Embedded track structure of high-speed railway

An embedded track, high-speed railway technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of increasing line maintenance costs, increasing rail maintenance costs, environmental vibration and noise, etc., to reduce maintenance costs, anchoring The force is not easy to change and the train runs smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

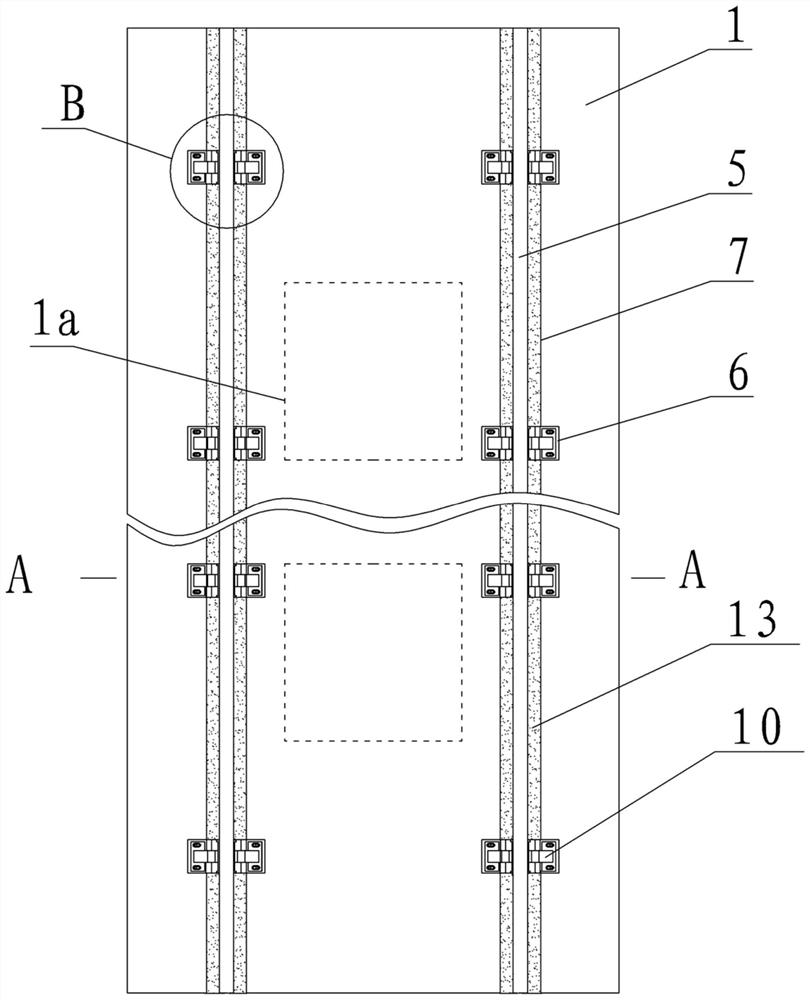

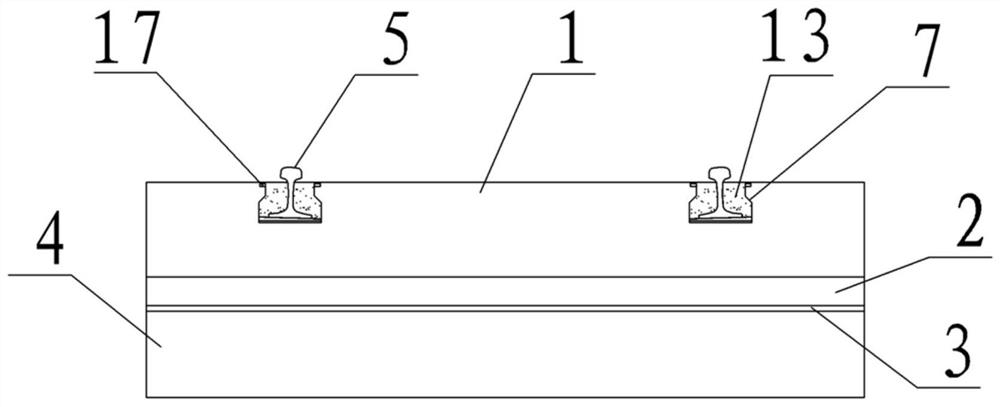

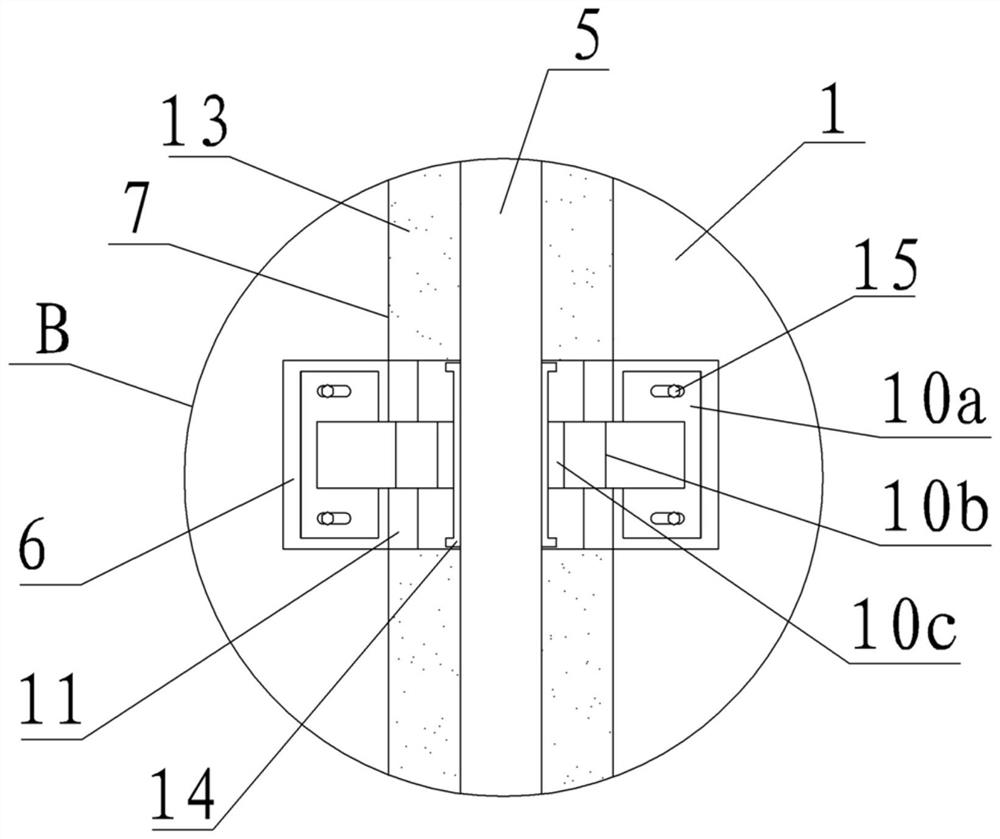

[0028] figure 1 - Figure 5 As shown, a specific embodiment of the present invention is: a high-speed railway embedded track structure, comprising a base 4 and a track slab 1 above the base 4, characterized in that:

[0029] The track slab 1 is prefabricated from reinforced concrete. There are two rail bearing grooves 7 longitudinally and symmetrically distributed on the track slab 1. The cross section of the rail bearing groove 7 is bottle-shaped. The height-adjusting backing plate 12, the elastic backing plate 11 and the rail 5 are laid, the width of the height-adjusting backing plate 12 and the elastic backing plate 11 is equal to the width of the rail bearing groove 7, the width of the rail 5 is smaller than the width of the rail bearing groove 7, and the rail The rail top of 5 is higher than the bearing groove 7;

[0030] Figure 5 and Figure 1-4 It is shown that the rail bearing groove 7 is equidistantly provided with rail adjustment grooves 6 having a width greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com