Tea leaf pile fermentation device and method based on automatic splicing movable material bearing table

A technology of automatic splicing and receiving table, applied in the direction of tea processing before extraction, which can solve the problems of high labor intensity, large workload of picking up debris, and difficulty in ensuring the purity of tea materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

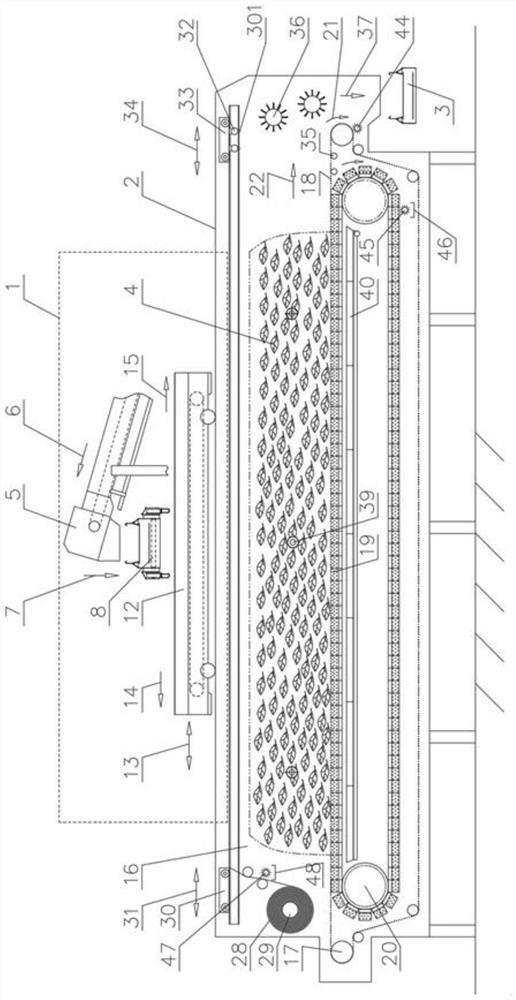

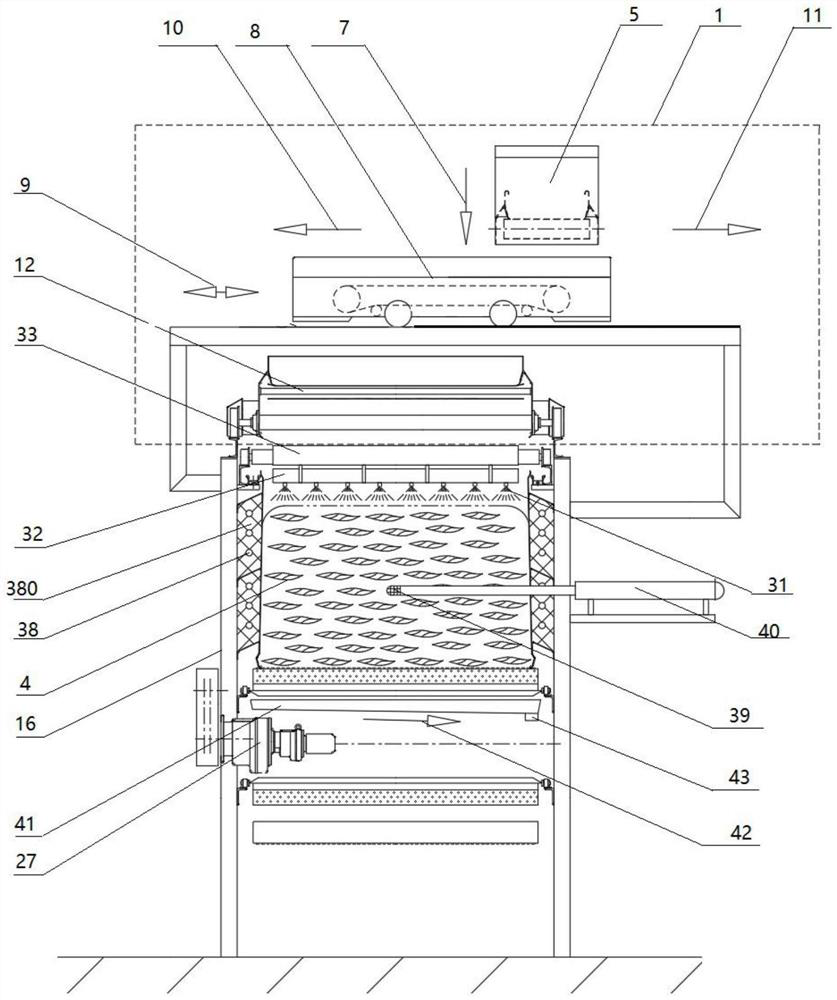

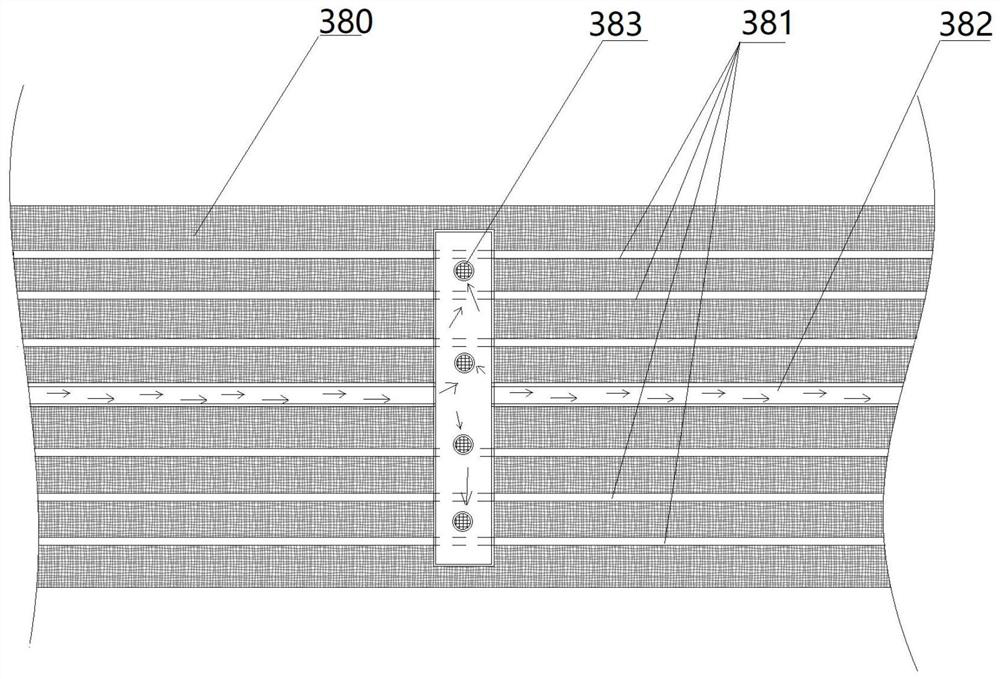

[0042] Embodiment 1: overall equipment structure and function

[0043] The tea stacking device based on the automatic splicing of the movable loading platform includes a stacking bin, and a movable loading platform is arranged at the bottom of the storage bin, and the loading platform includes a plurality of strip-shaped loading platform units along the The horizontal direction is sequentially spliced to form a chain plate structure that can rotate circularly in the stacking bin to realize the horizontal transportation of materials during discharge. The bar is used to fix and support the bar-shaped assembly, and the material of the bar-shaped assembly includes one or more of concrete, earthen pottery, wood or bamboo board.

[0044] Through the cooperative work of the spreading system 1, the stacking system 2 and the discharge conveying equipment 3, the automatic splicing of the tea stacks on the movable material receiving platform is realized.

[0045] Material spreading sy...

Embodiment 2

[0061] Example 2: use process

[0062] The main usage process of this device is as follows:

[0063] Step-by-step continuous feeding of tea materials—drill spreading——stock pile covering——stock pile leachate collection and discharge——core temperature monitoring and regulation, stock pile ventilation and oxygen supplement——stock pile cover recovery—— Spray water on the surface of the stockpile before turning over to humidify and regain moisture——movement of the stockpile—deblocking and discharging. Based on this flow process, set forth the structure of the present invention step by step:

[0064] Process 1: Step-by-step continuous feeding of tea materials

[0065] The feeding system is composed of feeding conveying equipment 5 and reciprocating belt distributing machine 8. Tea material 4 is sent to the reciprocating belt distribution machine 8 continuously along the material delivery direction 6 on the feeding conveyor and the material output direction 7 on the feeding conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com