Agricultural machine capable of automatically finishing planting preparation of mulching film cultivation technology

An automatic completion and agricultural machinery technology, applied in the field of agricultural machinery, can solve the problems of long time-consuming and uneven punching of mulch film, and achieve the effect of improving automation, reducing impact, and facilitating planting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

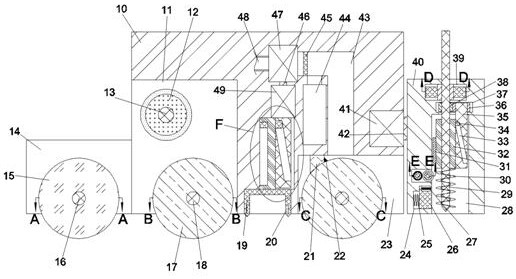

[0019] Combine below Figure 1-7 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

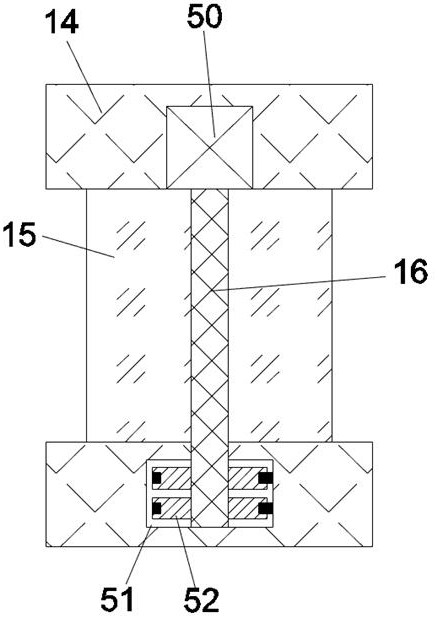

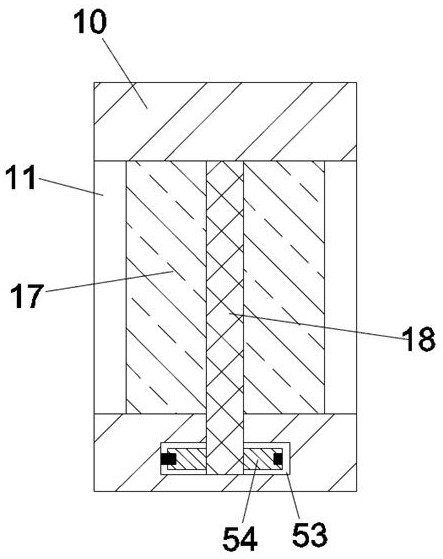

[0020] combined with Figure 1-7 The agricultural machinery that automatically completes the planting preparation of the plastic film cultivation technology includes a housing 10, and a front and rear symmetrical power fixing block 14 is fixed on the left end surface of the housing 10, and the left end surface of the housing 10 is A laying cavity 11 with an opening downward is provided, a dust suction cavity 23 with an opening downward is provided on the right end surface of the housing 10, and a punching cavity 65 with an opening downward is provided on the bottom end surface of the housing 10, so A hydraulic cylinder 41 is fixed on the right end surface of the housing 10, and a hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com