Device and method for laying fibers

A technology for laying devices and optical fibers, which is applied in the direction of optical fiber/cable installation, measuring devices, instruments, etc. It can solve the problems of low construction efficiency, slow optical fiber speed, and unsightly appearance, and achieve the effects of improving construction efficiency, easy processing, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

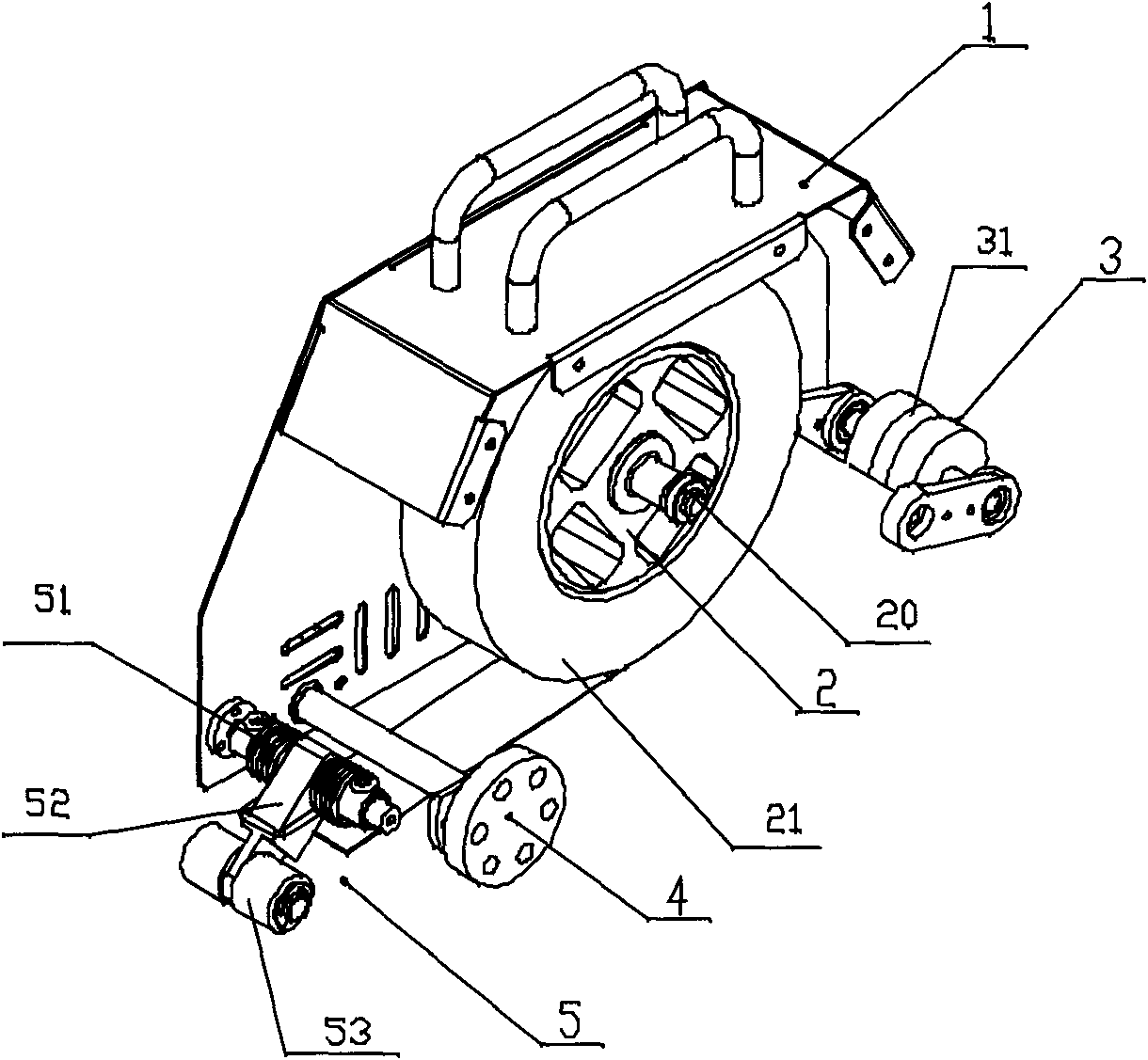

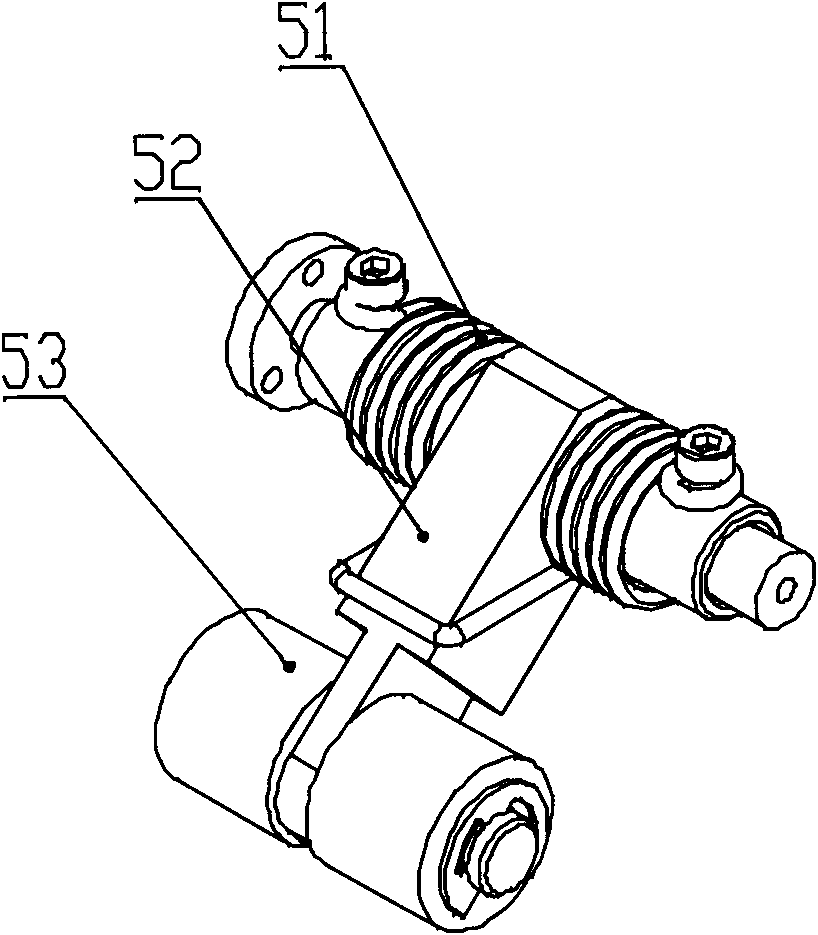

[0042] see figure 1 , figure 2 , an optical fiber laying device, comprising a housing 1, a gluing module 2, a limiting module 3, and a pressing module 5;

[0043] The gluing module 2, the limiting module 3, and the pressing module 5 are all installed on the housing 1;

[0044] The gluing module 2 rotates around its central axis 20 and is used to install the tape roll 21 and apply the tape to cover the optical fiber.

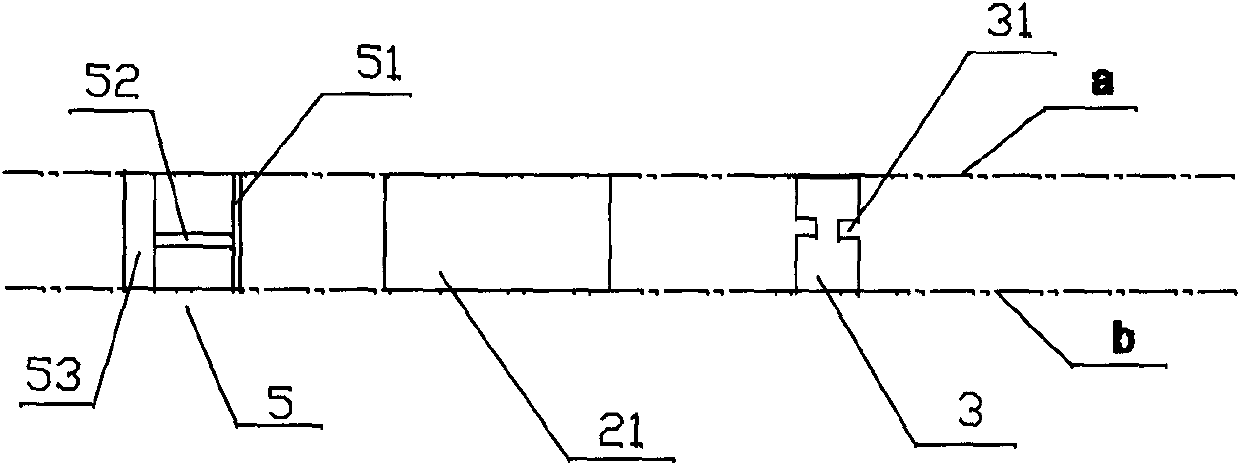

[0045] The planes where the edges of the tape of the tape roll 21 are located are plane a and plane b, and the distance between the plane a and plane b is not greater than the width of the tape.

[0046] The central axis 20 is perpendicular to the application direction of the adhesive tape of the tape roll 21, that is, perpendicular to the moving direction of the optical fiber laying device during construction, that is, when the tape roll 21 is installed on the gluing module 2, the tape roll 21 is in the The optical fiber laying device is placed vertically, t...

Embodiment 2

[0061] see Figure 5 , a kind of optical fiber laying device, is different from the optical fiber laying device described in embodiment 1:

[0062] The optical fiber laying device also includes a tightening module 32; the tightening module 32 is a double-arm slot structure, and the junction of the two arms is a slot for the passage of the optical fiber; the slot is arranged on the tightening module 32 a portion between said plane a and plane b;

[0063] The two arms of the tightening module 32 are elastic structures, and the elastic structures have opposite thrusts on the optical fibers passing through the slot, so that the optical fibers can be fastened in the slot without slipping; The area between the pressing module and the tightening module 32 is in a stretched state; for example, the elastic structure can be two opposite springs, both of which are in a compressed state.

[0064] This embodiment also provides an optical fiber laying method, which is different from the o...

Embodiment 3

[0068] see Figure 6 , a kind of optical fiber laying device, is different from the optical fiber laying device described in embodiment 1:

[0069] The limiting module 33 is a suspension beam arranged on the inner casing 1 of the optical fiber laying device, and the center of the suspension beam is provided with a through hole for the optical fiber to pass through; the through hole is provided when the suspension beam is on the plane a and plane b During construction, after the optical fiber passes through the through hole, it is always limited in the space between plane a and plane b, so that the optical fiber can always be covered by adhesive tape, avoiding the swing of the optical fiber during construction The amplitude is too large, thus achieving the purpose of adhesive tape to cover the optical fiber;

[0070] This embodiment also provides an optical fiber laying method, which is different from the optical fiber laying method described in Embodiment 1 in that:

[0071]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com