Flexible adjustable manipulator for catching high-temperature steel plate

An adjustable, manipulator technology, applied in the field of hot stamping, can solve the problems of no manipulator, high cost, narrow range of use, etc., and achieve the effect of reducing extrusion deformation and compensating for brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

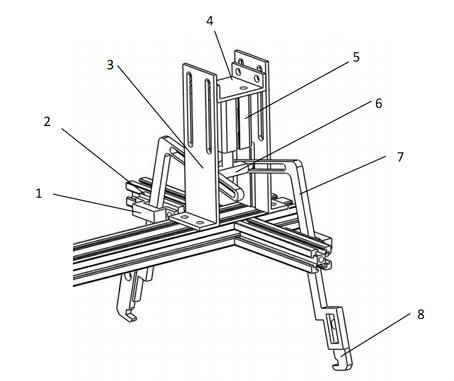

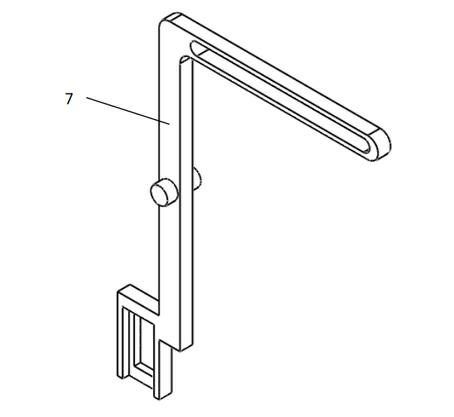

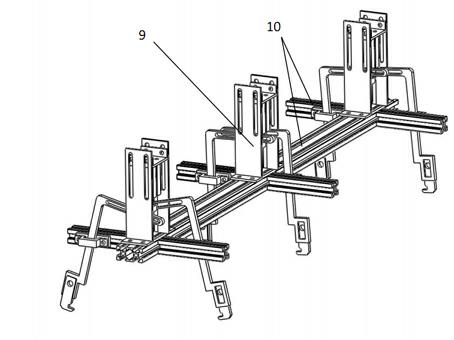

[0021] Such as image 3 As shown, the gripper is composed of several pairs of finger movement assemblies 9, and the number and installation positions of the pair finger movement assemblies 9 are determined according to the specific blank size. Such as figure 1 As shown, the cylinder bracket 2 is fixed on the aluminum profile frame, and there are long holes on the cylinder bracket to facilitate the installation of the cylinder base 4. A short cylinder with a compact structure is used as the power source, and a driving pin is installed on the head of the cylinder to drive the opening of the finger. swing together. There is a swivel pin in the middle section of the finger connector 7, which is embedded in the holes on the swivel bracket 1 and the swivel bracket base, and the cylinder connector 7 can swing by the swivel pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com