Spatial multi-degree-of-freedom additive manufacturing equipment based on continuous fiber reinforcement

A technology of additive manufacturing and continuous fiber, which is applied in the field of spatial multi-degree-of-freedom additive manufacturing equipment, can solve problems such as poor mechanical properties and complex manufacturing of continuous fiber composite materials, so as to enhance mechanical properties and reduce poor interlayer adhesion , The effect of reducing manufacturing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

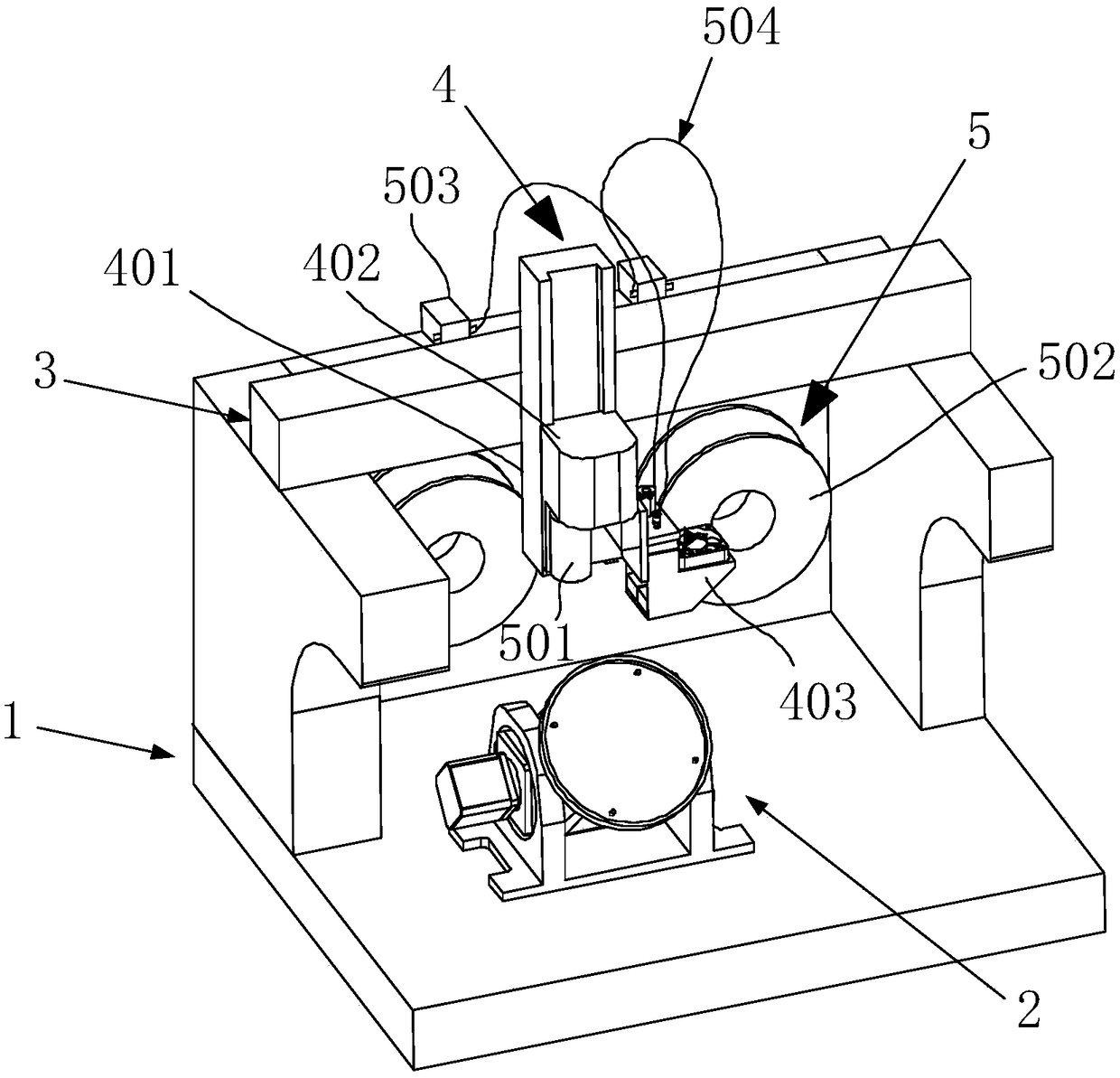

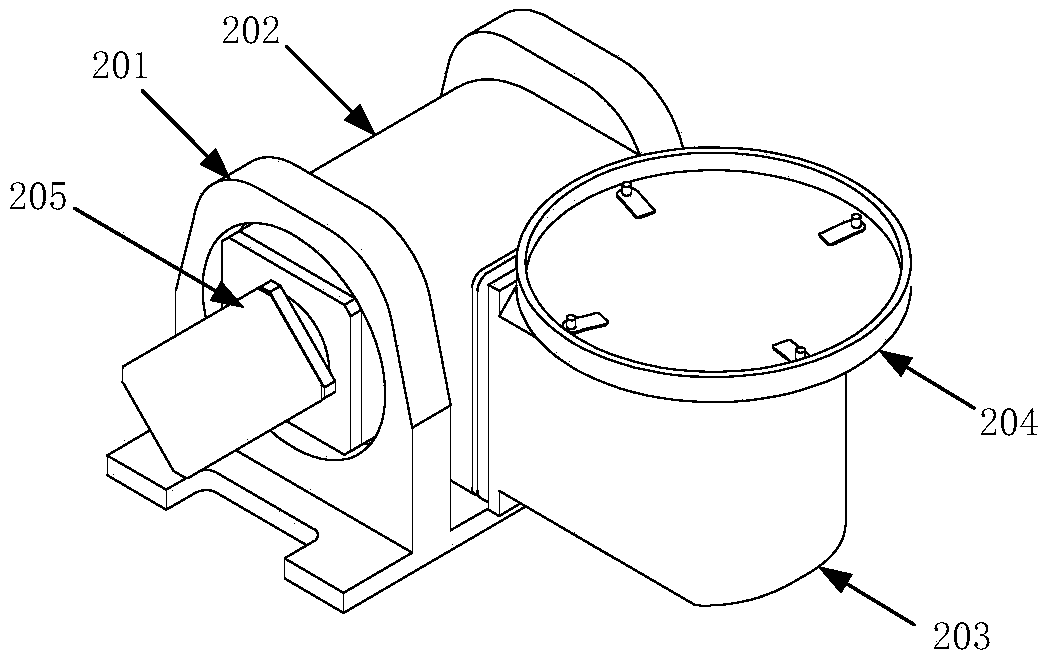

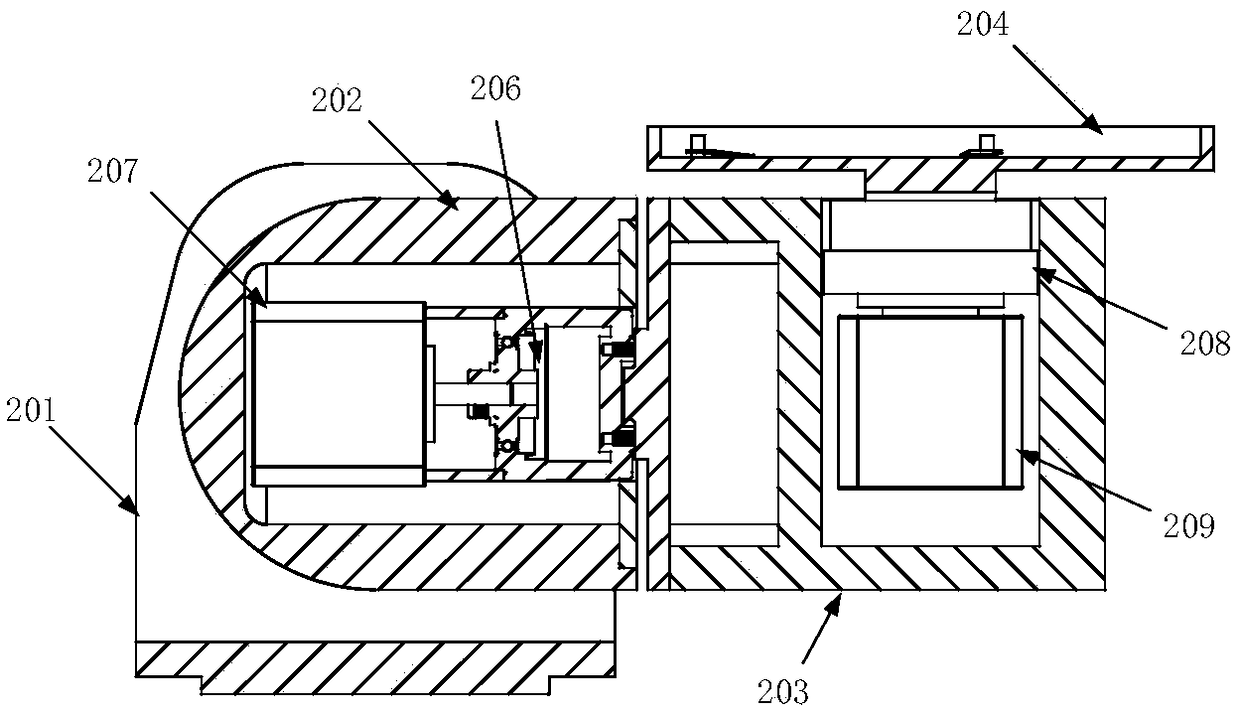

[0030] The present invention is based on continuous fiber-reinforced spatial multi-degree-of-freedom additive manufacturing equipment, including a base 1, a turntable 2, a horizontal and vertical axis moving unit 3, a vertical axis moving unit 4, and a feeding molding unit 5, such as figure 1 shown.

[0031] The base 1 includes a bottom installation platform 101 , a column 102 and a rear side plate 103 . Wherein, the bottom installation platform 101 provides installation positions for the column 102, the rear side plate 103 and the turntable 2, and is the bottom support of the whole equipment. Upright columns 102 are installed on the left and right sides of the bottom installation platform 101, and a rear rear side plate 103 is installed on the rear.

[0032] The horizontal and vertical axis moving units 2 are installed on the columns 102 on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com