Multi-station movable robot clamp

A robot fixture and multi-station technology, applied in the field of robot application technology and packaging, to meet market demand, the structure of the displacement mechanism is simple and reasonable, and the structure is compact and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

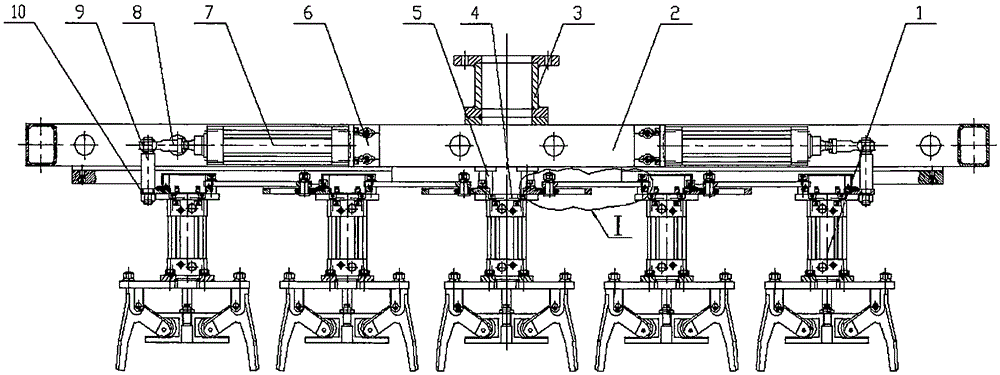

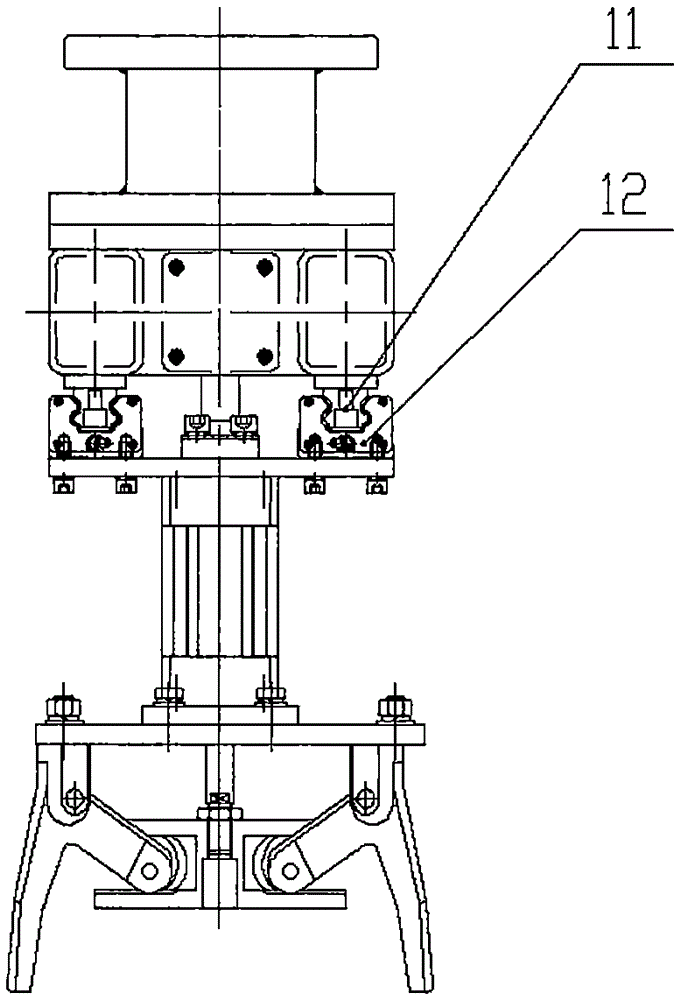

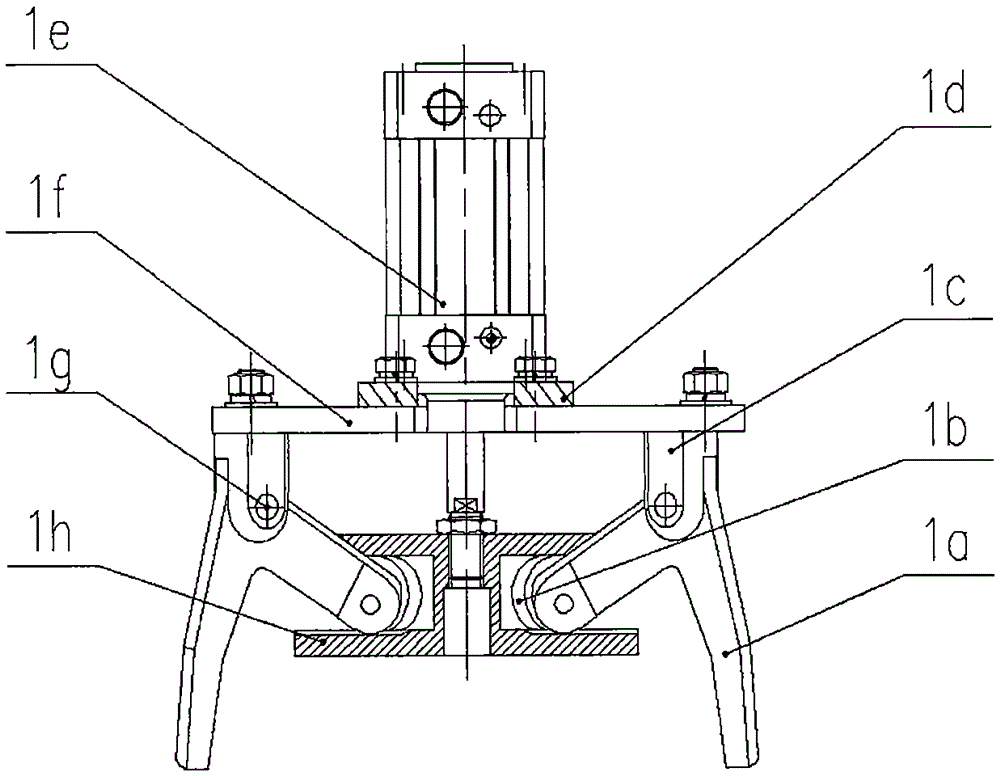

[0021] Such as Figures 1 to 5 As shown, a multi-station displaceable robot clamp of the present invention mainly includes N groups of clamping grippers 1 (N=5 in this embodiment), mounting bracket 2, robot connecting flange 3, gripper connection Plate 4, connecting column 5, cylinder mounting seat 6, shifting cylinder 7, floating joint 8, connecting strut 9, drive plate 10, slide rail 11, N-1 group slider 12, N-1 group shifting component, etc. part. One group of grippers 1 is fixed and screwed to the gripper connection plate 4, and the gripper connection plate 4 is fixed and screwed to the middle and lower part of the installation bracket 2 through the connection column 5, and the two sets of slide rails 11 are parallel and symmetrically installed on the installation bracket 2, four sets of sliders 12 are symmetrically placed on the slide rail 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com