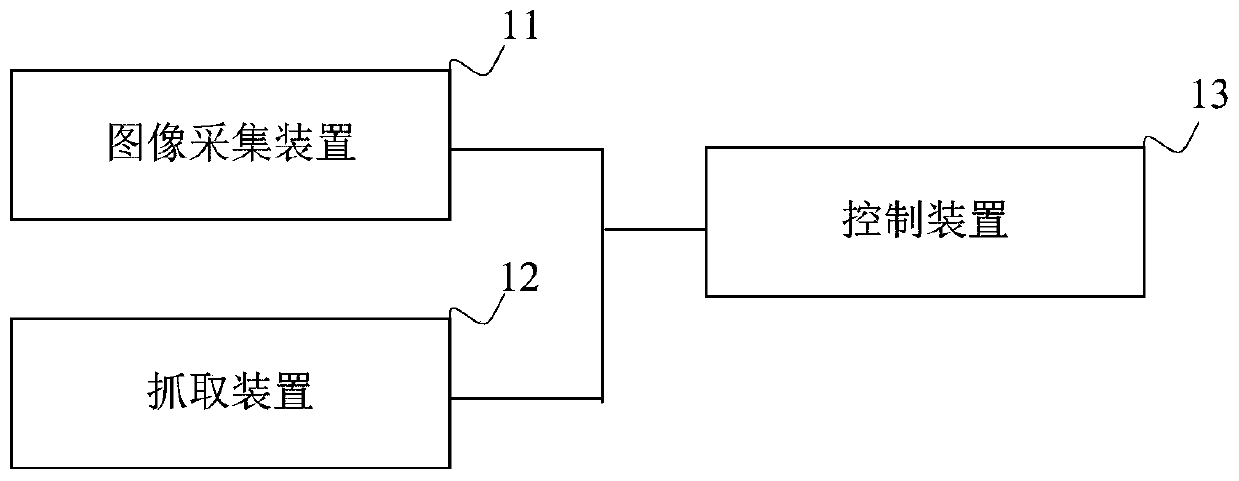

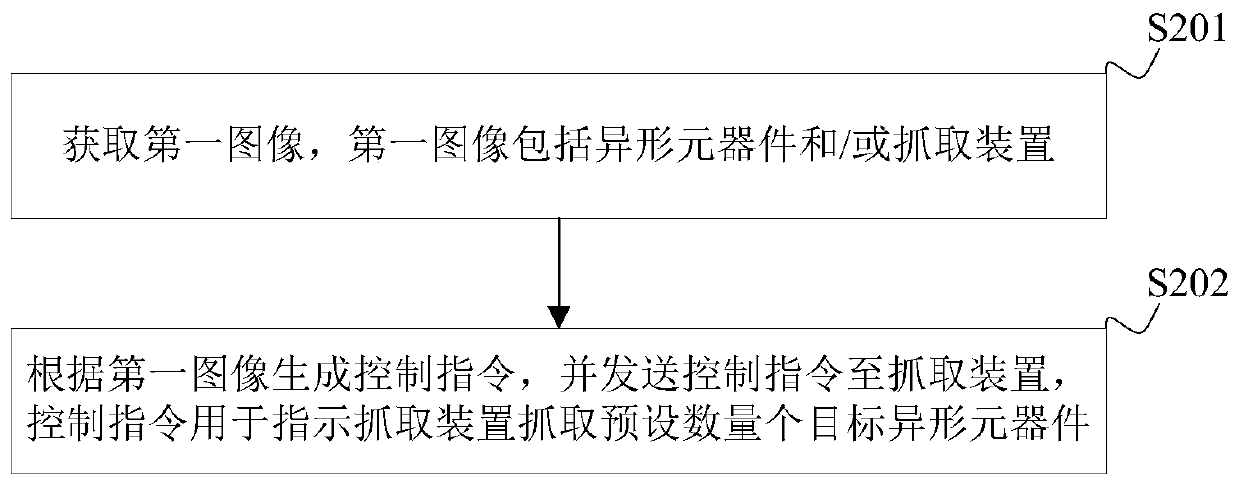

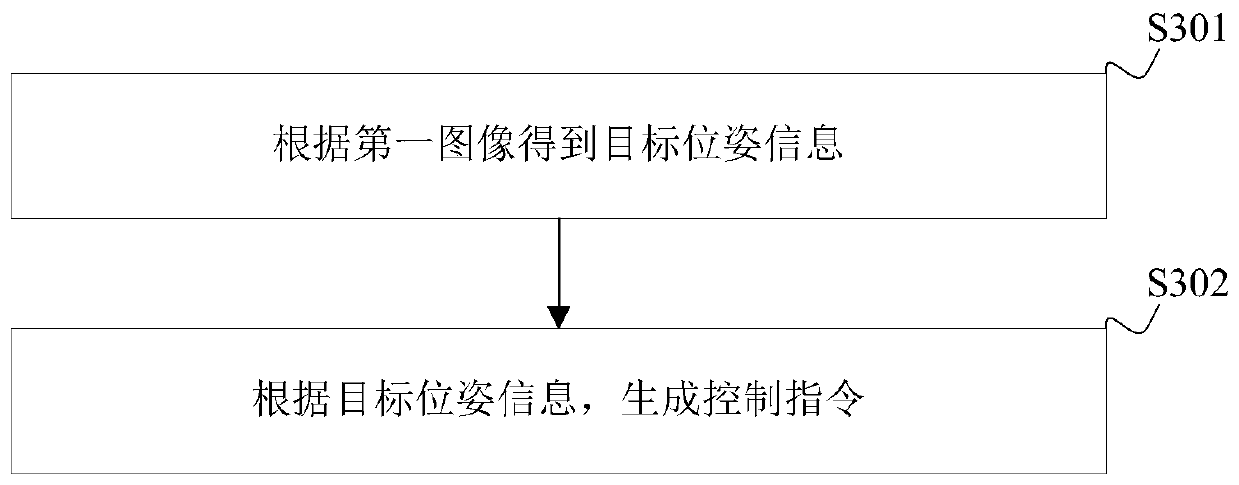

Method, device and system for grabbing special-shaped component, control device and storage medium

ActiveCN110712202AAutomated crawlingReduce labor costsProgramme-controlled manipulatorConveyor partsRobot handProcess engineering

The embodiment of the invention belongs to the technical field of automation, and discloses a method, device and system for grabbing a special-shaped component, a control device and a computer readable storage medium. The method includes the steps of obtaining a first image, wherein the first image comprises the special-shaped component and / or the grabbing device; generating a control instructionaccording to the first image and sending the control instruction to the grabbing device, wherein the control instruction is used for indicating the grabbing device to grab the target special-shaped component. By obtaining the first image with the special-shaped component and / or the grabbing device and controlling a mechanical hand according to the first image to grab the target special-shaped component, the automatic grabbing of the special-shaped component is realized, traditional manual grabbing is replaced, lots of labor cost is saved, production cost is reduced, and production efficiency is improved.

Owner:ROBOTICS ROBOTICS SHENZHEN LTD +1

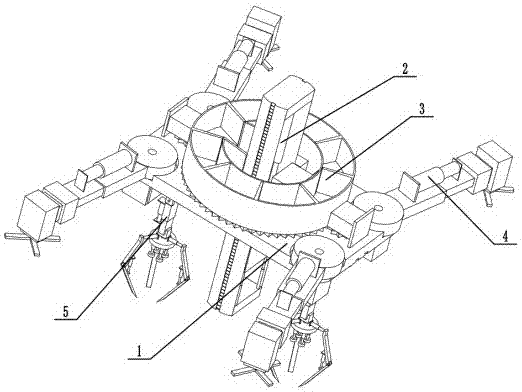

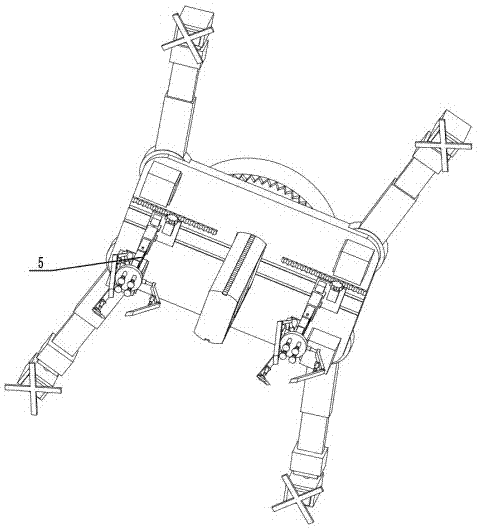

Large-scale bulb fritillaria catching robot

InactiveCN107877525AAutomated crawlingImprove crawling efficiencyPisciculture and aquariaMechanical energy handlingHydraulic cylinderEngineering

The invention discloses a large-scale pearl oyster catching robot. The catching robot comprises a base, a pearl oyster loading part, a pearl oyster storing part, four turbine parts and two pearl oyster grabbing parts, and is characterized in that the pearl oyster loading part is sliadably installed in an oval groove of the base, and two second racks are meshed with two second gears respectively. According to the large-scale pearl oyster catching robot, third gears are driven by fourth stepping motors of the two pearl oyster grabbing parts to drive the pearl oyster grabbing parts to move, foursuction discs are driven by four ninth hydraulic cylinders to suck pearl oysters, and next, three seventh hydraulic cylinders and three eighth hydraulic cylinders are coordinated to enable three second connecting rods to clamp the pearl oysters, and next, the pearl oysters are put into a pearl oyster storage box through the pearl oyster grabbing parts; and therefore automatic pearl oyster grabbingis realized, grabbing efficiency is improved, and grabbing operation is facilitated.

Owner:韩朝锋

Connector assembly automatic production line having cooperative dual robots

ActiveCN107104347AAvoid scratchesImprove surface qualityContact member assembly/disassemblyProduction lineEngineering

The invention relates to an automatic assembly device of an electronic component and particularly relates to an automatic assembly line device for outputting a connector. A connector assembly automatic production line having cooperative dual robots comprises a workbench, a storage mechanism, a conveyor belt mechanism, a feed mechanism, a contact piece correction mechanism and a contact piece robot, wherein the storage mechanism is used for storing the connector; the conveyor belt mechanism is used for conveying the connector; the feed mechanism is used for placing the connector from the storage mechanism to the conveyor belt mechanism; the contact piece correction mechanism implements position correction on a contact piece; and the contact piece robot is used for picking up the contact piece from the contact piece correction mechanism and assembling the contact piece to an automatic clamping mechanism. According to the connector assembly automatic production line having the cooperative dual robots, the storage mechanism and the feed mechanism are utilized to guarantee a moving process of the connector to be smooth and controllable, a feed robot is utilized to finish the pickup of the connector, and the automatic clamping mechanism is utilized to implement centered positioning and fixing on the connector, and the contact piece robot is utilized to implement automatic correction and assembly on the contact piece.

Owner:苏州祥瑞凯机电设备有限公司

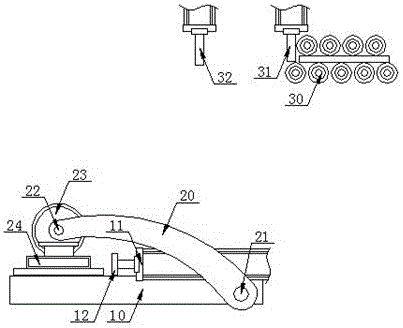

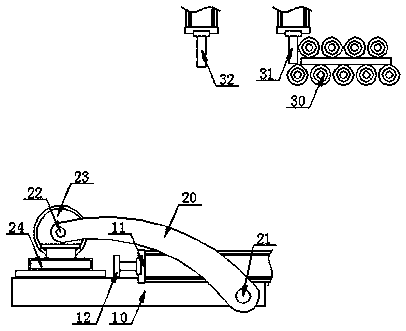

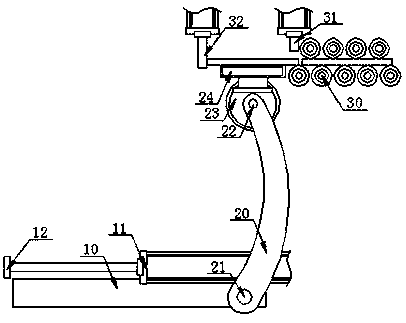

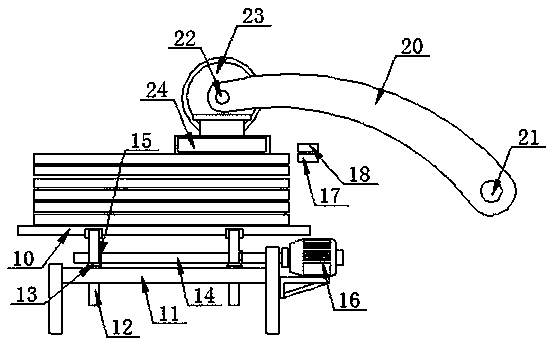

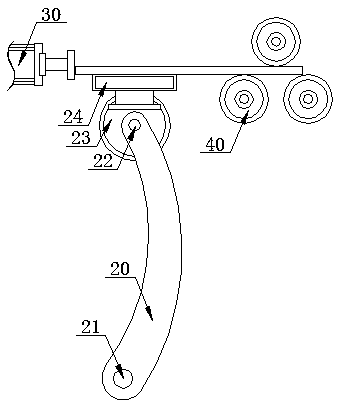

Automatic feeding and punching system for automobile supporting arm assembly

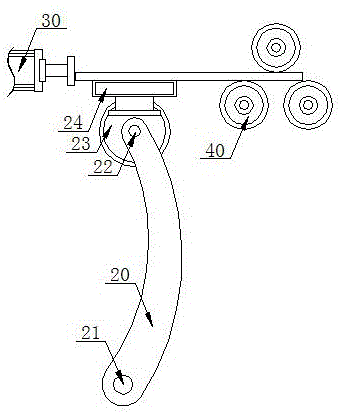

InactiveCN106734690AAutomated crawlingPrecise control over placementMetal-working feeding devicesPositioning devicesPunchingEngineering

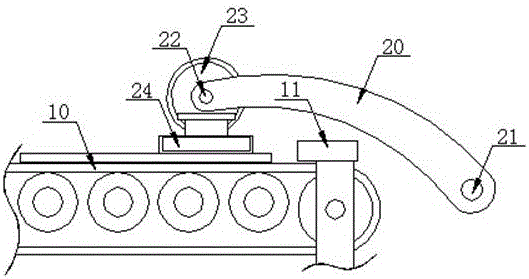

The invention discloses an automatic feeding and punching system for an automobile supporting arm assembly. The automatic feeding and punching system for the automobile supporting arm assembly comprises a plate feeding platform, a plate feeding pushing air cylinder and a rotary piece taking swinging arm; one end of the rotary piece taking swinging arm is connected with a rotating driving rotating shaft of which the axis position is fixed; an electromagnetic piece taking sucking disc is arranged at the other end of the rotary piece taking swinging arm; the plate feeding platform is arranged horizontally, and one end of the plate feeding platform faces punching moulding equipment; the rotating driving rotating shaft and the plate feeding pushing air cylinder are arranged at the other end of the plate feeding platform; a piston rod of the plate feeding pushing air cylinder is arranged horizontally, and faces the punching moulding equipment; a plate feeding pushing baffle is arranged at the tail end of the piston rod of the plate feeding pushing air cylinder. According to the automatic feeding and punching system for the automobile supporting arm assembly provided by the invention, the actions of automatically grabbing and feeding of a plate punching operation of the automobile supporting arm assembly can be realized.

Owner:长春市宏宇汽车零部件有限公司

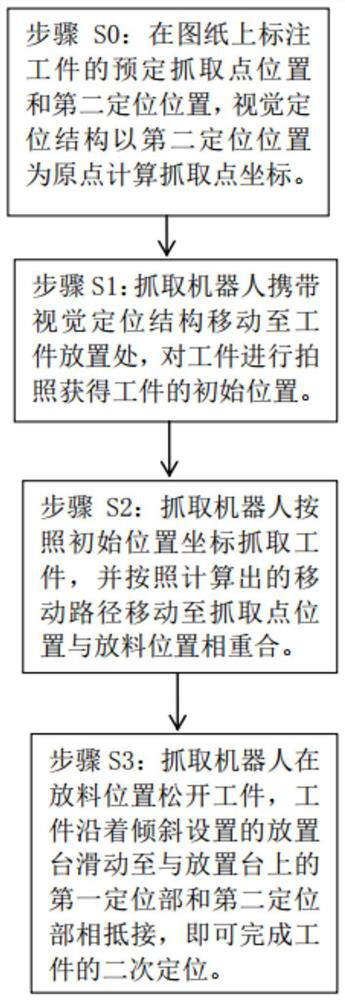

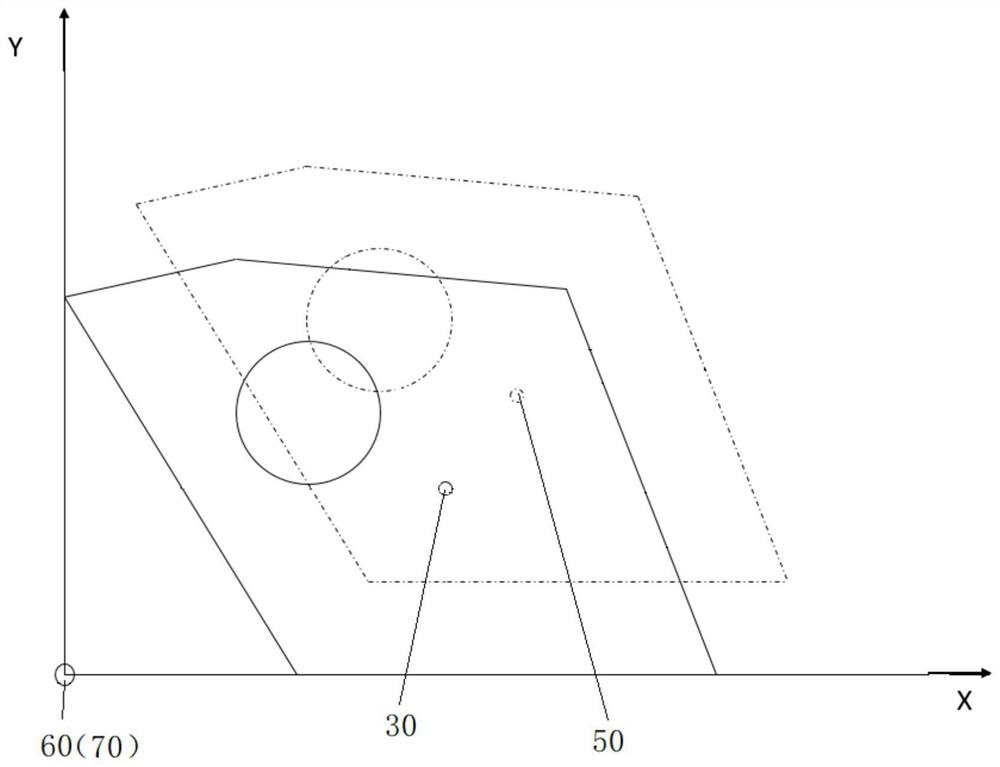

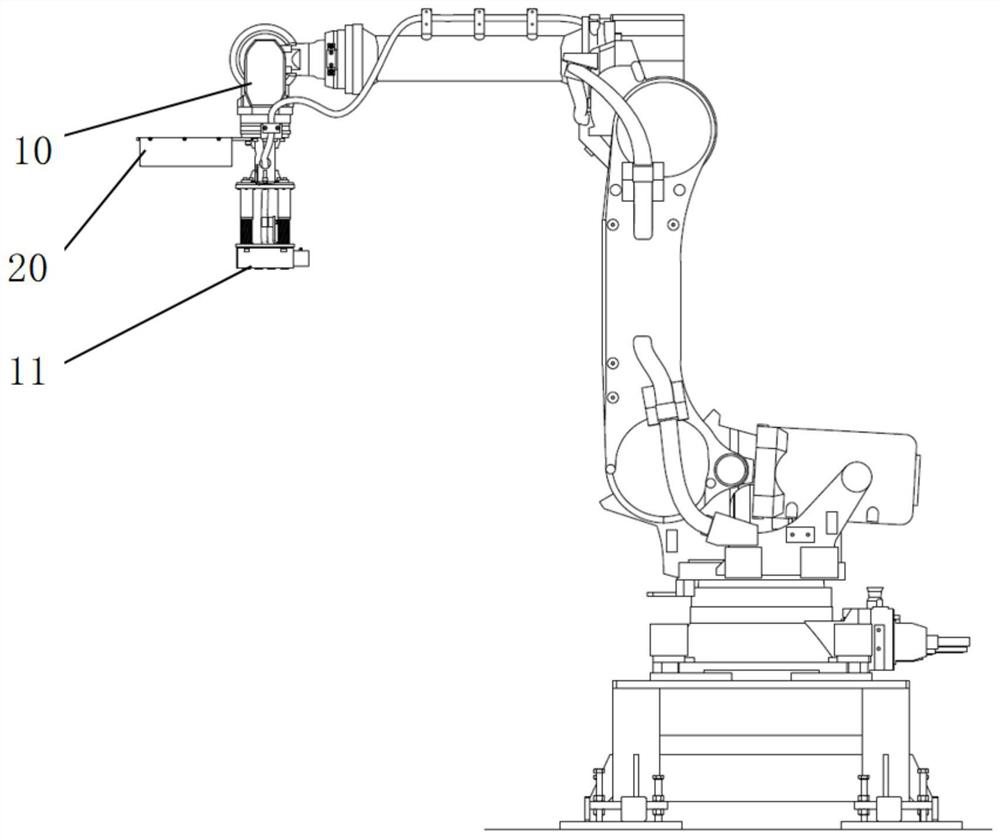

Workpiece positioning method, workpiece positioning device and groove cutting workstation

ActiveCN113829346AEliminate positioning errorsAccurate locationProgramme-controlled manipulatorWork holdersEngineeringWorkstation

The invention provides a workpiece positioning method, a workpiece positioning device and a groove cutting workstation, and belongs to the technical field of workpiece positioning. The workpiece positioning method includes the steps that S1, a grabbing robot carries a visual positioning structure to move to a workpiece placement position, and a workpiece is photographed to obtain the initial position of the workpiece; S2, the grabbing robot grabs the workpiece at the preset grabbing point of the workpiece and moves the workpiece to a preset placing position of the workpiece on a placing table; and S3, the grabbing robot loosens the workpiece, and the workpiece slides along the obliquely-arranged placing table to abut against a first positioning part and a second positioning part on the placing table. According to the workpiece positioning method provided by the invention, the visual positioning structure is used for grabbing the workpiece so as to carry out preliminary positioning on the carried workpiece, then the workpiece is placed on the placing table, and the placing table is used for carrying out secondary positioning on the workpiece, so that the positioning errors of the visual positioning structure are eliminated. The position is made more accurate when the carrying robot takes down the workpiece from the placing table for machining, and the machining precision is guaranteed.

Owner:三一机器人装备(西安)有限公司

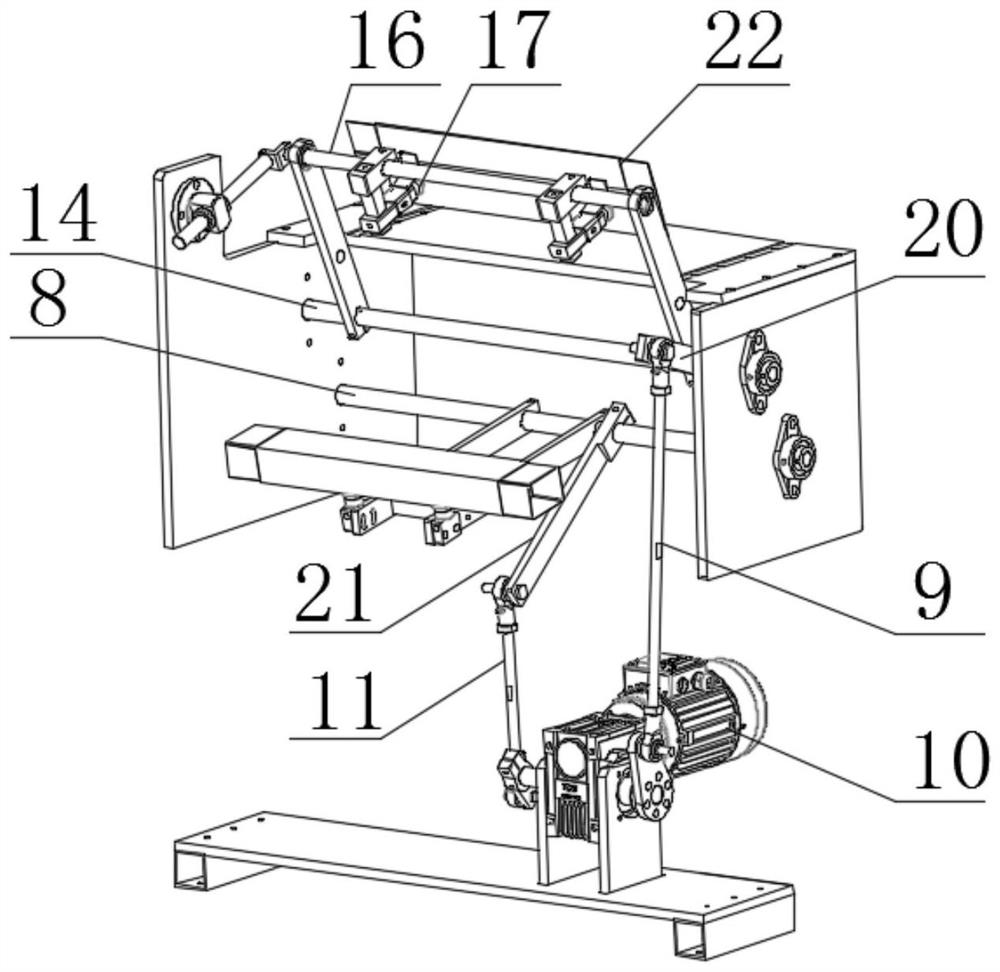

Grabbing mechanism of automatic laminating machine

InactiveCN108481905AIncrease productivityImprove lamination efficiencyPrinting press partsElectric machineryLeather belt

The invention provides a grabbing mechanism of an automatic laminating machine, and belongs to the technical field of machines. According to the grabbing mechanism, the problem of low grabbing efficiency in the prior art is solved. According to the grabbing mechanism of the automatic laminating machine, the automatic laminating machine comprises a working table which is provided with a conveyor belt, and the conveyor belt is provided with a feeding end and a discharging end; the grabbing mechanism is arranged on one side of the conveyor belt, and comprises a fixed rack and a sliding rail; thefixed rack is fixed to one side of the working table, and the sliding rail is fixed to the fixed rack; the sliding rail is slidably provided with a sliding block III and a sliding block IV, and one end of the sliding block is fixedly provided with a motor III of which an output shaft is fixedly provided with a belt pulley I coaxially; the other end of the sliding rail is rotatably provided with abelt pulley II, and the belt pulley I is connected to the belt pulley III through a belt; the sliding block III is fixed to the belt, and the sliding block IV is fixed to the belt; and the sliding block III is fixedly provided with a grabbing component I. The grabbing mechanism has the advantages that the grabbing effect is improved.

Owner:嘉兴涌锦服饰有限公司

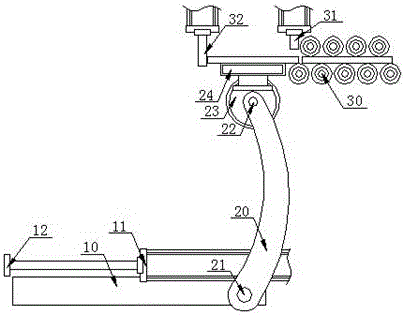

Automatic blanking processing system for sheet metal parts of suspensions of electric vehicles

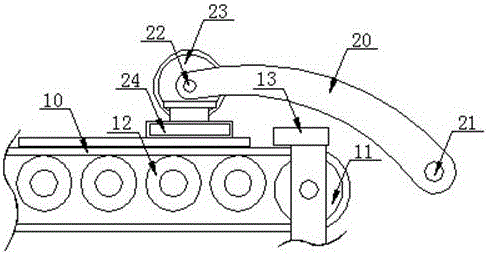

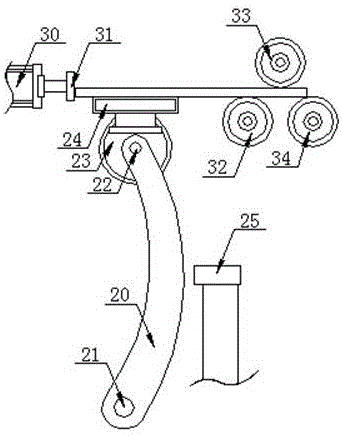

ActiveCN106563723AAutomated crawlingRealize the feeding actionMetal-working feeding devicesPositioning devicesSteel platesElectric vehicle

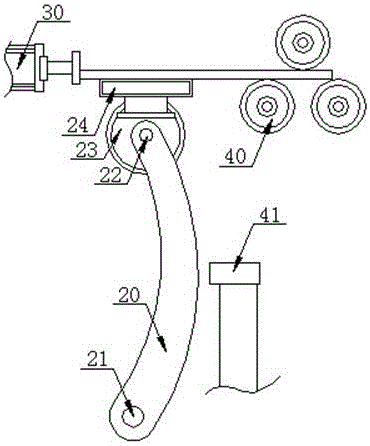

The invention discloses an automatic blanking processing system for sheet metal parts of suspensions of electric vehicles. The system comprises a plate lifting supporting platform and a rotating taking swing arm; a fixed supporting base and a plurality of lifting supporting screw rods are arranged below the plate lifting supporting platform; a plurality of axially vertically arranged screw rod mounting through holes are formed in the fixed supporting base; a screw rod lifting gear sleeving each lifting supporting screw rod is further arranged on each screw rod mounting through hole; horizontal driving rotating shafts provided with rotating shaft driving bevel gears are further horizontally arranged on the fixed supporting base; one end of the rotating taking swing arm is connected with a rotating driving rotating shaft fixed in the axis position and a rotating driving motor for driving the rotating taking swing arm to rotate around the rotating driving rotating shaft; and an electromagnetic taking suction cup is arranged at the other end of the rotating taking swing arm. With the system, automatic grasping and sending actions of the steel plate blanking operation can be realized.

Owner:徐州格哩雅车业有限公司

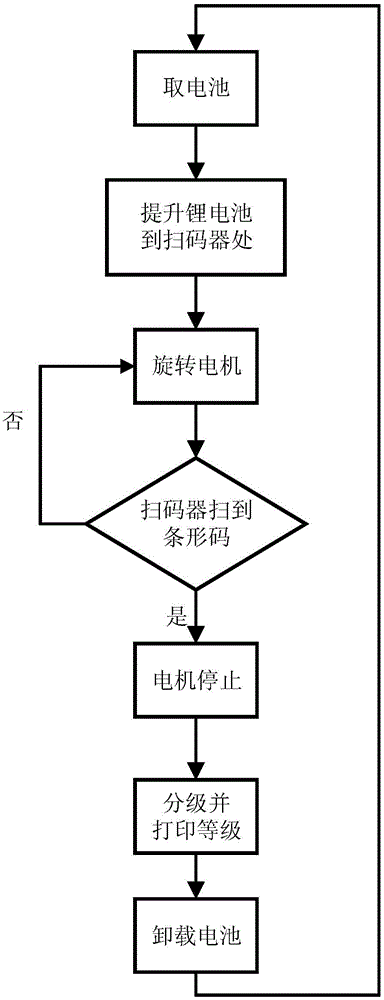

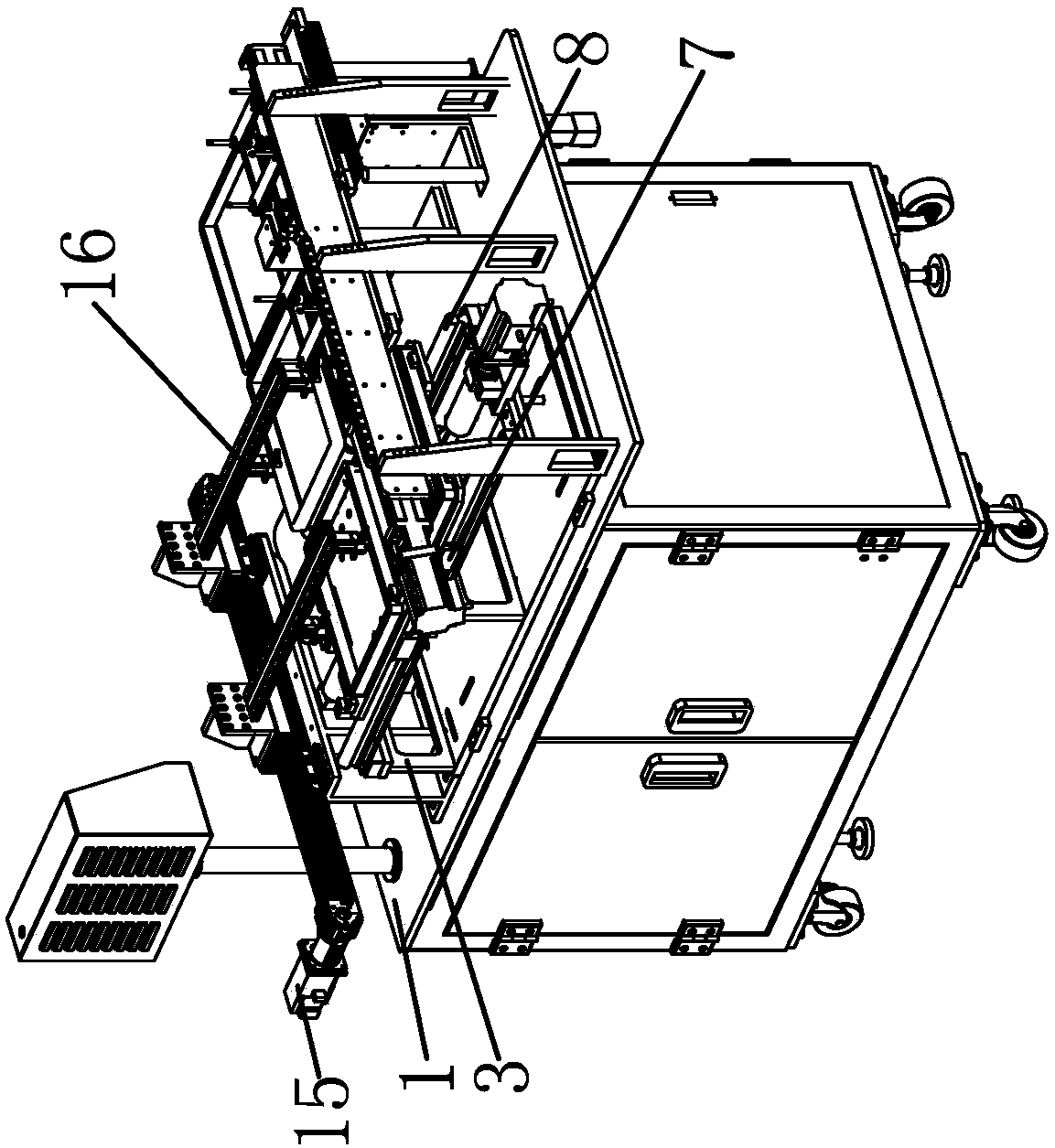

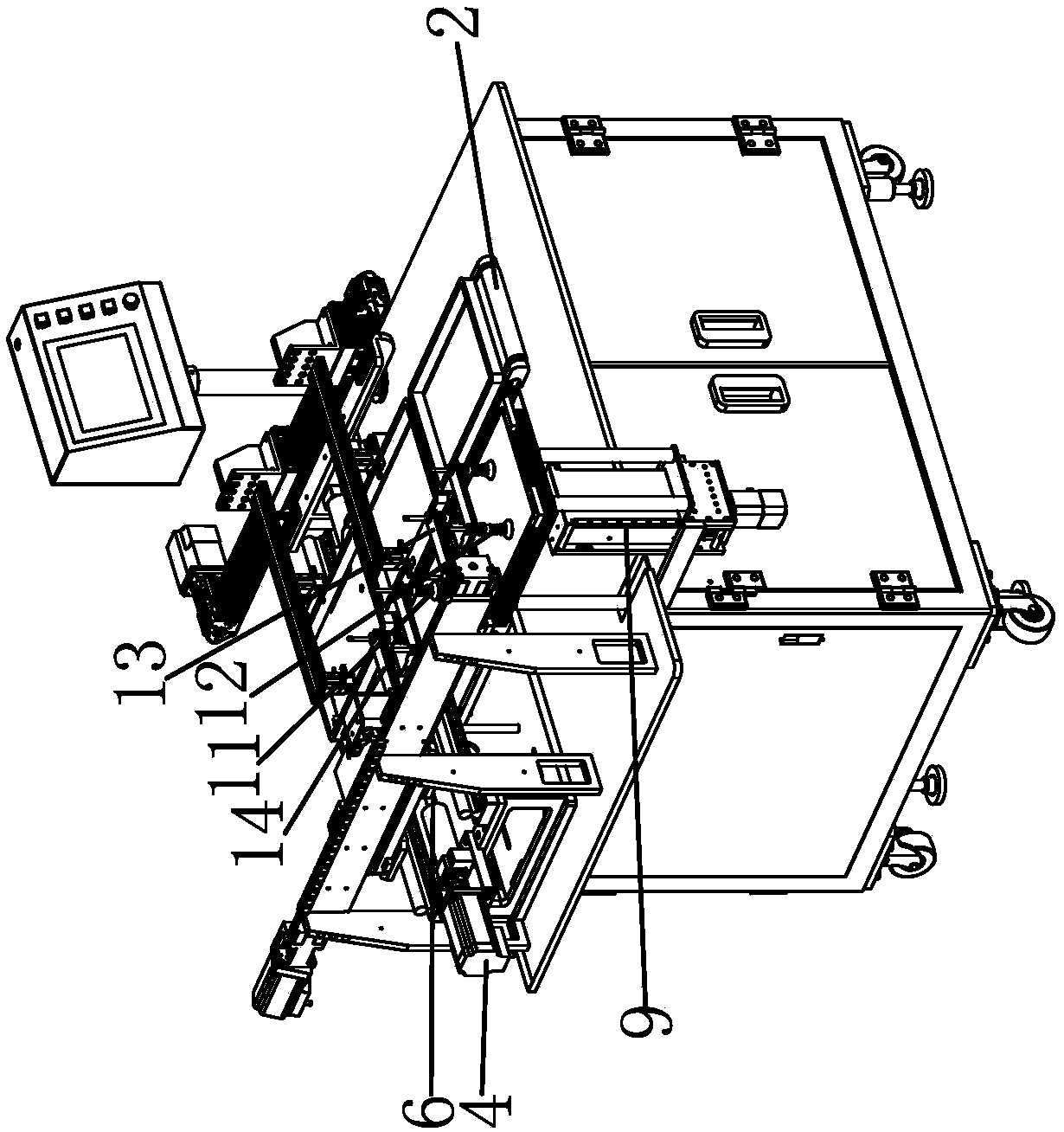

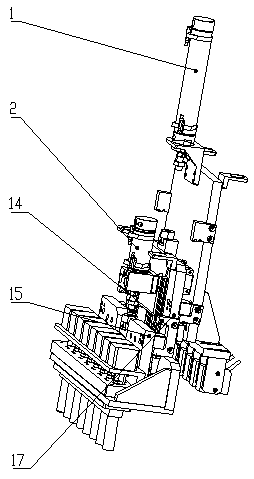

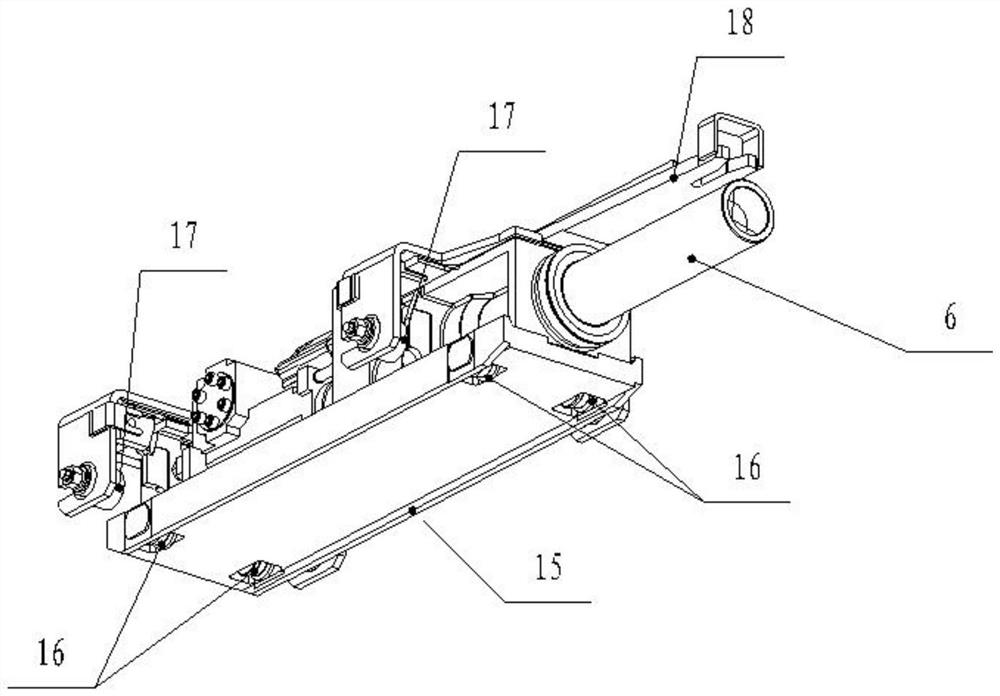

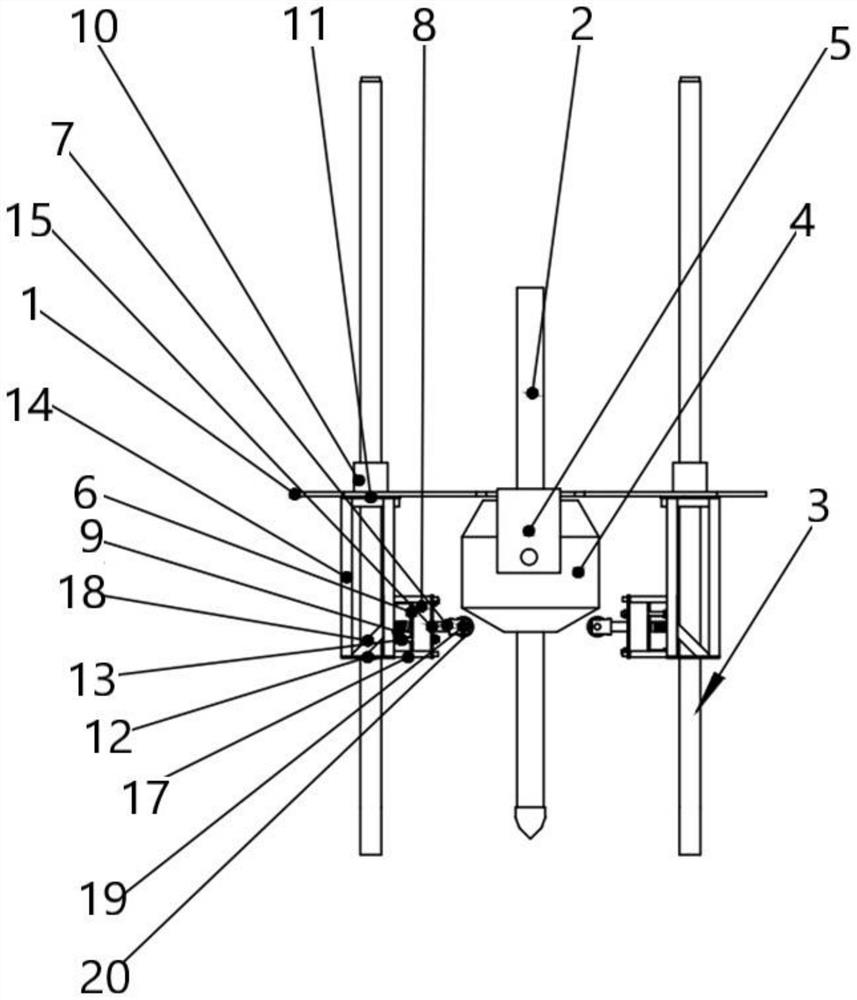

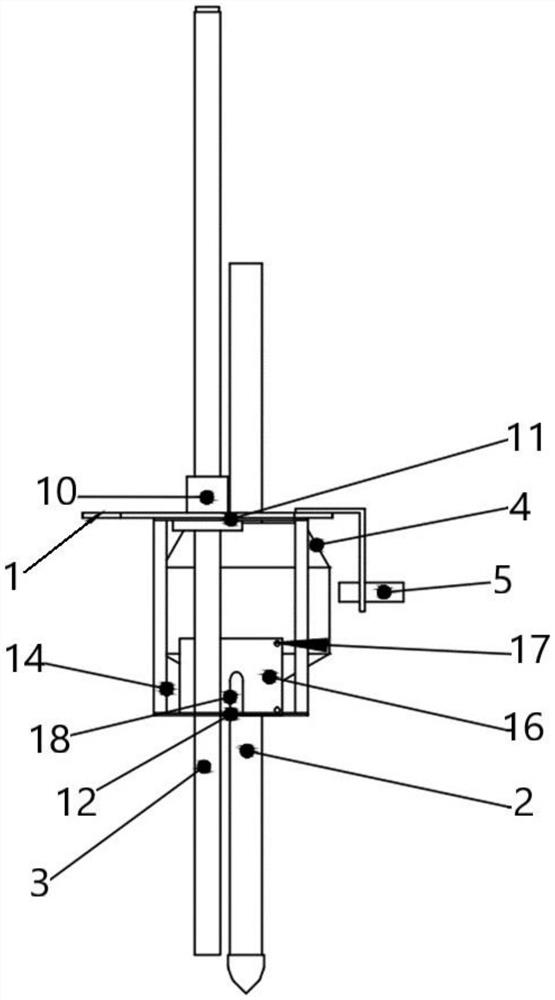

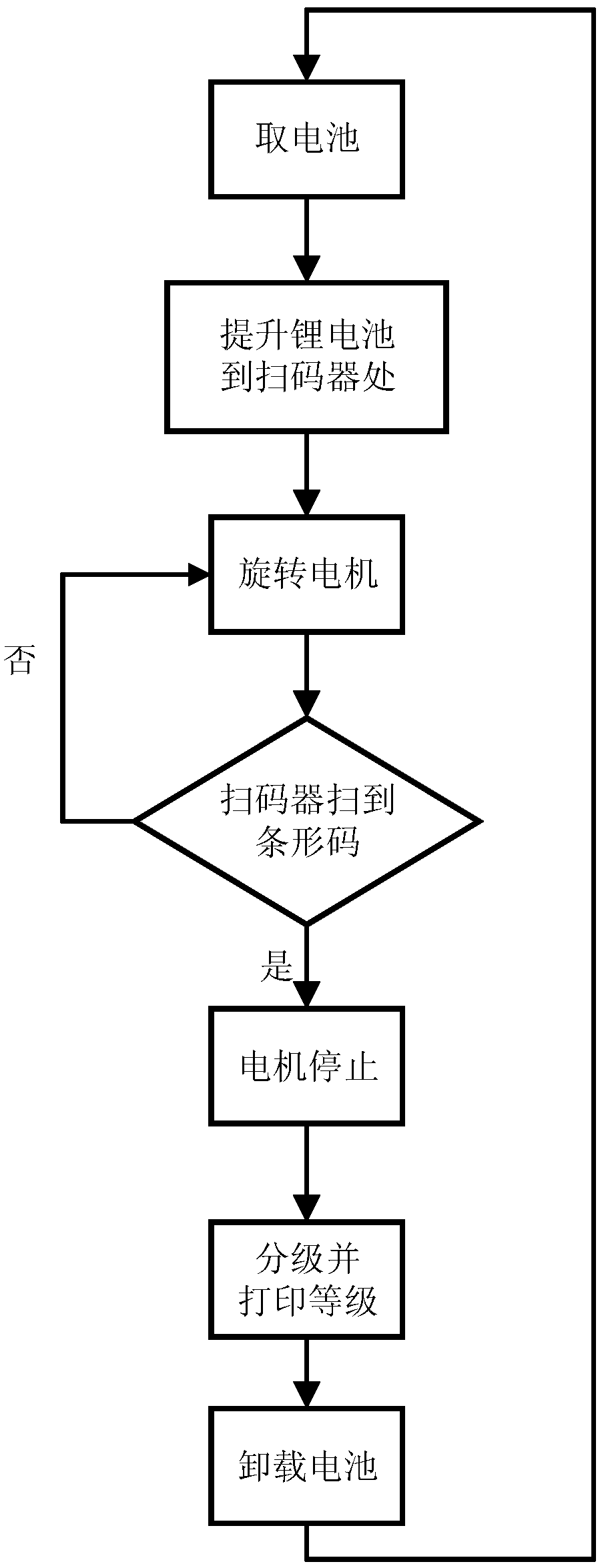

Columnar lithium battery automated screening method

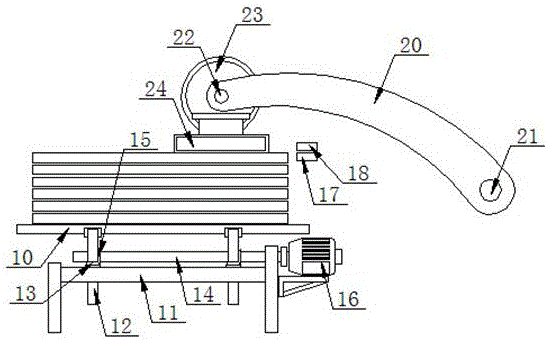

InactiveCN107694968ARealize the function of comparison and error correctionAutomated crawlingProgramme-controlled manipulatorFinal product manufactureElectrical batteryScreening method

A columnar lithium battery automated screening method is disclosed. A mechanical power arm structure is included. The columnar lithium battery automated screening method comprises the following stepsthat (1) batteries are taken, specifically, when a mechanical power arm moves to the position above lithium batteries (7), under the situation that a second oil cylinder (2) jacks a second-level moving plate (15) to the position of a lower limiting point of a first limiting block (14), a first oil cylinder (1) drives a first-level moving plate (17) to move downwards, firstly the lithium batteries(7) are positioned by a protecting bush (6) till the distances between permanent magnets (8) and the lithium batteries (7) are 4-5 mm, the lithium batteries (7) are attracted to the permanent magnets(8), and grabbing is completed; (2) code scanning and grading are conducted; and (3) the batteries are dismounted. According to the columnar lithium battery automated screening method, automated grabbing, code scanning, grading and dismounting of the columnar lithium batteries can be achieved, code scanning data is compared with data obtained by scanning a tray, and the comparison and self-inspection functions are achieved.

Owner:SEESA HLDG

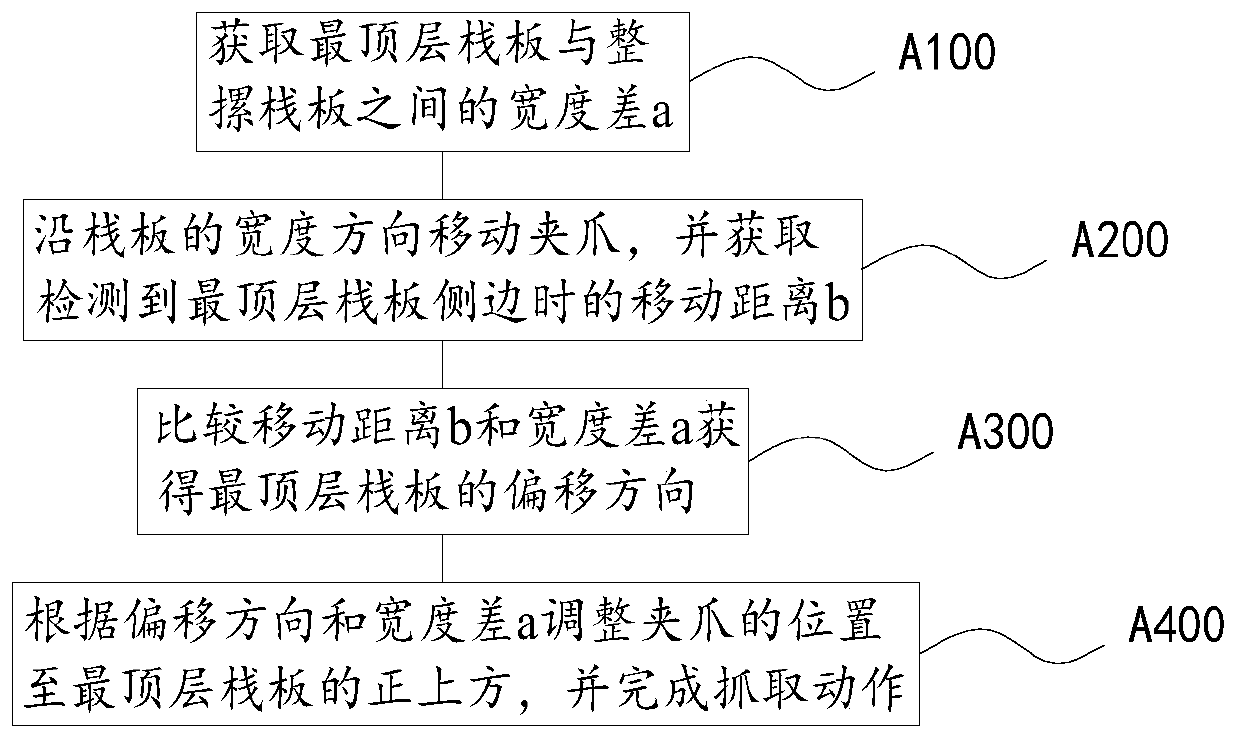

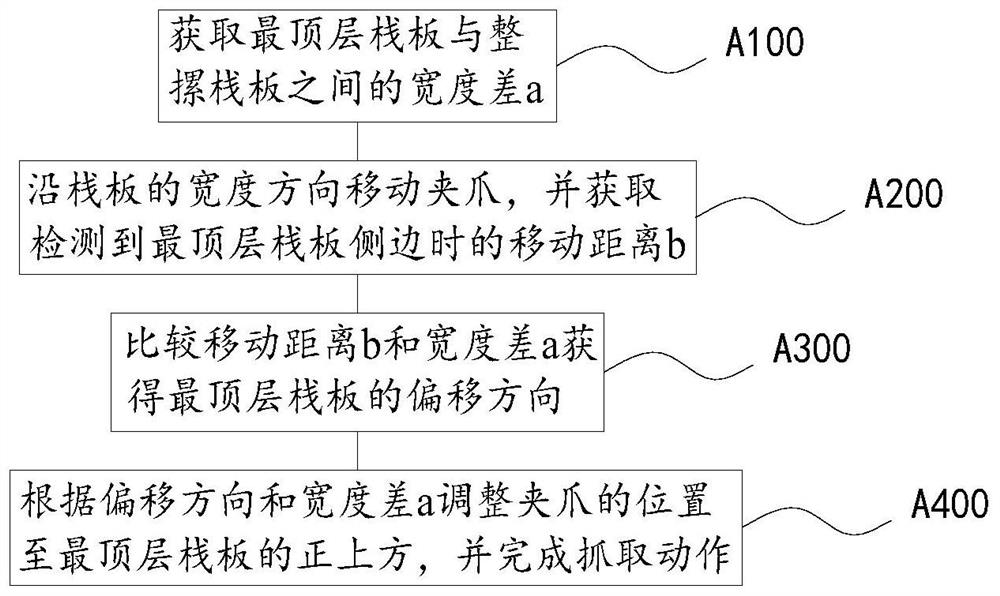

Workpiece dislocation grabbing method

ActiveCN110255168AAutomated crawlingStacking articlesDe-stacking articlesDislocationMechanical engineering

The invention relates to the technical field of feeding equipment, particularly relates to a workpiece dislocation grabbing method, and provides a device of the workpiece dislocation grabbing method. The workpiece dislocation grabbing method is used for grabbing left and right staggered workpieces and is based on two groups of clamping jaws which take the central axis of the whole stack of workpieces as the axis and are symmetrically arranged in the width direction of the whole stack of workpieces. The method comprises the following steps of acquiring the width difference a between a topmost-layer workpiece and the whole stack of workpieces; moving the clamping jaws in the width direction of the workpieces, and acquiring the moving distance b when the side edge of the topmost-layer workpiece is detected; comparing the moving distance b and the width difference a to obtain the deviation direction of the topmost-layer workpiece; and adjusting the clamping jaws to reach positions over the topmost-layer workpiece according to the deviation direction and the width difference a, and completing grabbing actions. By means of the technical scheme of the workpiece dislocation grabbing method, the technical problem that a workpiece cannot be automatically grabbed is solved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

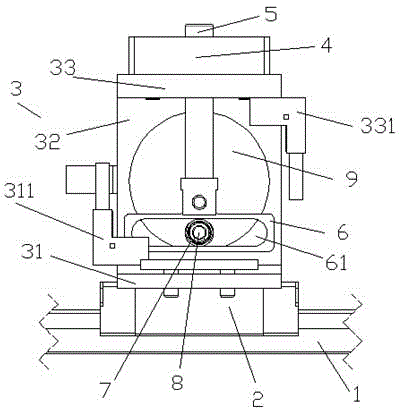

Grabbing device used for blood cell analyzer

ActiveCN104913946ASimple structureGuaranteed uptimeWithdrawing sample devicesControl using feedbackCircular discBiochemical engineering

The invention belongs to the technical field of medical apparatus and instruments, and especially relates to a grabbing device used for a blood cell analyzer. The grabbing device comprises a guide rail, an installation pedestal, and a fixing pedestal; the installation pedestal is arranged on the guide rail; the fixing pedestal is arranged on the installation pedestal; the fixing pedestal comprises a bottom plate, a side plate, and a top plate; the base plate and the top plate are arranged on the two ends of the side plate respectively; the top plate is provided with a bushing; the bushing is penetrated through by a grabbing guide rod; one end of the grabbing guide rod is connected with a lead rod; a bearing is arranged in the lead rod; an eccentric pin is arranged in the bearing; the eccentric pin is arranged at the eccentric part of a circular disc; the center of the circular disc is provided with a rotating shaft; and one end of the rotating shaft is connected with a motor. The grabbing device is simple in structure; operation is stable and reliable; assembling complexity is reduced; it is convenient for assembling and maintenance; moving and positioning accuracy is high; operation is smooth; the grabbing device is durable; service life is long; processing is convenient; and cost is low.

Owner:ZHONGSHAN CHUANGYI BIOCHEM ENG

Agricultural and sideline product packaging machine

InactiveCN110002031AAutomated pouringAutomate the packaging processWrappingWrapper twisting/gatheringAgricultural engineeringScrew thread

The invention discloses an agricultural and sideline product packaging machine comprising a supporting mechanism, a storage drum, a particle storage mechanism, a packaging part and a gripping part. The packaging part comprises a lead screw seat, a lead screw, a polished shaft, a lead screw motor and a lead screw slider; the lead screw and the polished shaft are arranged on the lead screw seat; a motor shaft of the lead screw motor is fixedly connected with the lead screw; a thread on the inner side of the lead screw slider is engaged with the lead screw; the bottom end surface of the lead screw seat is fixedly connected with a rotating part of a round electric rotary disc; the gripping part comprises an electric rotating base and a D telescopic mechanism; the bottom end of the D telescopicmechanism is fixedly connected with a rotating part of the electric rotating base; the electric rotating base is fixedly mounted on the upper end surface of an L-shaped aluminum profile; and the electric rotating base, the D telescopic mechanism, an A electric joint, an E telescopic mechanism, a B electric joint and an F telescopic mechanism cooperate with each other to drive a gripper to grasp agricultural products and place the agricultural products in the drum, and automatic grasping and placing of agricultural and sideline products are achieved.

Owner:易群

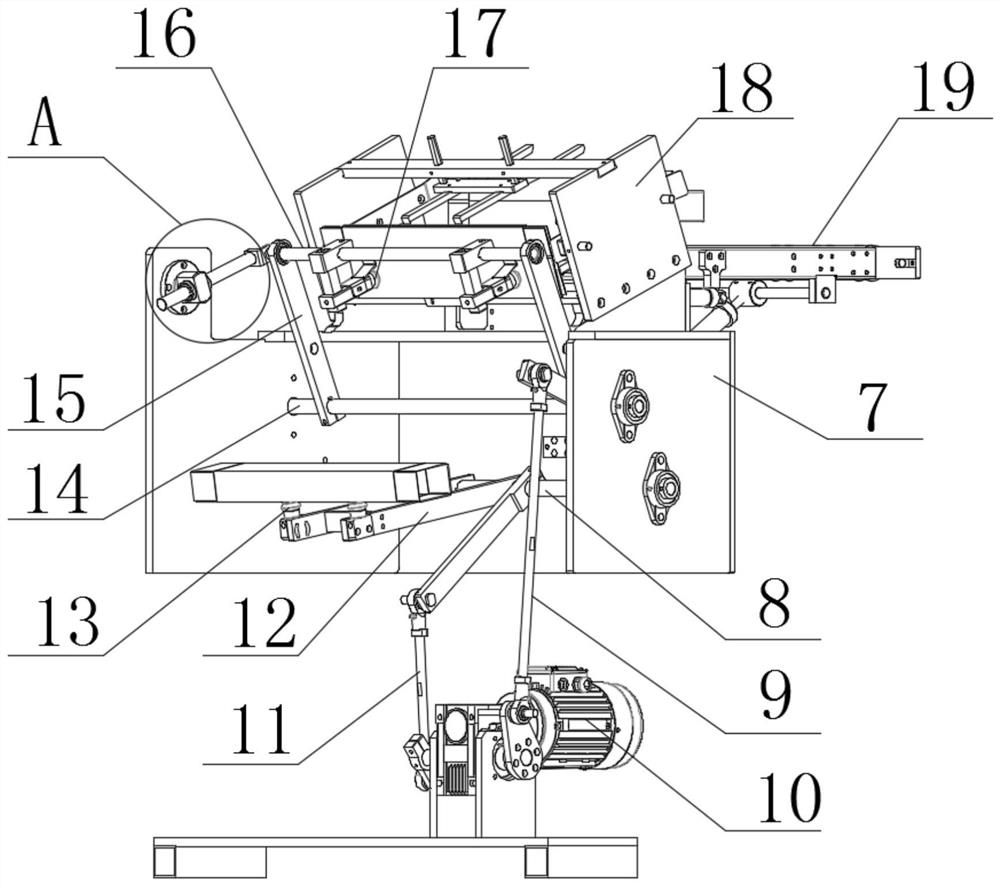

Welding rod packing equipment

PendingCN112224496AHigh degree of automationSimple and compact structureRod-shaped articlesStructural engineeringManufacturing engineering

The invention provides welding rod packing equipment. The welding rod packing equipment comprises: a rack; a welding rod packaging box opening device which is used for opening a packaging box; a conveying and folding device which is used for conveying and folding the packaging box and specifically comprises a conveyor belt and a folding mechanism; and a welding rod tidying and conveying device which is used for tidying the welding rods and pushing the tidied welding rods into the packaging box. In the embodiment of the invention, automatic box opening, folding and gluing of the welding rod packaging box can be achieved, so that the automation degree is high, the structure is simple and compact, the box opening speed is high, and the efficiency is high; automatic grabbing and feeding of welding rods and tidying and aligning of the welding rods can be achieved, and the tidied welding rods can be automatically loaded into a box, so that work efficiency is improved, and labor cost is reduced; the welding rod packing equipment can clamp and convey the folded and glued welding rod packaging box and consolidate the glued welding rod packaging box to make bonding of the welding rod packaging box tighter and firmer.

Owner:天津惠坤诺信包装设备有限公司

Container taking mechanism and container simulation testbed

PendingCN109533954ARealize pick and placeAutomated crawlingPackagingConveyor partsEngineeringTestbed

The invention belongs to the technical field of container devices and particularly discloses a container taking mechanism and a container simulation testbed. The container taking mechanism is used forpicking up or putting a container and comprises a connecting frame for connection with an external connector, grabbing parts arranged on the connecting frame, and a grabbing driving assembly arrangedon the connecting frame and used for driving grabbing parts to rotate so as to make the grabbing parts clamp-connected with or disconnect with the container legs, wherein each corner of the containeris provided with a container leg, and at least two grabbing parts correspond to the two opposite corners of one side face of the container and can extend into corresponding container legs. The container simulation testbed comprises the above the container taking mechanism. By adopting the container taking mechanism and the container simulation testbed, the container can be unloaded, accordingly the container unloading process can be simulated to optimize the design of the container and a twistlock structure in cooperation with the container.

Owner:中船华海船用设备有限公司

Unloading mechanism for automatic membrane covering machine

InactiveCN108820867AAutomated crawlingIncrease productivityConveyor partsLoad cellMechanical engineering

The invention provides an unloading mechanism for an automatic membrane covering machine, belongs to the technical field of machinery and aims at solving the problem of low unloading efficiency in prior art. For the unloading mechanism for the automatic membrane covering machine, the automatic membrane covering machine comprises a workbench; the workbench is provided with a conveyor belt; and theconveyor belt is provided with a feeding end and an unloading end. One side, arranged at the workbench and close to the unloading end, of the unloading mechanism comprises a base and an unloading tank; the base is in an L shape; the unloading tank is internally provided with a plurality of placement plates which are horizontally arranged at an equal interval; the base is rotationally provided witha third screw rod vertically; a lifting block is in threaded connection to the third screw rod and is arranged on the base in a sliding manner; a storage tank is connected with the lifting block; a fourth motor which can enable the lower end of the third screw rod to rotate is connected to the lower end of the third screw rod; and the lower side of the base is fixed with a weighing sensor. The unloading mechanism has the advantage that the unloading efficiency is improved.

Owner:嘉兴涌锦服饰有限公司

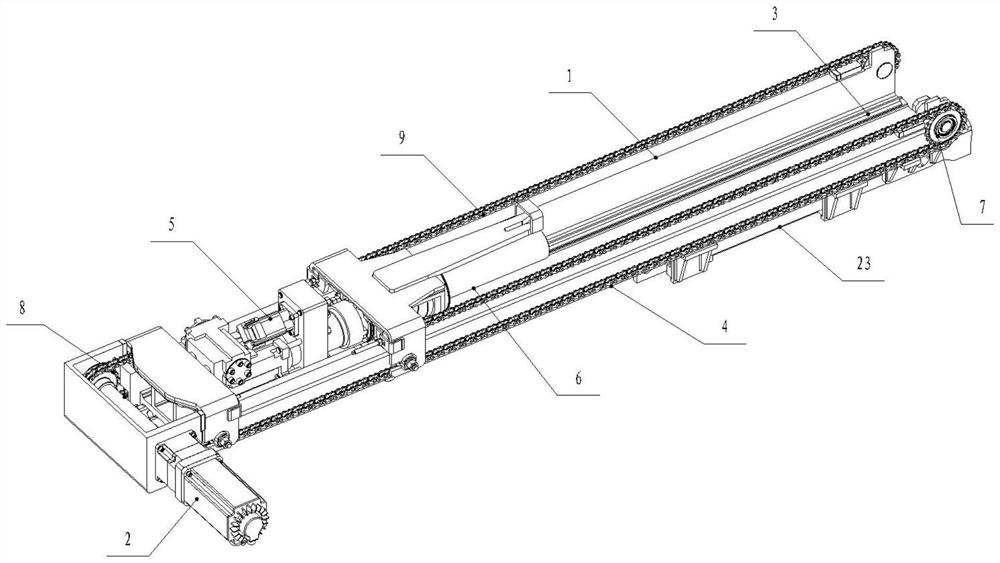

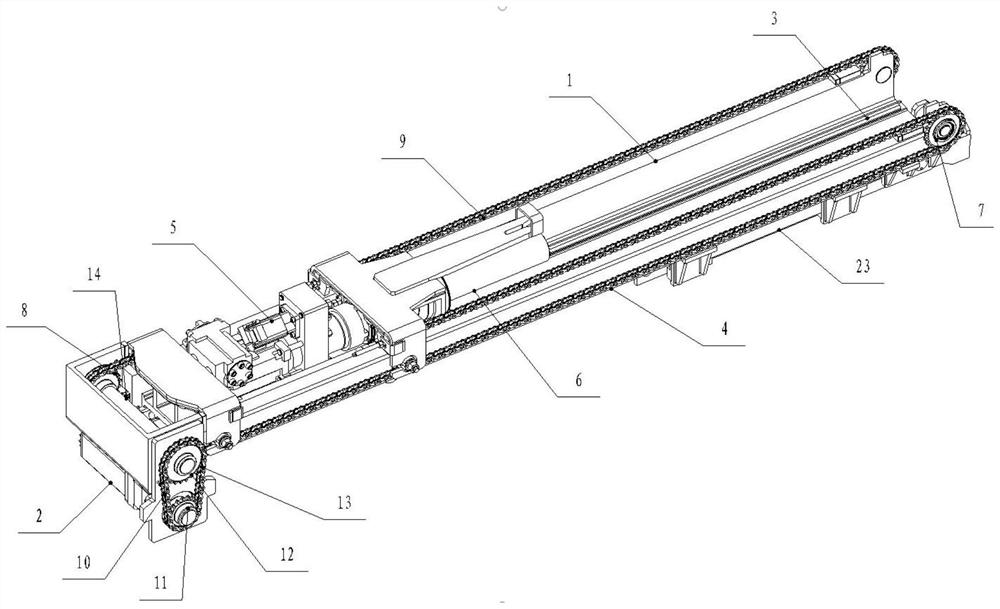

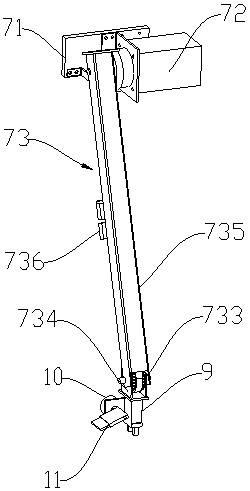

Robot telescopic arm

PendingCN114750198AAchieve crawlingRealize drilling functionGripping headsArmsWorking environmentEngineering

The invention relates to a robot telescopic arm, and belongs to the technical field of robots. The invention solves the problems of high risk and high labor intensity of furnace discharge operation. Comprising a support assembly, a telescopic driving part, a guide rail, a telescopic transmission assembly, a moving trolley and a grabbing executing mechanism, the guide rail is arranged on the upper portion of the support assembly, the support assembly is connected with the moving trolley through the guide rail, the telescopic driving part is arranged at the rear end of the support assembly, and the support assembly is connected with the telescopic transmission assembly; the telescopic driving component is connected with the telescopic transmission assembly, the telescopic transmission assembly and the moving trolley are installed, and a grabbing executing mechanism is arranged on the moving trolley. The device can complete various complex operations, improve the working environment, guarantee the personal and property safety, improve the working efficiency and reduce the labor intensity and difficulty.

Owner:HARBIN BOSHI AUTOMATION

An automatic feeding and stamping system for automobile support arm components

InactiveCN106734690BAutomated crawlingPrecise control over placementMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses an automatic feeding and punching system for an automobile supporting arm assembly. The automatic feeding and punching system for the automobile supporting arm assembly comprises a plate feeding platform, a plate feeding pushing air cylinder and a rotary piece taking swinging arm; one end of the rotary piece taking swinging arm is connected with a rotating driving rotating shaft of which the axis position is fixed; an electromagnetic piece taking sucking disc is arranged at the other end of the rotary piece taking swinging arm; the plate feeding platform is arranged horizontally, and one end of the plate feeding platform faces punching moulding equipment; the rotating driving rotating shaft and the plate feeding pushing air cylinder are arranged at the other end of the plate feeding platform; a piston rod of the plate feeding pushing air cylinder is arranged horizontally, and faces the punching moulding equipment; a plate feeding pushing baffle is arranged at the tail end of the piston rod of the plate feeding pushing air cylinder. According to the automatic feeding and punching system for the automobile supporting arm assembly provided by the invention, the actions of automatically grabbing and feeding of a plate punching operation of the automobile supporting arm assembly can be realized.

Owner:长春市宏宇汽车零部件有限公司

Bending clamp, carrying device, assembly system and assembly method thereof

PendingCN113859972ASimple bending processEasy to bendConveyorsMetal working apparatusPhysicsEngineering

The invention relates to the technical field of assembly tools, in particular to a bending clamp, a carrying device, an assembly system and an assembly method thereof. The assembly system comprises a conveying device and the carrying device, wherein the conveying device is used for conveying materials to be assembled; the carrying device comprises the bending clamp; the bending clamp is installed on a cantilever of the carrying device; the bending clamp comprises a first limiting piece, a movable component and a second limiting piece which are sequentially arranged in the first direction; the movable component is used for fixing a first area of a to-be-bent piece; the movable component can reciprocate in the second direction; the second direction is perpendicular to the first direction; and in the moving process of the movable component, the first limiting piece and the second limiting piece are used for limiting a second area and a third area of the to-be-bent piece correspondingly. According to the assembly system, automatic grabbing, bending and assembling of the to-be-bent piece are achieved, automation is achieved in the whole operation process, the bending operation process is very simple, time and labor are saved, and bending operation is convenient.

Owner:GREE ELECTRIC APPLIANCES INC

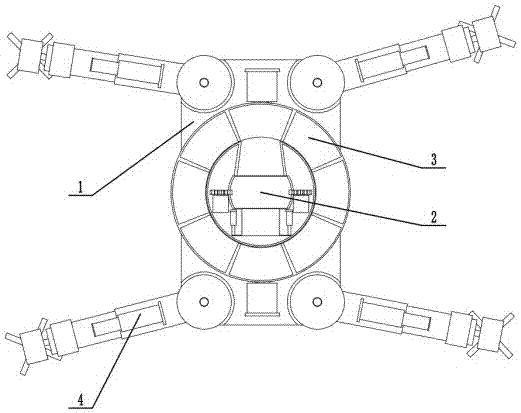

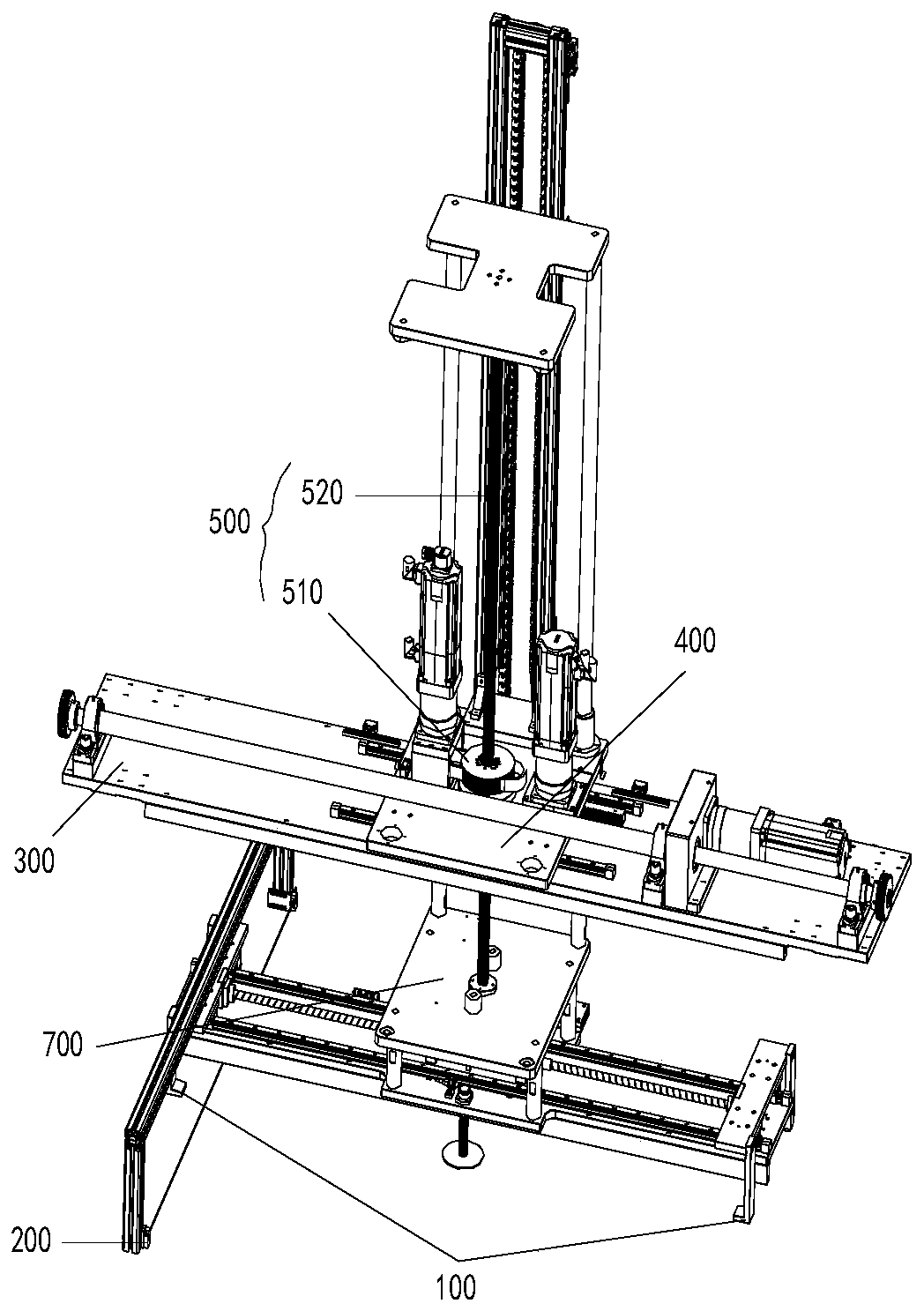

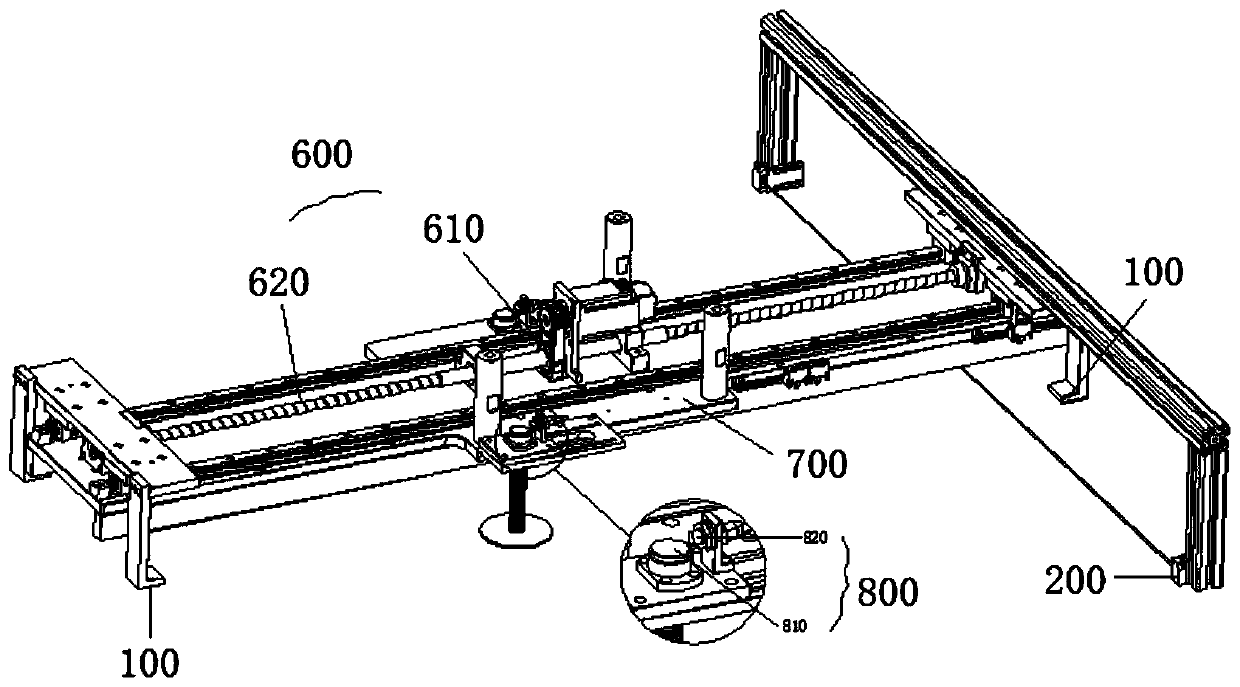

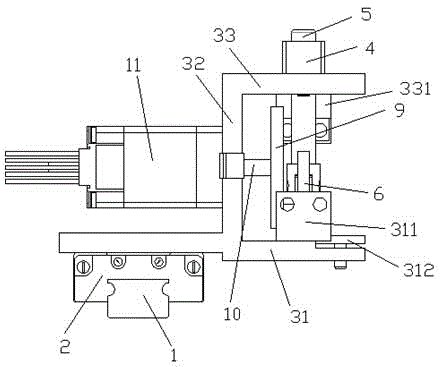

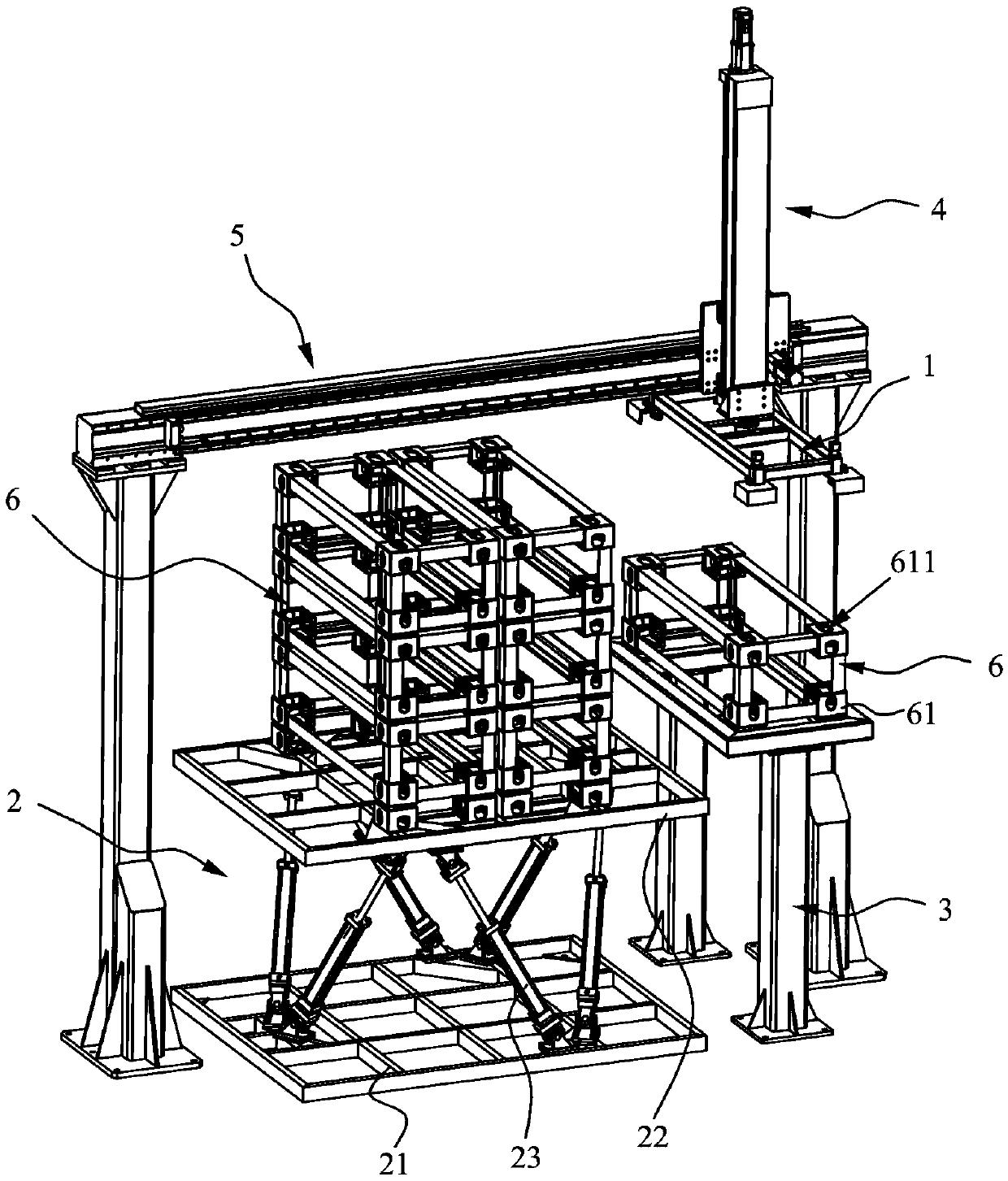

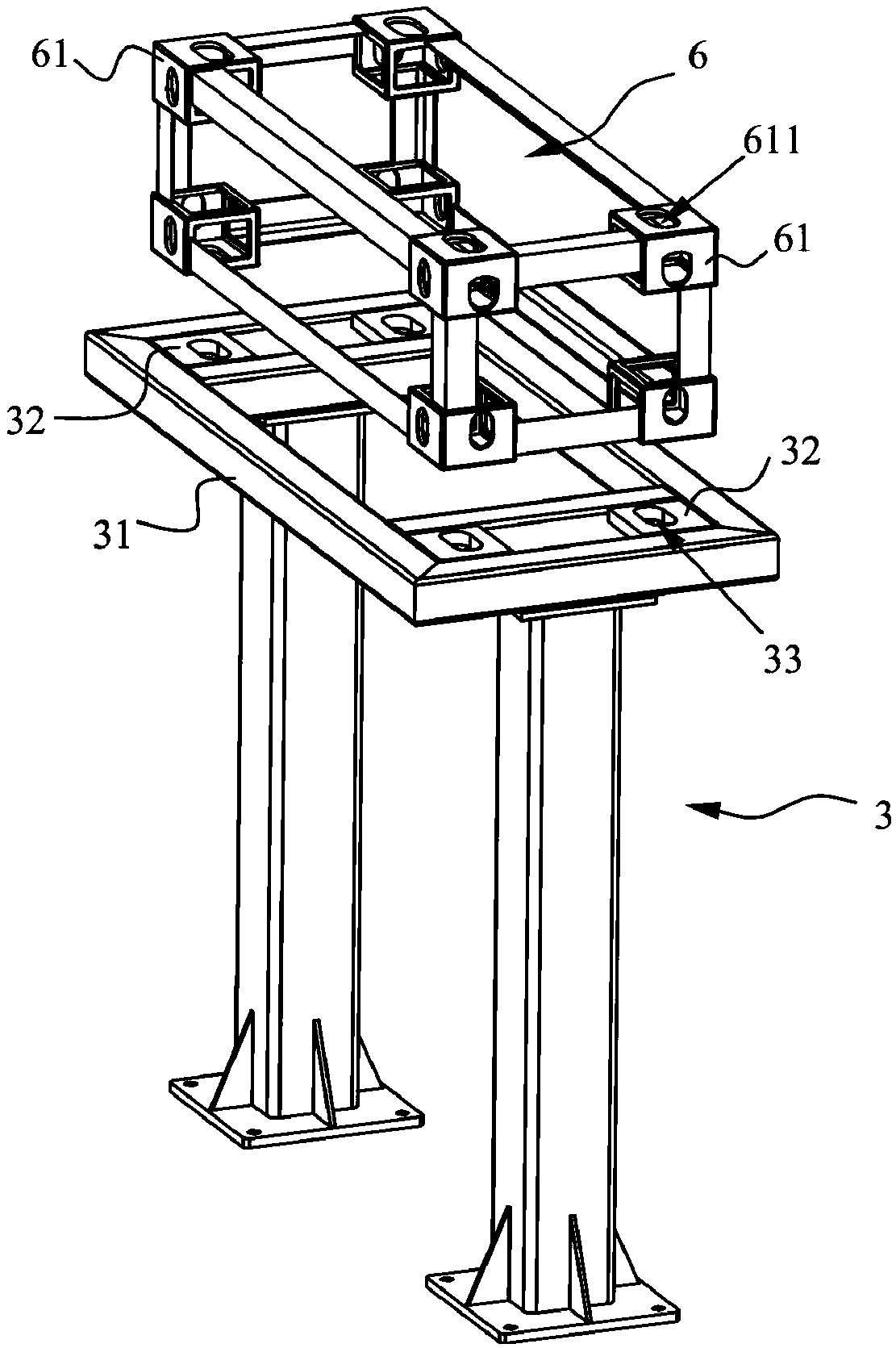

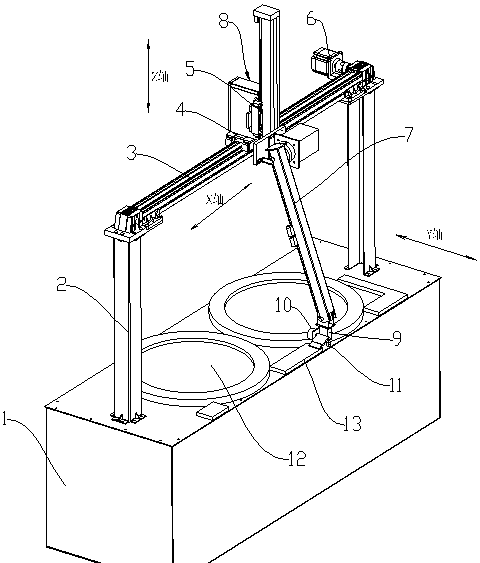

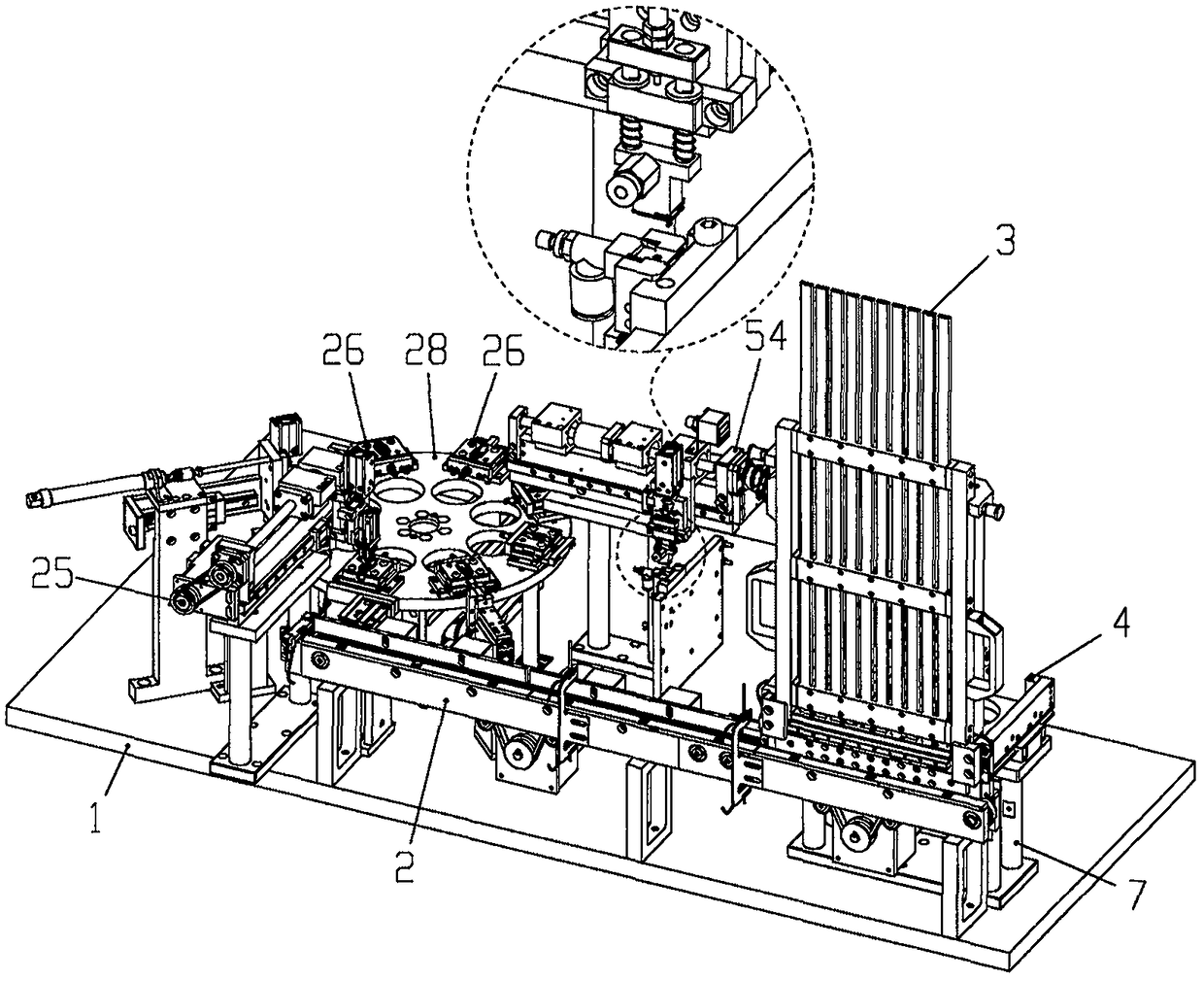

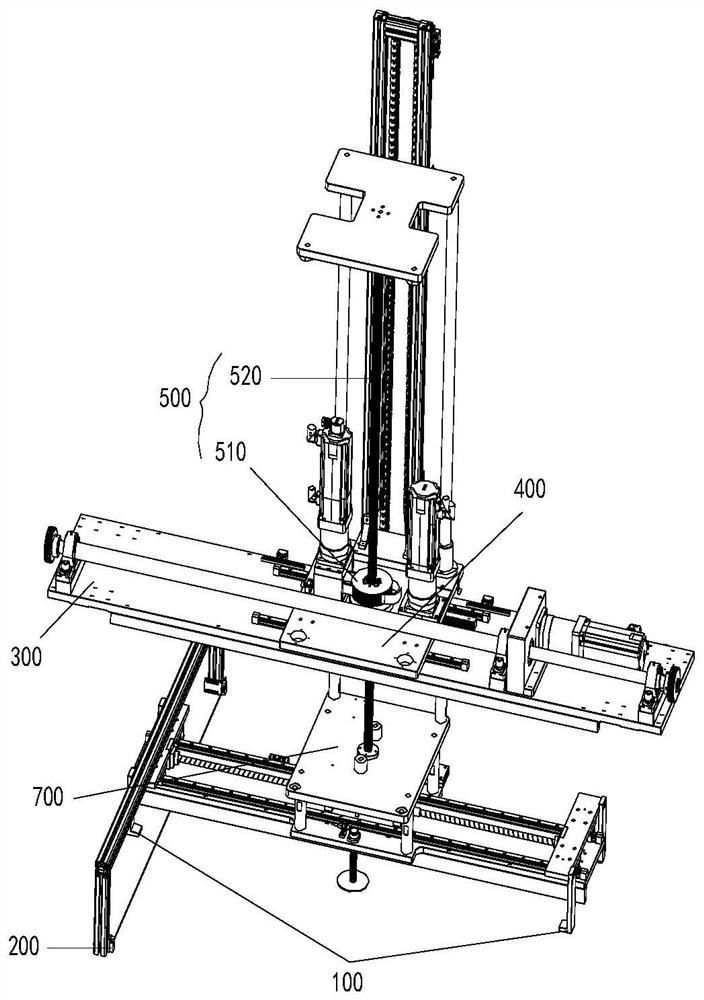

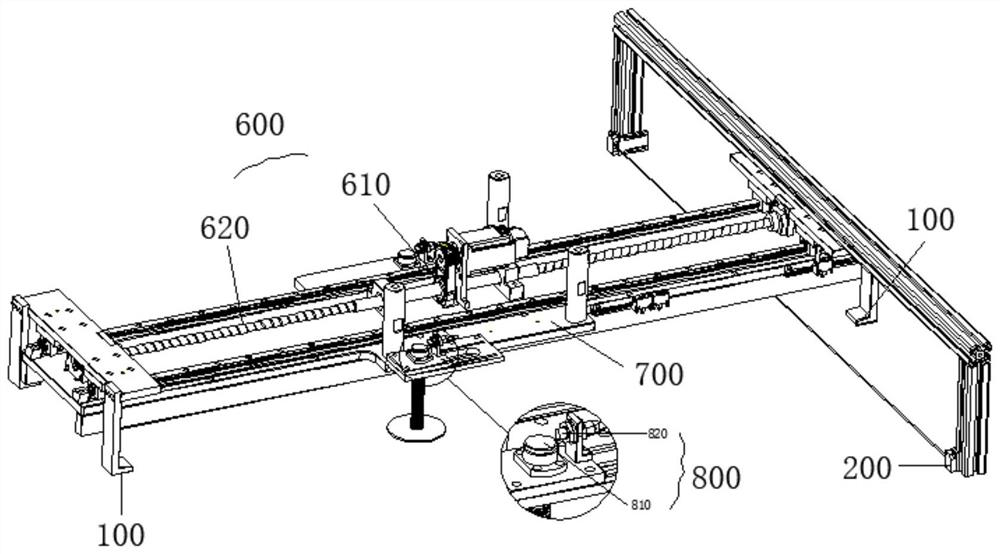

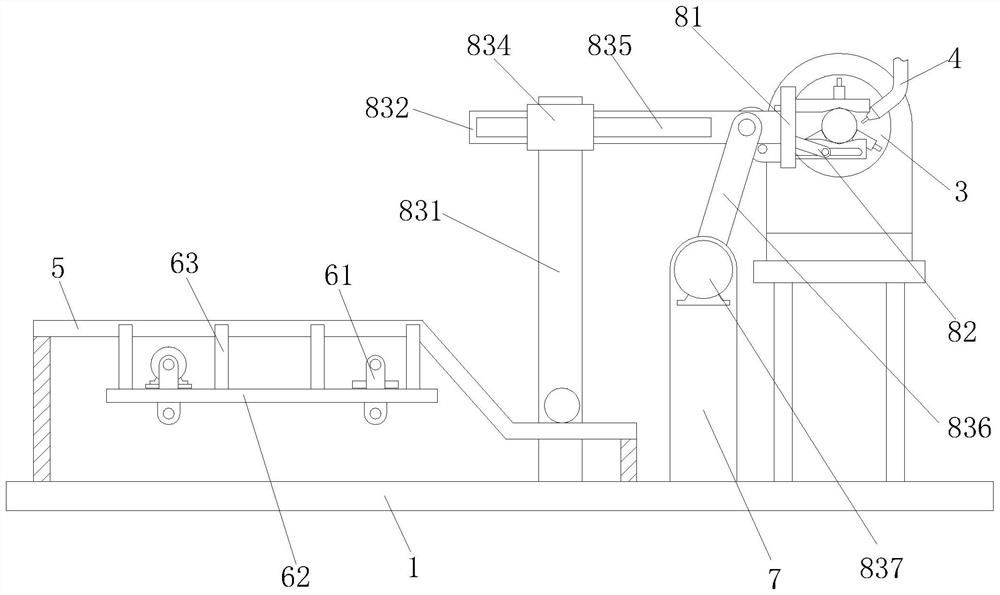

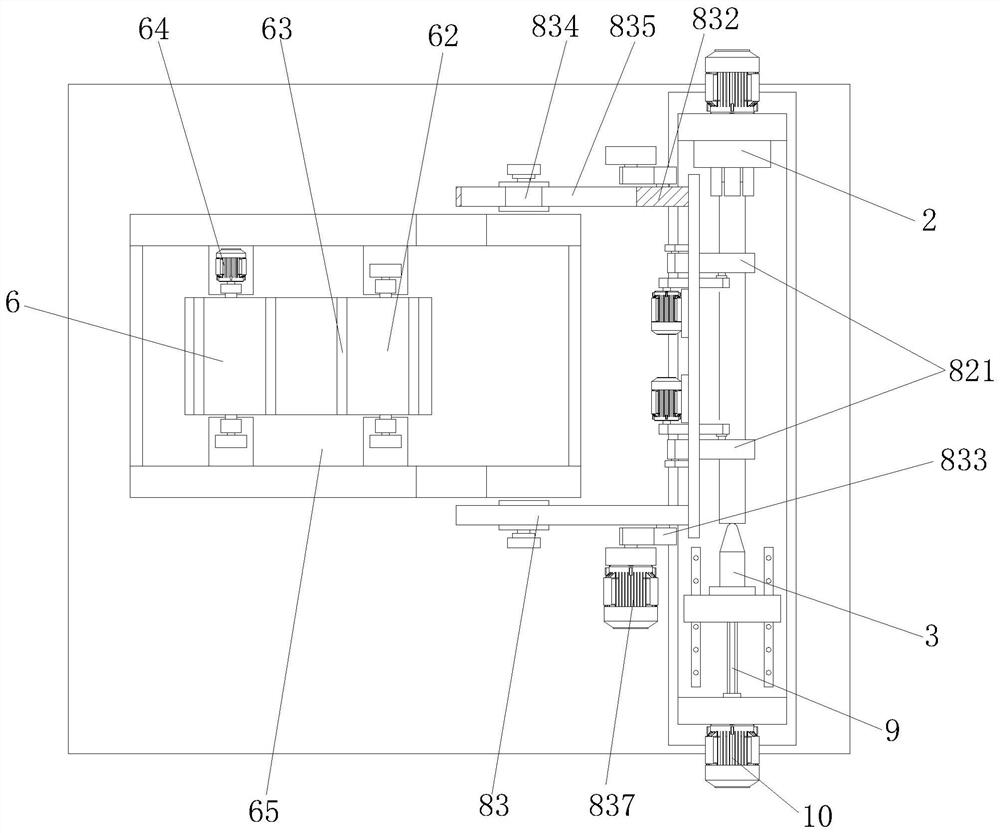

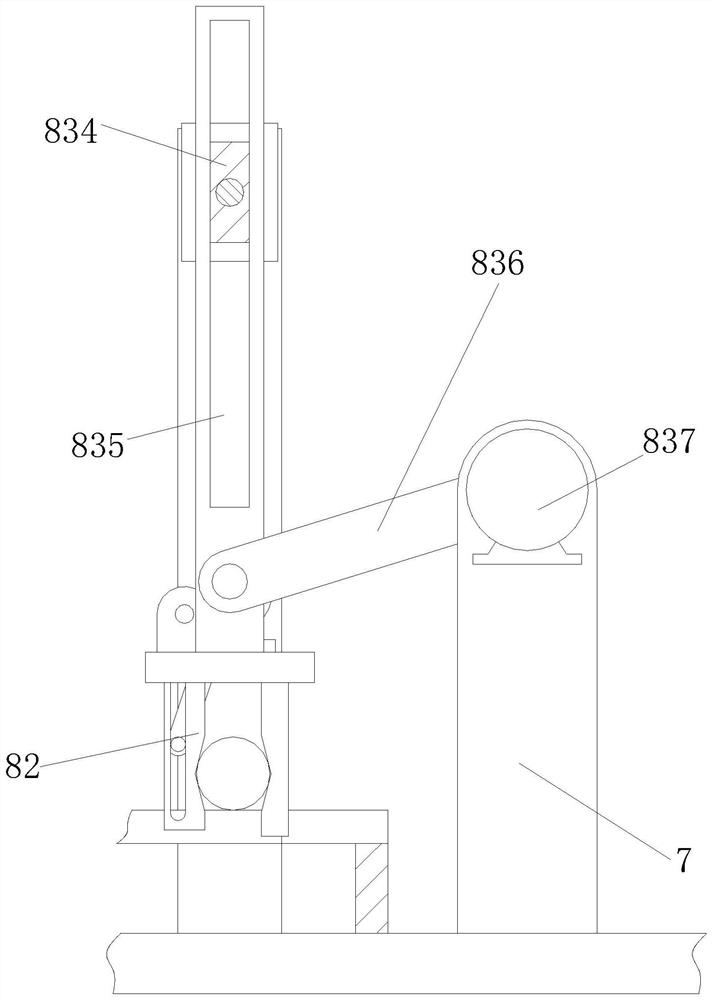

Powder metallurgy robot and its grasping method

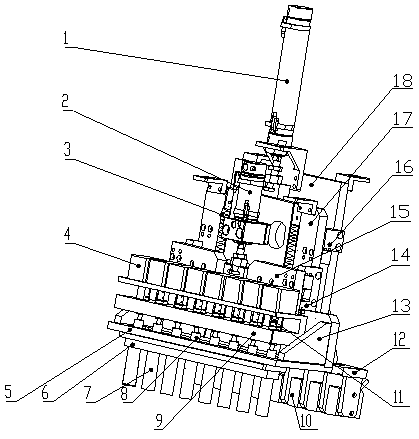

ActiveCN105598969BAutomated crawlingRealize three-axis linkageProgramme-controlled manipulatorEngineeringPowder metallurgy

The invention discloses a powder metallurgy robot and a grasping method of the powder metallurgy robot. The robot comprises a worktable, a bracket mounted on the worktable, an X-axis transverse movement slide rail mounted on the bracket, a Z-axis movement slide rail mounted on the X-axis transverse movement slide rail, and a Y-axis swinging device mounted on the Z-axis movement slide rail; under the driving of a second motor, the Y-axis swinging device moves on the Z-axis movement slide rail back and forth; the Y-axis swinging device further comprises a motor mounting plate mounted on the Z-axis movement slide rail; a third motor is mounted on the motor mounting plate; a swinging arm is fixedly mounted on a rotary shaft of the third motor; a grasping hand is mounted at the tail end of the swinging arm; under the driving of the third motor, the swinging arm swings in the Y-axis direction back and forth; under the cooperative effect of the X-axis transverse movement slide rail, the Z-axis movement slide rail and the Y-axis swinging device, the grasping hand can realize three-axis linkage, so that the grasping hand can move freely after grasping a metallurgical block, and furthermore, automatic grasping of the metallurgical block is realized.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST

Automatic connector assembly production line with dual robot coordination

ActiveCN107104347BAvoid scratchesImprove surface qualityContact member assembly/disassemblyProduction lineEngineering

The invention relates to an automatic assembly device of an electronic component and particularly relates to an automatic assembly line device for outputting a connector. A connector assembly automatic production line having cooperative dual robots comprises a workbench, a storage mechanism, a conveyor belt mechanism, a feed mechanism, a contact piece correction mechanism and a contact piece robot, wherein the storage mechanism is used for storing the connector; the conveyor belt mechanism is used for conveying the connector; the feed mechanism is used for placing the connector from the storage mechanism to the conveyor belt mechanism; the contact piece correction mechanism implements position correction on a contact piece; and the contact piece robot is used for picking up the contact piece from the contact piece correction mechanism and assembling the contact piece to an automatic clamping mechanism. According to the connector assembly automatic production line having the cooperative dual robots, the storage mechanism and the feed mechanism are utilized to guarantee a moving process of the connector to be smooth and controllable, a feed robot is utilized to finish the pickup of the connector, and the automatic clamping mechanism is utilized to implement centered positioning and fixing on the connector, and the contact piece robot is utilized to implement automatic correction and assembly on the contact piece.

Owner:苏州祥瑞凯机电设备有限公司

An automatic blanking processing system for electric vehicle suspension sheet metal parts

ActiveCN106563723BAutomated crawlingHeight adjustableMetal-working feeding devicesPositioning devicesSheet steelGear wheel

Owner:徐州格哩雅车业有限公司

Penetrating hammer grabbing device

PendingCN114655689AReduce structural complexityReduce volumeConveyor partsStructural engineeringDrill

The invention provides a penetrating hammer grabbing device. The penetrating hammer grabbing device comprises a movable platform, a drill rod, a guide rail, a penetrating hammer, a metal sensor, an attracted plate, a plug pin rod, an electromagnet and a spring. Two guide rails are symmetrically arranged on the two sides of the movable platform. The drill rod is connected with the penetrating hammer; the metal sensor is connected with the movable platform and used for monitoring the dynamic position of the penetrating hammer. Two sucked plates are symmetrically arranged on the two sides of the penetrating hammer and connected with bolt rods, and the bolt rods are used for lifting the penetrating hammer. The electromagnet is adjacent to the attracted plate, and the electromagnet is used for attracting the attracted plate according to a corresponding instruction so as to fix the bolt rod; the spring is connected with the attracted plate and used for tightly attaching the attracted plate rebounded to the preset position to the electromagnet. The operation of grabbing the penetrating hammer is completed through mutual cooperation of the small electromagnet, the metal sensor, the attracted plate and other main components, and it can be guaranteed that when the attracted plate rebounds to the designated position, the attracted plate and the small electromagnet are tightly attached through cooperation of the bolt rod and the spring.

Owner:北京市地质机械厂有限责任公司

A kind of workpiece dislocation grasping method

ActiveCN110255168BAutomated crawlingStacking articlesDe-stacking articlesEngineeringMechanical engineering

The invention relates to the technical field of feeding equipment, particularly relates to a workpiece dislocation grabbing method, and provides a device of the workpiece dislocation grabbing method. The workpiece dislocation grabbing method is used for grabbing left and right staggered workpieces and is based on two groups of clamping jaws which take the central axis of the whole stack of workpieces as the axis and are symmetrically arranged in the width direction of the whole stack of workpieces. The method comprises the following steps of acquiring the width difference a between a topmost-layer workpiece and the whole stack of workpieces; moving the clamping jaws in the width direction of the workpieces, and acquiring the moving distance b when the side edge of the topmost-layer workpiece is detected; comparing the moving distance b and the width difference a to obtain the deviation direction of the topmost-layer workpiece; and adjusting the clamping jaws to reach positions over the topmost-layer workpiece according to the deviation direction and the width difference a, and completing grabbing actions. By means of the technical scheme of the workpiece dislocation grabbing method, the technical problem that a workpiece cannot be automatically grabbed is solved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Plasma processing system and method for realizing remanufacturing processing of railway vehicle wheel handle

The invention relates to a plasma processing system and method for realizing remanufacturing processing of a railway vehicle wheel handle. The plasma processing system comprises a bottom plate, a three-jaw chuck used for clamping a wheel handle is arranged on the bottom plate, an ejector rod used for abutting against the three-jaw chuck is slidingly installed on the bottom plate, gun heads are distributed above the three-jaw chuck, a storage frame used for storing unrepaired wheel handles is arranged on the bottom plate, a discharging mechanism for driving the wheel handles to leave the storage frame is arranged in the storage frame, a support is arranged on the bottom plate, and a feeding device for grabbing the wheel handles in the storage frame to the three-jaw chuck is arranged in thesupport; and the method comprises the steps that a second motor drives a second swing rod to rotate, a first clamping plate and a second clamping plate are matched, and the wheel handles are driven toconduct automatic feeding and discharging. The swing rod is driven by the second motor to swing, a transverse plate can rotate by 90 degrees, the wheel handles are automatically grabbed, meanwhile, acam is driven by a first motor, the wheel handles are driven by a push plate to be unloaded from the storage frame and then matched with the first clamping plate and the second clamping plate on thetransverse plate, and continuous feeding and discharging can be achieved.

Owner:WUHU DINGHAN REMFR TECH

Electromagnetic fetching suction cup for machining of automotive brake bottom plate

ActiveCN106475484AAutomated crawlingRealize the feeding actionMetal-working feeding devicesPositioning devicesEngineeringManipulator

The invention discloses an electromagnetic fetching suction cup for machining of an automotive brake bottom plate. The electromagnetic fetching suction cup for machining of the automotive brake bottom plate comprises a plate horizontal-conveying belt, a rotary fetching manipulator, a feeding push air cylinder, a feeding push roller set, a first proximity switch and a second proximity switch. The rotary fetching manipulator comprises a rotary driving shaft, a rotary fetching swing arm, an angle adjustment turnplate and a magnetic fetching suction cup body, wherein one end of the rotary fetching swing arm is fixedly connected with the rotary driving shaft, the angle adjustment turnplate and an angle adjustment motor used for driving the angle adjustment turnplate to rotate are arranged at the other end of the rotary fetching swing arm, and the angle adjustment motor is connected with the angle adjustment turnplate through a rotary angle adjustment shaft; and the magnetic fetching suction cup body is parallel to the axis of the rotary angle adjustment shaft and rotates synchronously along with the angle adjustment turnplate around the rotary angle adjustment shaft. By adoption of the electromagnetic fetching suction cup for machining of the automotive brake bottom plate, automatic grabbing and feeding for steel plate blanking work can be achieved.

Owner:WUHU YUANSHAN MACHINERY MFG CO LTD

A lithium battery sorting manipulator device

InactiveCN105935663BRealize the function of comparison and error correctionAutomated crawlingSortingEngineeringManipulator

Owner:CHINA UNIV OF MINING & TECH

Automobile brake bottom plate electromagnetic chuck working method

ActiveCN106391894AAutomated crawlingRealize the feeding actionMetal-working feeding devicesPositioning devicesSheet steelDrive motor

The invention discloses an automobile brake bottom plate electromagnetic chuck working method. The working method comprises the following steps that an electromagnetic fetching chuck falls freely to the bottom of an angle adjusting turnplate under the action of gravity and is parallel to the horizontal plane, and then a rotary fetching swing arm rotates towards a horizontal plate conveying belt around a rotation driving rotary shaft till the electromagnetic fetching chuck makes contact with a raw steel plate on the horizontal conveying belt; the angle adjusting turnplate is driven to rotate by 180 degrees through an angle adjusting motor; and the rotary fetching swing arm is driven by a rotation driving motor to rotate towards the position between a feeding pushing air cylinder and a feeding pushing roller set, meanwhile, the angle adjusting turnplate is driven by the angle adjusting motor to rotate, the rotation angular speed of the rotary fetching swing arm is made to be identical to that of the angle adjusting turnplate, and the rotation direction of the rotary fetching swing arm is made to be opposite to that of the angle adjusting turnplate. By the adoption of the working method, automatic grabbing and feeding of steel plate blanking operation can be achieved.

Owner:WUHU YUANSHAN MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com