Rapid asphalt paving and maintaining device based on municipal road engineering

A technology for municipal roads and maintenance devices, which is applied to roads, roads, and road repairs, etc., can solve problems such as slowing down of running speed, slow paving speed of asphalt paver, and different thickness of paving materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

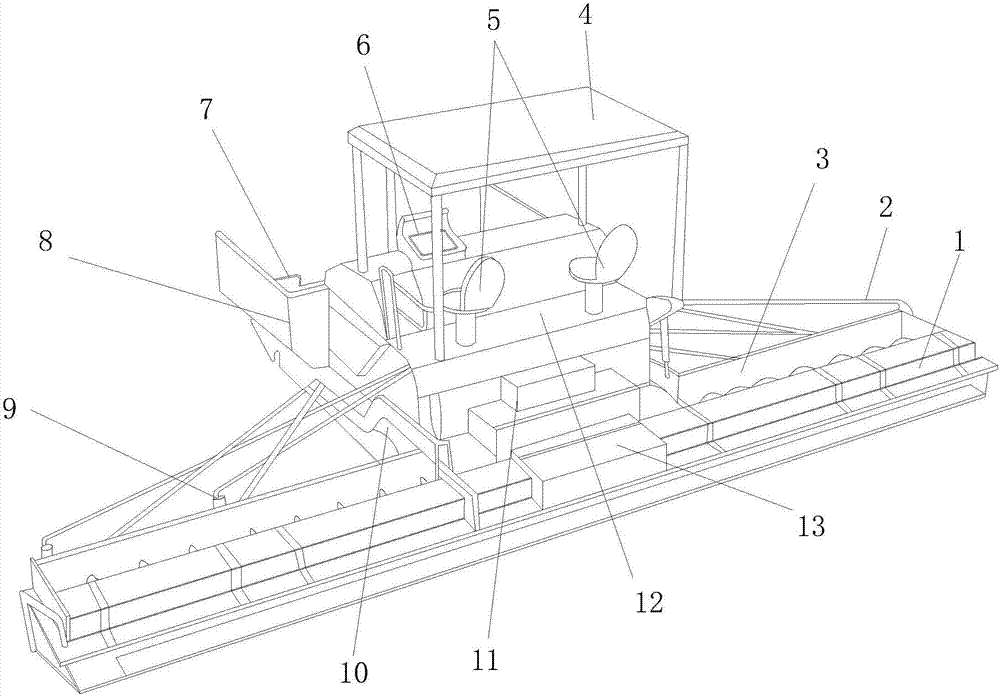

[0038] see Figure 1-Figure 5 , the present invention provides a quick asphalt paving and maintenance device based on municipal road engineering, its structure includes a paving mechanism 1, a control rod 2, a screed 3, a cover roof 4, a seat 5, a device operating platform 6, and a material pushing roller 7 , Hopper 8, connecting column 9, screw distributor 10, pedal 11, standing platform 12, middle connecting block 13.

[0039] The paving mechanism 1 is located at the front end of the covered ceiling 4, the paving mechanism 1 is mechanically connected to the device operating platform 6 through the control rod 2, and the screw distributor 10 is located at the bottom of the standing platform 12 and connected to the hopper 8 In communication, the other end of the screw distributor 10 communicates with the paving mechanism 1, the screed 3 is installed at the rear end of the paving mechanism 1, and the front end of the standing platform 12 is also fixed with a pedal 11, so A seat...

Embodiment 2

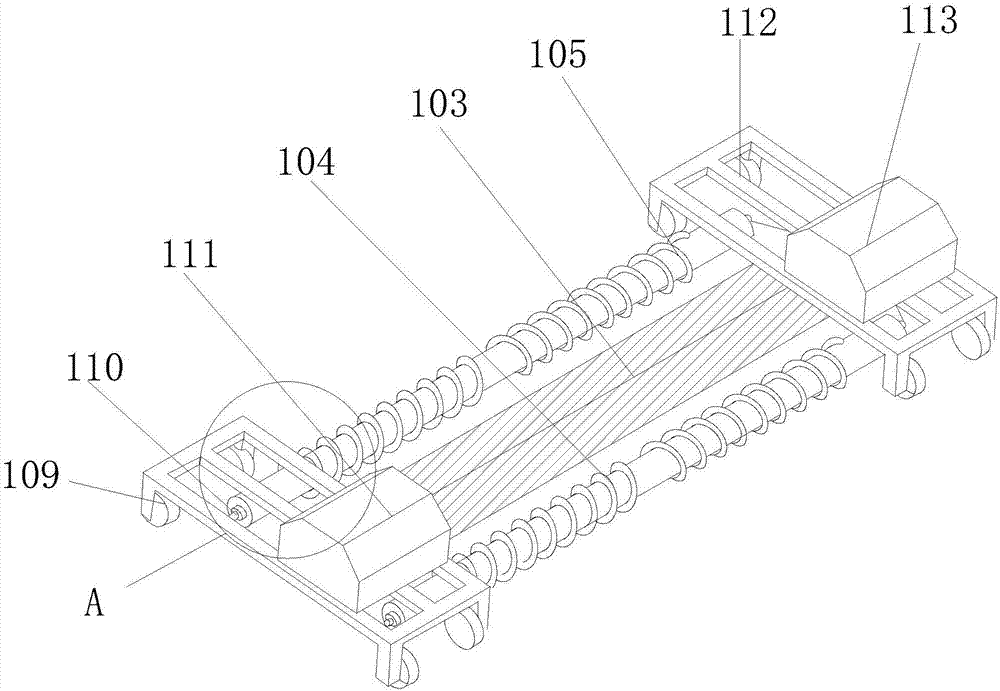

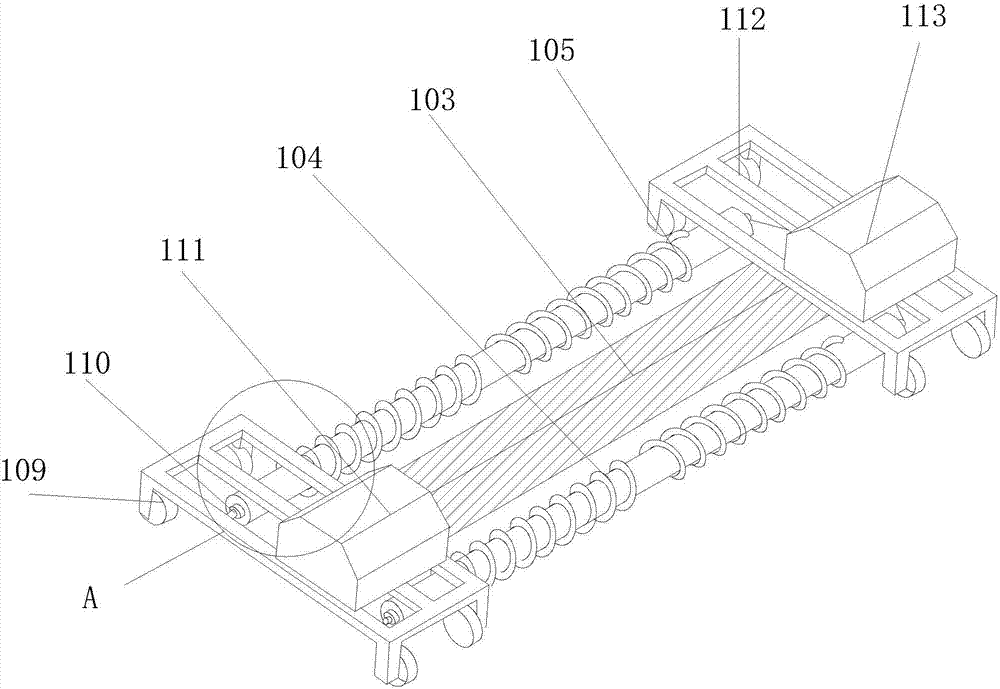

[0045] see Figure 1-Figure 9 , the left weighting mechanism 111 of the present invention and the right weighting mechanism 113 are all provided with rotating shaft connection hole 1111, left hanging wheel 1112, driven drive rod 1113, multi-faceted cam 1114, drive shaft 1115, right hanging wheel 1116, gravity plate 1117, Vibration plate 1118, first return spring 1119, right support rod 11110, bottom ring 11111, compaction beam 11112, telescopic rod 11113, left support rod 11114, second return spring 11115, fixed panel 11116, fixed nut 11117.

[0046] The left and right hanging wheels 1112 and the right hanging wheels 1116 are provided at the left and right ends of the fixed panel 11116, and the left hanging wheel 1112, the right hanging wheel and the fixed panel 11116 are fixedly connected by fixing nuts 11117, and the drive shaft 1115 The left end is provided with a rotating shaft connection hole 1111, and the drive shaft 1115 passes through the left hanging wheel 1112, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com