Installation device for wall hidden pipeline

A pipeline installation and wall technology, applied to vertical pipelines, building components, buildings, etc., can solve the problems of uneconomical, damaged decoration effect, inconvenience, etc., and achieve the effect of convenient operation, economical and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

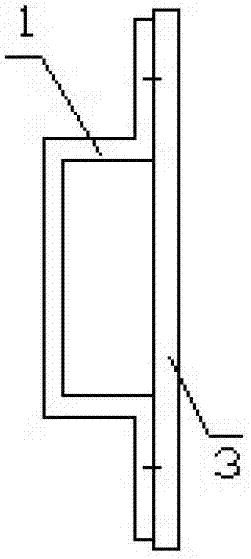

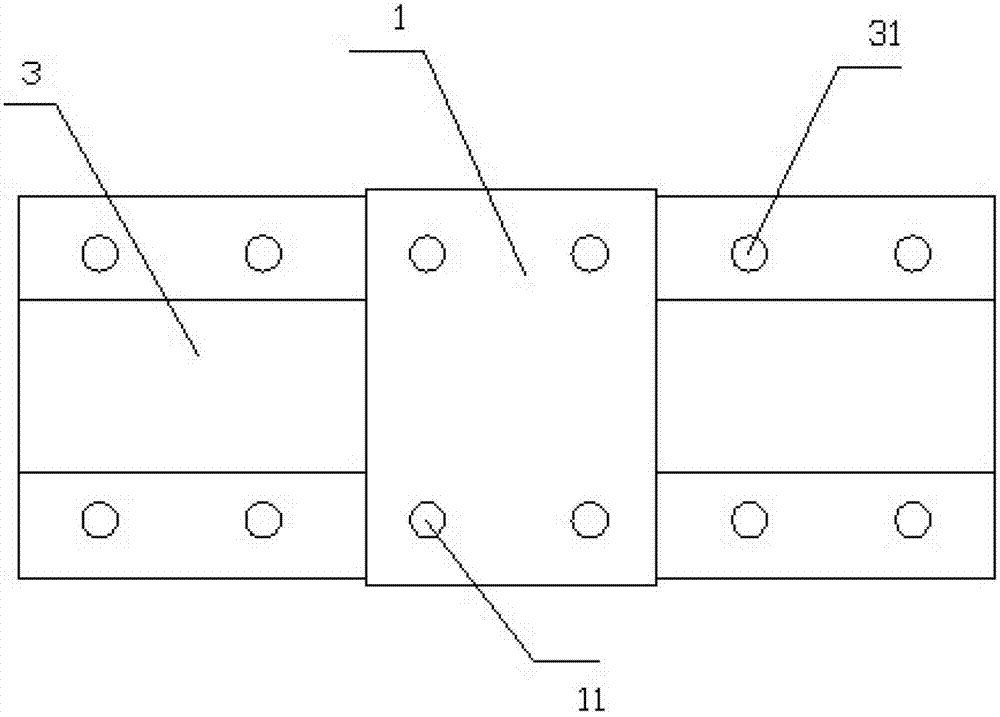

[0023] Such as image 3 , Figure 4 with Figure 5 As shown, there is a fixing hole A31 on the folding plates on both sides of the fixing frame 3, and a fixing hole B11 of the same size is opened on the outer sealing plate 1 corresponding to the fixing hole A31, and the fixing frame 3 passes through the folding plates on both sides. The fixing hole A31 on the top is fixedly connected with the fixing hole B11 of the outer sealing plate 1 .

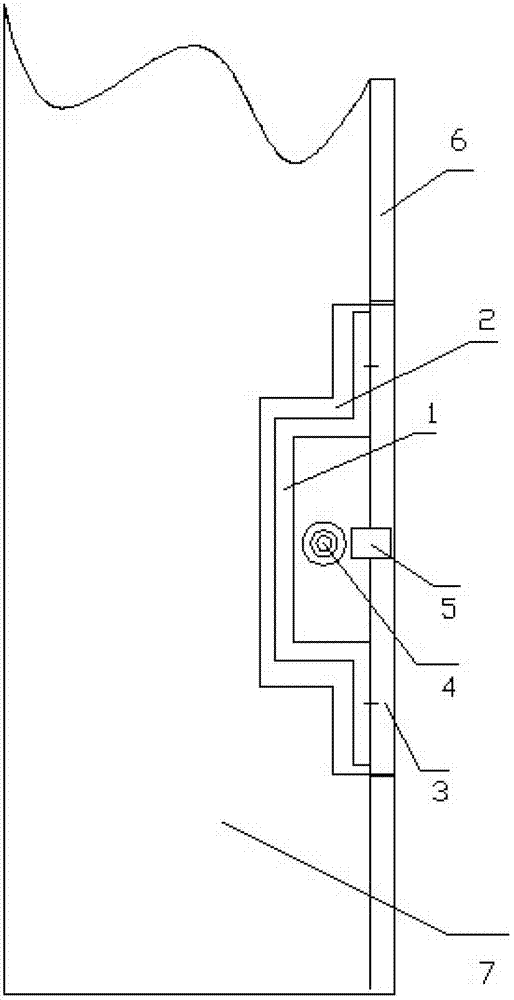

[0024] When in use, first, according to the actual laying needs of the pipeline 4, reserve or excavate the groove 2 on the inner wall body 7 for installing the fixing frame 3 and match it, and then install the fixing frame 3 in the groove 2 , the pipeline 4 is laid in the detour part of the fixing frame 3, and the outer sealing plate 1 and the fixing frame 3 are fixedly connected through the fixing hole B11 on the outer sealing plate 1 and the fixing holes A31 on the folded plates on both sides of the fixing frame 3, and the pipeline 4 c...

Embodiment 2

[0026] Such as Image 6 , Figure 7 with Figure 8 As shown, a locking part 32 is provided on both side flaps of the fixed frame 3, and a locking matching part 12 is provided on the inner side of the outer sealing plate 1 corresponding to the locking part 32. The locking part 32 Including the hinge A321 and the locking groove 322, the locking fitting part 12 includes the hinge B121 and the locking head 122, the hinge A321 is connected with the hinge B121, the locking groove 322 is fastened and connected with the locking head 122, which can facilitate Remove and open.

[0027] When in use, first, according to the actual laying needs of the pipeline 4, reserve or excavate the groove 2 on the inner wall body 7 for installing the fixing frame 3 and match it, and then install the fixing frame 3 in the groove 2 , the pipeline 4 is laid in the detour part of the fixing frame 3, and the outer sealing plate 1 and the fixing frame 3 are fixedly connected through the fixing hole B11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com