Clamping device for manipulator

A technology of manipulators and grippers, which is applied in the field of manipulator gripping devices, can solve the problems of unfavorable production capacity improvement, energy saving and emission reduction, inconvenient installation, commissioning and transportation, and bulky volume, etc., to improve production capacity and production efficiency, with simple structure and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

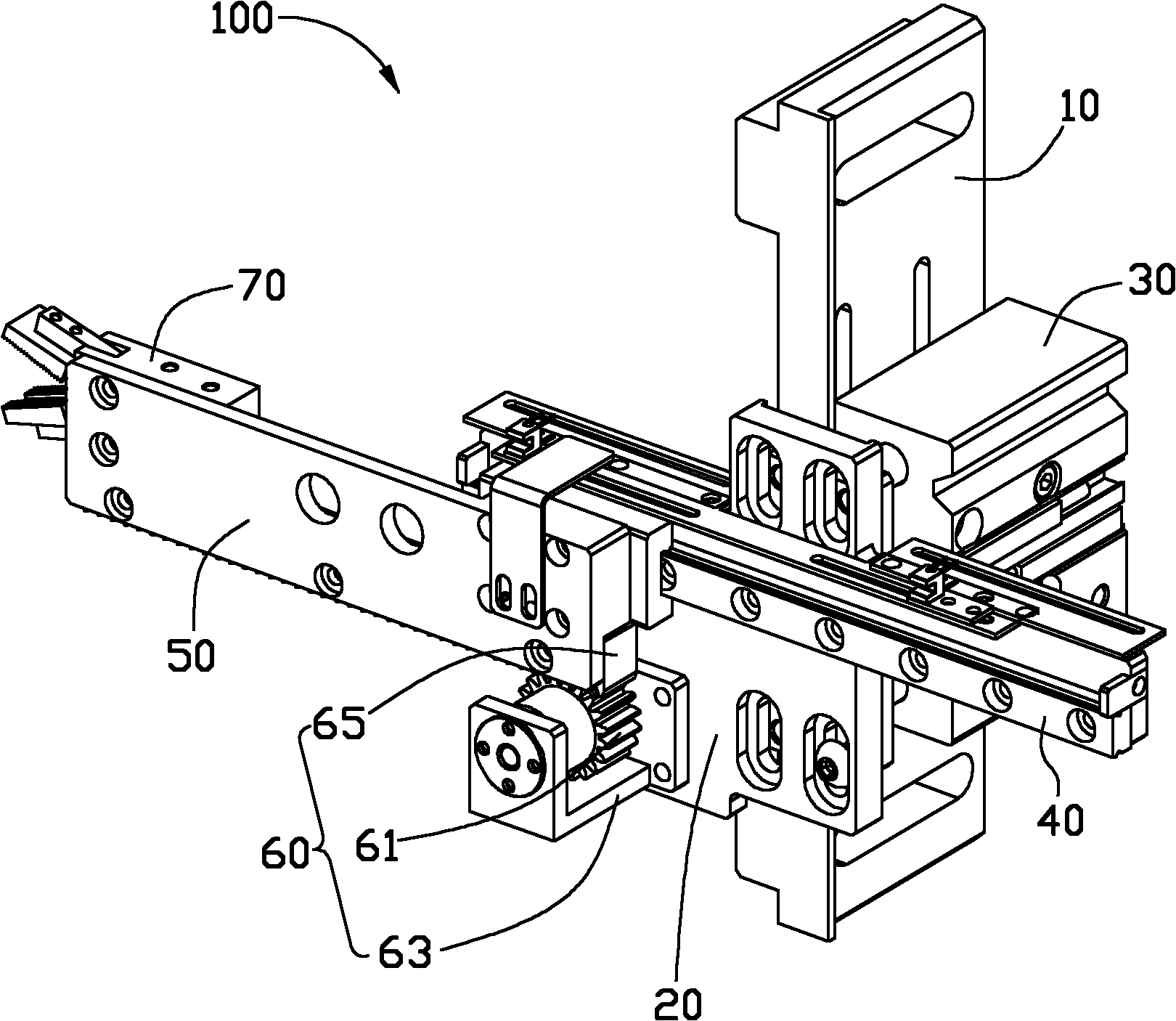

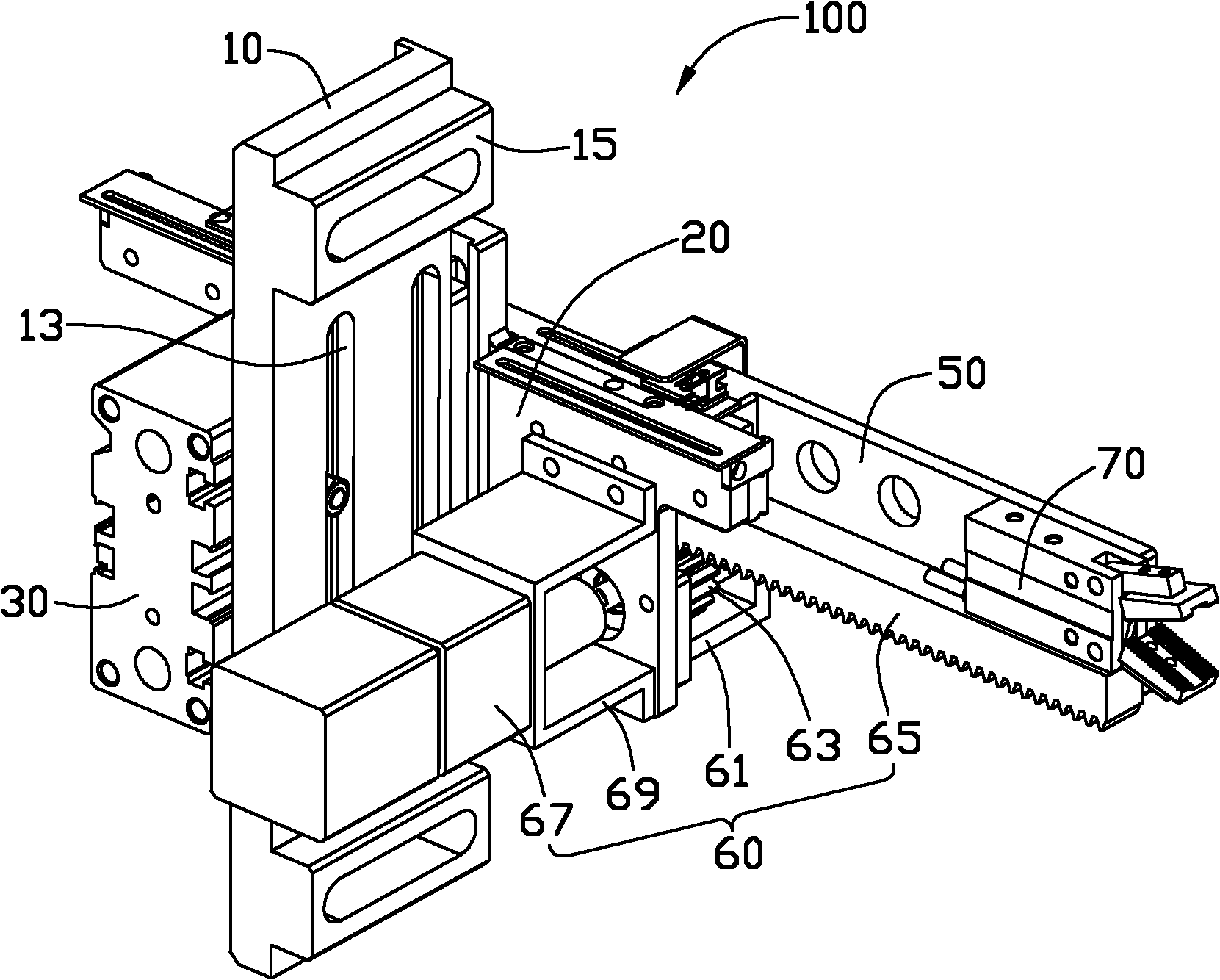

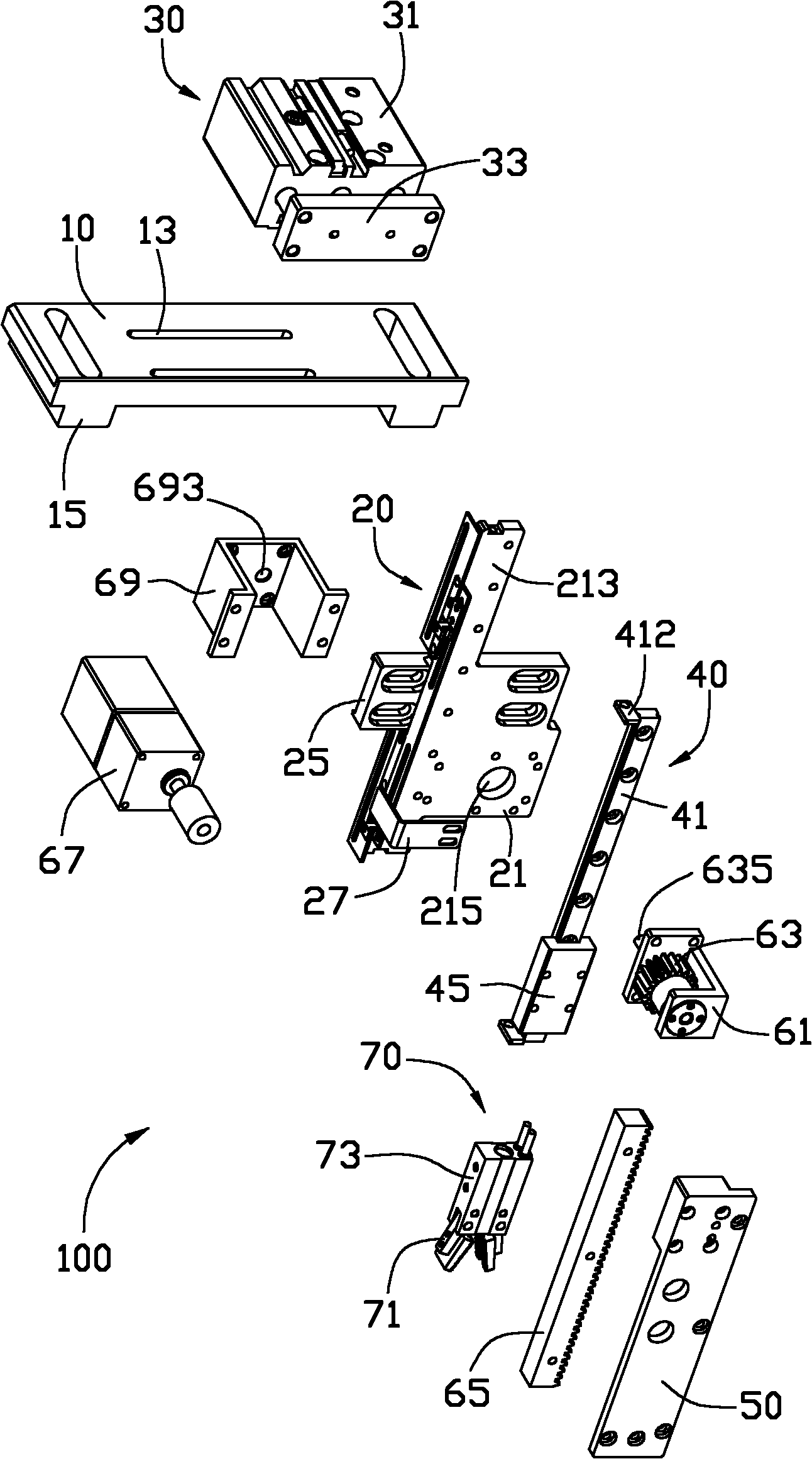

[0013] see figure 1 and figure 2 , the manipulator clamping device of the present invention is a preferred embodiment of the manipulator clamping device 100 applied in a molding equipment (not shown). The manipulator gripping device 100 can extend into the forming equipment to grip the formed workpiece and take out the gripped workpiece.

[0014] The manipulator gripping device 100 includes a support base 10 , a mounting frame 20 , an elevating driving device 30 , a sliding mechanism 40 , a connecting plate 50 , a horizontal driving device 60 and a jaw device 70 . The support base 10 is substantially perpendicular to the installation frame 20 . The installation frame 20 is driven by the lifting driving device 30 and is slidably installed with the support base 10 along a first direction (eg, vertical direction). The sliding mechanism 40 is installed on the mounting frame 20 and connected with the connecting plate 50, so that the connecting plate 50 and the mounting frame 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com