Workpiece positioning method, workpiece positioning device and groove cutting workstation

A positioning method and technology for positioning position, which can be applied to workpiece clamping devices, manufacturing tools, manipulators, etc., can solve problems such as limited positioning accuracy of workpieces, and achieve the effects of ensuring accuracy, eliminating positioning errors, and accurate positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

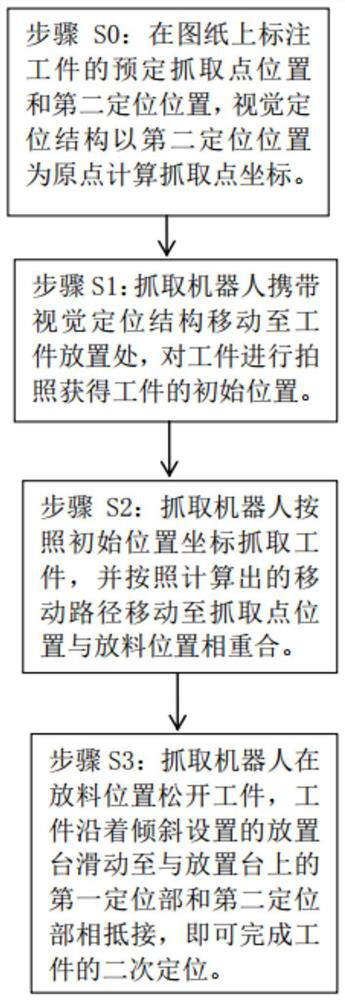

[0043] Such as figure 1 and 2 A specific implementation of the workpiece positioning method shown includes:

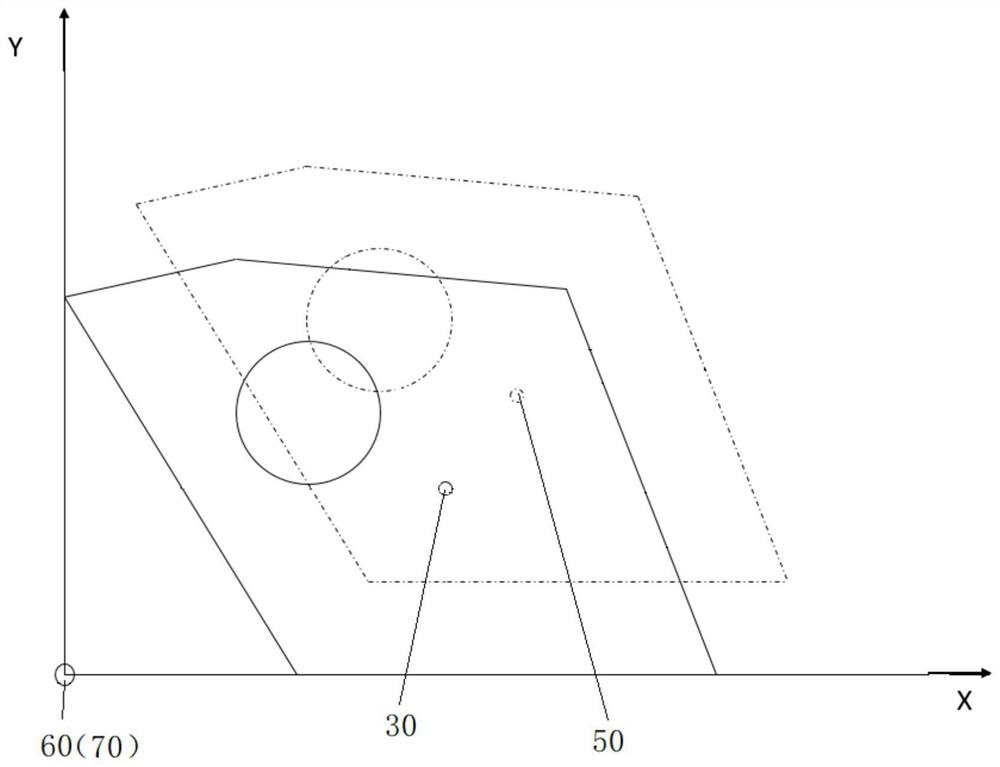

[0044] Step S0: mark the position of the predetermined grabbing point 30 and the second positioning position 70 of the workpiece on the drawing, and the visual positioning structure 20 calculates the coordinates of the grabbing point with the second positioning position 70 as the origin;

[0045] Set the first positioning position 60 on the placing table 40, when the workpiece is set on the placing table 40, the first positioning position 60 and the second positioning position 70 coincide;

[0046] Calculate the predetermined discharge position 50 coordinates of the workpiece on the placement table 40, take the first positioning position 60 as the origin, take the extension direction of the first positioning part 41 and the extension direction of the second positioning part 42 as coordinate axes to establish a coordinate system, by The coordinates of the grabbing poi...

Embodiment 2

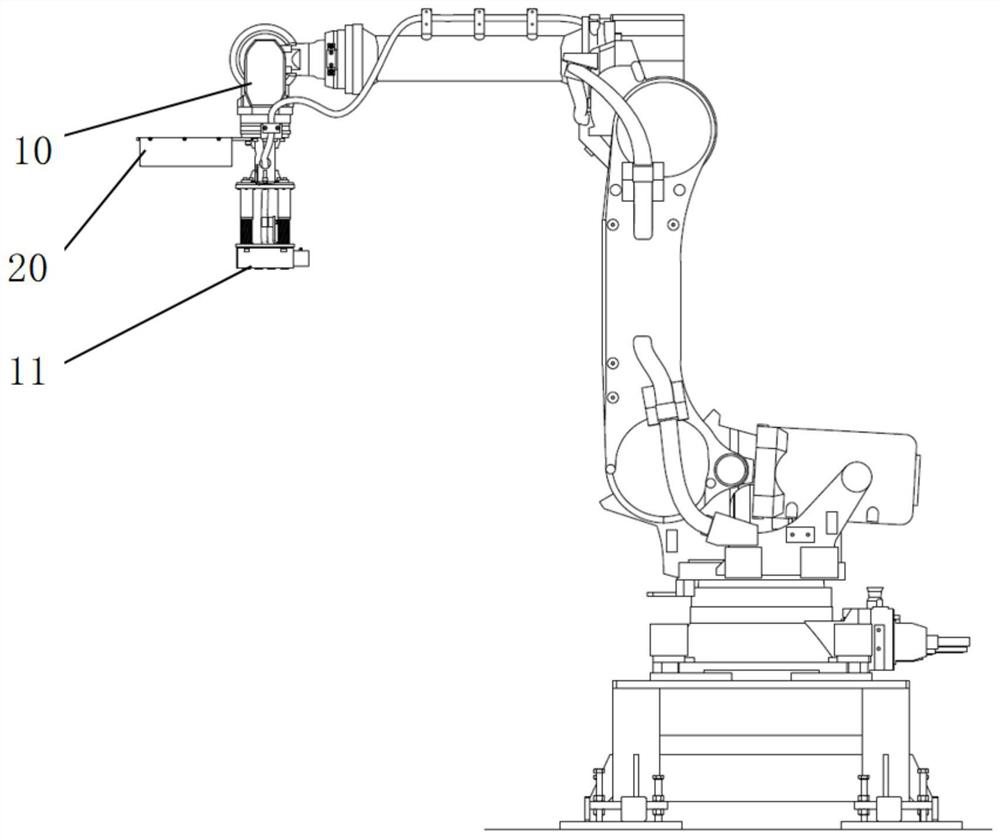

[0059] Such as image 3 and 4 A specific implementation manner of the workpiece positioning device shown includes: a grabbing robot 10 , a visual positioning structure 20 and a placement table 40 . The visual positioning structure 20 is arranged on the grasping robot 10 , and is used for identifying and locating the initial position of the workpiece and calculating the moving path of the grasping robot 10 . The placing table 40 is provided with a first positioning part 41 and a second positioning part 42 , the first positioning part 41 and the second positioning part 42 are arranged at an angle, and the placing table 40 is arranged obliquely.

[0060] The workpiece is initially positioned by setting the visual positioning structure 20, and then the first positioning part 41 and the second positioning part 42 on the placement table 40 are used for secondary positioning. Through the secondary positioning, the positioning error of the visual positioning structure 20 is eliminate...

Embodiment 3

[0069] This embodiment provides a specific implementation of the bevel cutting workstation, which includes the above-mentioned workpiece positioning device and a cutting platform. The grabbing robot 10 places the workpiece on the placement table 40 on the cutting platform according to the predetermined grabbing point 30 . The workpiece after secondary positioning is grabbed and placed on the cutting platform for cutting and processing, and the processing of the workpiece is more accurate.

[0070] To sum up, the workpiece positioning method provided in this embodiment uses the visual positioning structure to grasp the workpiece to perform preliminary positioning on the handling of the workpiece, and then places the workpiece on the placement table, using the first positioning part and the The second positioning part performs secondary positioning on the workpiece. Through the secondary positioning, the positioning error of the visual positioning structure is eliminated, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com