Penetrating hammer grabbing device

A technology for grabbing devices and through-holes, applied in the field of dynamic penetration testing, which can solve the problems of time-consuming and labor-intensive operations, complex overall structure of the penetrating hammer grabbing device, and low degree of automation, so as to achieve high portability and reduce the complexity of the overall structure , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

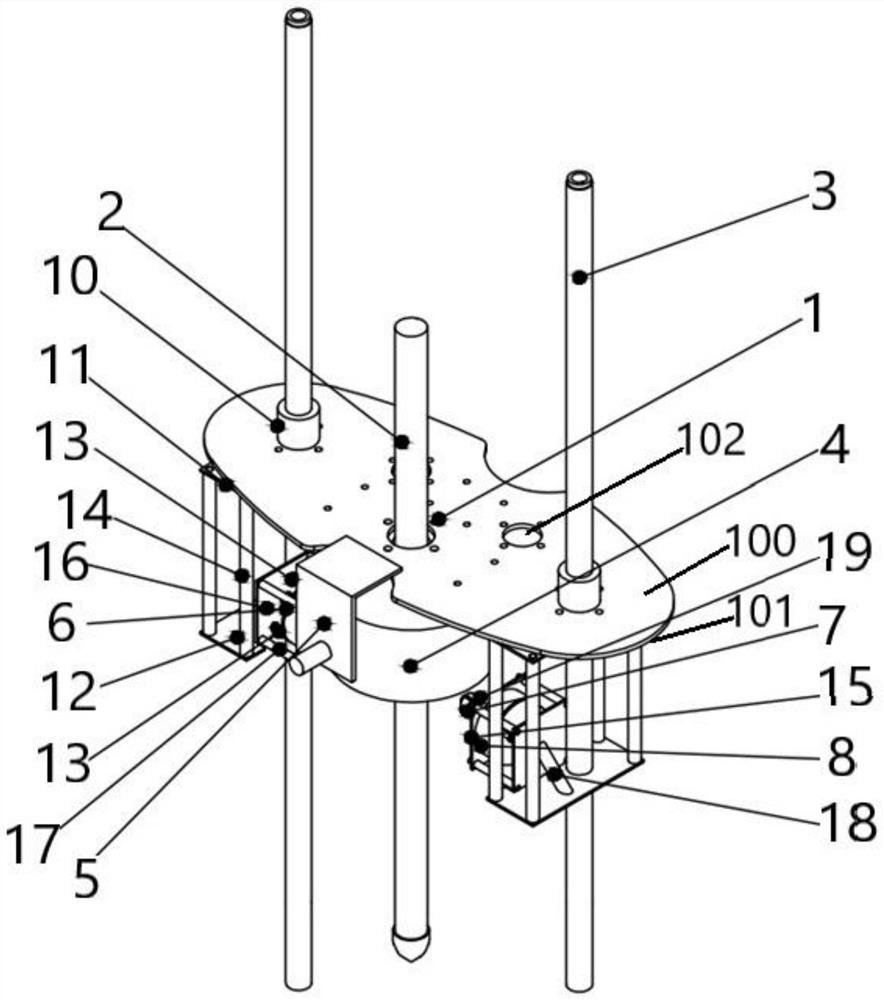

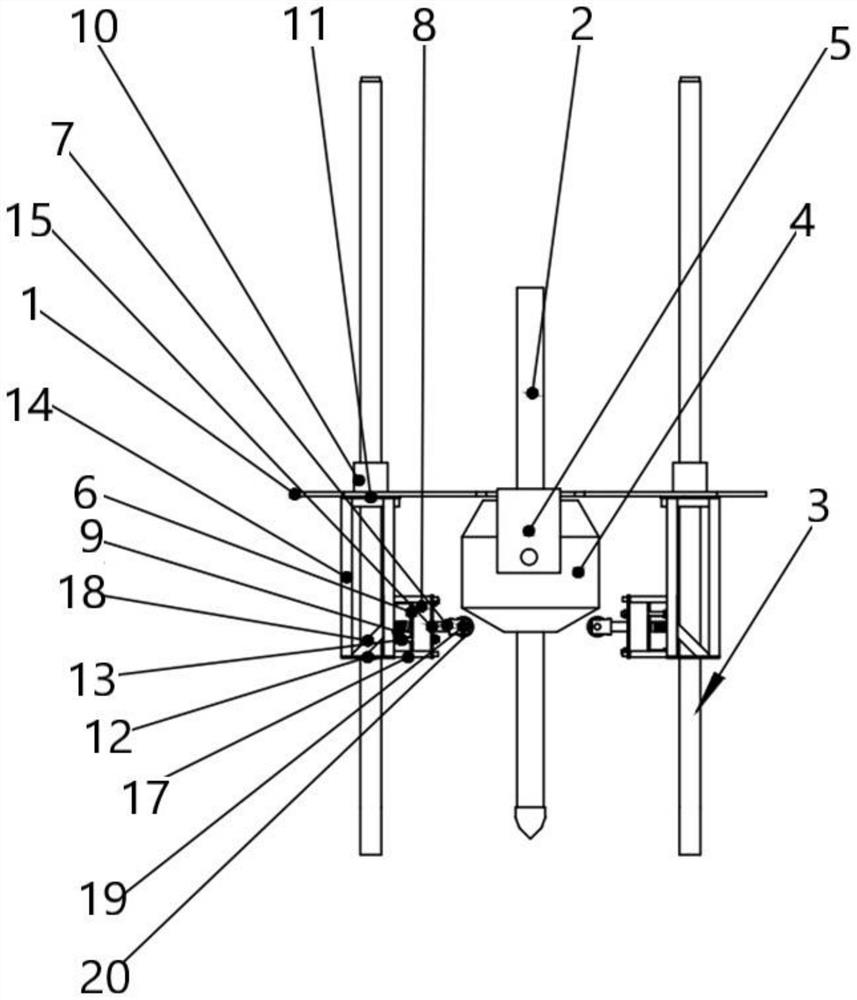

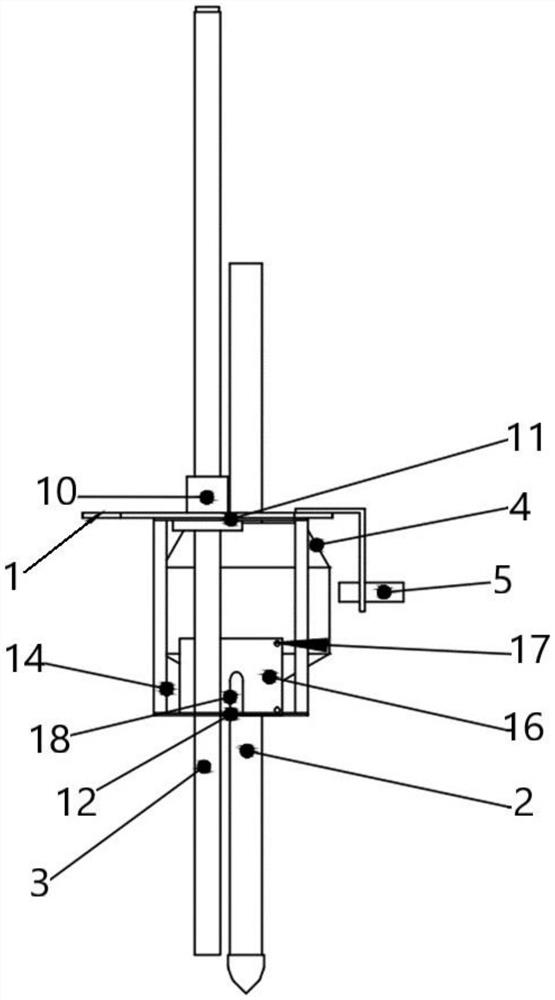

[0048] like Figure 1 to Figure 3 As shown, Embodiment 1 provides a penetrating hammer grabbing device, and the penetrating hammer grabbing device includes:

[0049] Moving platform 1, drill rod 2, guide rail 3, penetration hammer 4, metal sensor 5, sucked plate 6, latch rod 7, electromagnet 8 and spring 9;

[0050] Wherein, two guide rails 3 are symmetrically arranged on both sides of the moving platform 1, and the moving platform 1 is slidably connected with the guide rails 3;

[0051] The drill rod 2 is arranged in the middle of the moving platform 1, and is detachably connected with the penetration hammer 4;

[0052] The metal sensor 5 is fixedly connected to the moving platform 1 for real-time monitoring of the dynamic position of the penetration hammer 4;

[0053] The two sucked plates 6 are symmetrically arranged on both sides of the through hammer 4, and the sucked plates 6 are fixedly connected with the latch rod 7;

[0054] There are two latch rods 7 for lifting t...

Embodiment 2

[0076] The present application provides a terminal device, including a memory, a processor, and a computer program stored in the memory and running on the processor. When the processor executes the computer program, the control mechanism in Embodiment 1 is implemented. steps of a software program.

Embodiment 3

[0078] The present application provides a computer-readable storage medium, where the computer-readable storage medium stores a computer program, and when the computer program is executed by a processor, implements the steps of the software program in the control mechanism of Embodiment 1.

[0079] This application works as follows:

[0080] When the movable platform 1 grabs the penetrating hammer 4, the penetrating hammer 4 is divided into an upper end face and a lower end face, both of which are conical surfaces. At this time, the electromagnet 8 is not energized. 7 moves to the lower end face of the penetrating hammer. At the same time, the moving platform 1 stops moving downward under the control of the metal sensor 5, and uses a mobile power source, namely a battery, to continuously supply power to the electromagnet 8, and the electromagnet 8 absorbs the sucked plate 6. After the electromagnet 8 adsorbs the sucked plate 6 , the metal sensor 5 controls the moving platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com