Robot telescopic arm

A telescopic arm and robot technology, applied in the field of robots, can solve problems such as hidden safety hazards, harsh working environment, frequent splashing of hot materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

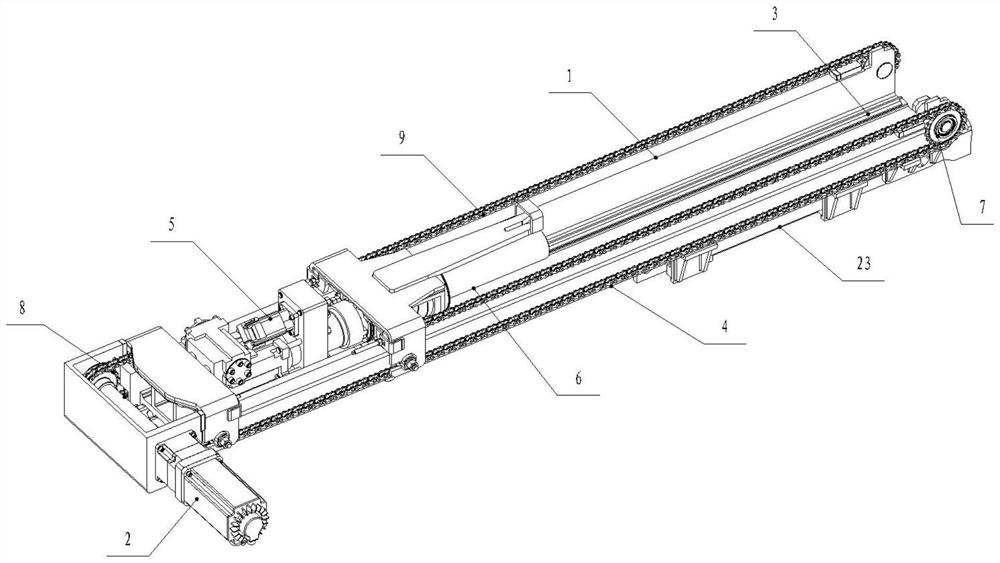

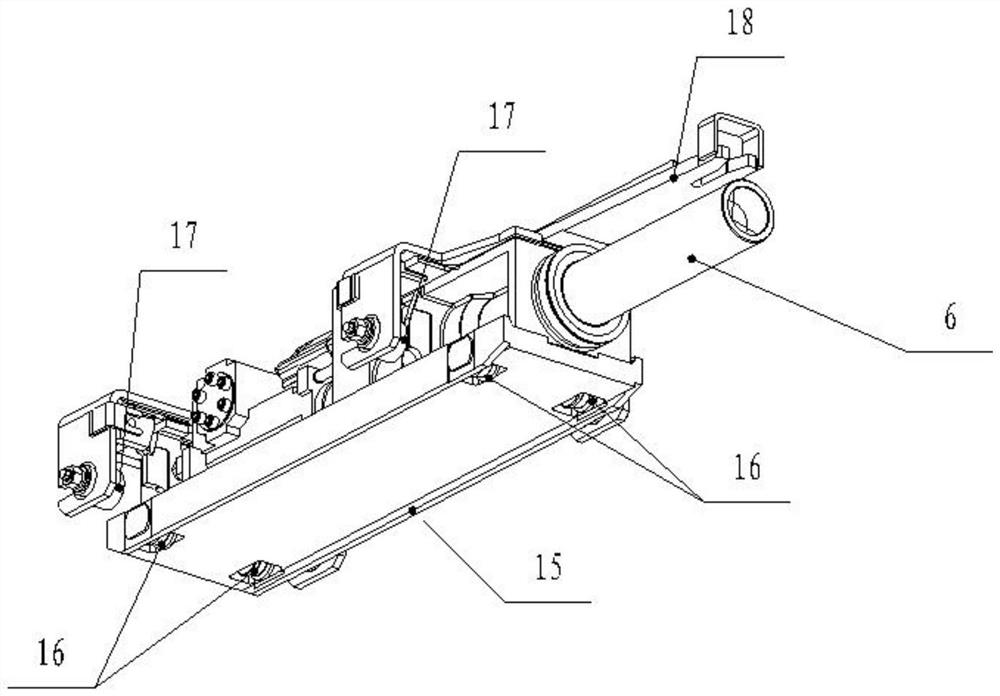

[0035] Embodiment 1: Combining Figure 1-Figure 10This embodiment will be described. A robotic telescopic arm of this embodiment includes a bracket assembly 1, a telescopic drive member 2, a guide rail 3, a telescopic transmission assembly 4, a mobile trolley 5 and a grabbing actuator 6. The upper part of the bracket assembly 1 is provided with There are guide rails 3, the bracket assembly 1 is connected with the moving trolley 5 through the guide rails 3, the rear end of the bracket assembly 1 is provided with a telescopic drive part 2, the bracket assembly 1 is connected with the telescopic transmission assembly 4, and the telescopic drive part 2 is connected with the telescopic transmission The assembly 4 is connected, the telescopic transmission assembly 4 is installed with the mobile trolley 5, the mobile trolley 5 is provided with a grabbing actuator 6, the number of the telescopic transmission assembly 4 is two groups, and the two sets of the telescopic transmission asse...

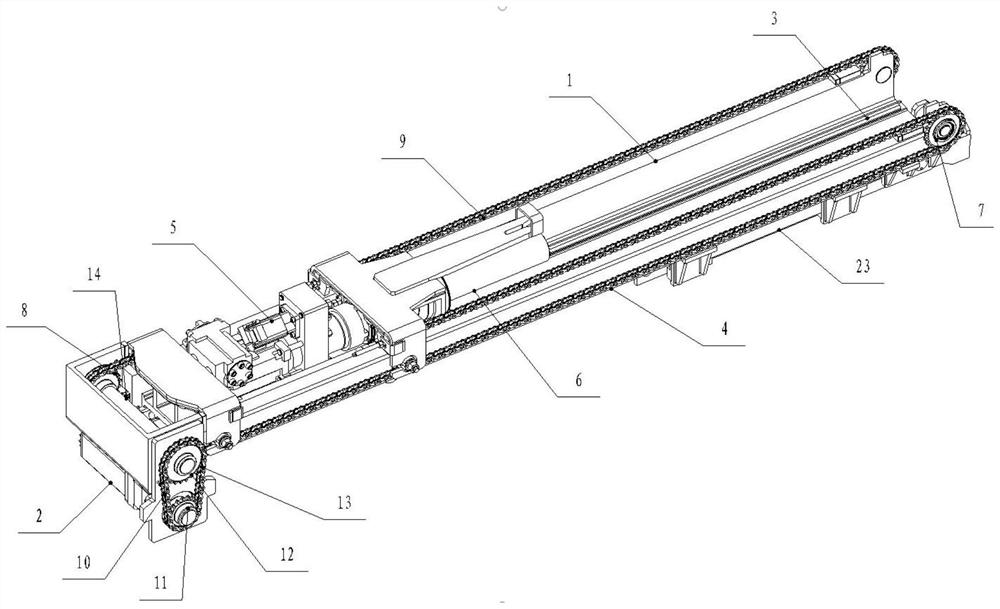

specific Embodiment approach 2

[0036] Specific implementation mode 2: Combining Figure 1-Figure 10 This embodiment will be described. A robotic telescopic arm of this embodiment includes a bracket assembly 1, a telescopic drive member 2, a guide rail 3, a telescopic transmission assembly 4, a mobile trolley 5 and a grabbing actuator 6. The upper part of the bracket assembly 1 is provided with There are guide rails 3, the bracket assembly 1 is connected with the moving trolley 5 through the guide rails 3, the rear end of the bracket assembly 1 is provided with a telescopic drive component 2 and a first-level telescopic transmission assembly 10, and the bracket assembly 1 is connected with the telescopic transmission assembly 4, The first-level telescopic transmission assembly 10 is respectively established and installed with the telescopic drive component 2 and the telescopic transmission assembly 4, and the telescopic transmission component 4 is established and installed with the mobile trolley 5. The mobil...

specific Embodiment approach 3

[0037] Specific implementation three: combination Figure 1-Figure 10 This embodiment will be described. A robotic telescopic arm of this embodiment includes a bracket assembly 1, a telescopic drive member 2, a guide rail 3, a telescopic transmission assembly 4, a mobile trolley 5 and a grabbing actuator 6. The upper part of the bracket assembly 1 is provided with There are guide rails 3, the bracket assembly 1 is connected with the moving trolley 5 through the guide rails 3, the rear end of the bracket assembly 1 is provided with a telescopic drive component 2 and a first-level telescopic transmission assembly 10, and the bracket assembly 1 is connected with the telescopic transmission assembly 4, The first-level telescopic transmission assembly 10 is respectively established and installed with the telescopic drive component 2 and the telescopic transmission assembly 4, and the telescopic transmission component 4 is established and installed with the mobile trolley 5. The mobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com