A nest connector and its manufacturing method

A technology of connectors and cells, which is applied in the field of connectors connecting honeycomb restraint systems or geocell cells, can solve the problems of no anchoring effect, difficult cutting or drilling, and heavy workload, etc., and achieves good connection effect , wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

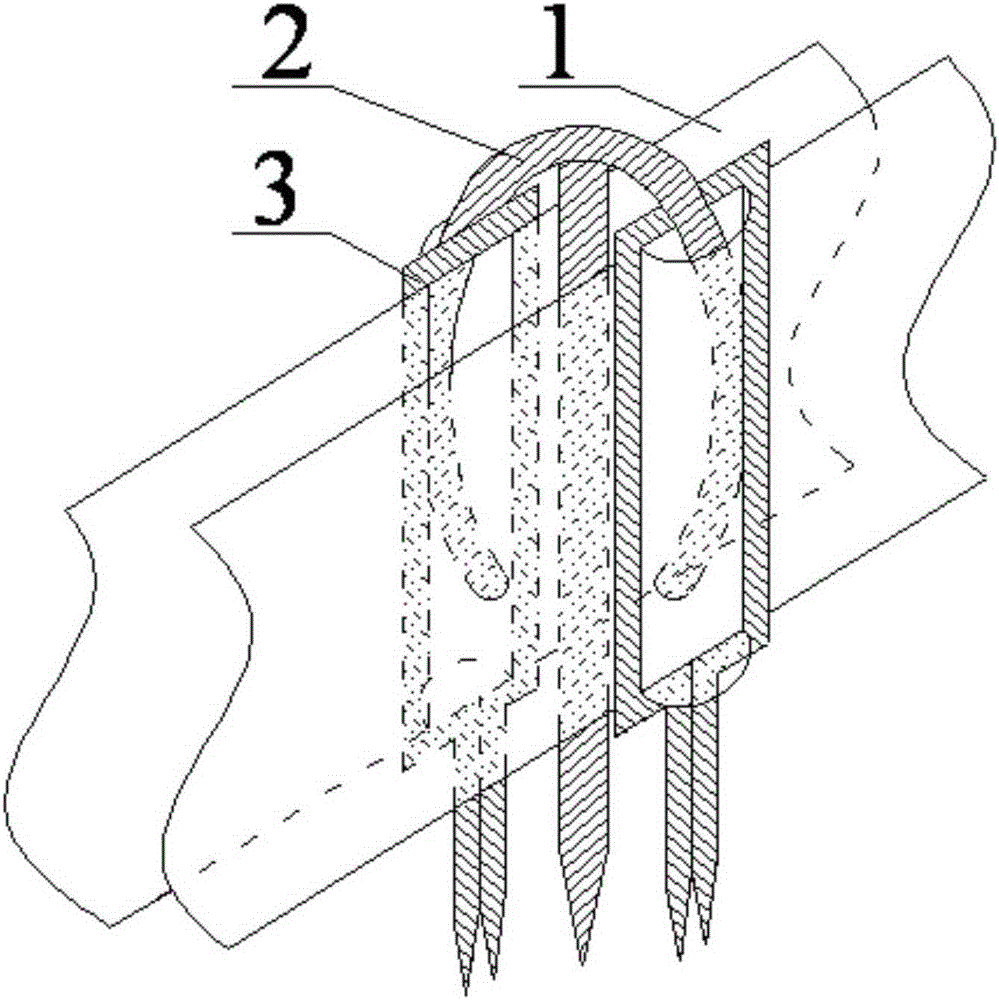

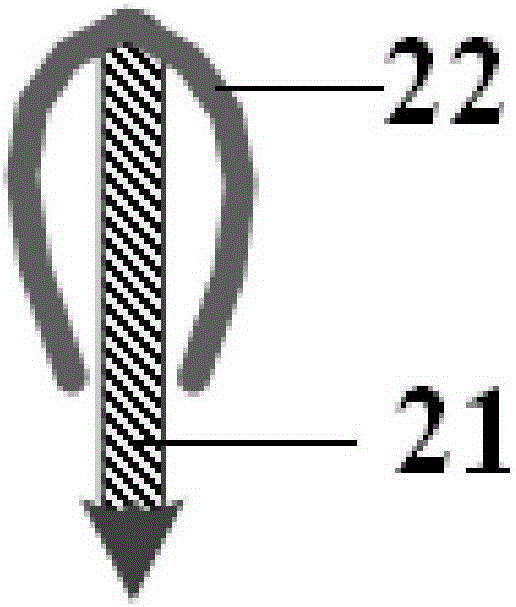

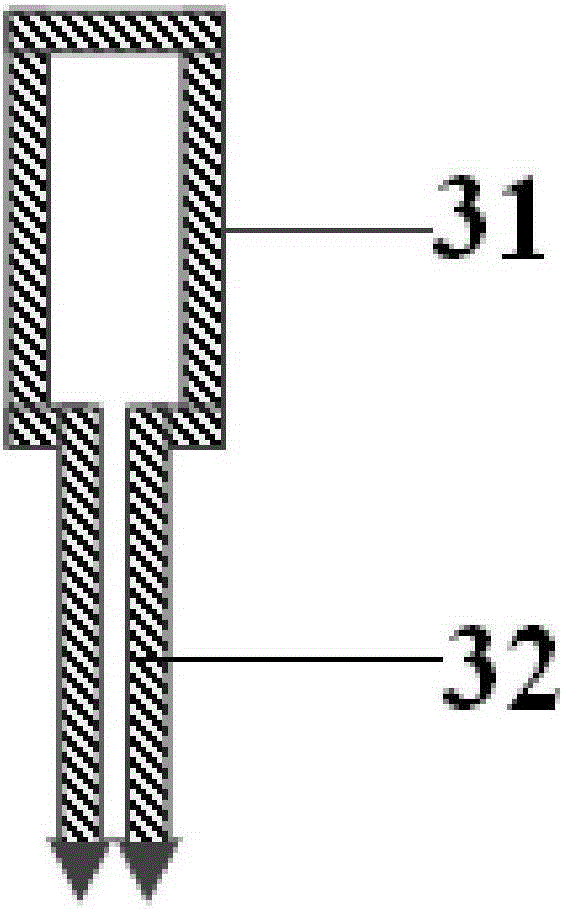

[0027] The cell connector provided by the invention has a structure such as figure 1 As shown, it includes two collars 3 parallel to each other and an insert 2 connecting the two collars; the structure of the insert is as follows figure 2 As shown, it includes a main rod 21 and an arc-shaped shrinking buckle 22 with an opening. The main rod passes through the opening and is embedded in the arc-shaped shrinking buckle, and its upper end is fixedly connected with the arc-shaped shrinking buckle. The rod is symmetrical, and two pin arms are formed on both sides of the main rod, and the bottom ends of the two pin arms shrink toward the opening to form a constriction; the structure of the collar is as follows image 3 As shown, the upper half of the collar is a square frame 31, the lower half is an anchor rod 32, the upper end of the anchor rod is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com