Insulation board laying device for floor heating

A technology for laying devices and insulation boards, which is applied in the direction of construction and building construction, can solve the problems of large tidal volume, high labor intensity of workers, and low efficiency, and achieve the effects of improving work efficiency, improving work effect, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The application will be described in further detail below in conjunction with the accompanying drawings.

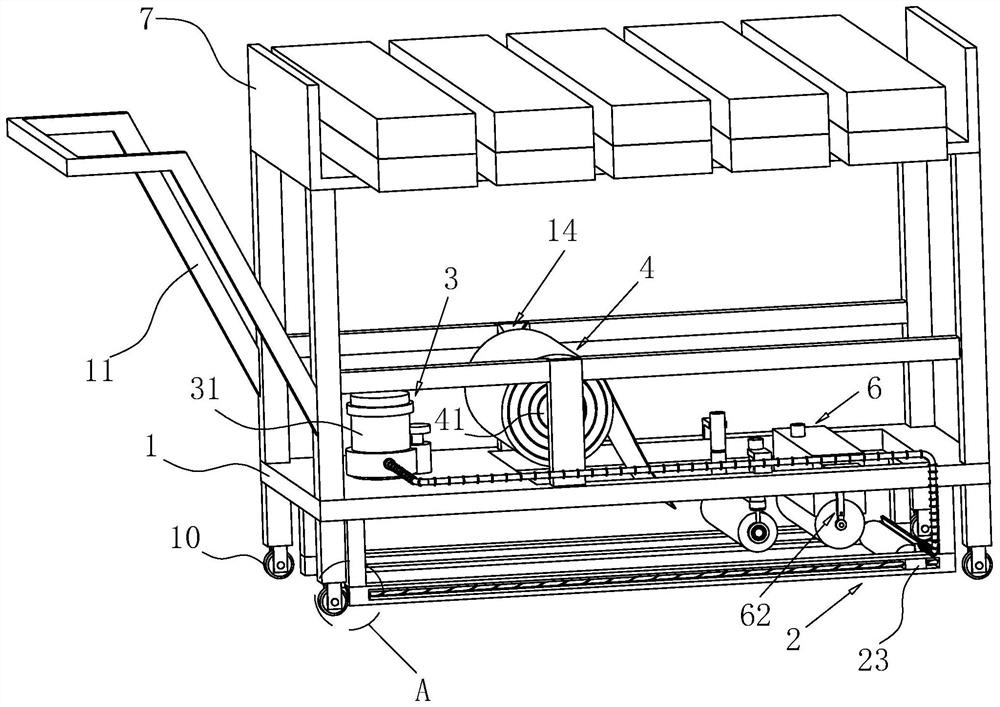

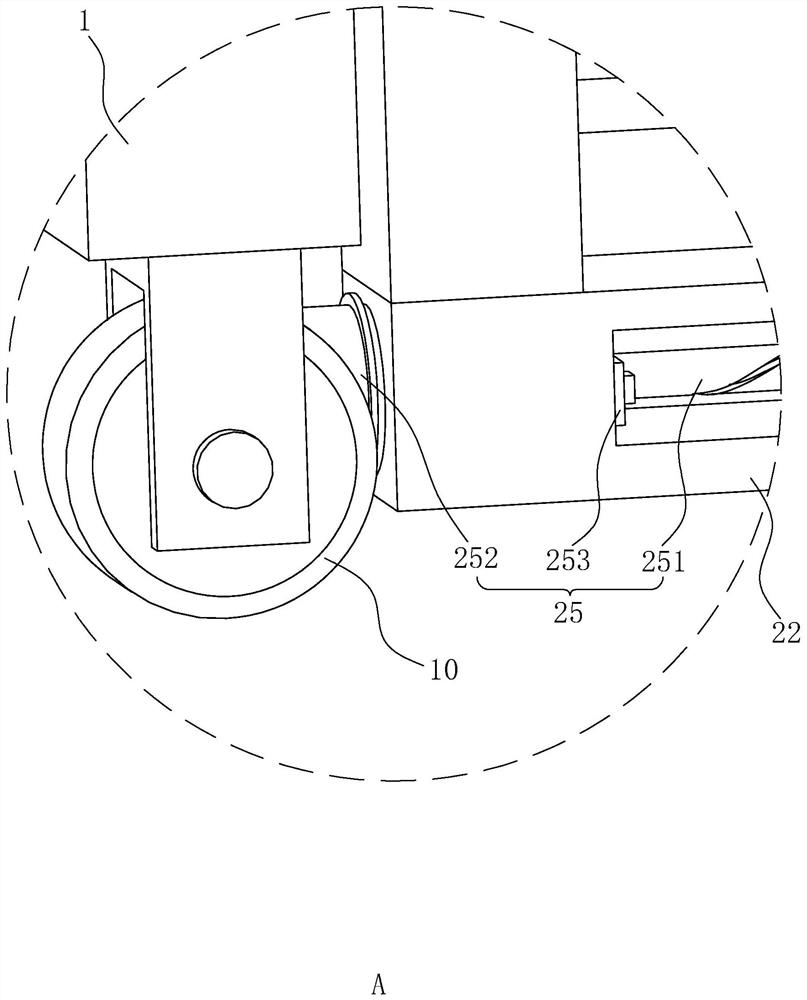

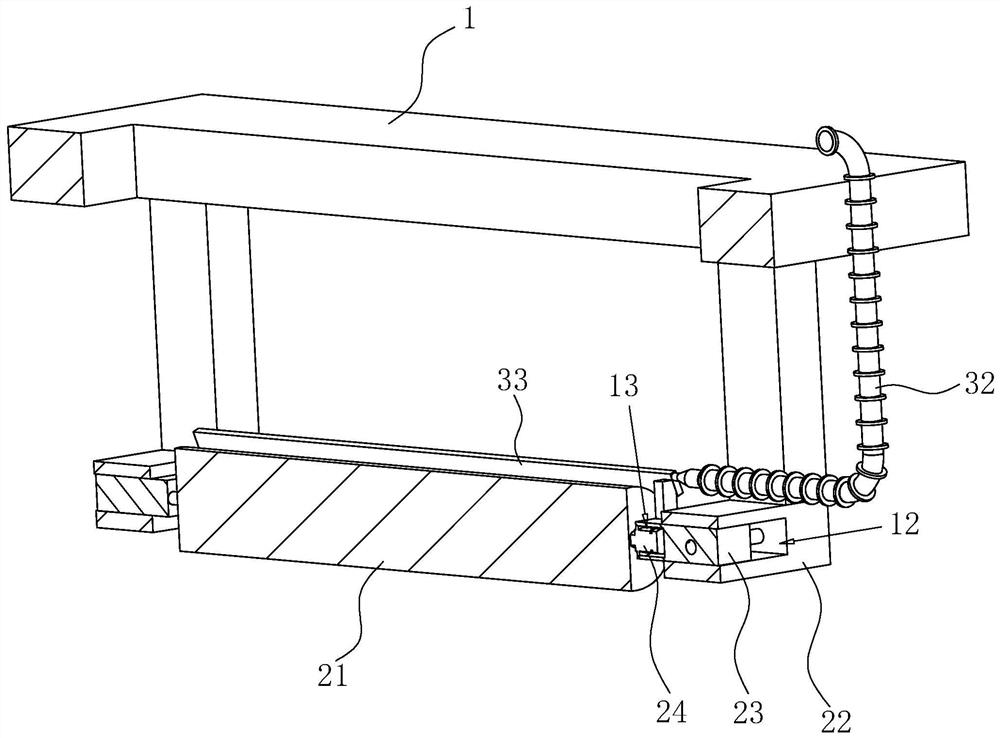

[0031] The embodiment of the present application discloses a device for laying insulation boards for floor heating, such as figure 1 As shown, it includes a mobile frame 1 that can be moved. The bottom of the mobile frame 1 is provided with rollers 10 to facilitate sliding of the mobile frame 1. One side of the mobile frame 1 is provided with a push handle 11 to facilitate the movement of the mobile frame 1. Simple Convenient; the top of the mobile frame 1 is provided with a placement box 7 for stacking insulation boards, and the top opening of the placement box 7 is set. Since the length of the insulation boards for floor heating is mostly longer, the two sides of the placement box 7 are set through to facilitate the placement of longer Insulation board, some insulation boards are stacked in the placement box 7, so that the laying of the insulation board is carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com