Automatic blanking processing system for sheet metal parts of suspensions of electric vehicles

A processing system and sheet metal parts technology, which is applied in the field of automatic blanking processing system of electric vehicle suspension sheet metal parts, can solve the problems of high labor intensity, unfavorable steel plate position and feeding progress, low operation efficiency, etc., and achieve low labor intensity , Improve the efficiency of processing operations, the effect of high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

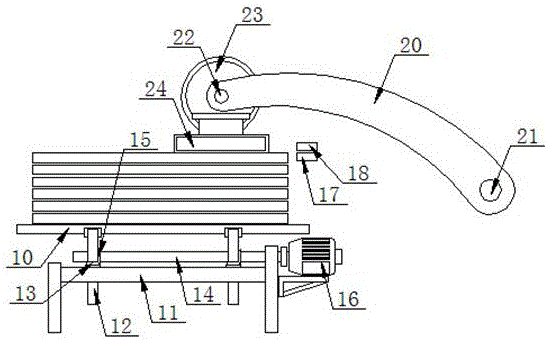

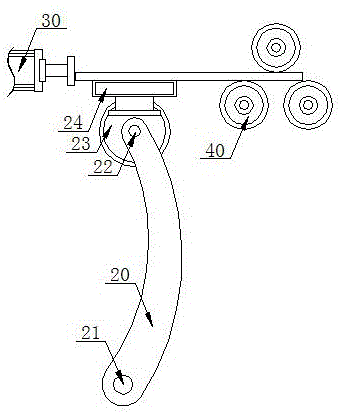

[0016] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as Figure 1 to Figure 2 As shown, an automatic blanking processing system for electric vehicle suspension sheet metal parts includes a plate lifting support platform 10 and a rotary pick-up swing arm 20; a fixed support base 11 is provided below the plate lifting support platform 10, and the The bottom of the plate lifting support platform 10 is fixed and vertically provided with a plurality of lifting support screw rods 12, and the fixed support base 11 is provided with a plurality of axially vertically arranged screw rod installation through holes, and each of the screw rods is installed A lifting support screw 12 is arranged in the through hole, and a screw lifting gear 13 is also arranged on each of the screw mounting through holes. The lifting gear 13 of the screw is a ring structure and is sleeved on the I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com