Powder metallurgy robot and its grasping method

A technology of powder metallurgy and robotics, applied in the field of robotics, can solve problems such as increased labor costs and low efficiency, and achieve the effect of automatic grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

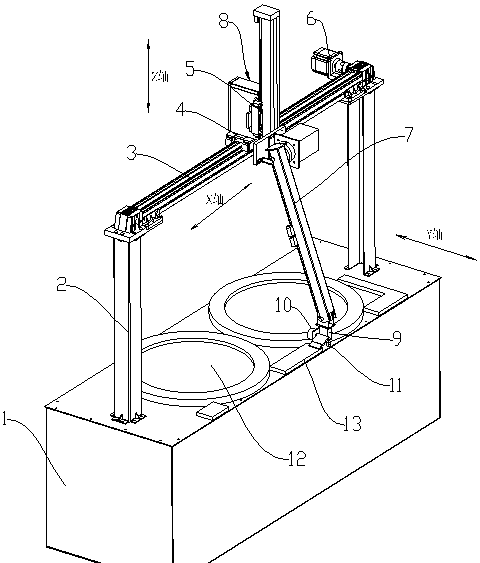

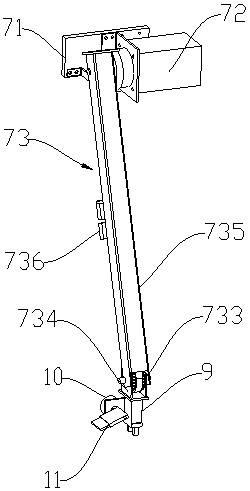

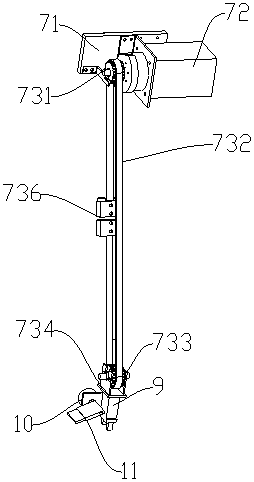

[0030] like figure 1 As shown, it is a schematic structural diagram of a powder metallurgy robot in a preferred embodiment of the present invention, including a workbench 1, inside the workbench 1 is an electrical cabinet for the robot control system, and two brackets 2 are installed on the surface of the workbench 1, and the X-axis is horizontal The sliding rail 3 is installed on the two brackets 2, and the horizontal sliding rail seat 4 is installed on the X-axis horizontal sliding rail 3, and the Z-axis mobile sliding rail 5 is installed on the horizontal sliding rail seat 4. One end of the traversing slide rail 3 is installed with a first motor 6, and the first motor 6 drives the traversing slide rail seat 4 to reciprocate on the X-axis traversing slide rail 3, thereby driving the Z-axis moving slide rail 5 to move horizontally on the X-axis. Move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com